Composite high-cleanness fuel oil additive and preparation method thereof

A compound additive and cleaning technology, which is applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of aggravated carbon deposition, poor fuel spray effect, unsatisfactory cleaning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

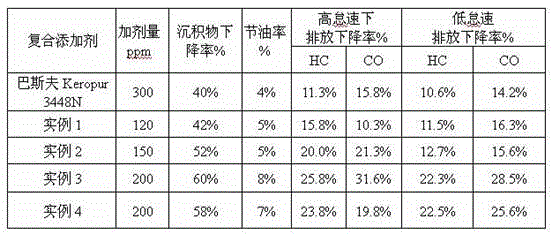

Examples

Embodiment 1

[0018] A high clean fuel compound additive, composed of the following components by mass fraction: main detergent 60%, antiwear agent 5%, anticorrosion agent 3%, antioxidant 3%, carrier oil 15%, thinner 14%.

[0019] The mass percentage of polyisobutylene phenol Mannich base in the detergent main agent is 60%, the mass percentage of PEA polyetheramine in the detergent main agent is 20%, and the polymethacrylamide in the detergent main agent The mass percentage in is 20%.

[0020] In the antiwear agent, the mass percentage of capric acid in the antiwear agent is 20%, the mass percentage of butyl caprate in the antiwear agent is 20%, the mass percentage of dodecanoic acid in the antiwear agent is 50%, and triglyceride oil The mass percentage of acid ester in the antiwear agent is 10%.

[0021] The mass percent of heptadecyl hydroxyethyl imidazoline in the anticorrosion agent is 50%, and the mass percent of oleic acid imidazoline in the anticorrosion agent is 50%.

[0022] In t...

Embodiment 2

[0029] A high-clean fuel compound additive, which is composed of the following components by mass fraction: main detergent 50%, anti-wear agent 6%, anti-corrosion agent 3%, antioxidant 4%, carrier oil 25%, thinner 12%.

[0030] The mass percentage of polyisobutylene phenol Mannich base in the detergent main agent is 40%, the mass percentage of PEA polyetheramine in the detergent main agent is 40%, and the polymethacrylamide in the detergent main agent The mass percentage in is 20%.

[0031] In the anti-wear agent, the mass percentage of butyl caprate in the anti-wear agent is 20%, the mass percentage of ethyl dodecanoate in the anti-wear agent is 40%, and the mass percentage of dodecanoic acid in the anti-wear agent is 30%. , the mass percentage of triolein in the antiwear agent is 10%.

[0032] The mass percentage of oleic acid-based imidazoline in the anticorrosion agent is 100%.

[0033] In the antioxidant, the mass percentage of T551 in the antioxidant is 40%, and the ma...

Embodiment 3

[0039] A high-clean fuel compound additive, composed of the following components by mass fraction: main detergent 45%, anti-wear agent 4%, anti-corrosion agent 7%, antioxidant 4%, carrier oil 30%, thinner 10%.

[0040] The mass percentage of polyisobutylene phenol Mannich base in the detergent main agent is 40%, and the mass percentage of PEA polyetheramine in the detergent main agent is 60%.

[0041] In the antiwear agent, the mass percentage of capric acid in the antiwear agent is 20%, the mass percentage of butyl caprate in the antiwear agent is 10%, and the mass percentage of dodecanoic acid in the antiwear agent is 20%. The mass percent of ethyl acetate in the antiwear agent is 30%, and the mass percent of triolein in the antiwear agent is 20%.

[0042] The mass percentage of heptadecyl hydroxyethyl imidazoline in the anti-corrosion agent is 30% in the anti-corrosion agent; The mass percentage in the etchant is 40%.

[0043] In the antioxidant, the mass percentage of T5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com