Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about How to "Effective noise reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

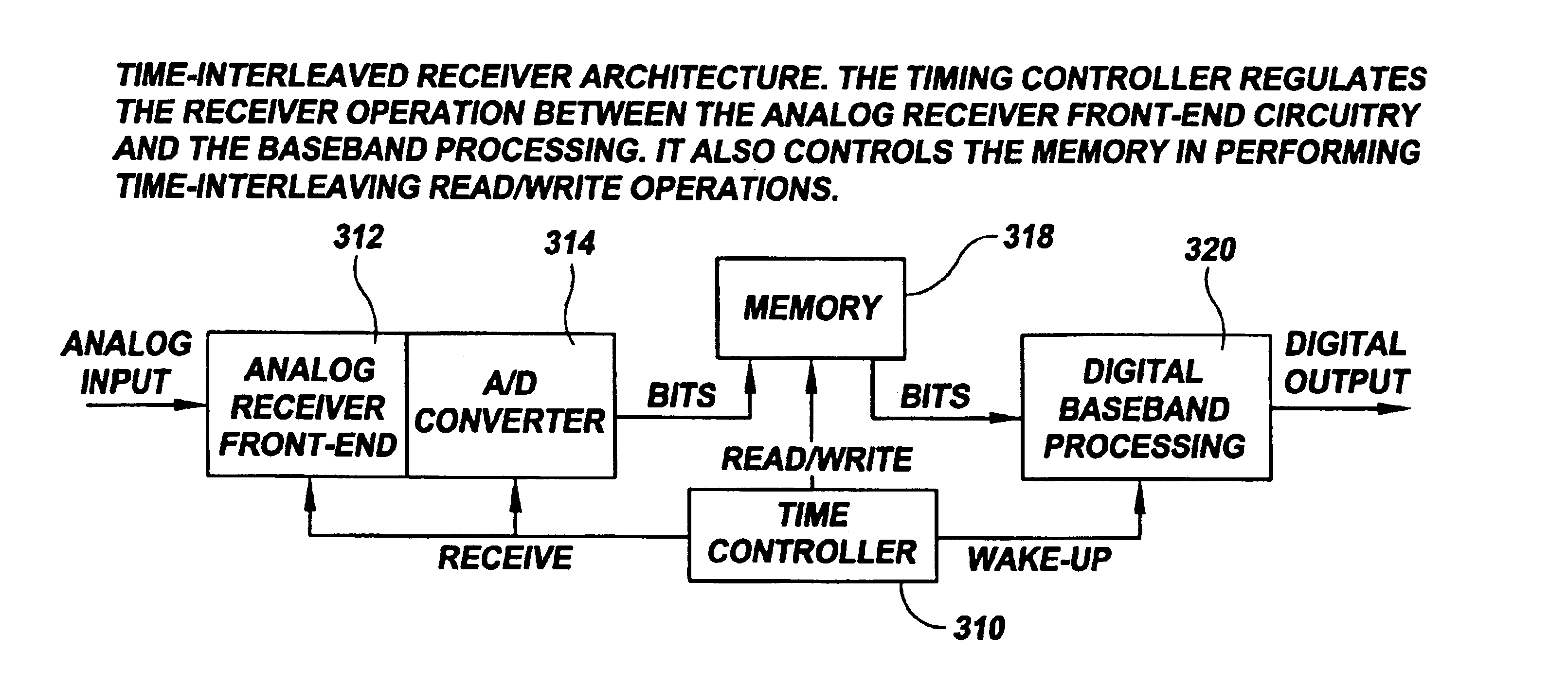

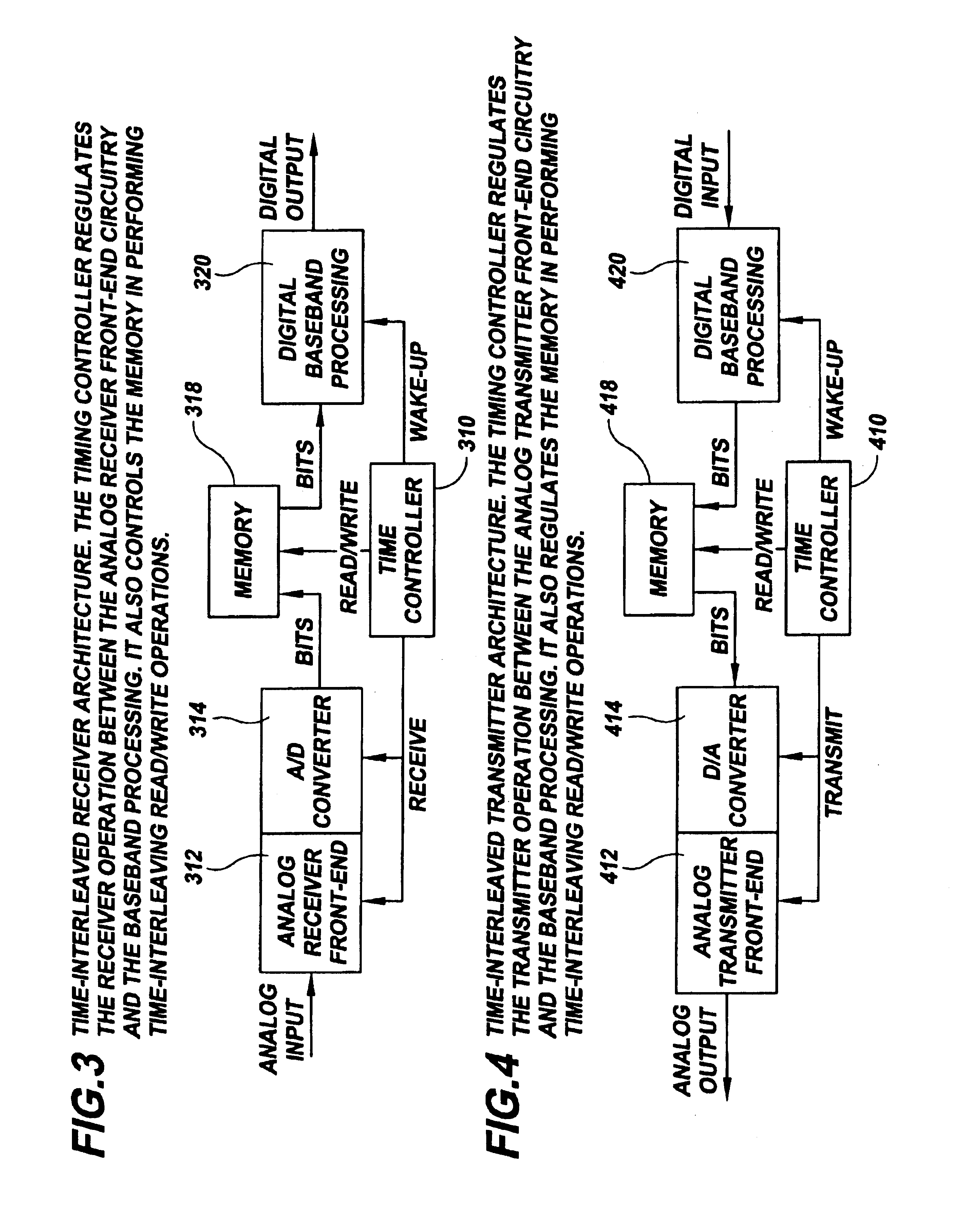

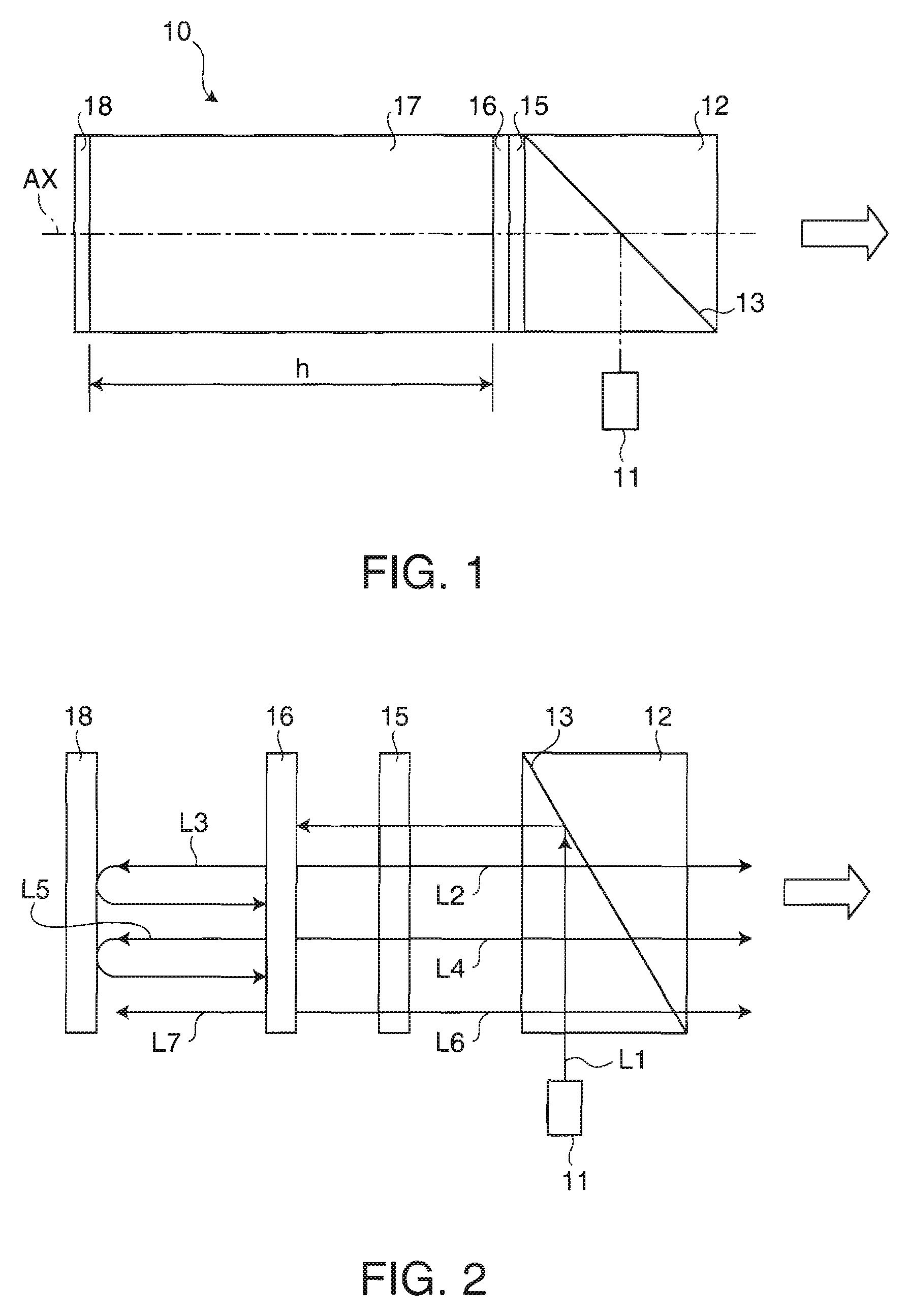

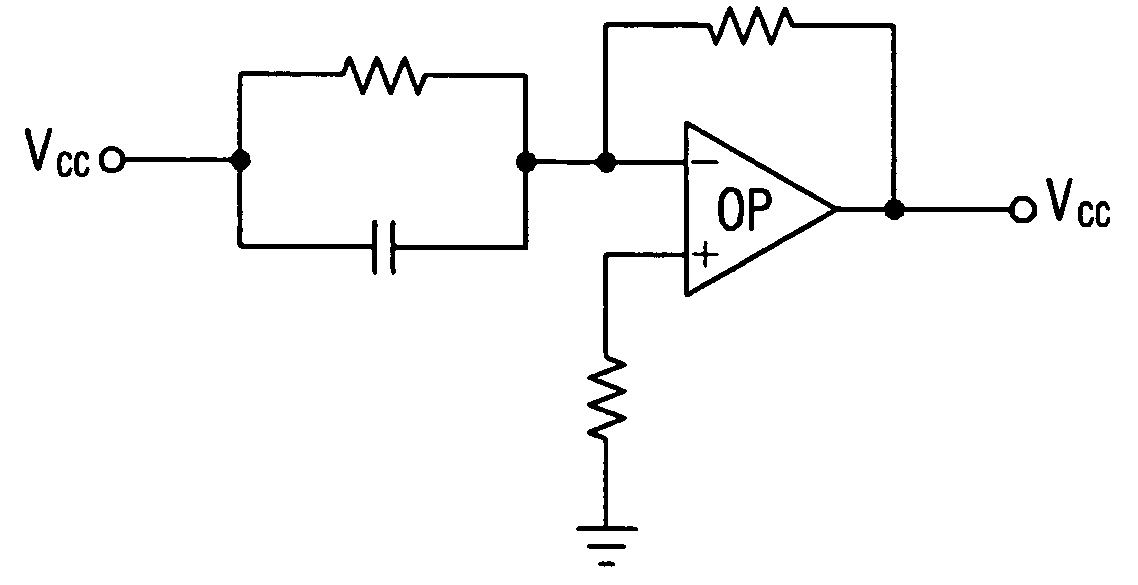

Noise-reducing arrangement and method for signal processing

InactiveUS6963626B1Effective noise reductionImprove noiseError preventionLine-faulsts/interference reductionCommunications systemDatapath

A communication system uses analog and digital circuits along the same data path in a manner that permits the analog circuitry to avoid adverse affects caused by the digital circuitry. Consistent with one embodiment directed to a signal processing system that detects faint incoming signals, the analog and digital circuits are implemented on a single piece of silicon. In such signal processing systems, noise generated by digital processing blocks can degrade the performance of sensitive analog portions. The effective noise is reduced