Quick-curing organosilicon pressure-sensitive adhesive and adhesive tape

A silicon pressure-sensitive adhesive, fast-curing technology, used in adhesives, adhesive additives, pressure-sensitive films/sheets, etc. High problems, to achieve the effect of wide range of adhesion, fast curing rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

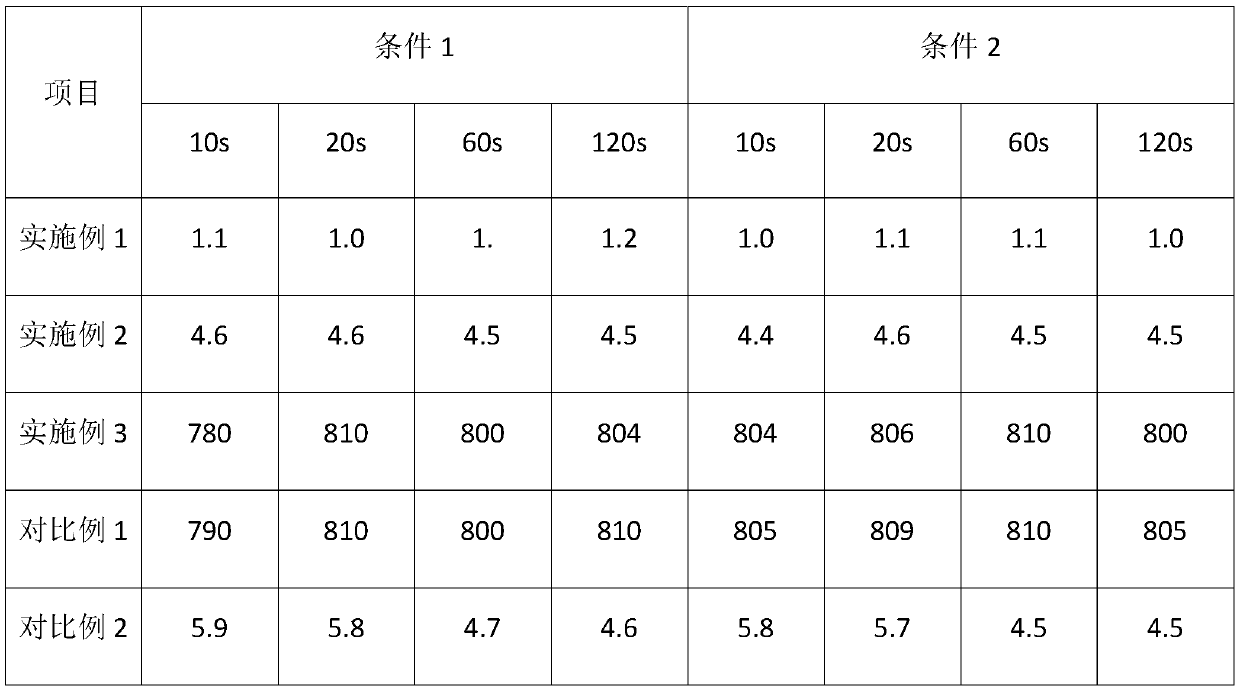

Examples

preparation example Construction

[0102] At the same time, the present invention also discloses a method for preparing a fast-curing silicone pressure-sensitive adhesive, which is used to prepare the above-mentioned silicone pressure-sensitive adhesive, which mainly includes the following steps:

[0103] 1) adding the solvent and vinyl-containing polysiloxane into the reaction kettle, stirring at a temperature of 40-50°C for 3 hours to obtain a silicone rubber dispersion with a solid content of 24.5%-25.5%;

[0104] 2) Take the solvent again, and stir and mix it with the silicone rubber dispersion in step 1) in a ratio of 1:1 by mass;

[0105] 3) During the stirring process, sequentially add methyl vinyl MQ silicone tackifier, crosslinking agent, reaction inhibitor and catalyst, and mix thoroughly to obtain the silicone pressure-sensitive adhesive.

[0106] The above-mentioned adhesive and the preparation method of the adhesive in the present invention can be used for PET substrate silicone protective film, su...

Embodiment 1

[0142] Take 25 parts of vinyl-terminated silicone rubber with a weight-average molecular weight of 550,000 and a vinyl content of 0.08%, and disperse them in 75 parts of a mixed solvent with a mass ratio of toluene and ethyl acetate of 1:1 to obtain a silicone rubber dispersion with a solid content of 25%. Then add 1 part of silicone oil with silicon hydrogen content of 1.1mol / 100g and 0.5 part of reaction inhibitor to fully disperse; then add 1 part of platinum catalyst dispersed and diluted in 10 parts of toluene solution and fully disperse for 30 minutes , the glue was obtained by stirring with a pump, and the glue was applied to a 50-micron thick PET substrate through a slit-type coating head, and the wet glue thickness was controlled to be 80 μm to obtain a tape.

[0143] Send the above-mentioned adhesive tape into 7 sections of 40-meter blast drying tunnel, with temperature gradients of 110°C, 135°C, 150°C, 160°C, 165°C, 160°C, 120°C, and line speed of 20m / min to obtain t...

Embodiment 2

[0145]Take 25 parts of vinyl-terminated silicone rubber with a weight-average molecular weight of 550,000 and a vinyl content of 0.08%, and 4.5 parts of MQ silicone tackifier with a vinyl content of 0.2% and a M / Q ratio of 0.7, and disperse them in 140 parts of toluene A silicone rubber dispersion with a solid content of 25% is obtained in a mixed solvent with a mass ratio of 1:1 to ethyl acetate, and is fully swollen; then add 1 part of silicone oil with a silicon hydrogen content of 1.1mol / 100g and 0.5 part of a reaction inhibitor, Fully disperse; then add 1 part of the platinum catalyst previously dispersed and diluted in 10 parts of toluene solution to fully disperse for 30 minutes, and get the glue by stirring with a pump, and put the glue into the slit coating head and coat it on the PET substrate with a thickness of 50 microns. Control the thickness of the wet glue to 70 μm to obtain an adhesive tape.

[0146] Send the above-mentioned adhesive tape into 7 sections of 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com