Hot air-penetration external circulating-type coal sample dehumidification device having automatic sample feeding/taking function

A technology of hot air penetration and sampling, applied in the preparation of test samples, etc., can solve the problems of low efficiency, slow ventilation speed, and low ventilation efficiency of high-moisture materials, so as to increase the evaporation surface area and improve the accuracy , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

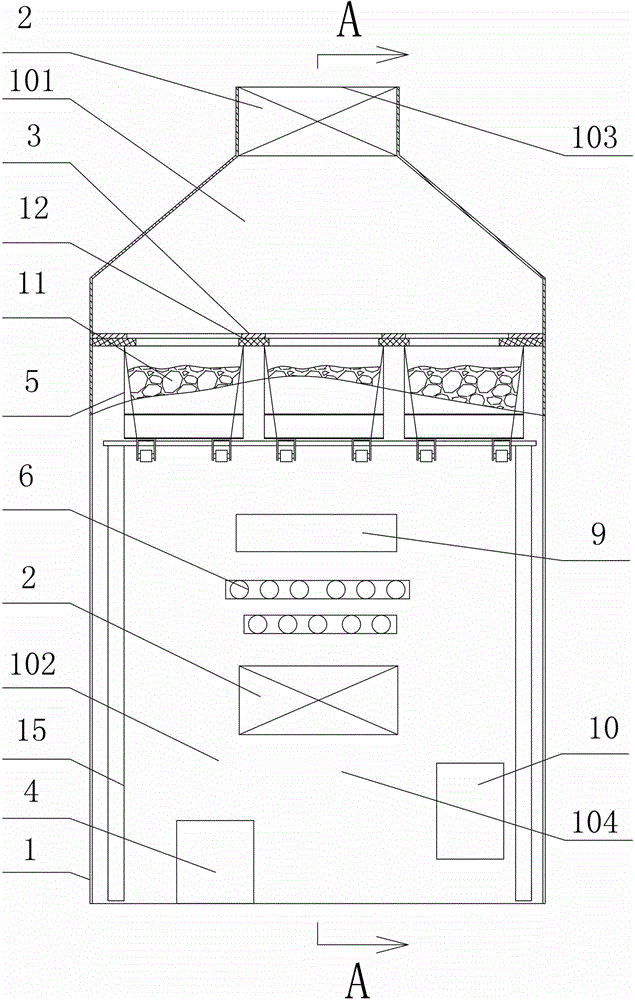

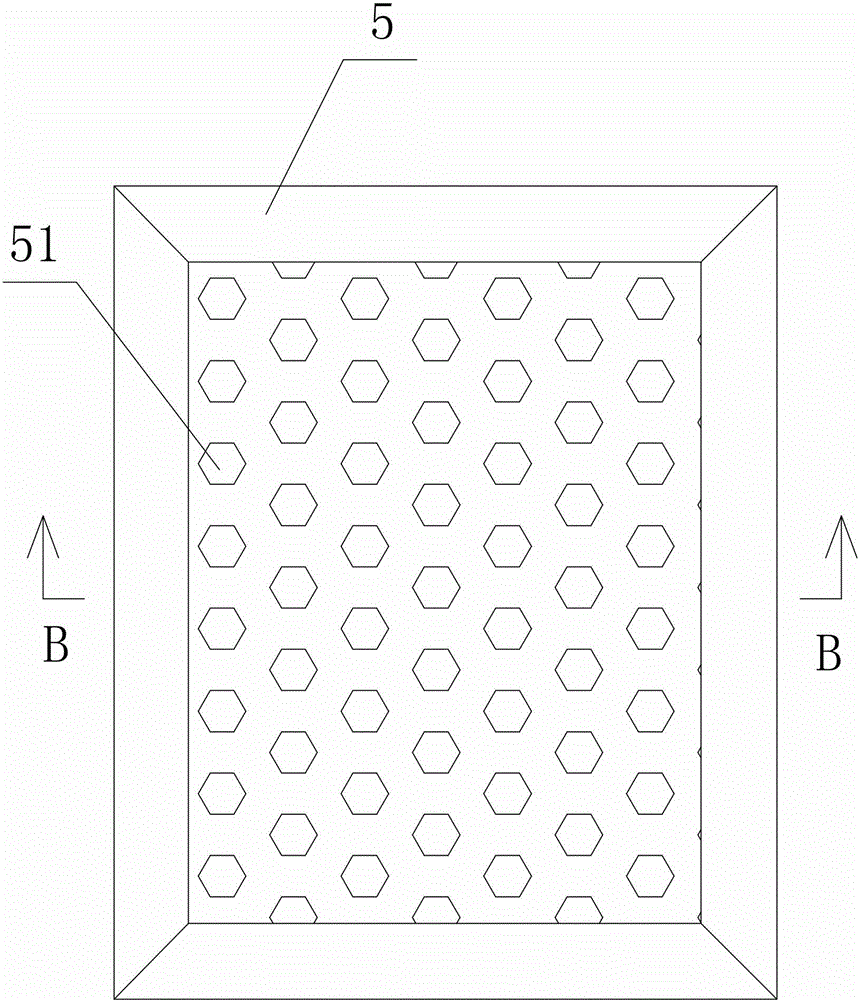

[0030] Such as figure 1 and figure 2 As shown, the hot air penetrating outer circulation type coal sample dehumidifier that can automatically send and sample samples of the present invention includes a box body 1, a controller 4, a sampling mechanism 15, and a fan 2 installed in the box body 1, and a partition 3. The gas heater 6, the sample holding mechanism, the partition 3 divides the box body 1 into an upper chamber 101 and a lower chamber 102, the top or side of the upper chamber 101 is provided with an air outlet 103, and the top of the box body 1 in this embodiment is open The air outlet 103 is the entire top; the bottom or side of the lower chamber 102 is provided with an air inlet 104, the fan 2 is located in the upper chamber 101 near the air outlet 103, and the gas heater 6 is located in the lower chamber 102. It needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com