by causing the analog and digital portions of the system to function during separate time intervals. The noise-generating portions of the system may then be turned off during a first data-communication interval while the analog block operates. The data acquired during this period is stored for subsequent processing by the digital portion during a second shorter data-communication interval. Other aspects are applicable to reception arrangements in which part of the incoming signal may be disregarded without significant degradation in performance of the rest of the system, and other aspects are directed to transmission arrangements in which the inverse of the above reception arrangement is used.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

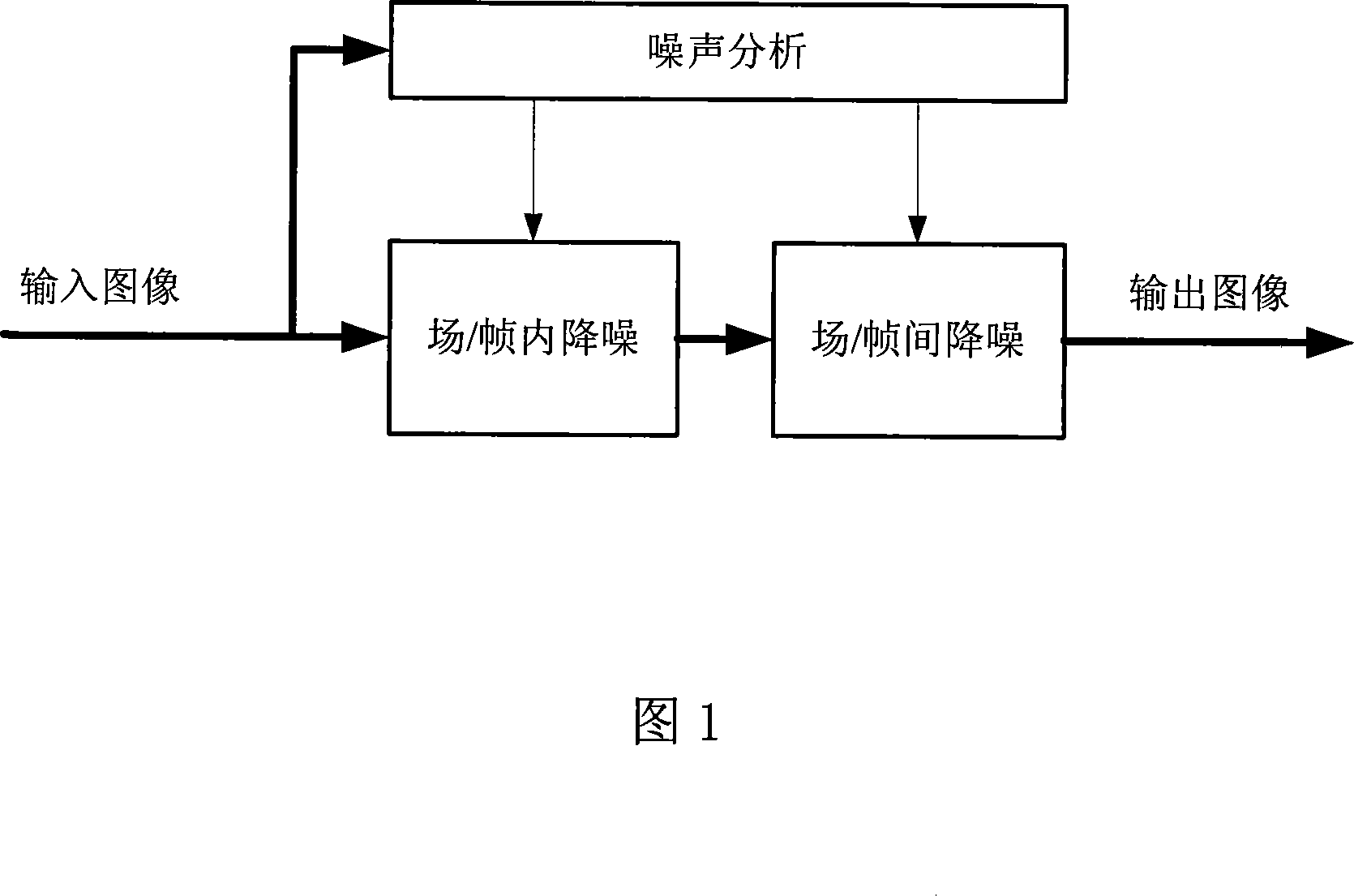

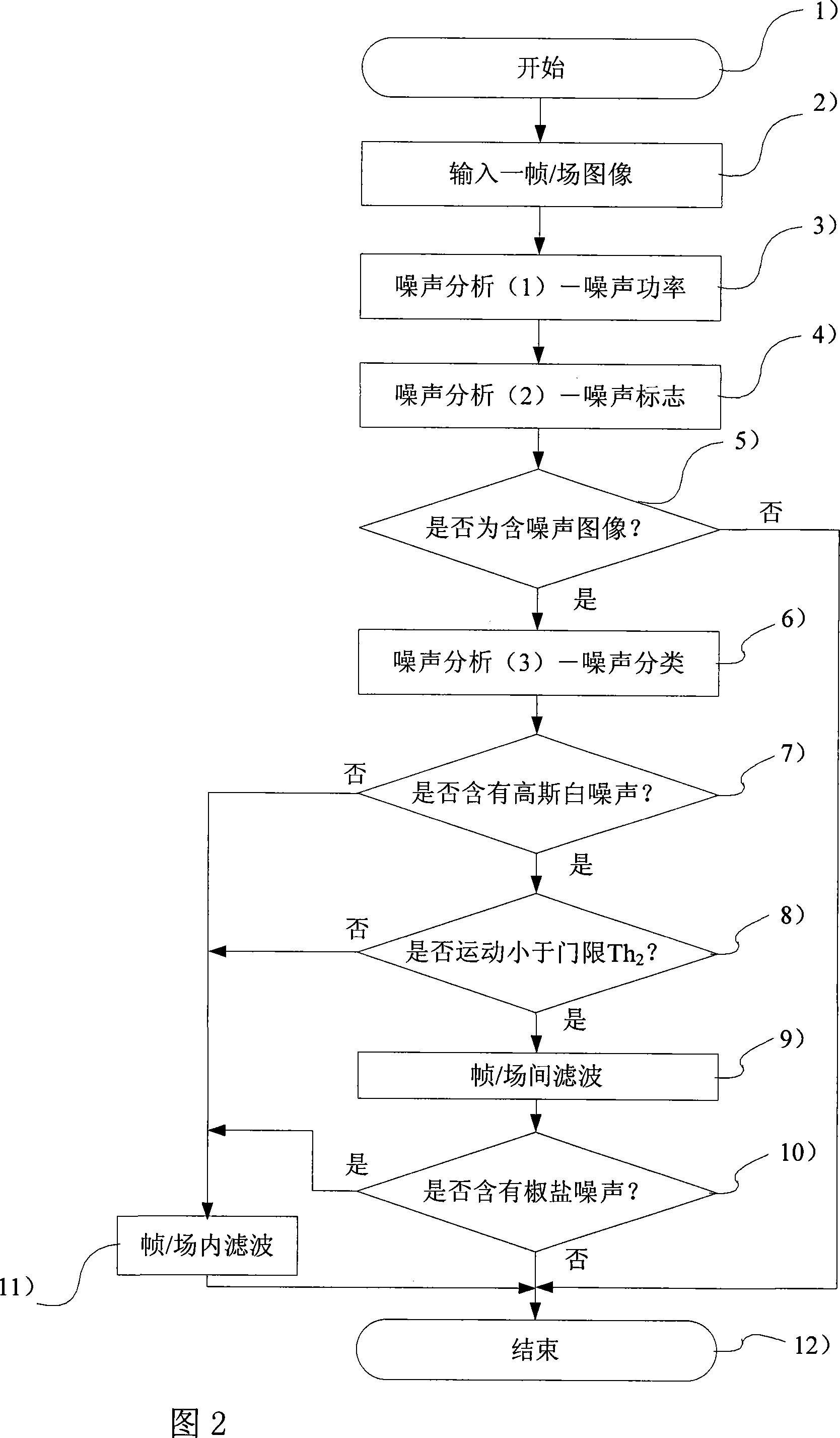

A digital image noise reduction method and device

InactiveCN101123681AReduce misjudgmentReduce missed judgmentsTelevision system detailsColor television detailsImaging analysisNoise classification

