High oil absorption resin and synthetic method thereof

An oleoresin and synthesis method technology, applied in the field of functional polymer synthetic materials, can solve the problems of low polymerization activity of long-chain acrylic acid esters, stay in the laboratory research stage, and resins cannot be reused, etc., to achieve convenient recycling, fast The effect of shortening the oil absorption ratio and the polymerization reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

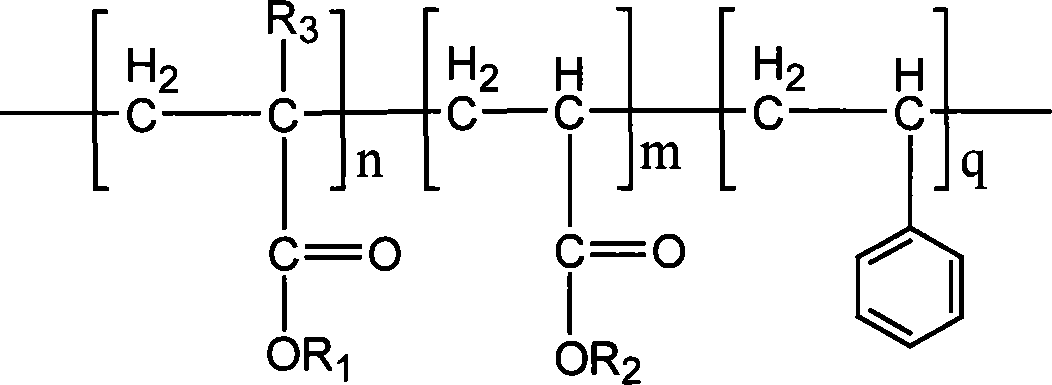

Method used

Image

Examples

Embodiment 1

[0033] Add hydroxyethyl cellulose to 200 parts of water to prepare a 0.3-5.0% aqueous solution, add surfactant sodium oleate (0.1-0.3% of water), stir at 30-50°C to dissolve and cool.

[0034] Taking the weight of super oil-absorbing resin as 100 parts, add 40 parts of butyl acrylate, 10 parts of 2-ethylhexyl acrylate, 30 parts of styrene, and 20 parts of methyl methacrylate under stirring, and the total weight of monomers is 0.1% -0.6% of divinylbenzene, 0.5%-1.6% of benzoyl peroxide by total monomer weight, when the temperature reaches 75°C-80°C, the polymerization reaction starts. Keep the reaction at this temperature for 2-3 hours, then raise the temperature to 90° C. and mature for one hour. After the reaction is completed, the product is cooled, filtered, washed twice with hot water at 60-80°C and once with methanol, and dried in an oven at room temperature to obtain an oil-absorbing resin.

[0035] The oil-absorbing resin is a transparent bead-shaped polymer. The prima...

Embodiment 2

[0037] Add hydroxyethyl cellulose to 200 parts of water to prepare a 0.3-5.0% aqueous solution, add surfactant sodium oleate (0.1-0.3% of water), stir at 30-50°C to dissolve and cool.

[0038] Taking the weight of super oil-absorbing resin as 100 parts, add 50 parts of butyl acrylate, 15 parts of 2-ethylhexyl acrylate, 15 parts of styrene, and 20 parts of methyl methacrylate under stirring, and the total amount of monomers is 0.1%. ~.6% divinylbenzene, 0.5% ~ 6% benzoyl peroxide in the total amount of monomers, when the temperature reaches 75°C ~ 0°C, the polymerization reaction starts. Keep the reaction at this temperature for 2-hours and then raise the temperature to 90° C. for aging for one hour. After the reaction is completed, the product is cooled, filtered, washed twice with hot water at 60-0°C and once with methanol, and dried in an oven at room temperature to obtain an oil-absorbing resin.

[0039] The oil-absorbing resin is a milky white translucent spherical polyme...

Embodiment 3

[0041] Add hydroxyethyl cellulose to 200 parts of water to prepare a 0.3-50% aqueous solution, add surfactant sodium oleate (0.1-0.3% of water), stir at 30-50°C to dissolve and cool. Then add 40 parts of butyl acrylate, 30 parts of 2-ethylhexyl acrylate, 10 parts of styrene, 20 parts of methyl methacrylate, and 1,4-butanediene with 0.1% to 0.6% of the total amount of monomers under stirring. Alcohol ester diacrylate, benzoyl peroxide with 0.5% to 1.6% of the total amount of monomers, when the temperature reaches 75°C to 80°C, the polymerization reaction starts. Keep the reaction at this temperature for 2 to 3 hours and then raise the temperature to 90°C for aging for one hour. After the reaction is completed, the product is cooled, filtered, washed twice with hot water at 60-80°C and once with methanol, and dried in an oven at room temperature to obtain an oil-absorbing resin.

[0042] The resin is milky white, translucent to opaque spherical polymer, elastic, and the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com