Solid-phase-free high density well killing fluid

A high-density, well-killing fluid technology, applied in the chemical field, can solve problems such as poor thermal stability, poor reservoir compatibility, and secondary damage to near-well reservoirs, and achieve low system viscosity, strong corrosion resistance, and simple on-site preparation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The embodiment of the present application provides a solid-free high-density well killing fluid, including: oxygen scavenger, corrosion inhibitor, compound salt weighting agent, crystallization inhibitor, waterproof locking agent and water, wherein the mass percentage of each component The content is: 0.1-0.5% of oxygen scavenger, 0.5-3.0% of corrosion inhibitor, 40-70% of compound salt weighting agent, 5-15% of high-efficiency crystallization inhibitor, 0.1-1.5% of waterproof locking agent, and the rest is water. The sum of the mass percentages of the components is 100%.

[0021] In the solid-free high-density killing fluid: the oxygen scavenger can be a compound of sodium thiosulfate and thiourea, and the compounding ratio is 1:3, where the compounding ratio refers to the weight ratio;

[0022] The corrosion inhibitor can be a compound of Mannich base and chlorinated 2-alkyl-1-(N-polyoxyethylene-2-aminoethyl) imidazoline-1-benzyl ammonium fatty acid salt, the corrosio...

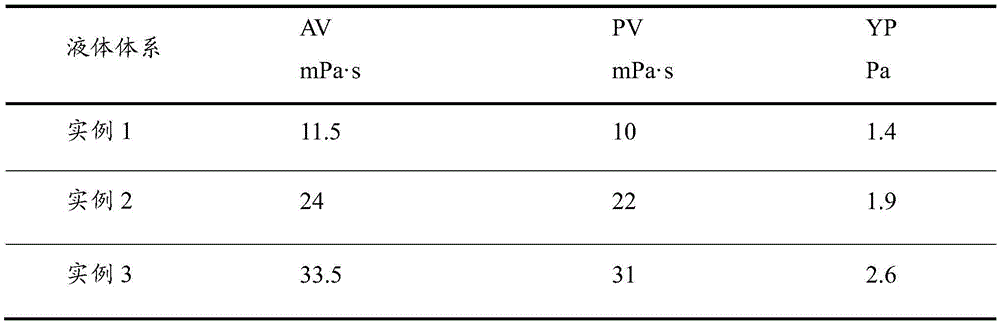

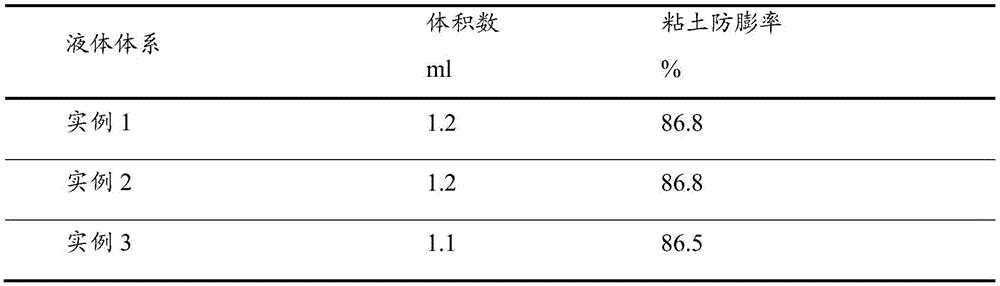

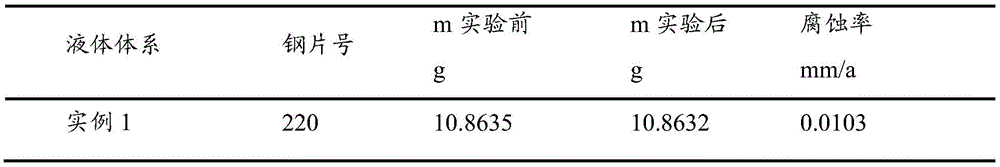

example 1

[0031] The components and mass percentages of the solid-free high-density killing fluid are: 0.1-0.2% oxygen scavenger, 0.5-3.0% corrosion inhibitor, 40-50% compound salt weighting agent, and 5% high-efficiency crystallization inhibitor. ~ 8%, waterproof locking agent 0.1 ~ 0.5%, the rest is water, the sum of the weight percentages of each component is 100%.

[0032] The solid-free high-density well killing fluid provided in Example 1 is suitable for low porosity and low permeability, well temperature ≤ 150°C, and formation pressure coefficient of 1.5-1.6g / cm 3 Reservoir testing and workover.

example 2

[0034] The components and mass percentages of the solid-free high-density well killing fluid are: 0.2-0.3% oxygen scavenger, 0.5-3.0% corrosion inhibitor, 50-60% compound salt weighting agent, and 8 high-efficiency crystallization inhibitors. ~10%, waterproof locking agent 0.5~1.0%, the rest is water, and the sum of the weight percentages of each component is 100%.

[0035] The solid-free high-density well killing fluid provided in Example 2 is suitable for low porosity and low permeability, well temperature 150-165°C, formation pressure coefficient 1.6-1.7g / cm 3 Reservoir testing and workover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com