The invention discloses a digital image noise reduction method and device. The noise reduction method includes: performing noise analysis on an input image, calculating the difference frame / field image between input image frames or between two fields separated by one field, and based on the difference frame Image analysis of the frame / field noise statistical characteristics; perform noise analysis, calculate noise power, determine noise signs and determine noise classification; adaptively select frame / intra-field noise reduction or / and frame / inter-field noise reduction methods. The device for digital image noise reduction includes: frame memory, noise analysis unit and frame / field noise reduction unit. Since the present invention selects and adopts frame / intra-field and / or frame / inter-field noise reduction methods by analyzing the noise characteristics of difference frame / field images, and selects appropriate weights according to the characteristics of noise and image information, the noise reduction Finally, images with better visual effects are obtained.

Owner:POWERLAYER MICROSYST HLDG

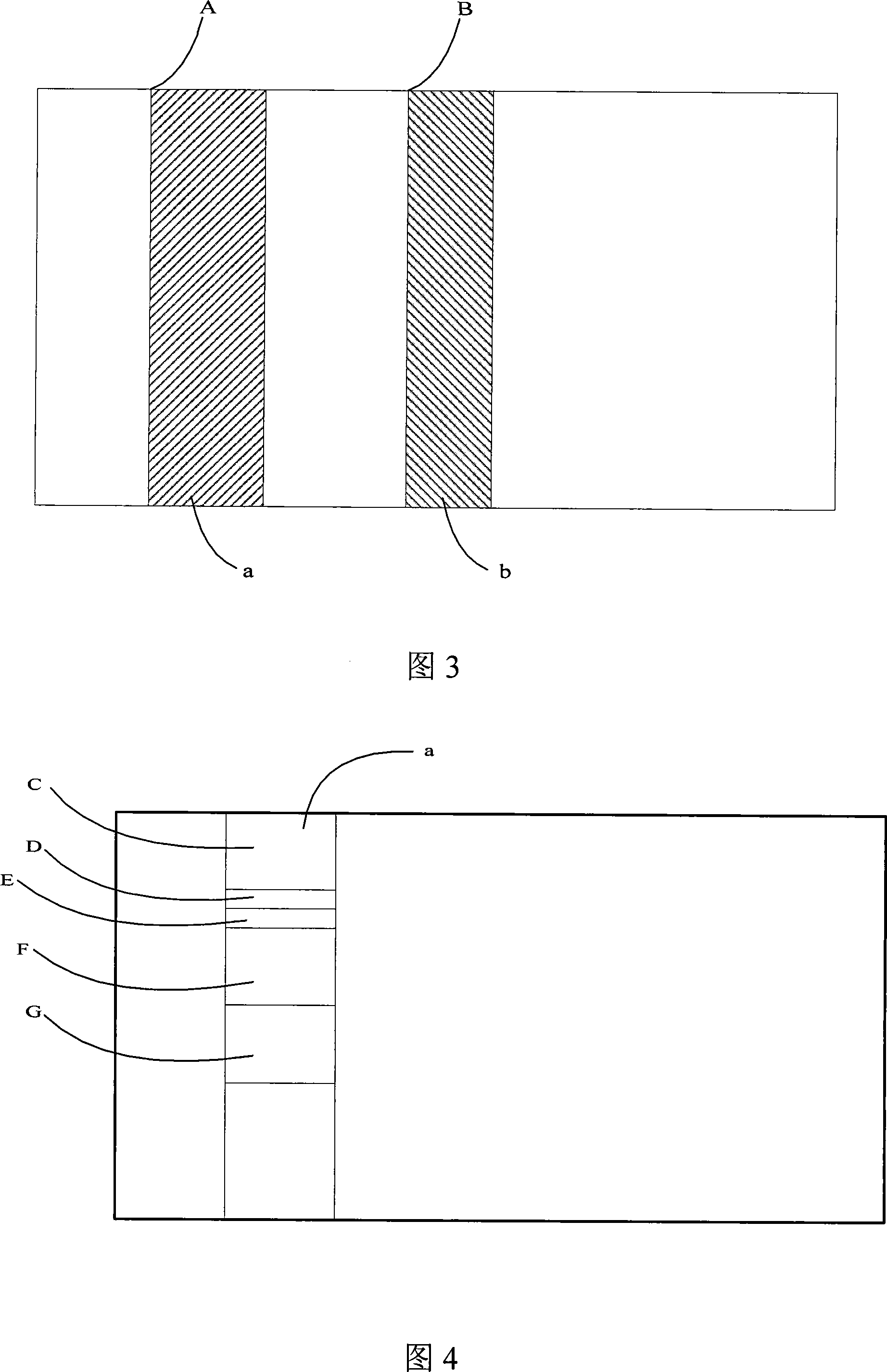

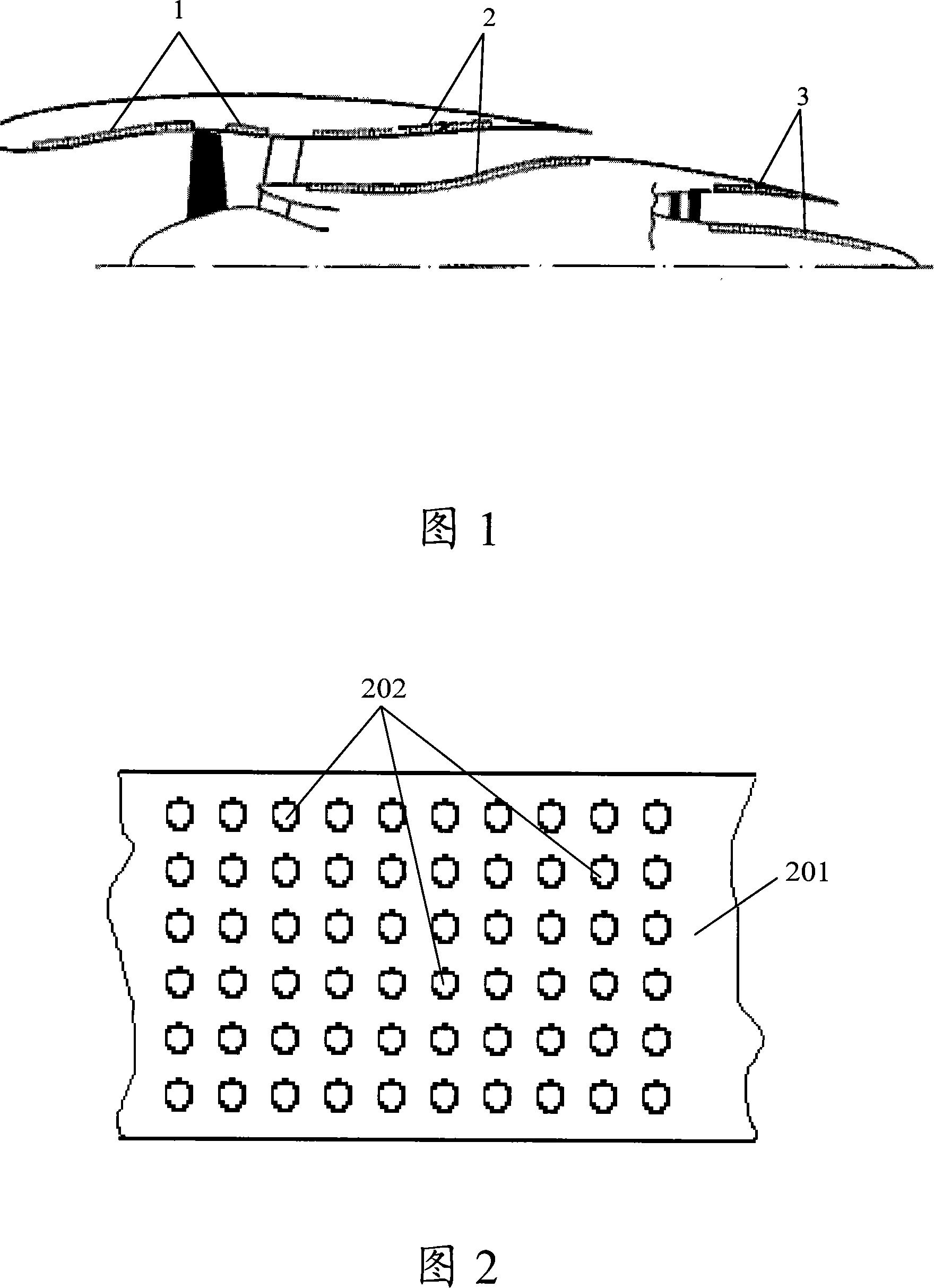

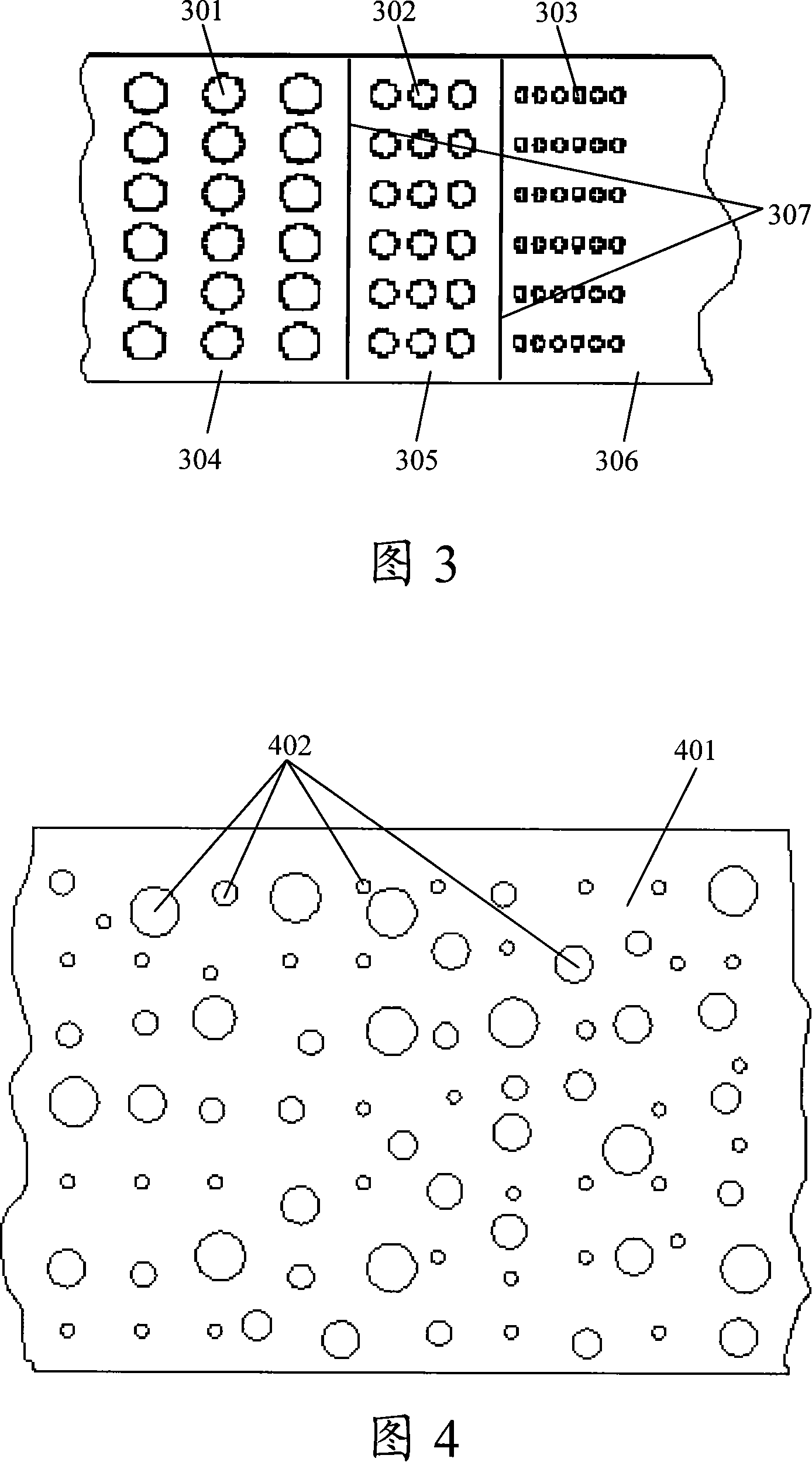

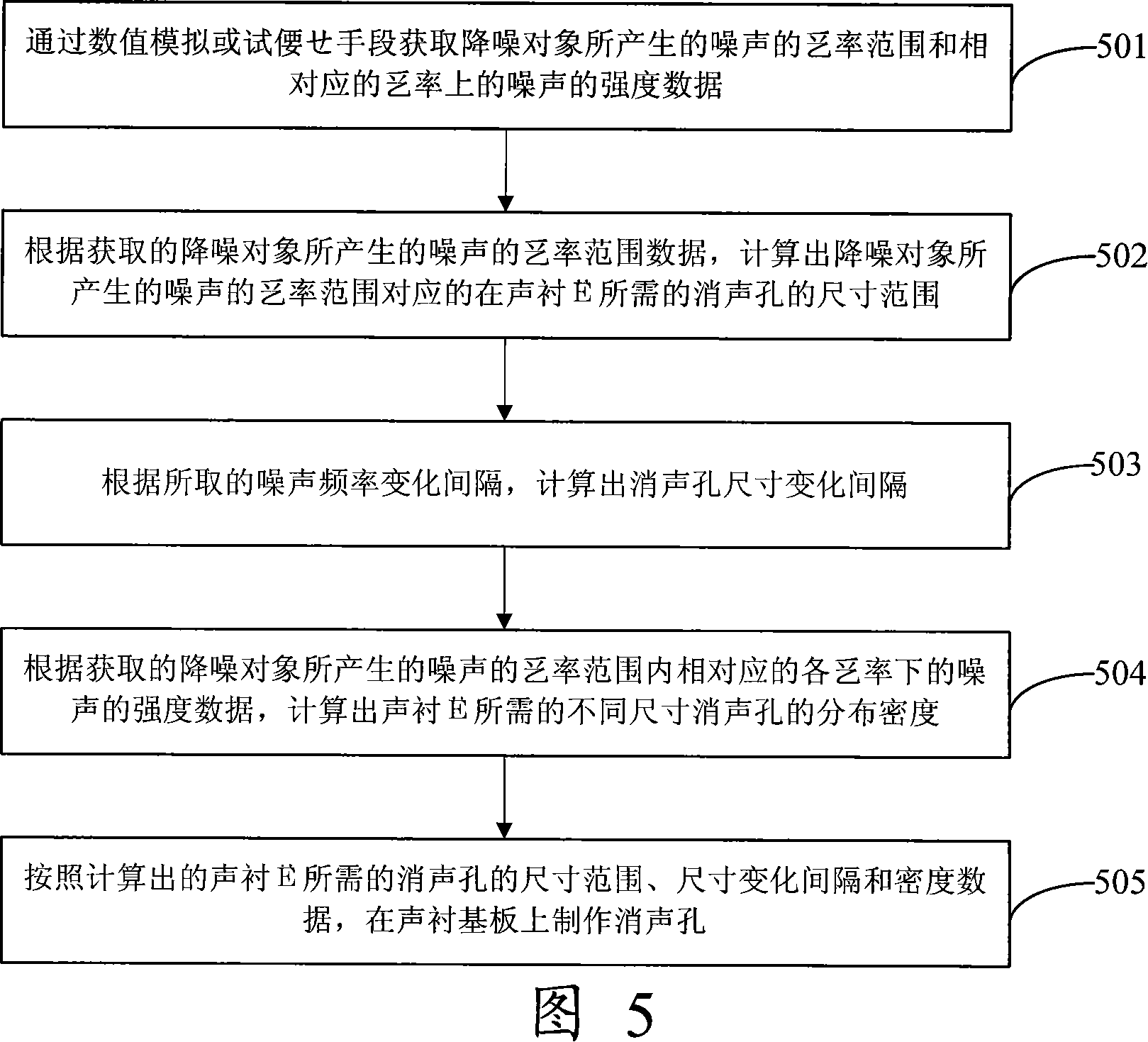

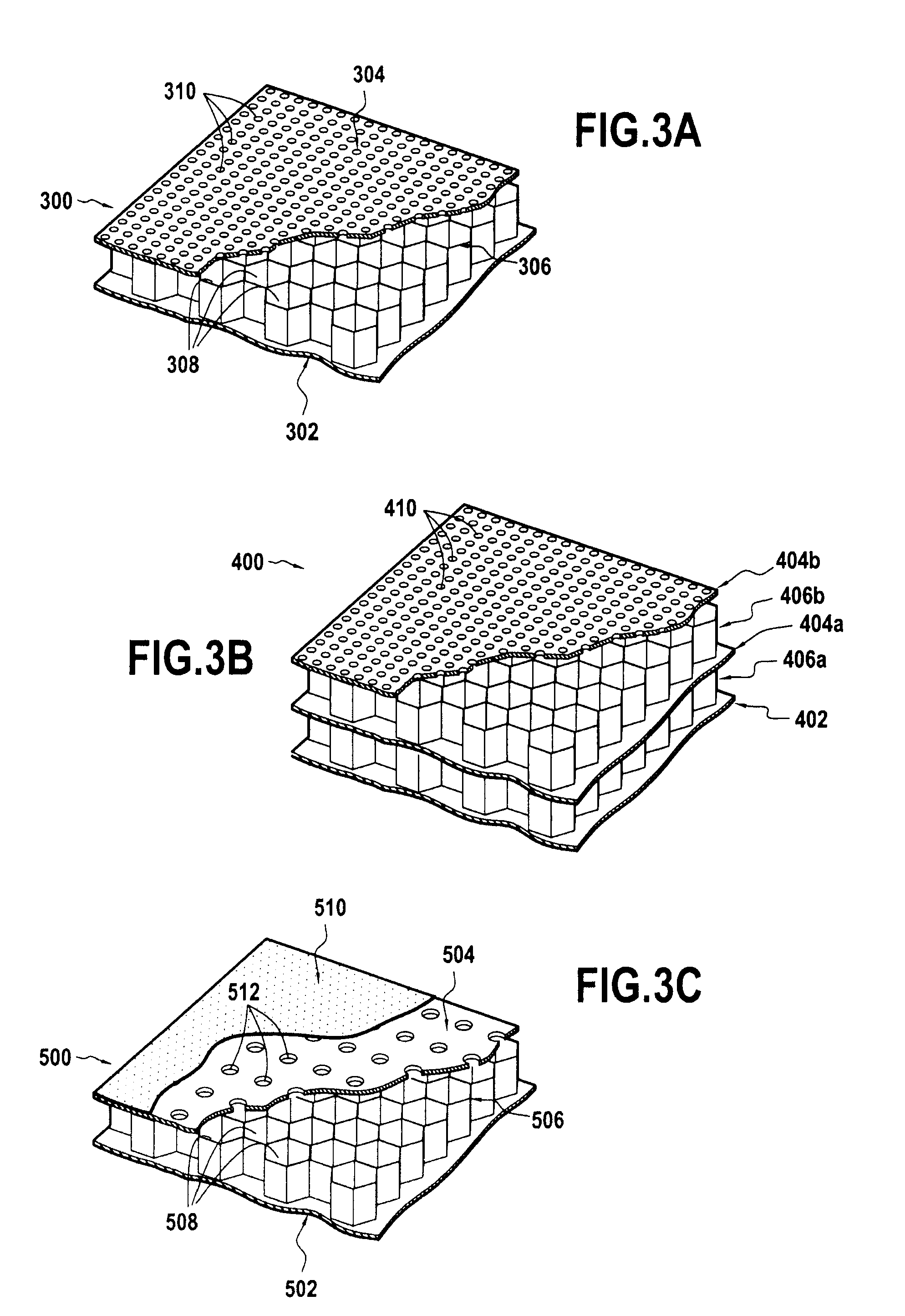

Broad-band noise-reducing acoustic liner and its manufacture method

InactiveCN101149296AEffective noise reductionPump componentsThermometers using physical/chemical changesBroadbandEngineering

The invention discloses a line to decrease noise for Broad Band and manufacture method. The sound line has the noise elimination hole which is distributed randomly and the size is changed continuously. So it can decrease the noise of broad frequency noise. Because of whole forming, it can not generate the noise dispersion phenomena caused by the sound line joint to influence the noise decreasing effect. In process of Broad Band noise decreasing line, it can get the noise frequency and corresponding noise intension by value simulation of test and get the size range, changing interface and density of noise elimination hole; also it distributes the hole on the sound line basal board to have the good noise decreasing effect.

