High oil suction resin and uses thereof

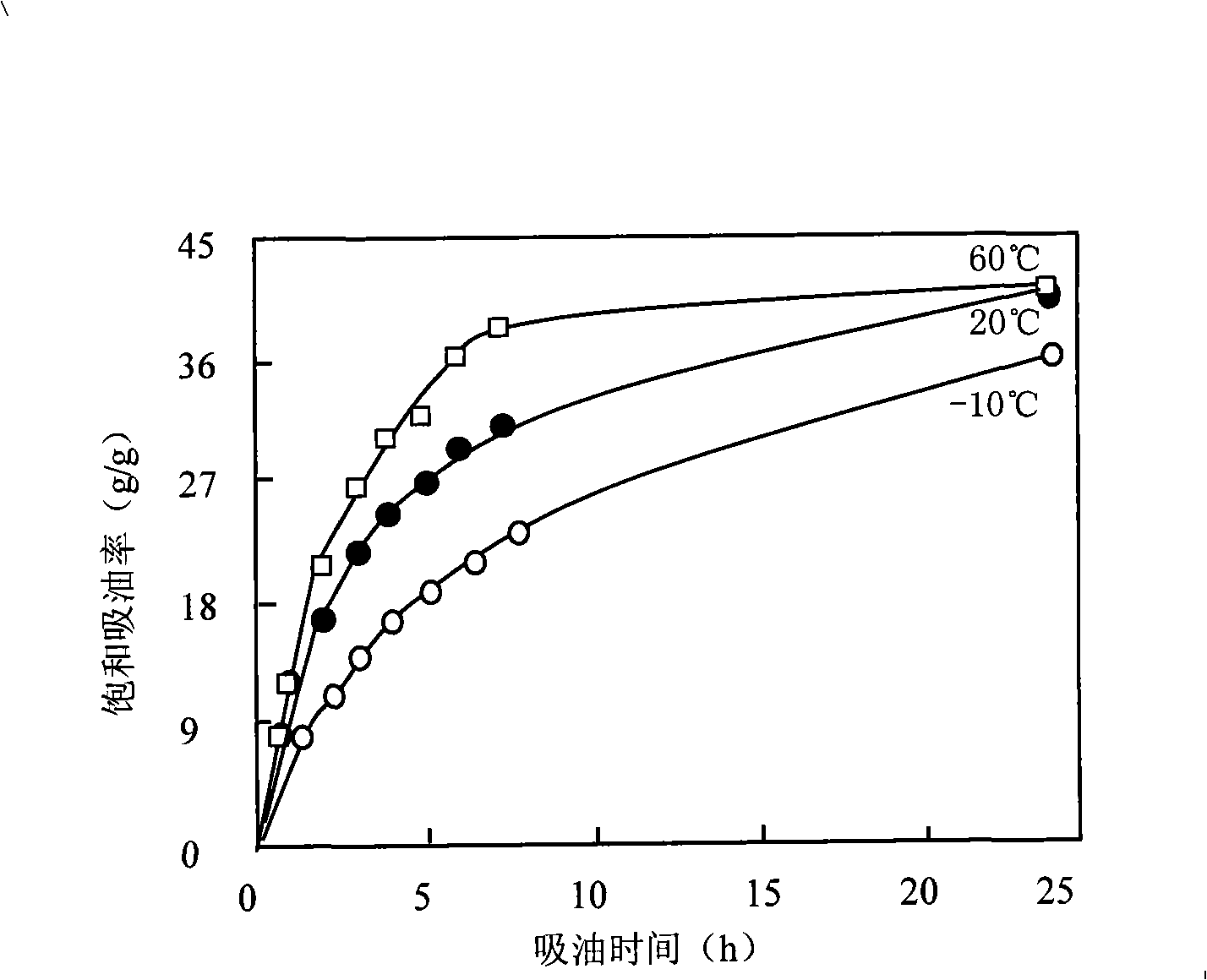

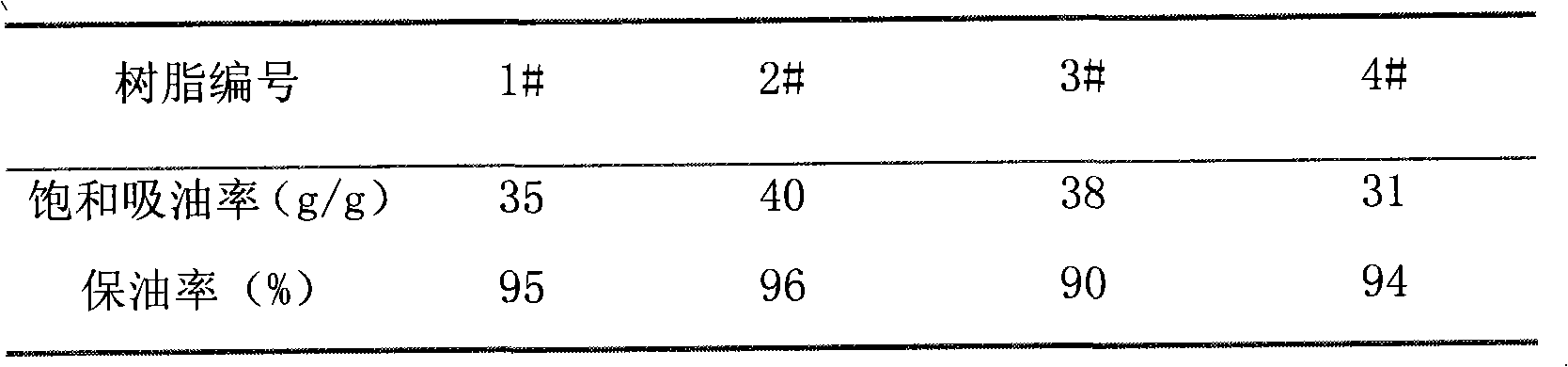

A super oil-absorbing resin, selected technology, applied in grease/oily substance/float removal devices, other chemical processes, adsorbed water/sewage treatment, etc., can solve the problems of low oil absorption rate, difficult oil and water, and complete separation, etc. High saturated oil absorption rate, fast oil absorption rate and good oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve 0.5g of methylcellulose in 200g of water, heat to 40-50°C, stir well to dissolve it, transfer it to a three-necked flask equipped with a mechanical stirring device, a condenser tube and a nitrogen inlet tube, and heat the solution to 50-50°C. 70°C, under the condition of nitrogen protection, add 10g of styrene, 90g of butyl methacrylate, 10g of chloroform, 1.5g of dipropylene glycol ester, 1.0g of dibenzoyl peroxide, and control the stirring speed at 800-1000 rpm , react for 1-2 hours under the protection of nitrogen; when the temperature is raised to 70-90 ° C, the stirring speed is controlled at 400-600 rpm under the protection of nitrogen, and the reaction is continued for 3-6 hours; Under nitrogen protection, the stirring speed was controlled at 200-300 rpm, and the reaction was performed for 0.5-2 hours. The obtained polymer was filtered, fully washed, dried in a blast oven at 80°C until constant weight, pulverized, and passed through an 80-mesh sieve to o...

Embodiment 2

