Falling film scraper type multi-pipe evaporation and concentration device

An evaporative concentration and scraper-type technology, which is applied in the direction of evaporation, chemical instruments and methods, and separation methods, can solve problems such as unfavorable saving of steam and electric energy consumption, increased difficulty of equipment management and maintenance, and increased equipment investment, so as to reduce equipment Quantity, save manpower input, increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

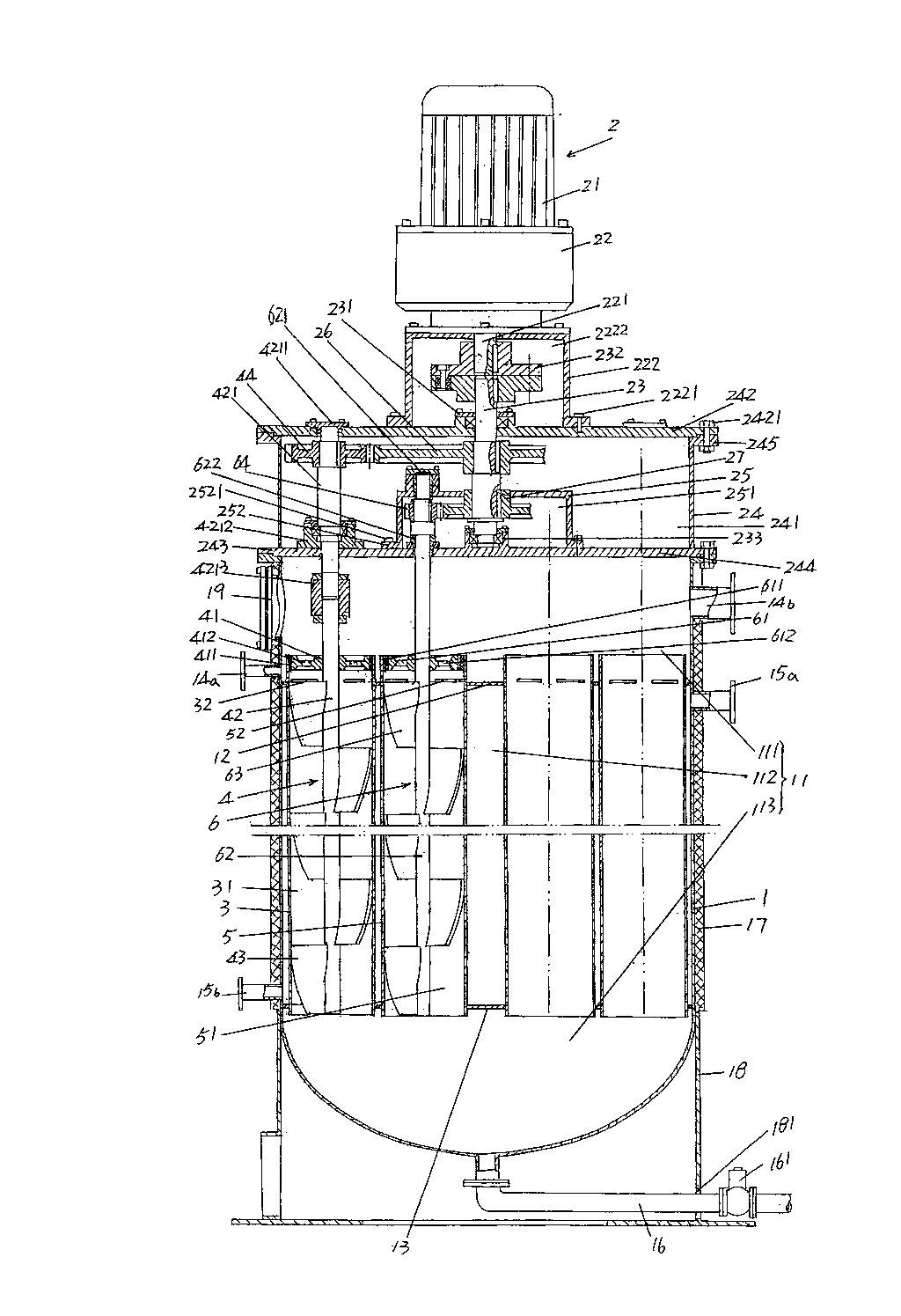

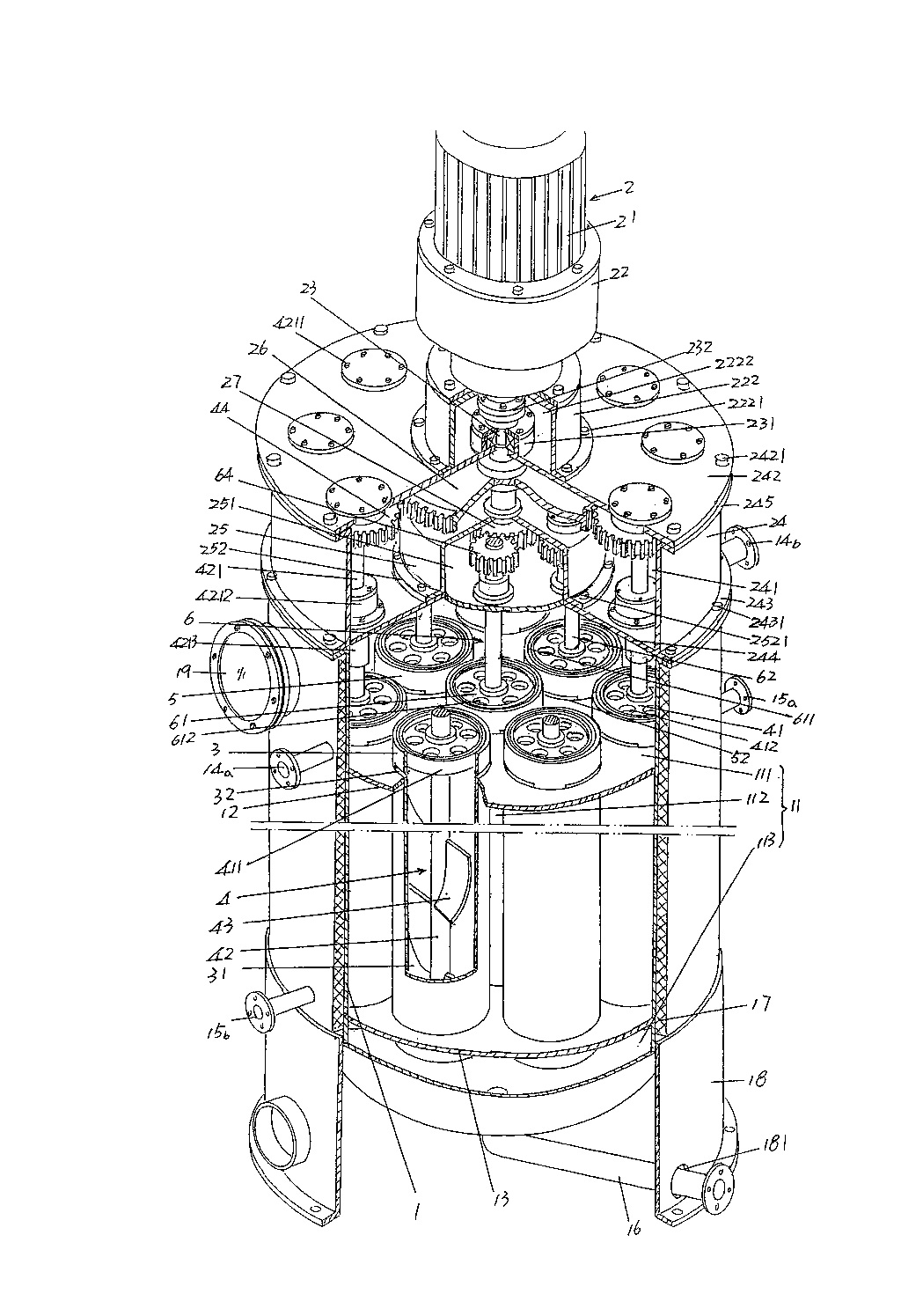

[0021] See figure 1 and figure 2, a cylindrical concentration tank body 1 is given, an upper sealing plate 12 is fixed in the tank cavity 11 of the concentration tank body 1 and is located at the upper part of the height direction of the tank cavity 11, and the tank cavity 11 A lower sealing plate 13 is fixed near the bottom. As shown in the figure, the height direction of the tank cavity 11 is divided into a distribution cavity 111 (also called a feeding cavity), a steam heating cavity 112 and a discharge cavity by the aforementioned upper sealing plate 12 and lower sealing plate 13. 113 , more precisely: the material distribution chamber 111 is located above the upper sealing plate 12 , the steam heating chamber 112 is located between the upper and lower sealing plates 12 and 13 , and the discharge chamber 113 is located below the lower sealing plate 13 .

[0022] On the side wall of the concentration tank body 1 and at a position corresponding to the aforementioned distr...

Embodiment 2

[0038] The figure is omitted, only the number of one group of peripheral concentrator cylinders 3 is changed to six, and the corresponding number of first scraping film mechanisms 4 is also six; the number of central concentration cylinders 5 is changed to one, and the corresponding second wiper film The number of mechanisms 6 is also one. All the other are the same as the description to embodiment 1.

[0039] applicant combined figure 1 and figure 2 And describe the working process of the present invention according to the explanation of embodiment 1. The high-temperature steam generated by a steam source such as a boiler is introduced into the steam heating chamber 112 of the tank chamber 11 through the steam inlet port 15a through the pipeline, and at the same time, the material to be concentrated is introduced into the material distribution chamber 111 through the feed port 14a through the pipeline. Because the peripheral concentrating cylinder chamber 31 of one group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com