Coal slime dehydration drying equipment and method

A technology for dehydration drying and coal slime, which is used in drying, dryer, lighting and heating equipment, etc., can solve the problems of dust and harmful gas being difficult to meet environmental protection standards, limited dehydration efficiency, etc., to improve the drying effect , the effect of speeding up the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

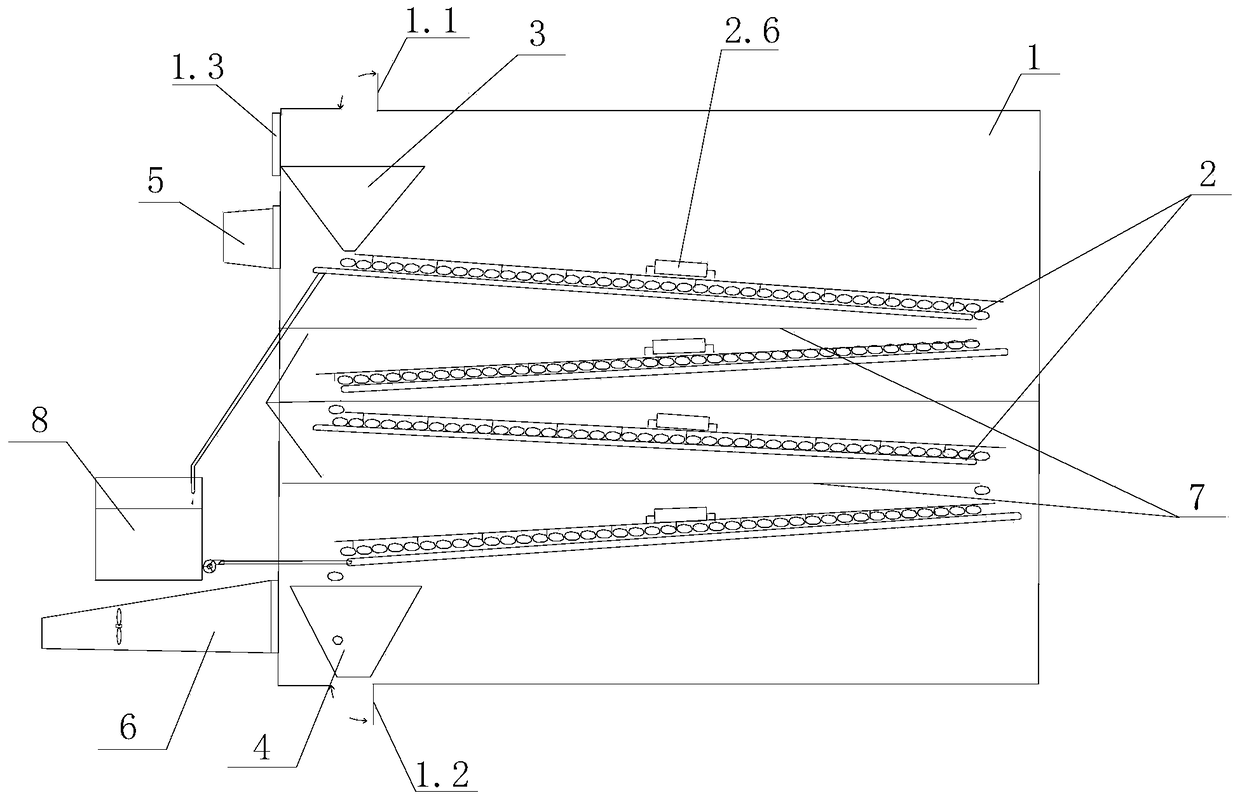

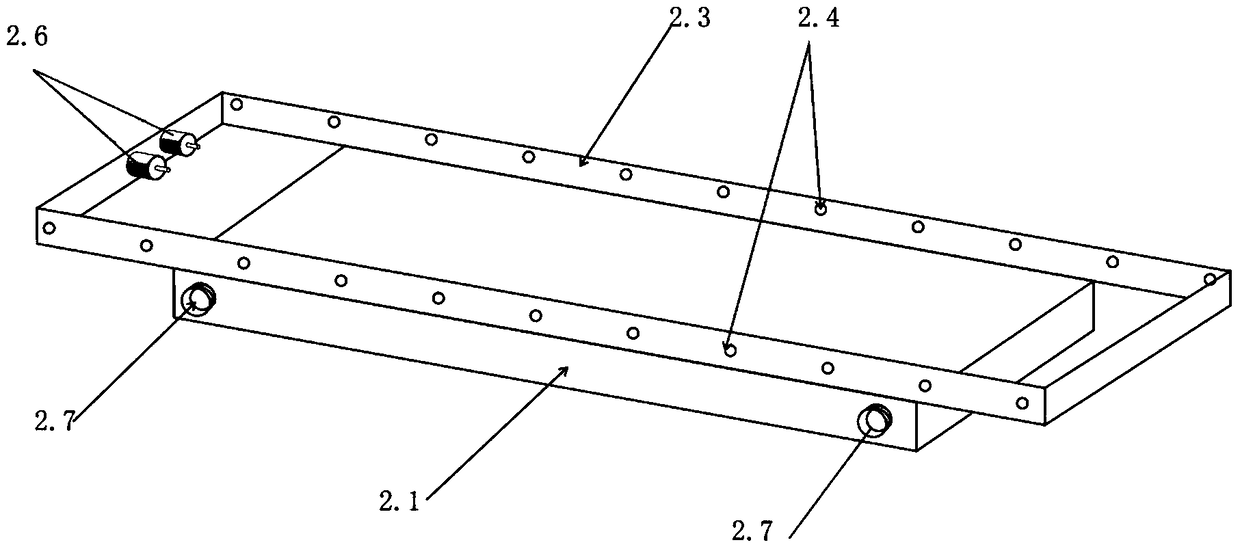

[0029] Example: such as figure 1 A coal slime dehydration drying equipment shown includes a drying room 1 and a coal slime conveying device arranged in the drying room 1. Belt 2, one end of the conveyor belt 2 is the coal slime inlet end, the other end of the conveyor belt 2 is the coal slime outlet end, and the coal slime outlet end of the conveyor belt 2 is correspondingly arranged at the bottom of the conveyor belt 2 adjacent to it. Above the coal slime inlet end, and the vertical position of the coal slime inlet end of the conveyor belt 2 is higher than the coal slime outlet end of the conveyor belt 2, and a plurality of conveyor belts 2 form a complete zigzag coal slime conveying device on the vertical plane as a whole A vibrating feeder 3 is provided above the coal slime inlet end of the conveyor belt 2 on the uppermost layer of the slime conveying device, and a feed sealing door 1.1 is provided at the position corresponding to the vibrating feeder 3 on the top of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com