[0033] Dissolve 0.2g of polyvinyl alcohol in 300g of water, heat to 40-60°C, stir well to dissolve, transfer it to a three-necked flask equipped with a mechanical stirring device, a condenser tube and a nitrogen inlet tube, and heat the solution to 60-80°C ℃, under the condition of nitrogen protection, add 4g of styrene, 56g of butyl acrylate, 40g of butyl methacrylate, 20g of ethyl acetate, 2.0g of dipropylene glycol ester, 0.8g of tert-butyl peroxybenzoate, and control the stirring The speed is 800-1000 rpm, and the reaction is under the protection of nitrogen for 1-2 hours; when the temperature is raised to 70-90°C, the stirring speed is controlled at 400-600 rpm under the protection of nitrogen, and the reaction is continued for 3-6 hours; continue to heat up to 80-100 Under the condition of ℃, under the protection of nitrogen, the stirring speed is controlled at 200-300 rpm, and the reaction is performed for 1-2 hours. The polymer was obtained by filtration, washed thorou...

Embodiment 3

[0035] Dissolve 0.2g of polyvinyl alcohol in 300g of water, heat to 40-60°C, stir well to dissolve, transfer it to a three-necked flask equipped with a mechanical stirring device, a condenser tube and a nitrogen inlet tube, and heat the solution to 60-80°C ℃, under the condition of nitrogen protection, add styrene 4g, butyl acrylate 96g, ethyl acetate 30g, diethylene glycol dimethacrylate 2.5g, tert-butyl peroxybenzoate 0.8g, control the stirring speed 800~1000 Turn, react for 1-2 hours under the protection of nitrogen; under the condition of heating up to 70-90°C, control the stirring speed at 400-600 rpm under the protection of nitrogen, and continue the reaction for 3-6 hours; continue to heat up to 80-100°C, Under the protection of nitrogen, the stirring speed is controlled at 200-300 rpm, and the reaction is performed for 0.2-2 hours. The obtained polymer was filtered, fully washed, dried in a blast oven at 80°C until constant weight, pulverized, and passed through an 80-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com