Resource-based and harmless treatment method for kitchen waste

A technology of kitchen waste and treatment method, applied in the field of resource recovery and recycling, can solve the problems of large equipment investment, soil salinization, and low treatment cost, and achieve the effects of small investment, prevention of land salinization, and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

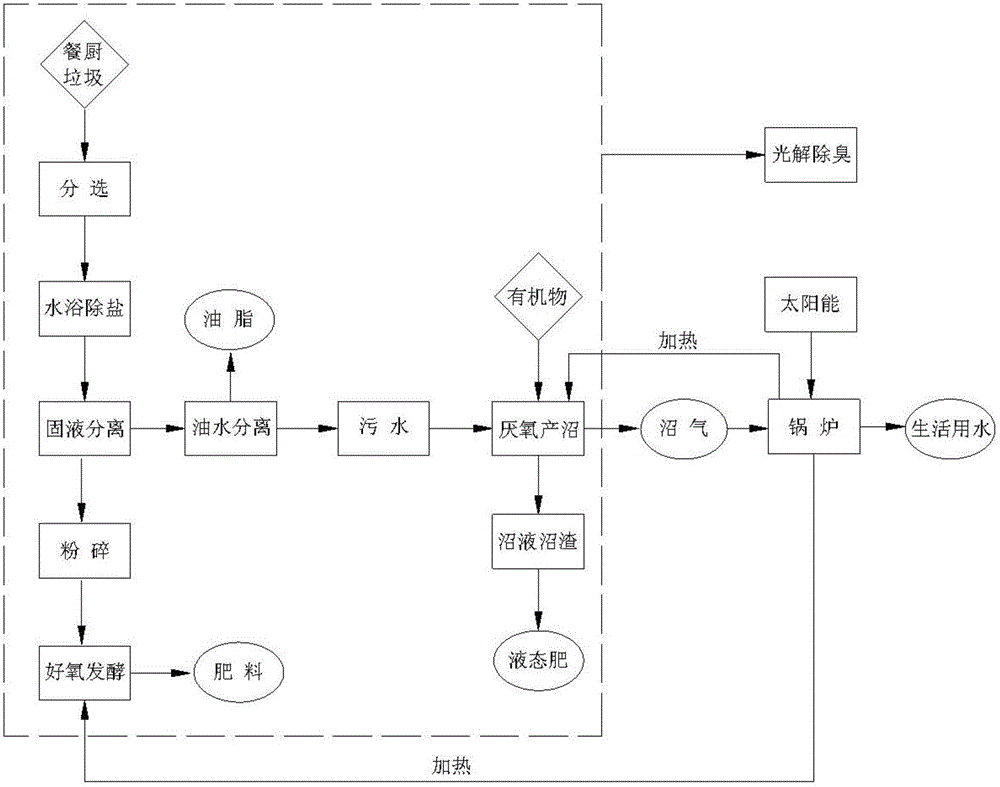

[0029] Embodiment 1: Referring to accompanying drawing 1, a kind of food waste recycling, harmless treatment method of the present invention is illustrated, and the steps are as follows:

[0030] (a) Sorting of food waste: unload the food waste into the hopper, send it to the mechanical sorter by the scraper conveyor, and then sort it mechanically and manually to ensure that the plastic and glass in the food waste Bottles, chopsticks, ceramics and other sundries are separated, recyclable sundries are recycled, and unusable sundries are transported to sanitary landfills for landfill.

[0031] (b) Water bath desalination: Put the sorted food waste into the water bath, then add water, heat and stir to make it fully mixed, which is the process of diluting and desalinating the salt content of the food waste. Optimum process conditions: V (volume of water) / V (volume of food waste) = 2, stirring time 10 minutes, temperature 25°C, the salt content of food waste decreased from (0.84±0....

Embodiment 2

[0041] Example 2: The difference from Example 1 is that in step (b) water bath desalination, process conditions: V (volume of water) / V (volume of food waste) = 1.5, stirring time 8 min, temperature 20°C. Step (d) During the aerobic fermentation of the solid content: the crusher crushes the solid content of the food waste into fine particles, adjusts the moisture content of the solid content to 50%, and puts in straw to adjust the carbon-nitrogen ratio (C / N) of the mixture to 25 : 1, the mass ratio of microbial inoculum inoculum is 1 / 100,000, heat preservation and mechanical stirring at a temperature of 80°C for 3 hours of high-temperature sterilization, then cool down and keep the temperature at 50°C for 8 hours, and the fermentation ends After sieving, it will be bagged and made into organic fertilizer after 6 days of decomposing. Step (e) During the anaerobic fermentation of waste liquid: the sewage is passed into the anaerobic fermentation tank, organic matter and water are...

Embodiment 3

[0042] Example 3: The difference from Example 1 is that in step (b) water bath desalination, process conditions: V (volume of water) / V (volume of food waste) = 2.5, stirring time 15 min, temperature 30°C. Step (d) During the aerobic fermentation of the solid content: the crusher crushes the solid content of the food waste into fine particles, adjusts the moisture content of the solid content to 60%, and puts in straw to adjust the carbon-nitrogen ratio (C / N) of the mixture to 30 : 1, the mass ratio of microbial inoculum inoculum is 2 / 100,000, heat preservation and mechanical stirring at a temperature of 90°C for 1 hour of high-temperature sterilization, then cool down and keep the temperature at 60°C for 6 hours, and the fermentation ends After sieving, it will be bagged and made into organic fertilizer after 6 days of decomposing. Through biological fermentation, it can kill harmful microorganisms in food waste and produce high-efficiency organic fertilizers. Step (e) During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com