Natural cold source unit

A natural cold source and unit technology, applied in refrigerators, refrigeration components, compressors, etc., can solve the problems of reduced heat exchange capacity, low operation efficiency, easy storage of dry spots, etc., to increase the evaporation surface area and improve heat exchange. Efficiency, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

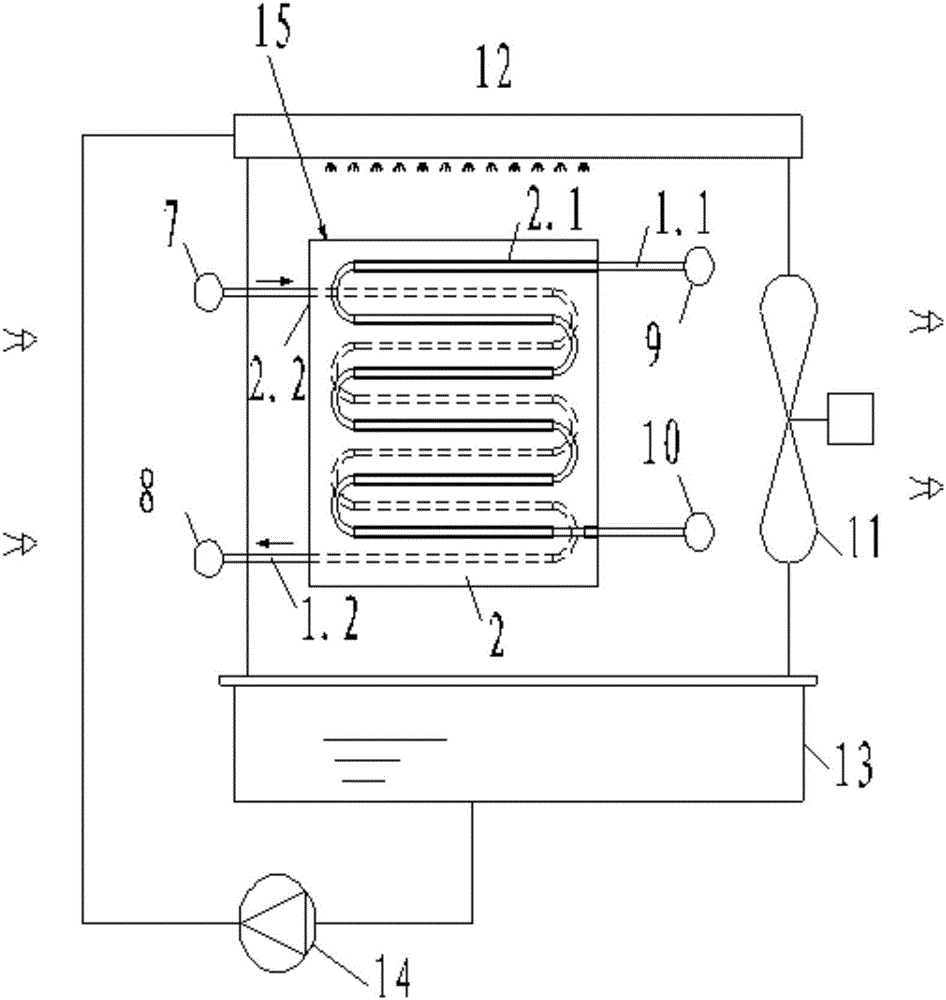

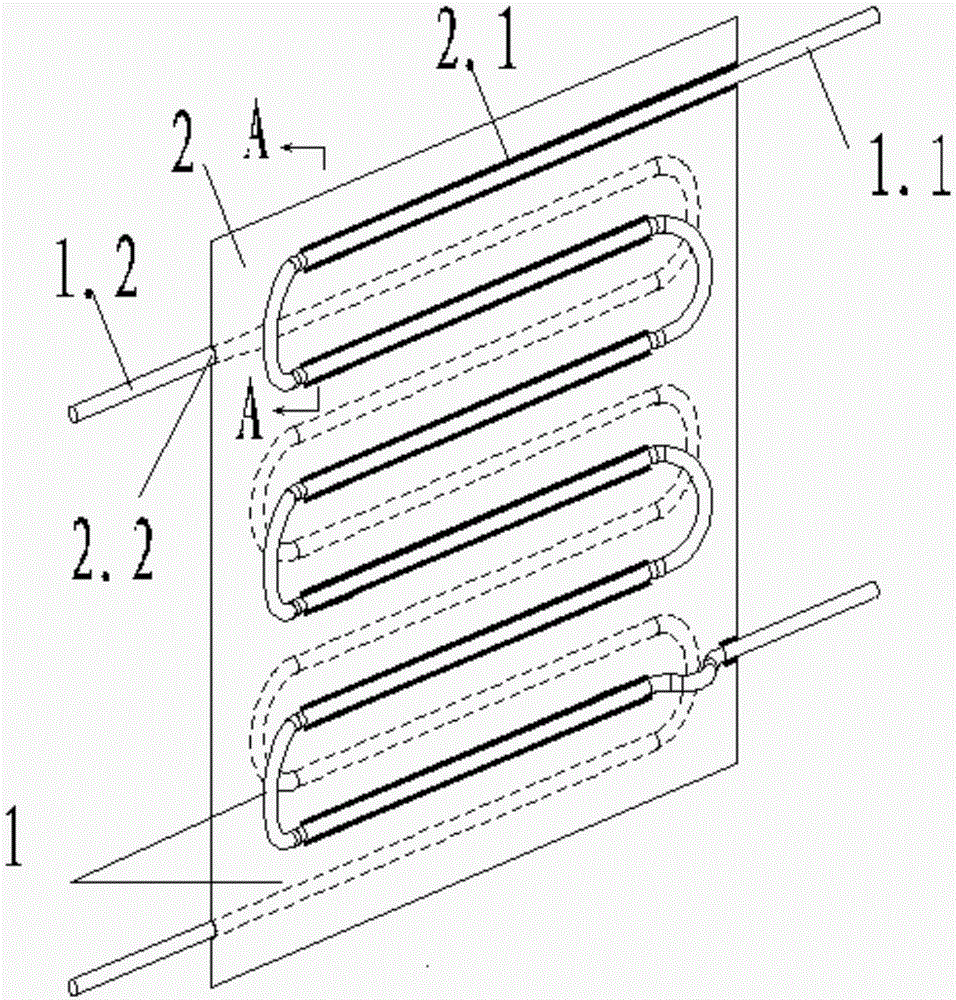

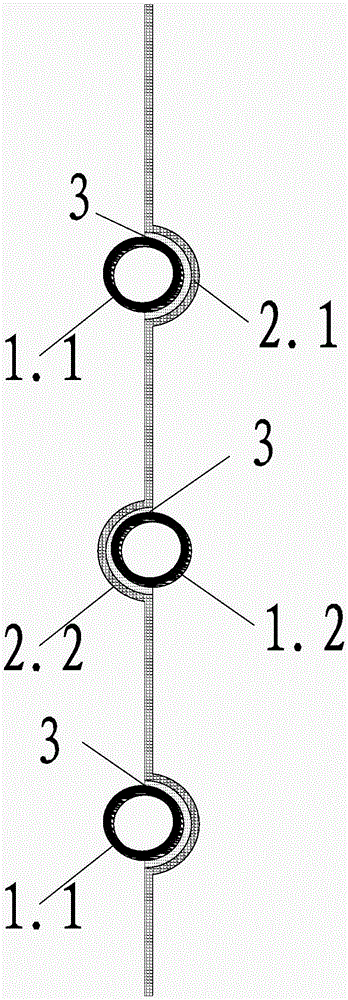

[0060] Figure 8 Shown is the first preferred embodiment of the natural cooling source unit of the present invention, the natural cooling source unit includes a compressor 16, an evaporative condenser 17, a throttling device 18, a water-cooled evaporator 19 and a shut-off valve 25. The exhaust port 16.1 of the compressor is connected to the inlet 17.2 of the heat exchange coil on one side of the sheet body, and the outlet 17.4 of the heat exchange coil on one side of the sheet body passes through the throttling device 18 and the The refrigerant inlet 19.1 of the water-cooled evaporator is connected, the refrigerant outlet 19.2 of the water-cooled evaporator is connected with the suction port 16.2 of the compressor, and the chilled water inlet 21 of the water-cooled evaporator passes through the The cut-off valve is connected to the inlet 17.1 of the heat exchange coil on the other side of the sheet, and the outlet 17.3 of the heat exchange coil on the other side of the sheet ...

Embodiment 2

[0065] Figure 9 Shown is the second preferred embodiment of the natural cooling source unit of the present invention, the natural cooling source unit includes a compressor 16, an evaporative condenser 17, a throttling device 18, a water-cooled evaporator 19 and three Shut-off valve. The exhaust port 16.1 of the compressor is connected to the inlet 17.2 of the heat exchange coil on one side of the sheet, and the throttling device and the stop valve 22 are connected to the heat exchange coil on one side of the sheet. Between the outlet 17.4 of the coil and the refrigerant inlet 19.1 of the water-cooled evaporator; the shut-off valve 23 is connected between the exhaust port of the compressor and the refrigerant outlet 19.2 of the water-cooled evaporator; the water-cooled The chilled water inlet 21 of the evaporator is connected to the inlet 17.1 of the heat exchange coil on the other side of the sheet through the shut-off valve 24, and the outlet 17.3 of the heat exchange coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com