Preparing method of mannich base

A technology for Mannich bases and derivatives is applied in the field of preparation of Mannich bases, which can solve the problems of increased operational risk, toxic solvents and high cost, and achieves the effects of low cost, easy operation and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

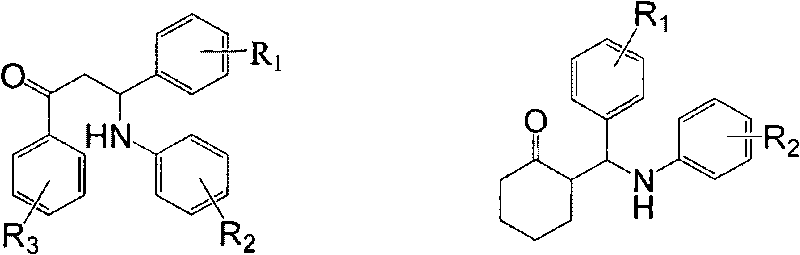

[0008] The present invention is a kind of preparation method of Mannich base, described product Mannich base structural formula is as shown in following formula 1, formula 2, formula 3, formula 4,

[0009]

[0010] Formula 1 Formula 2

[0011]

[0012] Formula 3 Formula 4

[0013] R1=H in formula 1, CH3, NH2, NO2, CH3O, Cl

[0014] R2=H in formula 1, CH3, NH2, NO2, CH3O, Cl

[0015] In formula 1, R3=H, CH3, NH2, NO2, CH3O, Cl

[0016] R1=H in formula 2, CH3, NH2, NO2, CH3O, Cl

[0017] R2=H in formula 2, CH3, NH2, NO2, CH3O, Cl

[0018] R1=H in formula 3, CH3, NH2, NO2, CH3O, Cl

[0019] R2=H in formula 3, CH3, NH2, NO2, CH3O, Cl

[0020] In formula 3, R3=H, CH3, CH3CH2CH3CH2CH2

[0021] In formula 3, R4=H, CH3, CH3CH2CH3CH2CH2

[0022] R1=H in formula 4, CH3, NH2, NO2, CH3O, Cl

[0023] R2=H in formula 4, CH3, NH2, NO2, CH3O, Cl

[0024] R3=H in formula 4, CH3, NO2, Cl

[0025] In order to more fully explain the practice of the present invention, an example o...

Embodiment 1

[0026] Example 1: Add in a 50mL single-necked flask, 1.06g (10mmol) benzaldehyde, 1.07g (10mmol) p-methylaniline and 1.2g (10mmol) acetophenone, add 3mL water as solvent, add 0.15g (1mmol) Trifluoromethanesulfonic acid was used as a catalyst, stirred vigorously by a magnetic stirrer for 16 hours, the crude product was separated, recrystallized from ethanol, and dried at room temperature to obtain 3.1 g of Mannich base with a yield of 98%.

Embodiment 2

[0027] Example 2: In a 50mL single-necked flask, add 1.06g (10mmol) benzaldehyde, 0.93g (10mmol) aniline and 0.98g (10mmol) cyclohexanone, add 3mL water as a solvent, add 0.015g (0.1mmol) trifluoro Methanesulfonic acid was used as a catalyst, stirred vigorously by a magnetic stirrer for 1 hour, and the crude product was separated, recrystallized from ethanol, and dried at room temperature to obtain 2.57 g of Mannich base, with a yield of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com