Owner:BEIHANG UNIV

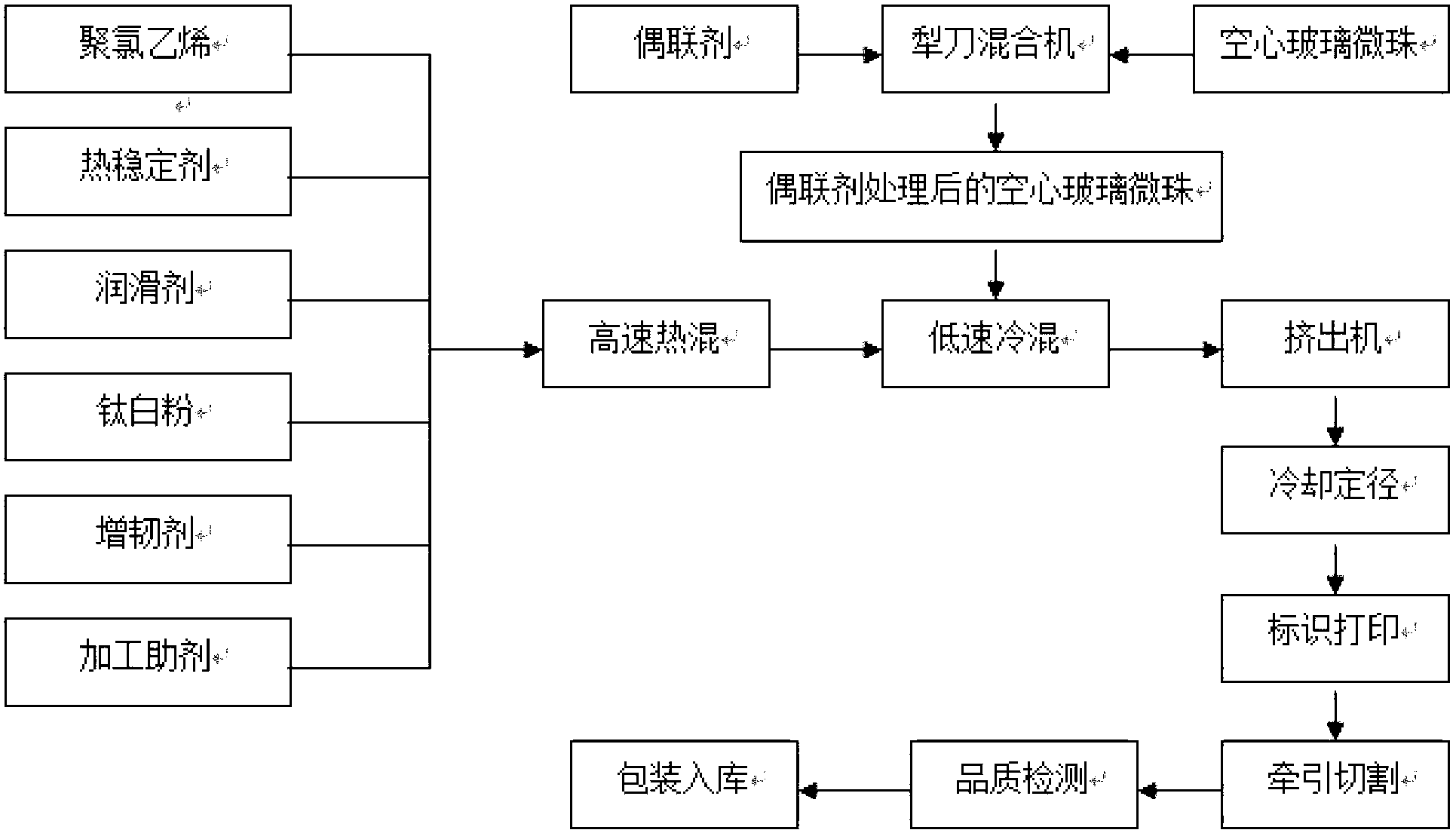

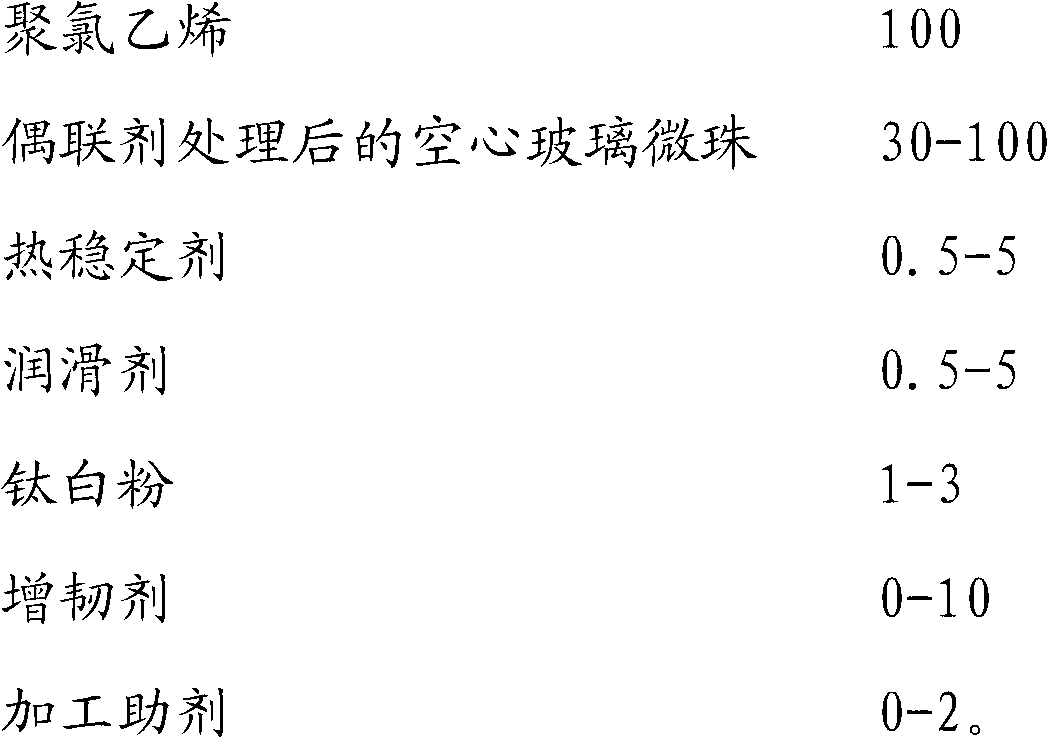

Polyvinyl chloride drain pipe and preparation method thereof

The invention discloses a polyvinyl chloride drain pipe and a preparation method thereof. The polyvinyl chloride drain pipe comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 30 to 100 parts of hollow glass microsphere processed by coupling agent, 0.5 to 5 parts of thermal stabilizer, 0.5 to 5 parts of lubricating agent, 1 to 3 parts of titanium dioxide, 0 to 10 parts of flexibilizer and 0 to 2 parts of processing agent. The method adopts the mode of plastic modifying, creatively introduces the hollow glass microsphere for filling, effectively improves the product toughness on the basis that the product rigidity is guaranteed, simultaneously effectively reducing noises through a hollow structure, greatly reduces the product density, reduces the product weight, and can also reduce the product cost.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +1

