Bisconical microchannel radiator with thermosyphon loop

A technology of micro-channels and heat sinks, applied in the field of heat pipes, can solve the problems of hindering the heat exchange of the refrigerator gas, the length of the micro-channel flow channel is too long, and the heat exchange efficiency is reduced, so as to increase the effective heat exchange area and maintain the wet characteristics , the effect of strong heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings and embodiments:

[0022] See Figure 1-5 .

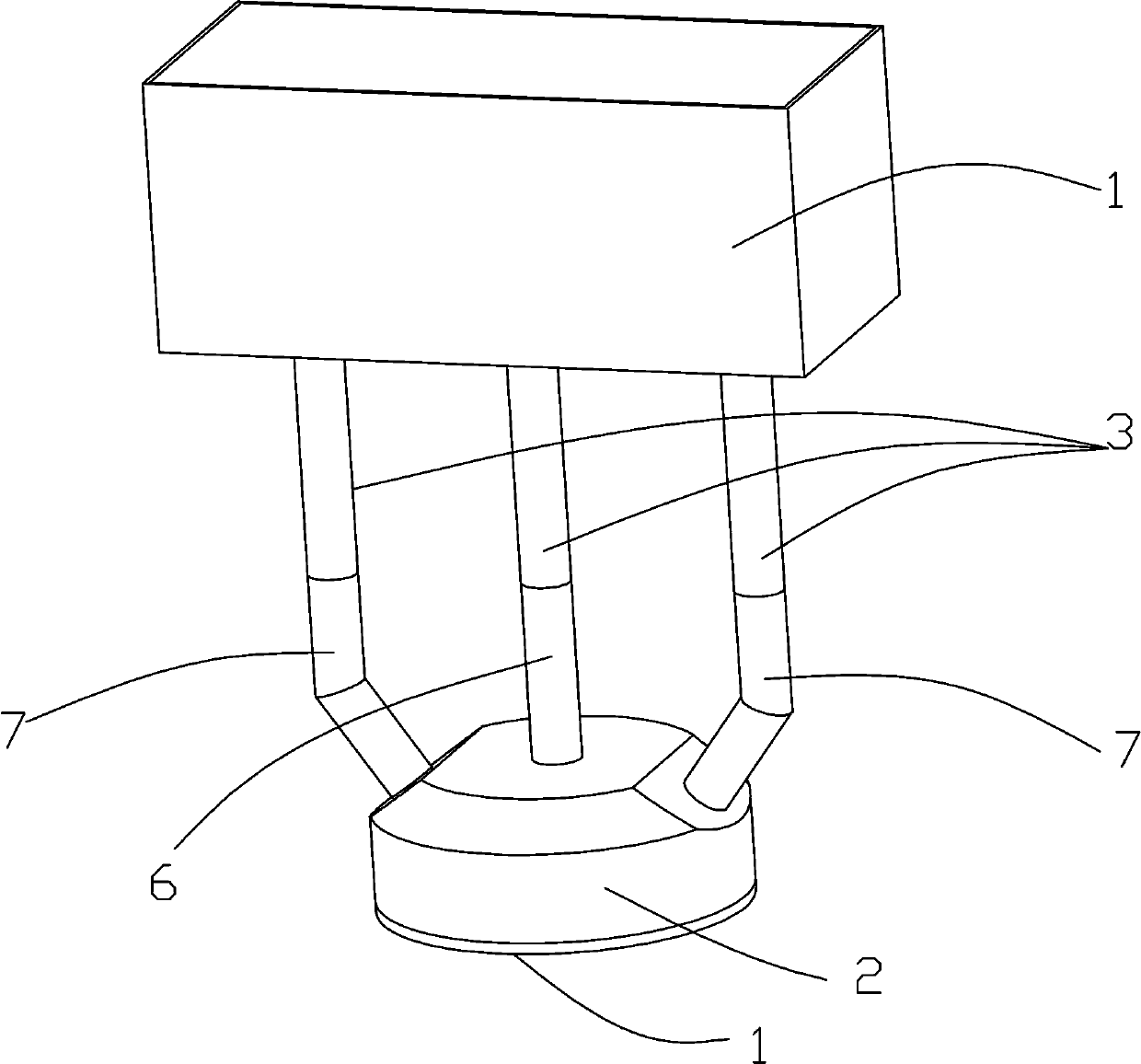

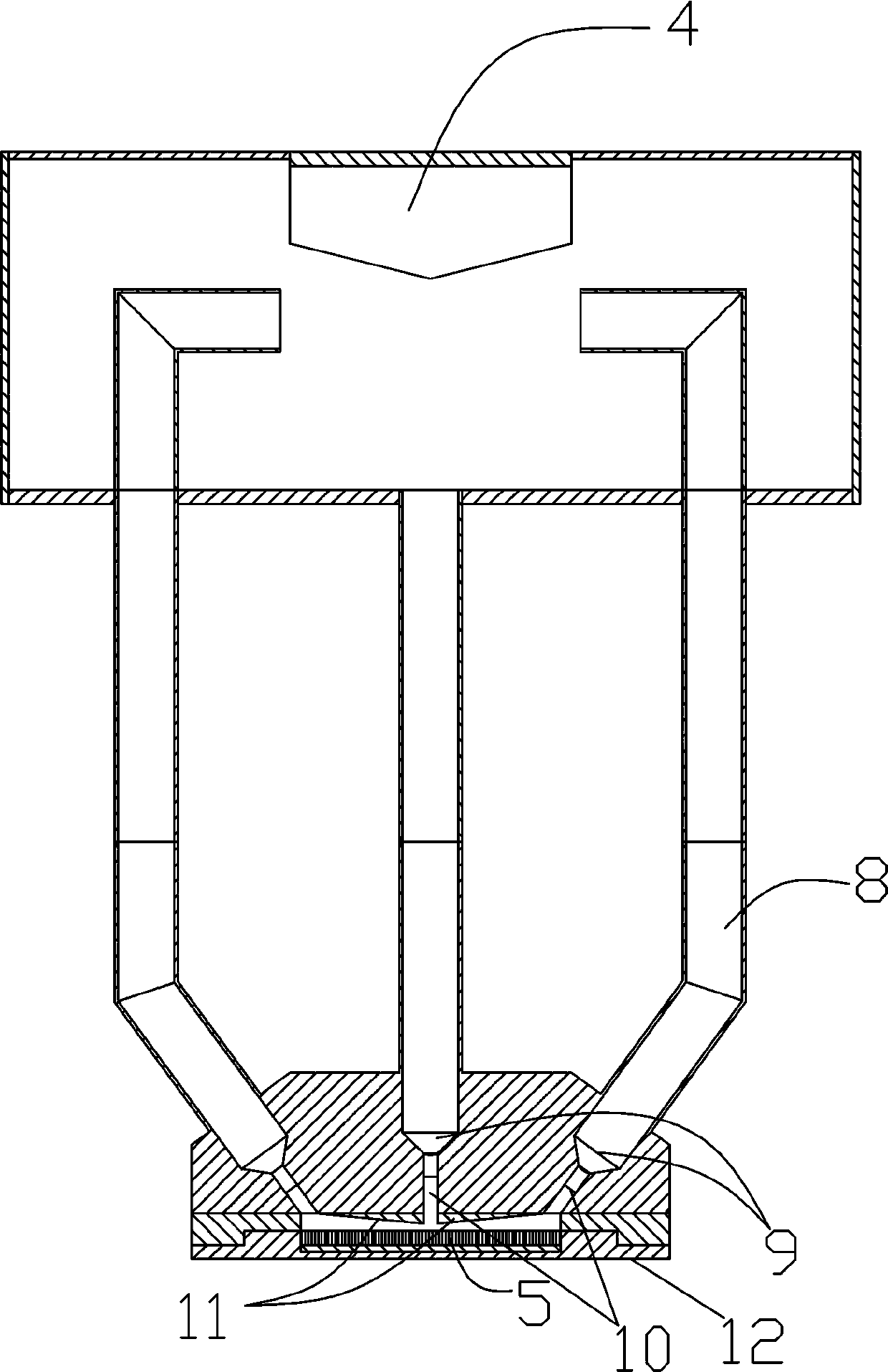

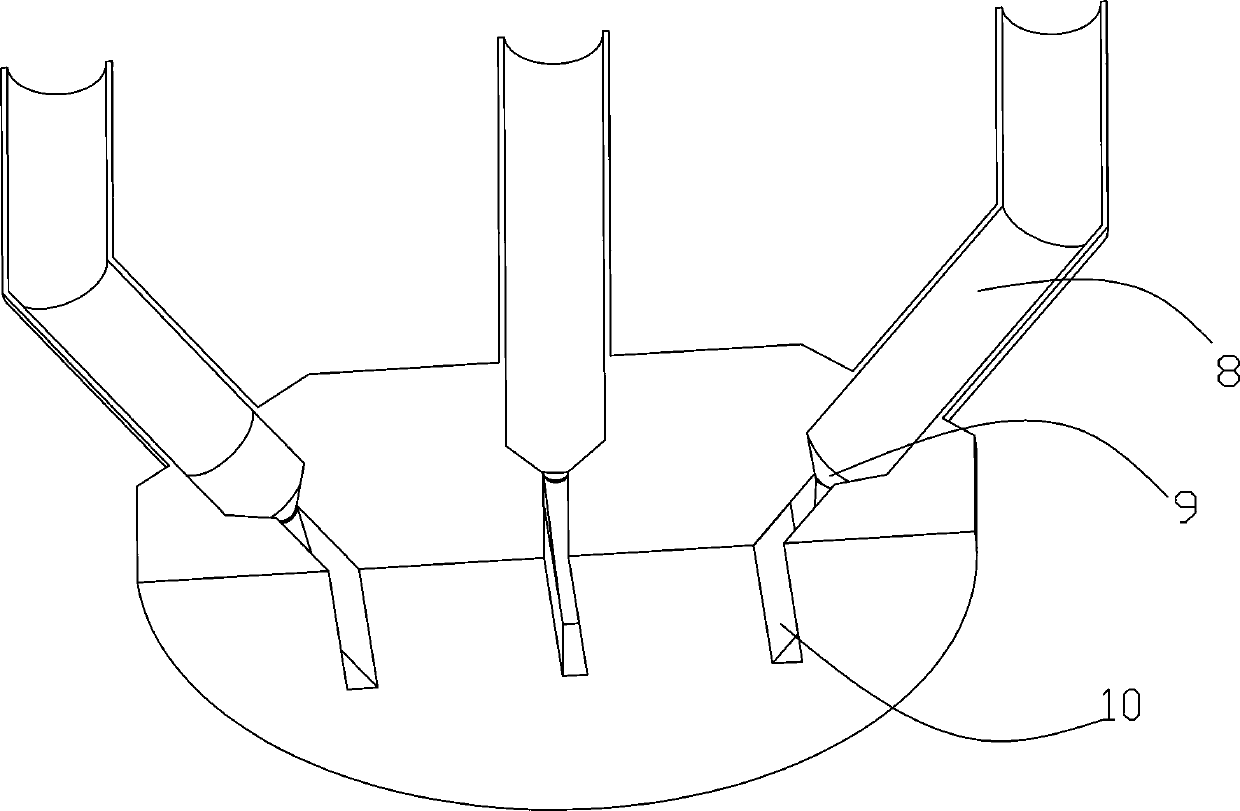

[0023] The invention discloses a double-taper microchannel radiator with a thermosiphon circuit, which comprises a condensation end, an evaporation end, and a refrigerant delivery pipe 3 communicating with the condensation end and the evaporation end. The condensation end is a cooling water tank 1, and the cooling A micro-channel condenser 4 is arranged in the cavity of the water tank 1; the evaporating end is a heat absorption box 2, and the heat absorption box 2 is a cavity structure provided with a cavity inside, and the cavity of the heat absorption box 2 is arranged There is a micro-channel radiator 5, the top of the micro-channel radiator 5 is provided with a refrigerant outlet hole 7 and a refrigerant inlet hole 6 passing through the top of the heat absorption box 2. The refrigerant outlet hole 7 and the refrigerant inlet hole 6 are bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com