Photosensitive resin-based carbon source/silicon carbide ceramic slurry, method for preparing porous carbon/silicon carbide green body, structural member and preparation method of structural member

A technology of silicon carbide ceramics and photosensitive resin, applied in the direction of additive processing, etc., can solve the problems that it is difficult to increase the carbon content of porous carbon/silicon carbide blanks, difficult to obtain high solid content slurry, and high viscosity of the mixture, and achieve high The effect of active light curing accuracy, high molding dimensional accuracy and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

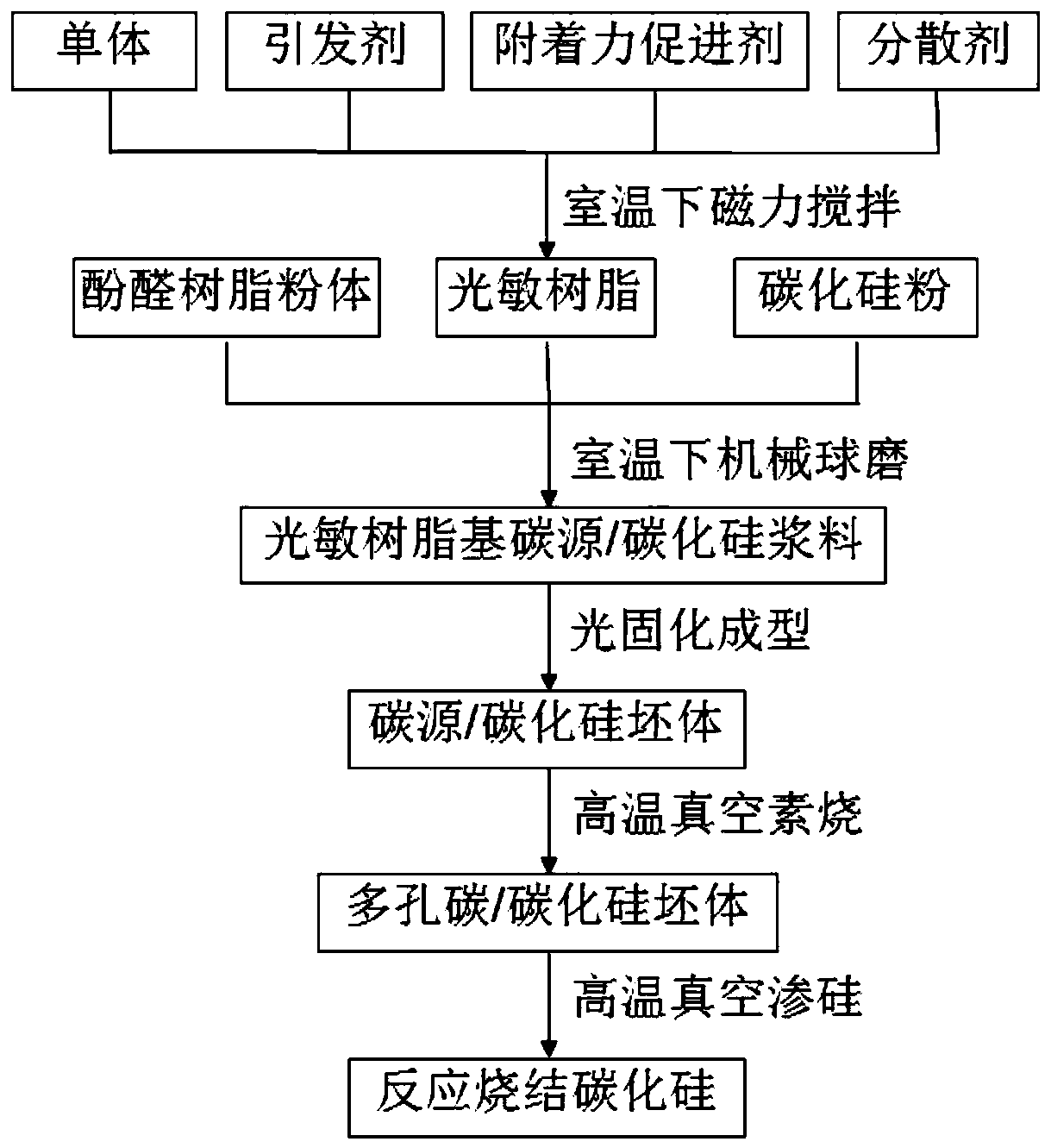

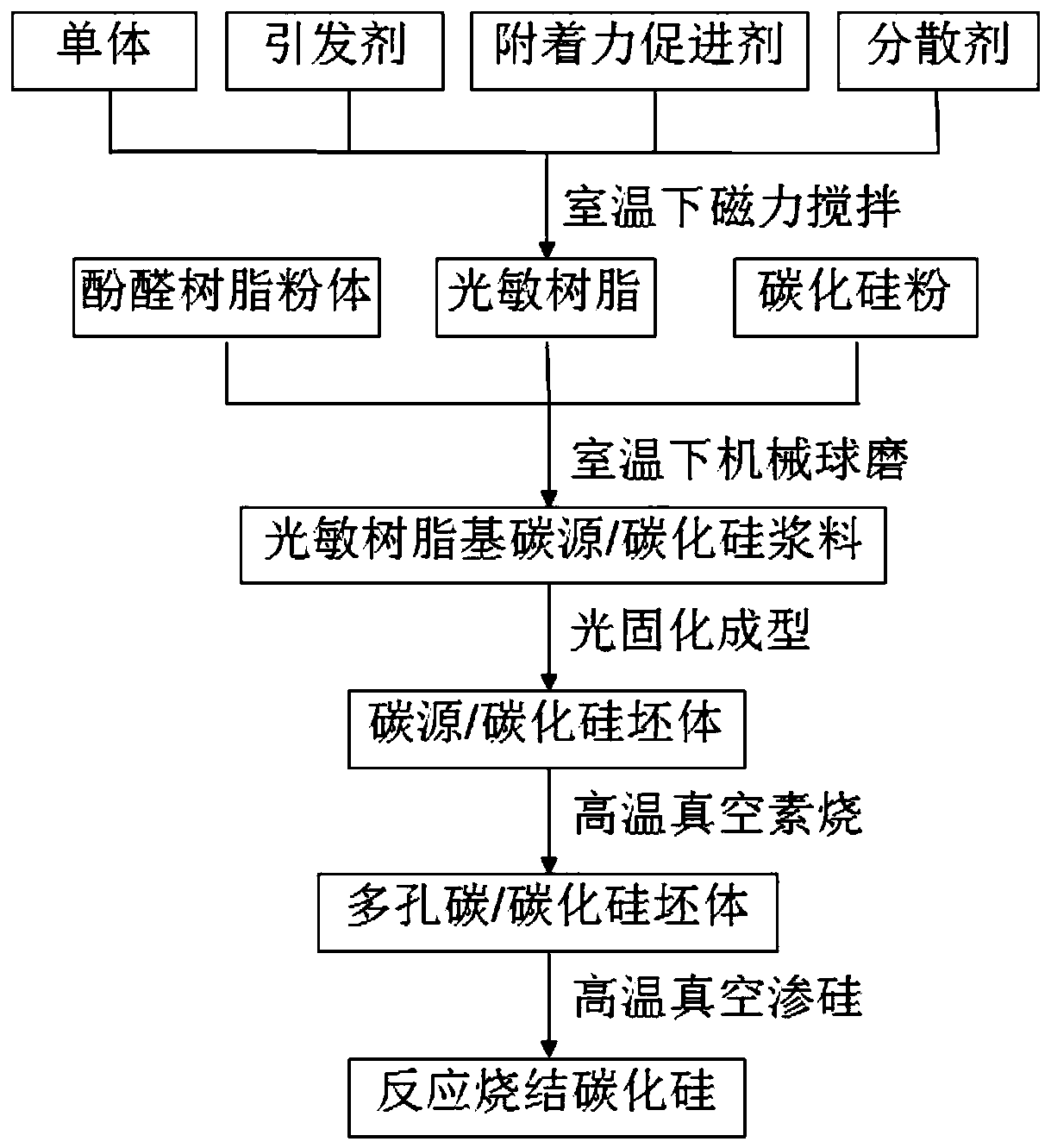

[0047] The present invention also proposes a method for preparing a porous carbon / silicon carbide green body, as shown in the attached figure 1 As shown, it includes the following steps: preparing photosensitive resin-based carbon source / silicon carbide ceramic slurry, molding, and vacuum bisque firing.

[0048] When preparing the slurry, first weigh the three monomers according to the formula, mix them, then add the measured photoinitiator, adhesion promoter and powder dispersant, and stir magnetically at room temperature for 20 minutes to 40 minutes to obtain a photosensitive resin. Then, two-stage compounding of silicon carbide powders with two different median diameters as raw materials, phenolic resin powder as carbon source, photosensitive resin as dispersion medium, and zirconia balls as ball milling medium, mechanically Ball milling for 6 to 12 hours to obtain a photosensitive resin-based carbon source / silicon carbide ceramic slurry with a solid phase volume content of...

Embodiment 1