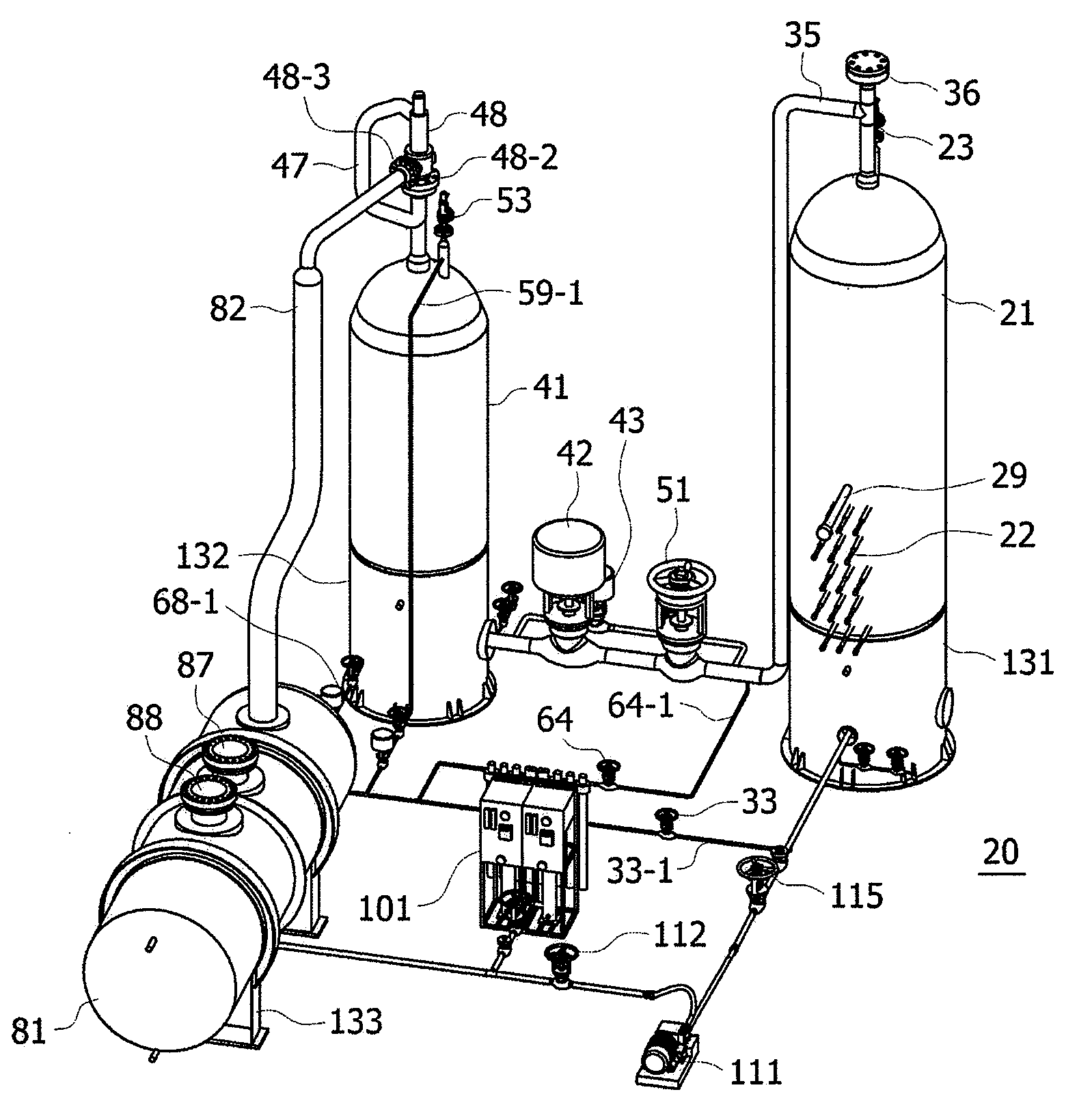

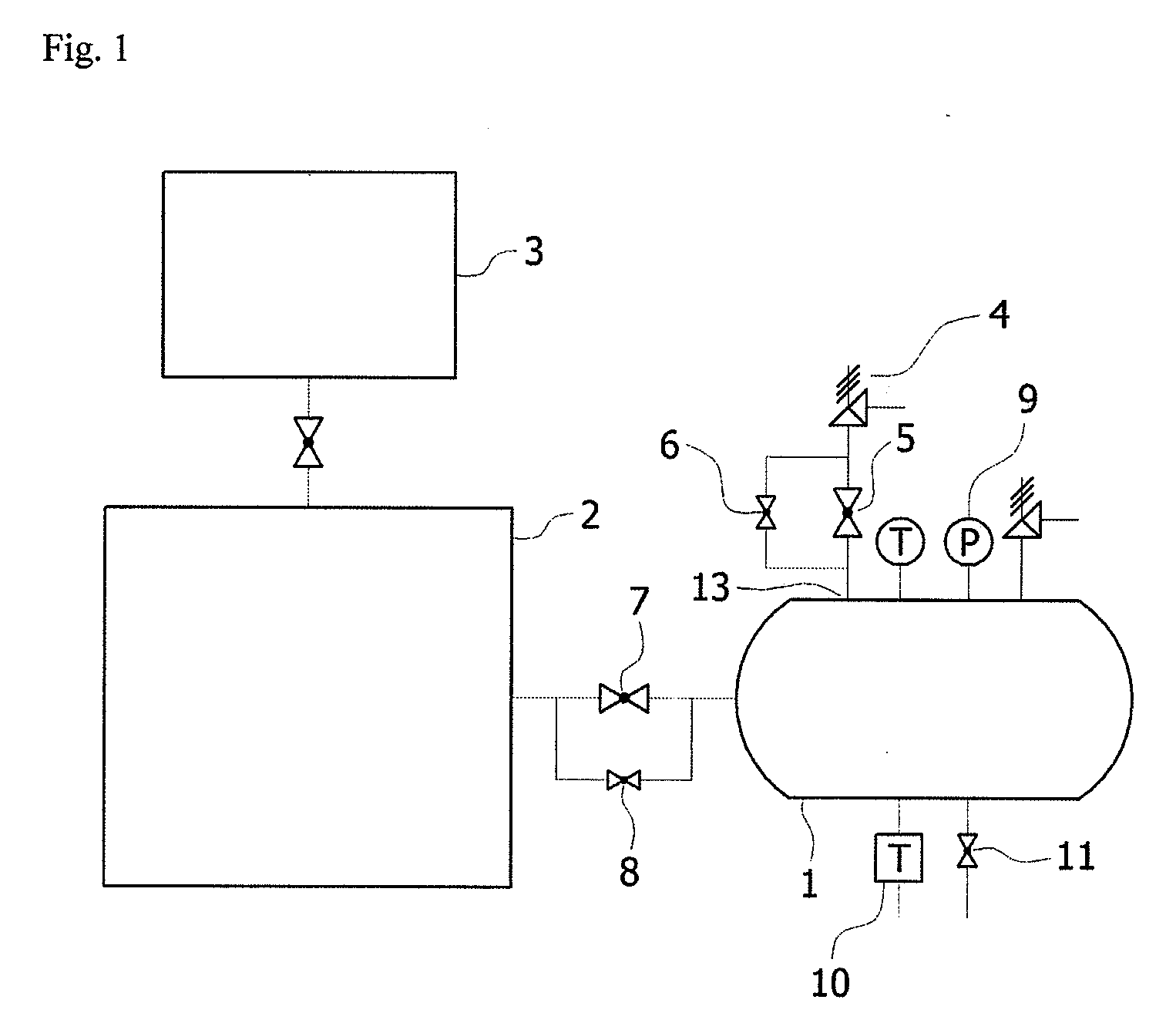

Test apparatus and method for safety valve

InactiveUS20100281954A1Ensure correct executionEasy to produceMeasurement of fluid loss/gain rateMachine valve testingControl flowEngineering

An apparatus and method for testing the performance of a safety valve. The apparatus includes an accumulator including at least one electric heater for heating a predetermined amount of water in the accumulator, and storing steam produced by the electric heater, a test vessel storing the steam supplied from the accumulator, and providing steam at a test pressure to a safety valve, the steam being supplied after controlling flow rate and pressure, a condensing tank storing demineralized water to be supplied to the accumulator, and condensing and collecting the steam discharged from the safety valve, and a water-supply pump supplying the water stored in the condensing tank to the accumulator.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

