Plate-tube composite heat exchange fin and manufacturing method thereof

A heat exchange fin, plate and tube technology, applied in the field of heat exchange equipment, can solve the problems that the heat exchange efficiency cannot be greatly improved, can not meet the problems of direct heat exchange, complicated installation and disassembly, etc., and can increase the cooling water. Evaporation area, reducing condenser volume and increasing effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

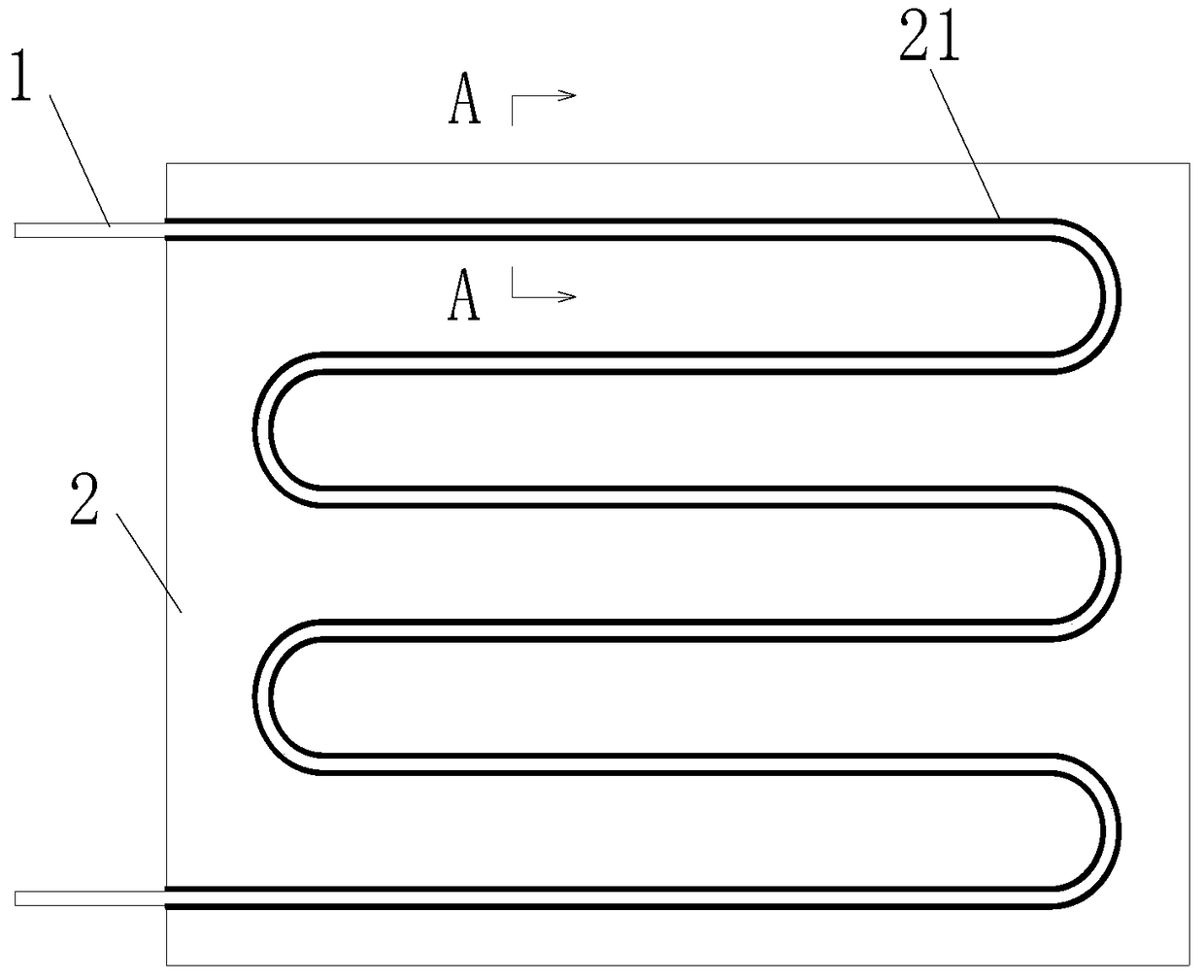

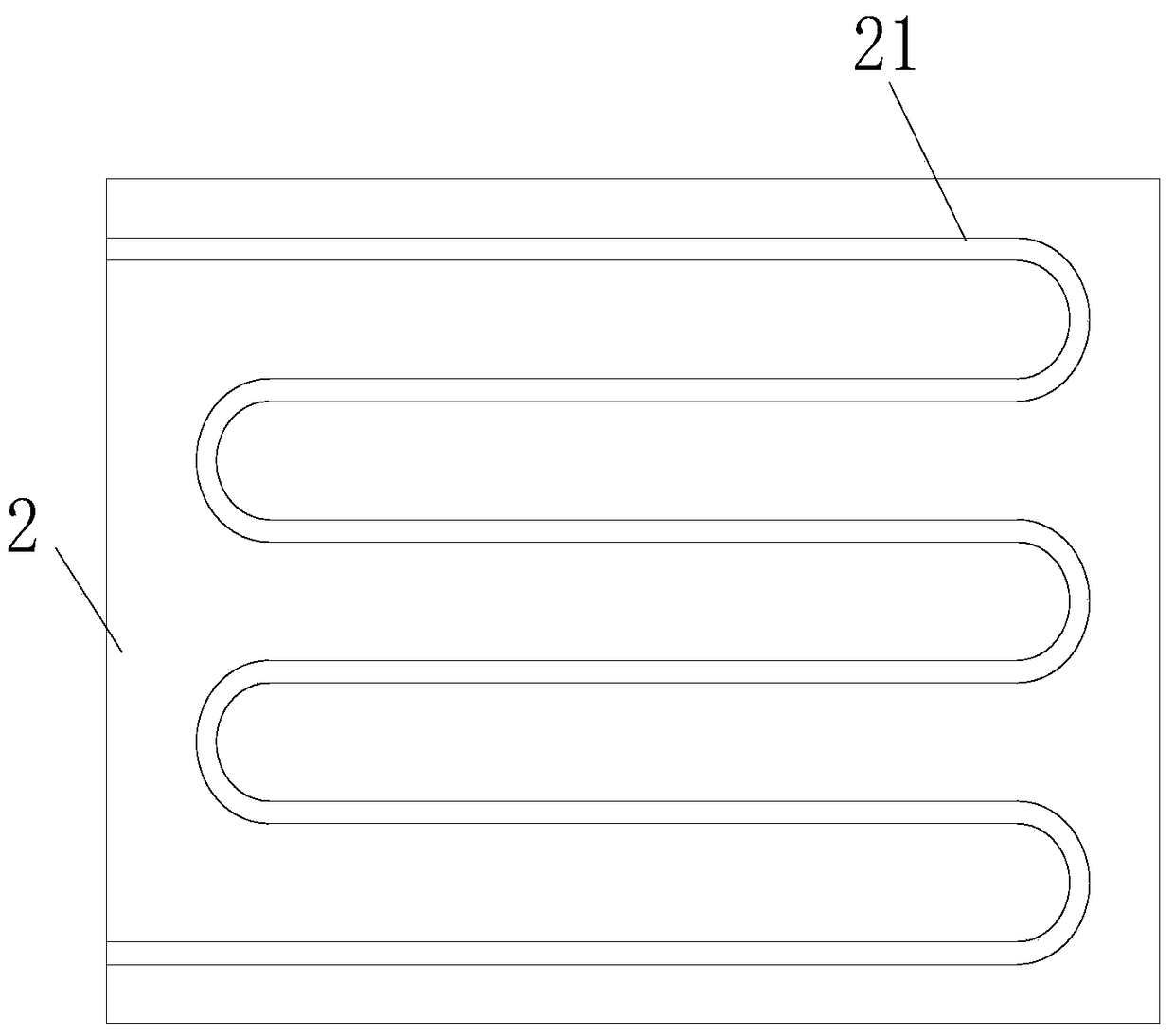

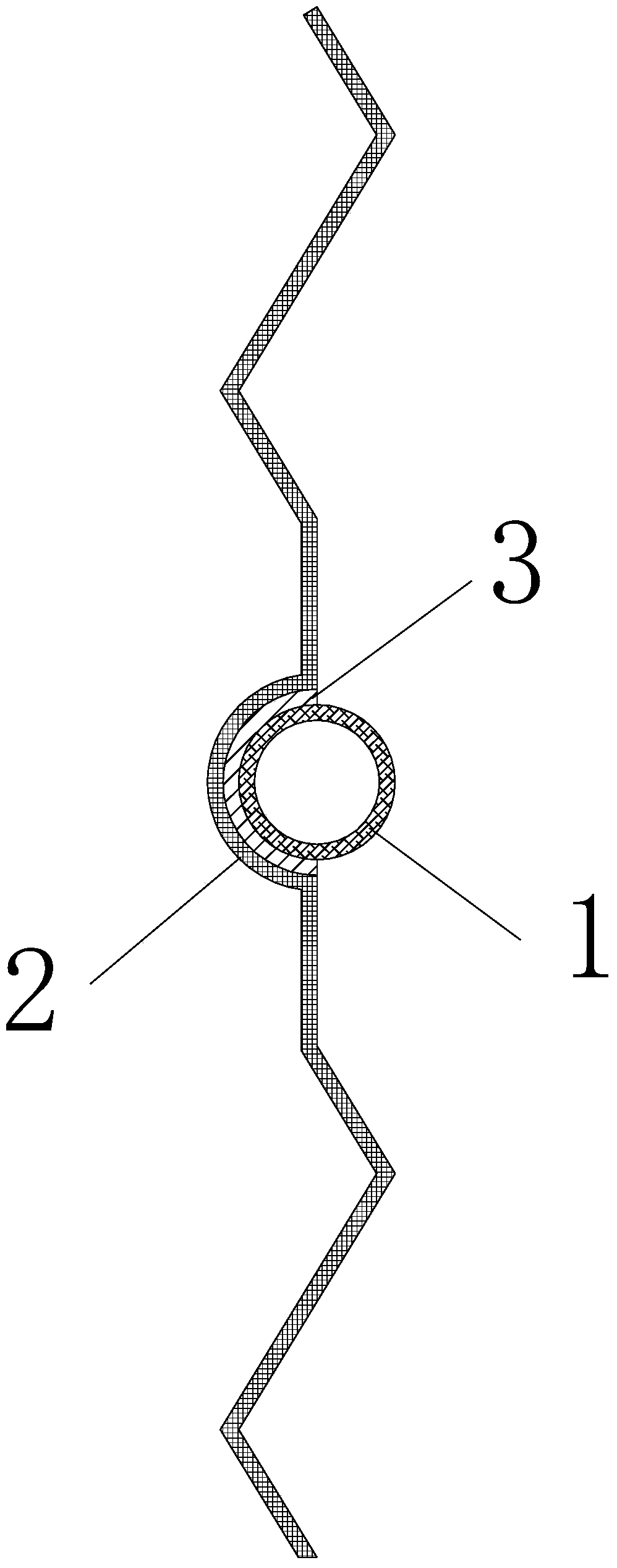

[0033] Such as figure 1 with figure 2 As shown, the plate-tube composite heat exchange fin of the present invention includes a coiled tube 1 processed by the heat exchange tube (the processing can be to bend the long heat exchange tube into a coil, or to bend the heat exchange tube of the bent section The tube is welded together with the heat exchange tube of the straight section to form a coil), and the heat transfer plate 2 is also included. In this embodiment, the coil 1 is formed by continuous S-shaped bending of the heat exchange tubes, and the straight sections of the heat exchange tubes are roughly parallel or not parallel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com