[0056] 1) Prepare 80ml of photosensitive resin-based carbon source / silicon carbide slurry with a solid phase content of 30vol.%: add 1,6 hexanediol diacrylate HDDA, morpholine acrylic acid ACMO and hexaethoxylated trimethylolpropane tris Acrylate TMP(EO) 6 TA each 25.88g, 15.51g and 10.34g, add photoinitiator bis(2,4,6-trimethylbenzoyl) phenylphosphine oxide BAPO, adhesion promoter 2-hydroxyethyl methacrylate phosphoric acid 1.55g, 2.16g and 2.16g of ester and amino acid ester copolymer 4200, and magnetically stirred at room temperature for 20 minutes to obtain photosensitive resin; add 5.75g and 26.47g of phenolic resin powder, silicon carbide powder F1200 and silicon carbide powder F240 respectively And 39.70g, with zirconia balls as the ball milling medium, mechanical ball milling at room temperature for 6 hours, to obtain photosensitive resin-based carbon source / silicon carbide slurry;

[0057] 2) Preparation of porous carbon / silicon carbide green body: print the slurry p...

Embodiment 2

[0061] 1) Prepare 80ml of photosensitive resin-based carbon source / silicon carbide slurry with 50vol.% solid phase content: add 1,6 hexanediol diacrylate HDDA, hydroxyethyl acrylate HEA and trimethylolpropane triacrylate TMPTA 16.40g, 9.84g and 6.56g with addition of photoinitiator bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide BAPO, adhesion promoter multifunctional acid acrylate and amino acid ester copolymer 4200 0.98g, 3.60g and 3.60g each, stirred magnetically at room temperature for 40 minutes to obtain a photosensitive resin; add 7.04g, 44.12g and 66.17g of phenolic resin powder, silicon carbide powder F1200 and silicon carbide powder F240 respectively, and use zirconia The ball is used as a ball milling medium, and it is mechanically milled at room temperature for 12 hours to obtain a photosensitive resin-based carbon source / silicon carbide slurry;

[0062] 2) Preparation of porous carbon / silicon carbide green body: print the slurry prepared in step 1) on a light-cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com