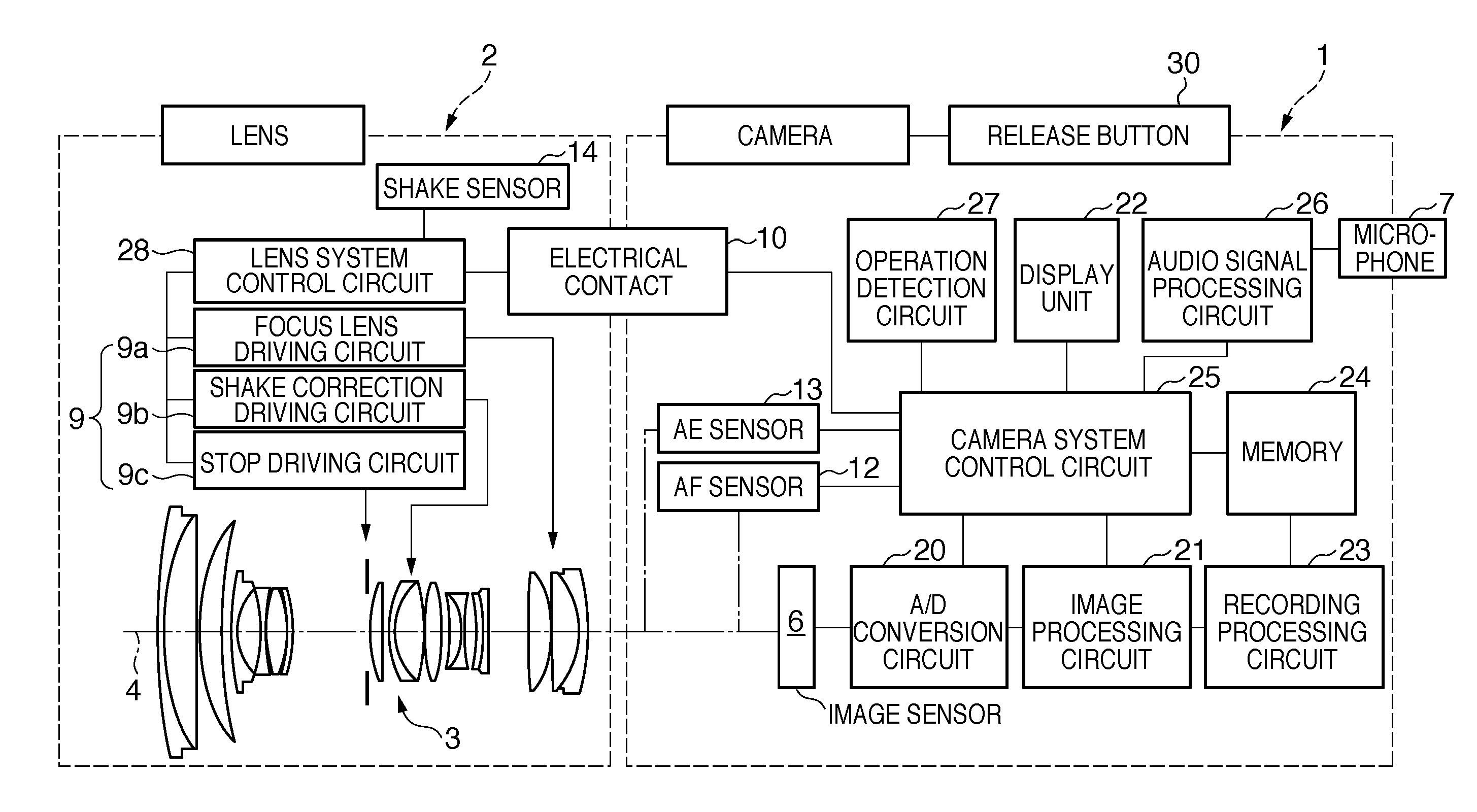

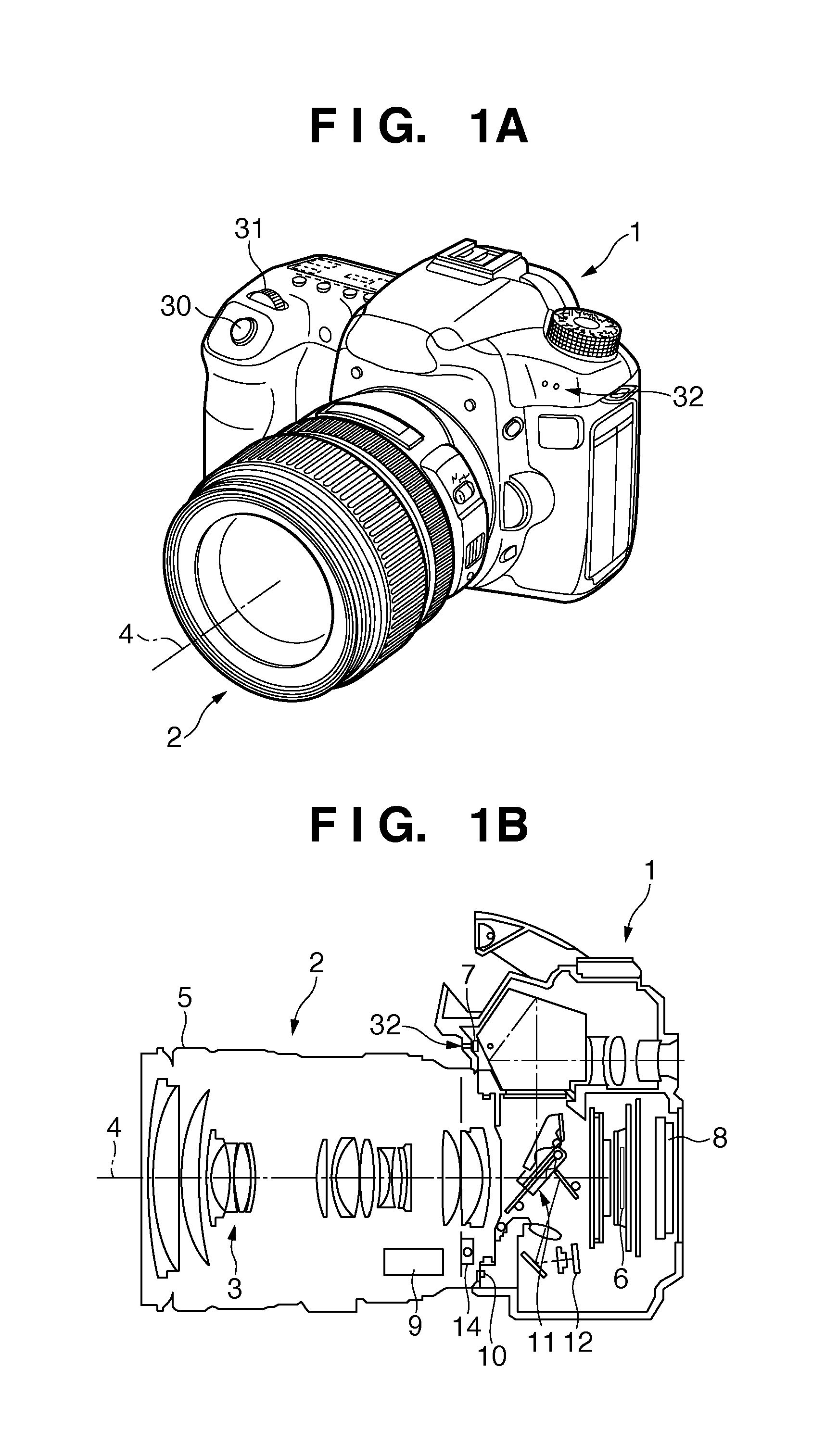

Audio signal processing apparatus and method of controlling the same

ActiveUS20110305351A1Effective noise reductionReduce operating loadSignal processing for reducing noiseProjectorsNoise reductionComputer science

When a first noise and second noise to be generated after the first noise are generated within a predetermined period, a noise reduction unit is controlled so as to execute a first noise reduction process for an audio signal in a period including the first noise and not to execute the first noise reduction process for an audio signal in a period including the second noise.

