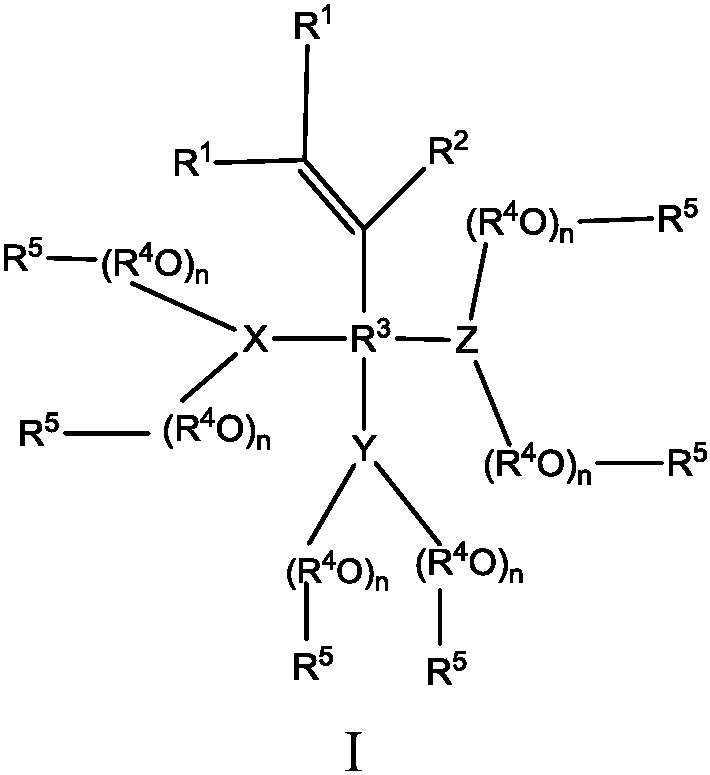

Solid polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of water reducer and polycarboxylic acid, which is applied in the field of solid polycarboxylate water reducer and its preparation, and can solve the problems of increasing preparation cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

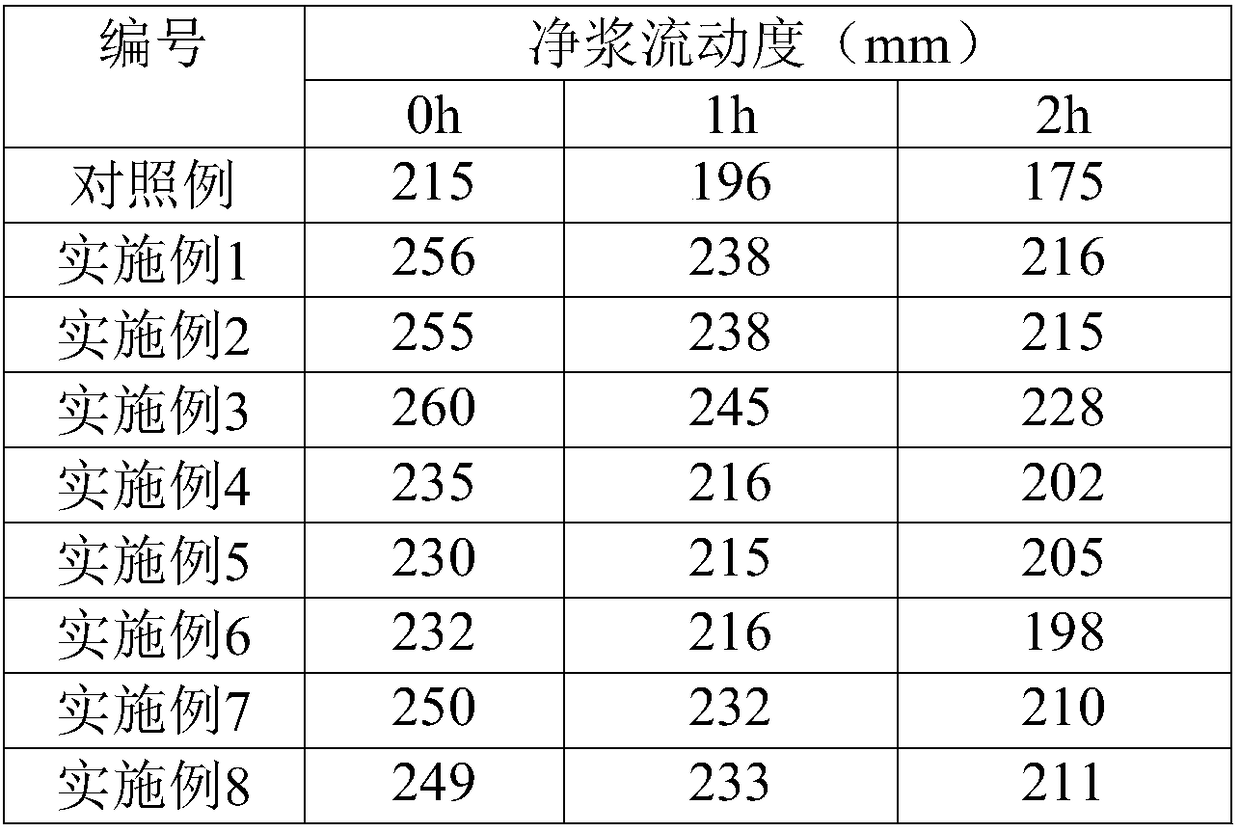

Examples

preparation example 1

[0066] With reference to the method described in Example 3 and Example 4 in patent document CN201510041919.X, with 2-methallyl alcohol or 3-methyl-3-butene-1-alcohol as initiator, the mass ratio of propylene oxide (PO): ethylene oxide (EO) = 21.5:100, and a liquid unsaturated polyether macromonomer with a molecular weight of 2400 was prepared.

Embodiment 1

[0068] The liquid unsaturated polyether macromonomer (molecular weight is 2400) prepared with 3-methyl-3-buten-1-ol as starter in 100g Preparation Example 1 is placed in the kettle, and 2.0g mercaptoacetic acid is added , 0.2gL-ascorbic acid, then began to drop a mixture of 15g acrylic acid and 0.1g tert-butyl peroxybenzoate, the time for the dropwise addition was 2h, after the completion of the dropwise aging for 1h, after cooling to room temperature, it was ground into solid particles . The product is characterized by infrared spectroscopy, in its infrared spectrum, 3440.79cm -1 It is the stretching vibration of O-H, 2871.40cm -1 and 2873.53cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1705.89cm -1 It is the stretching vibration of C=O, 1105.58cm -1 and 1259.99cm -1 The very strong absorption peak at is -C-O-C-stretching vibration; the infrared results show that the solid water reducer is successfully synthesized....

Embodiment 2

[0070] 100g of the liquid unsaturated polyether macromer (molecular weight is 2400) prepared with 3-methyl-3-buten-1-ol as a starter in Preparation Example 1 was placed in the kettle, and 0.05g of mercaptoacetic acid was added , 1.0gL-ascorbic acid, and then began to drop a mixture of 2.5g acrylic acid and 1g tert-butyl peroxybenzoate for 2 hours. After the addition was completed, it was matured for 1 hour. After cooling to room temperature, it was ground into solid particles . The product is characterized by infrared spectroscopy, in its infrared spectrum, 3440.85cm -1 It is the stretching vibration of O-H, 2871.45cm -1 and 2873.60cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1705.5cm -1 It is the stretching vibration of C=O, 1260.15cm -1 The very strong absorption peak at is -C-O-C-stretching vibration; the infrared results show that the solid water reducer is successfully synthesized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com