Gas turbine engine inlet with noise reduction features

a technology of gas turbine engines and inlet areas, applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of primarily generated aircraft noise, particularly disturbing noise, and attracted attention to noise generated by flying aircraft, so as to reduce the inlet area, and increase the acoustic attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

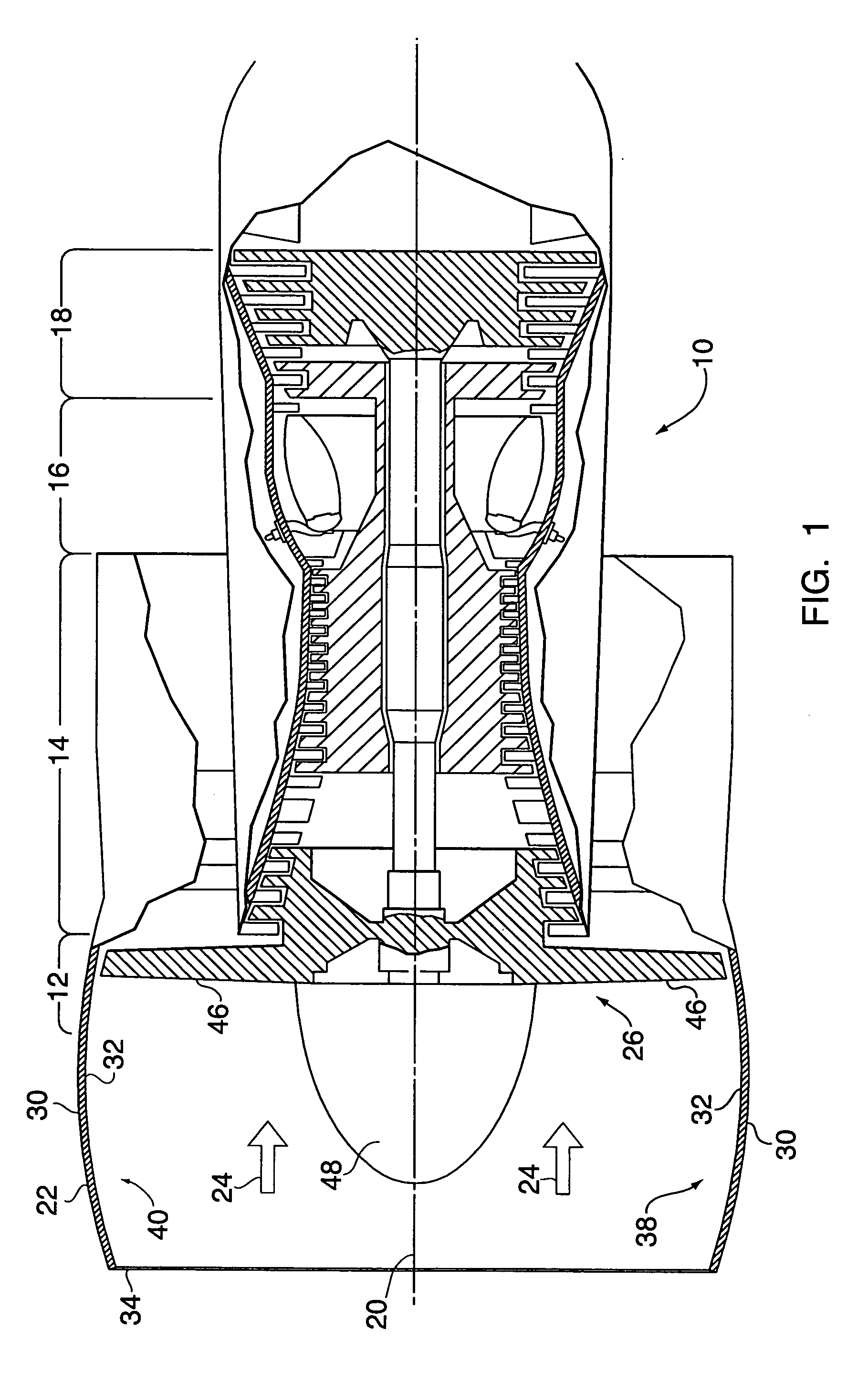

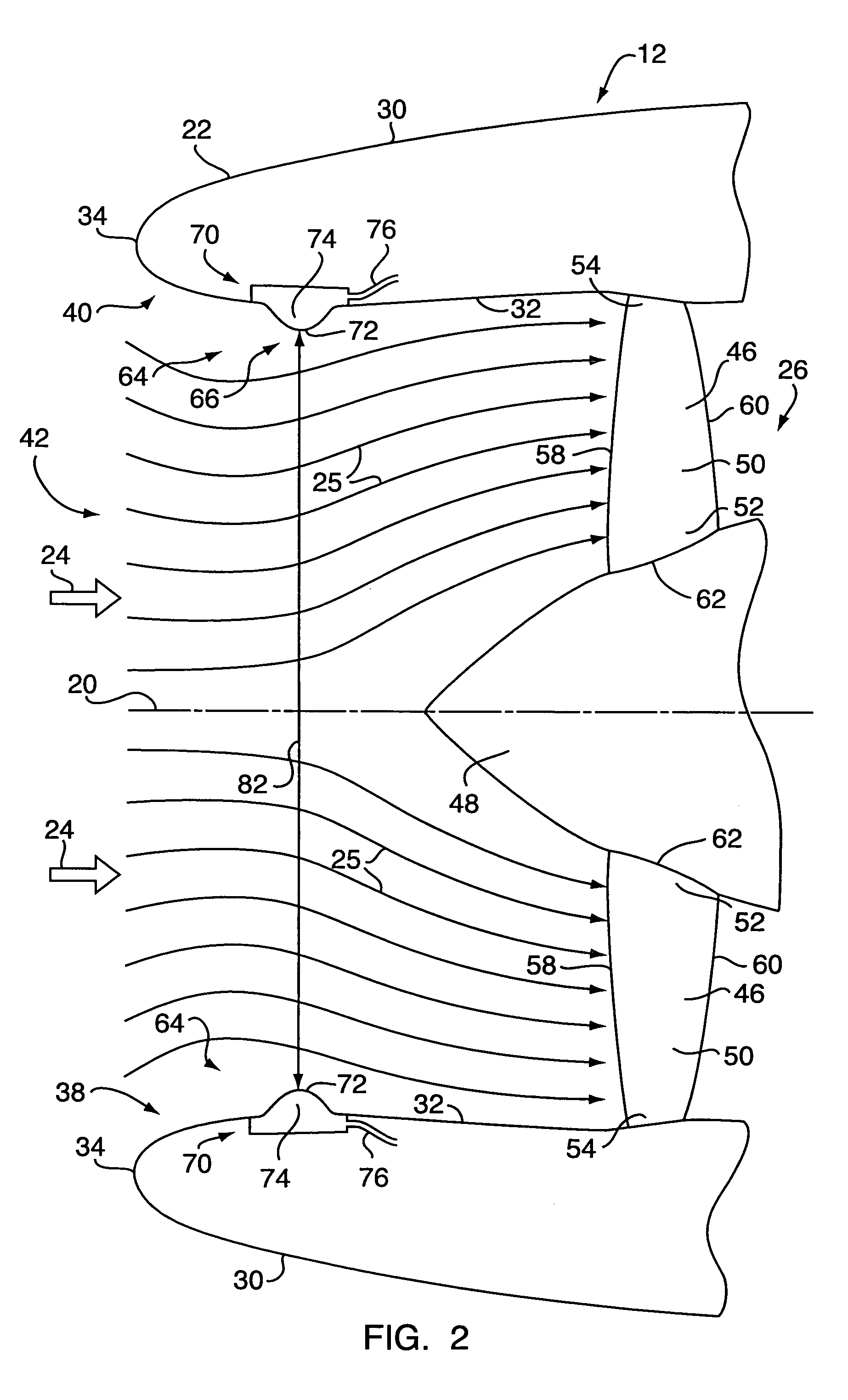

[0028] Referring to FIG. 1, a gas turbine engine 10 includes a fan section 12, a compressor 14, a combustor 16, and a turbine 18 centered around a central axis 20 and enclosed in a nacelle 22. Air 24 flows axially through the sections 12-18 of the engine 10 forming streamlines 25, as seen in FIG. 2. The fan section 12 includes a fan 26 which accelerates the air 24 to contribute to the overall thrust generated by the engine. As is well known in the art, the air 24, compressed in the compressor 14, is mixed with fuel and burnt in the combustor 16. Subsequently, the hot gases expand in the turbine 18 generating thrust to propel the engine 10 and to drive the turbine 18, which in turn drives the fan 26 and the compressor 14.

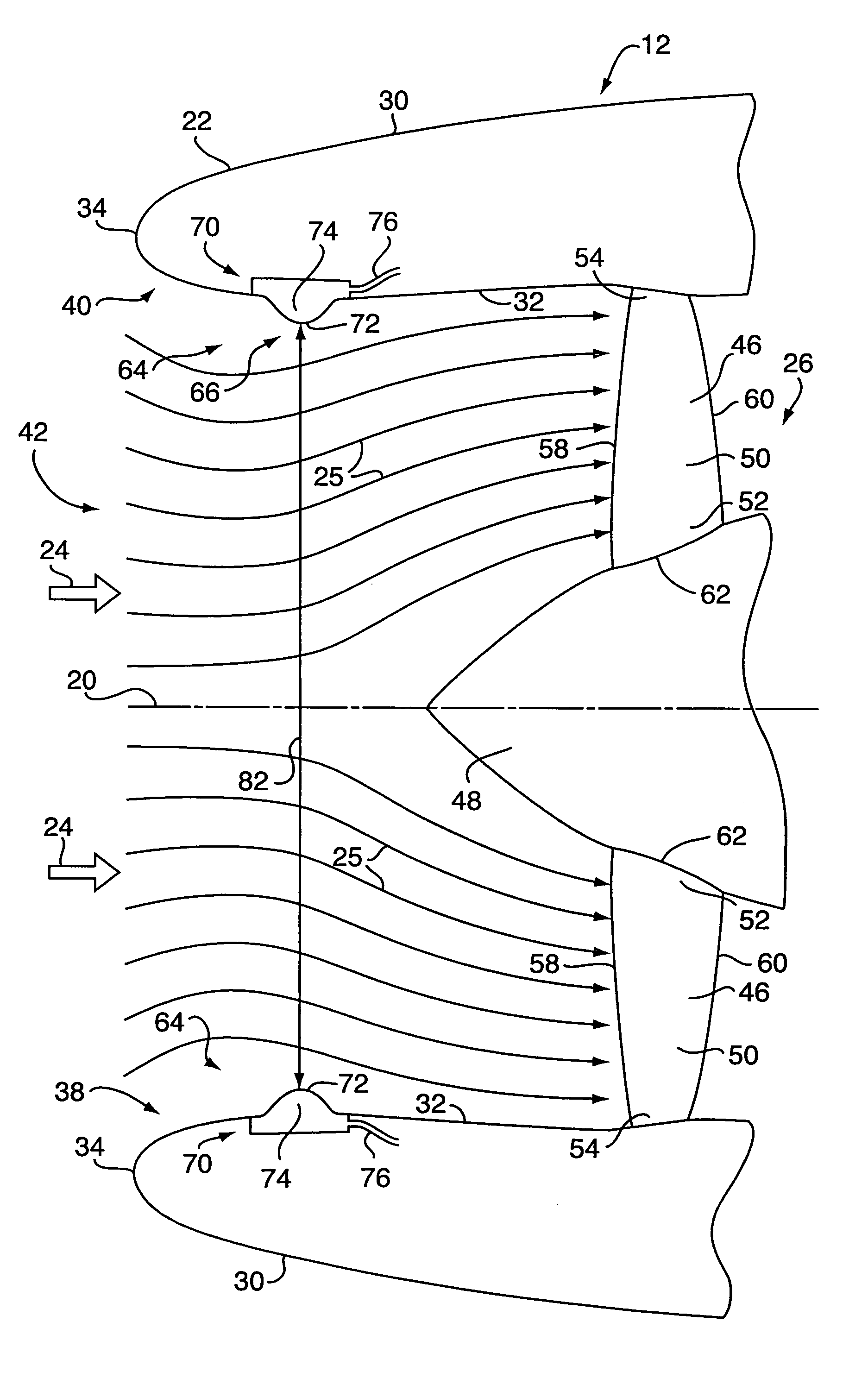

[0029] Referring to FIG. 2, the nacelle 22 includes an outer nacelle surface 30 and an inner nacelle surface 32 joined at a nacelle leading edge 34. The nacelle also includes a lower portion 38 and an upper portion 40. The inner nacelle surface 32 defines an inlet d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com