Owner:CANON KK

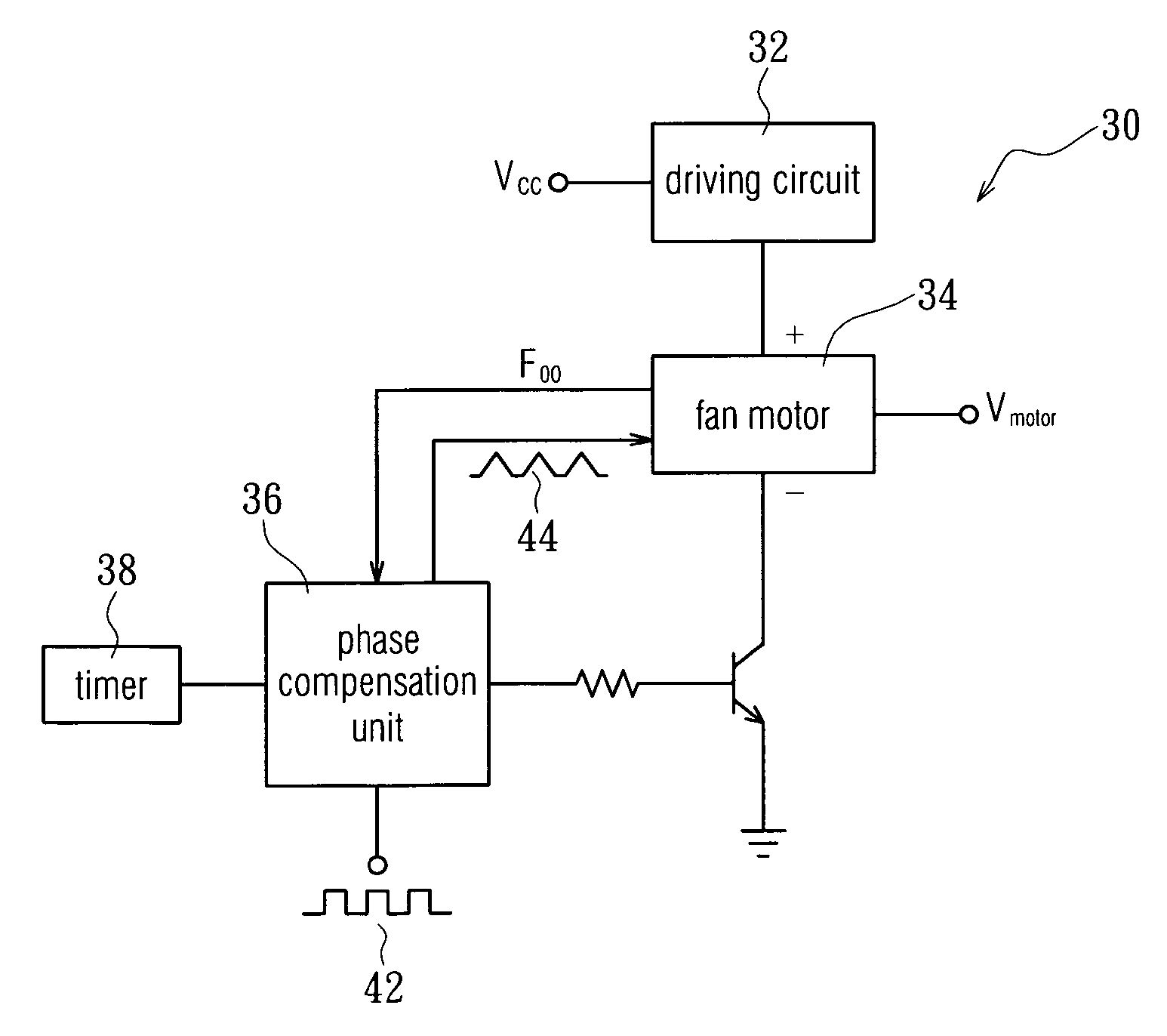

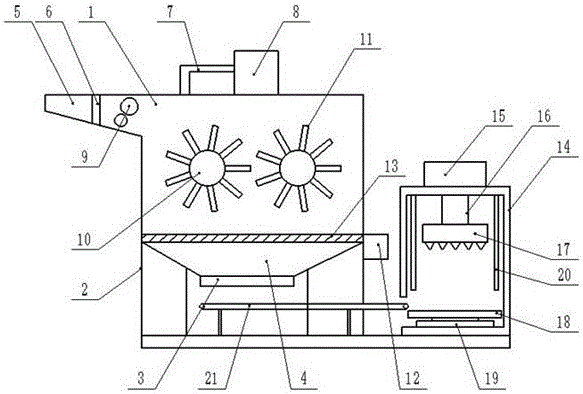

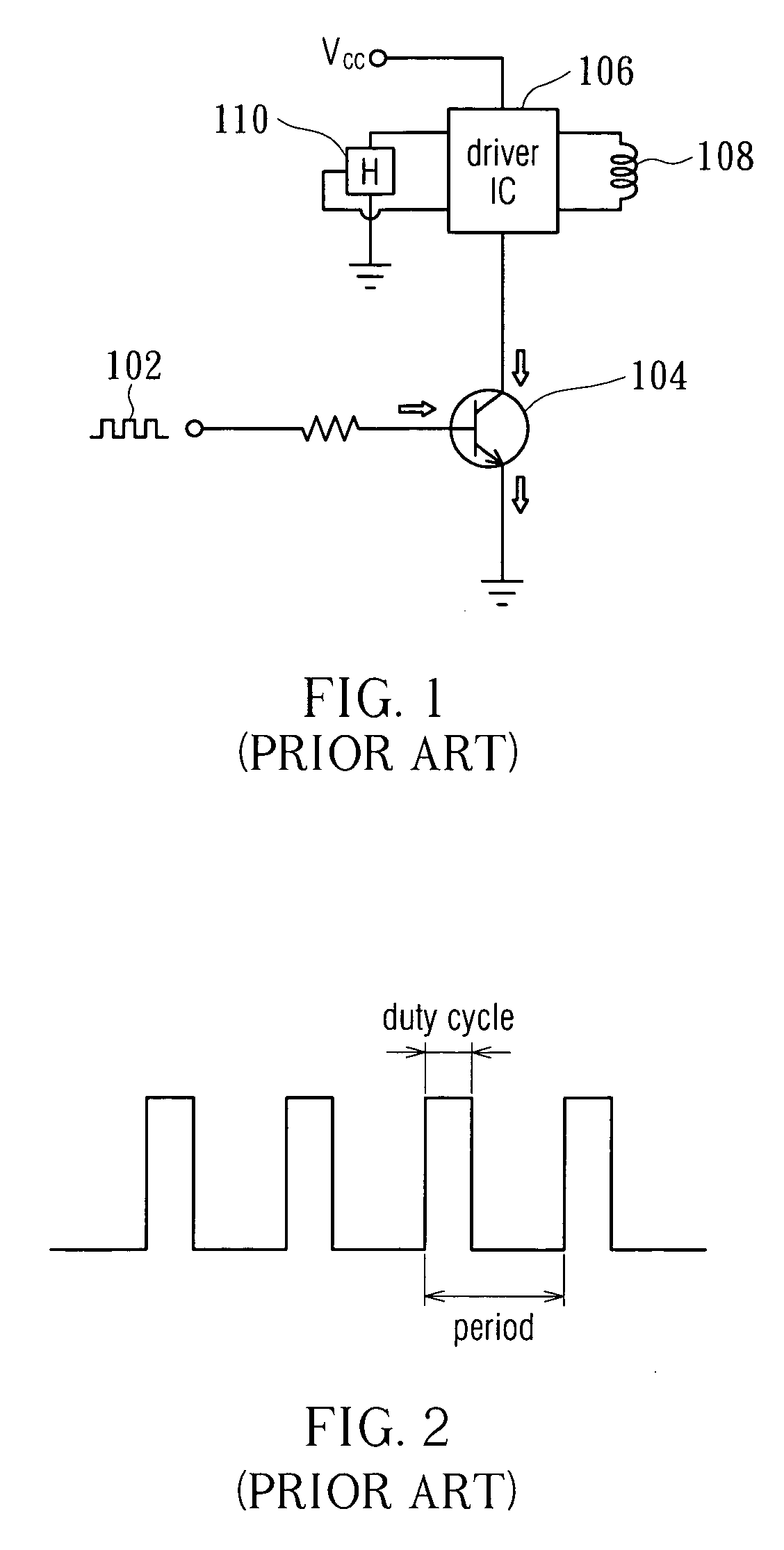

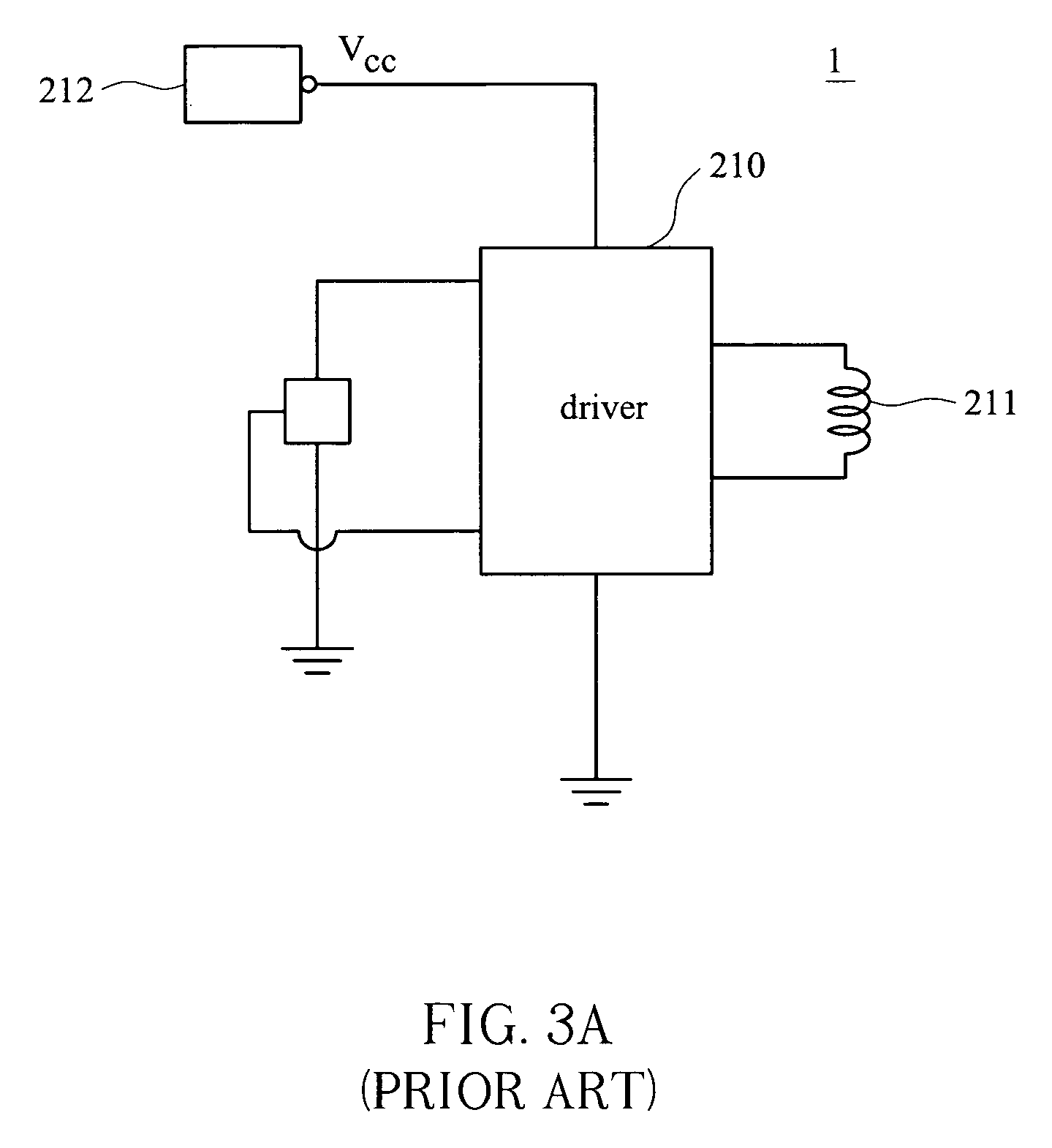

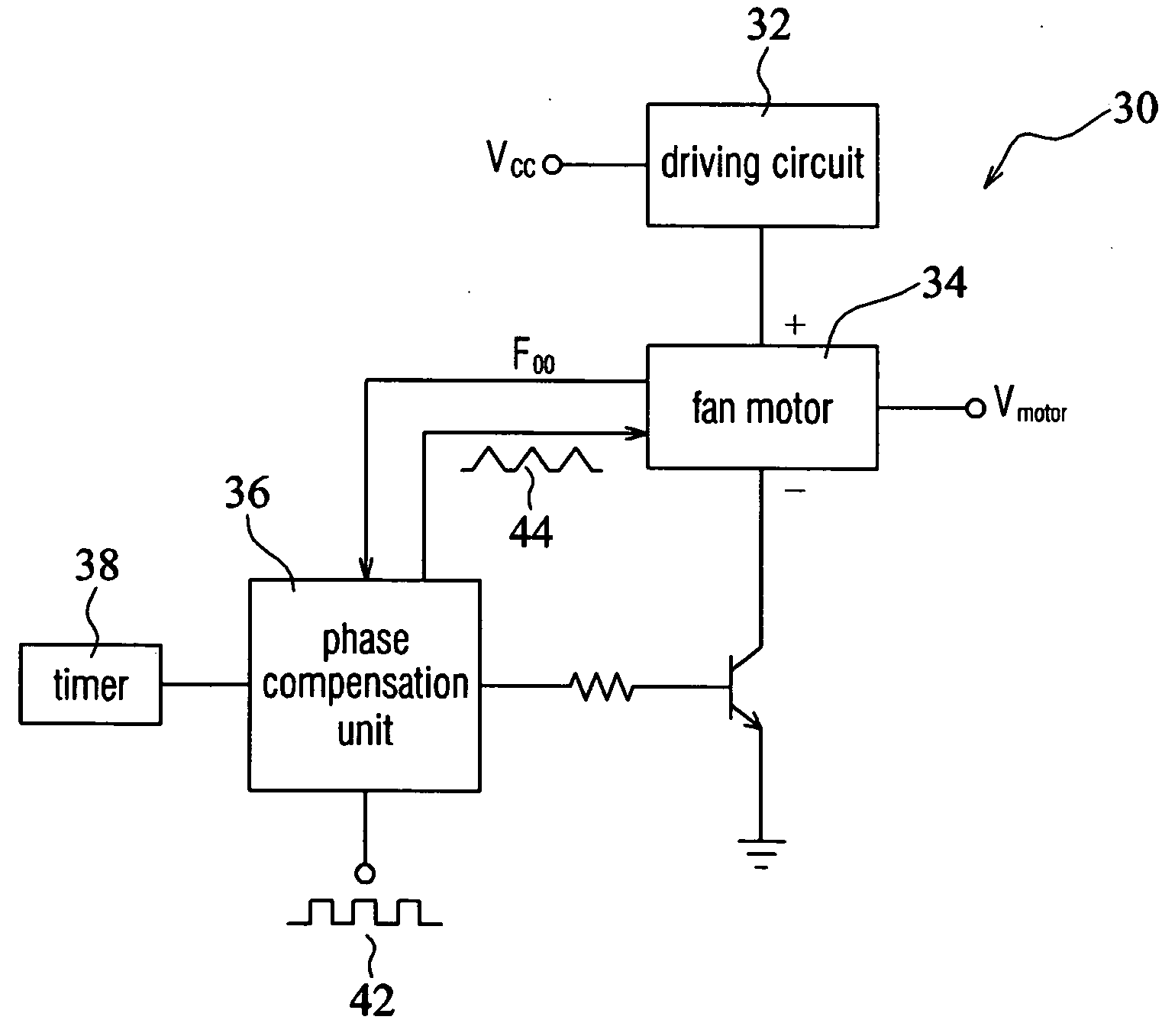

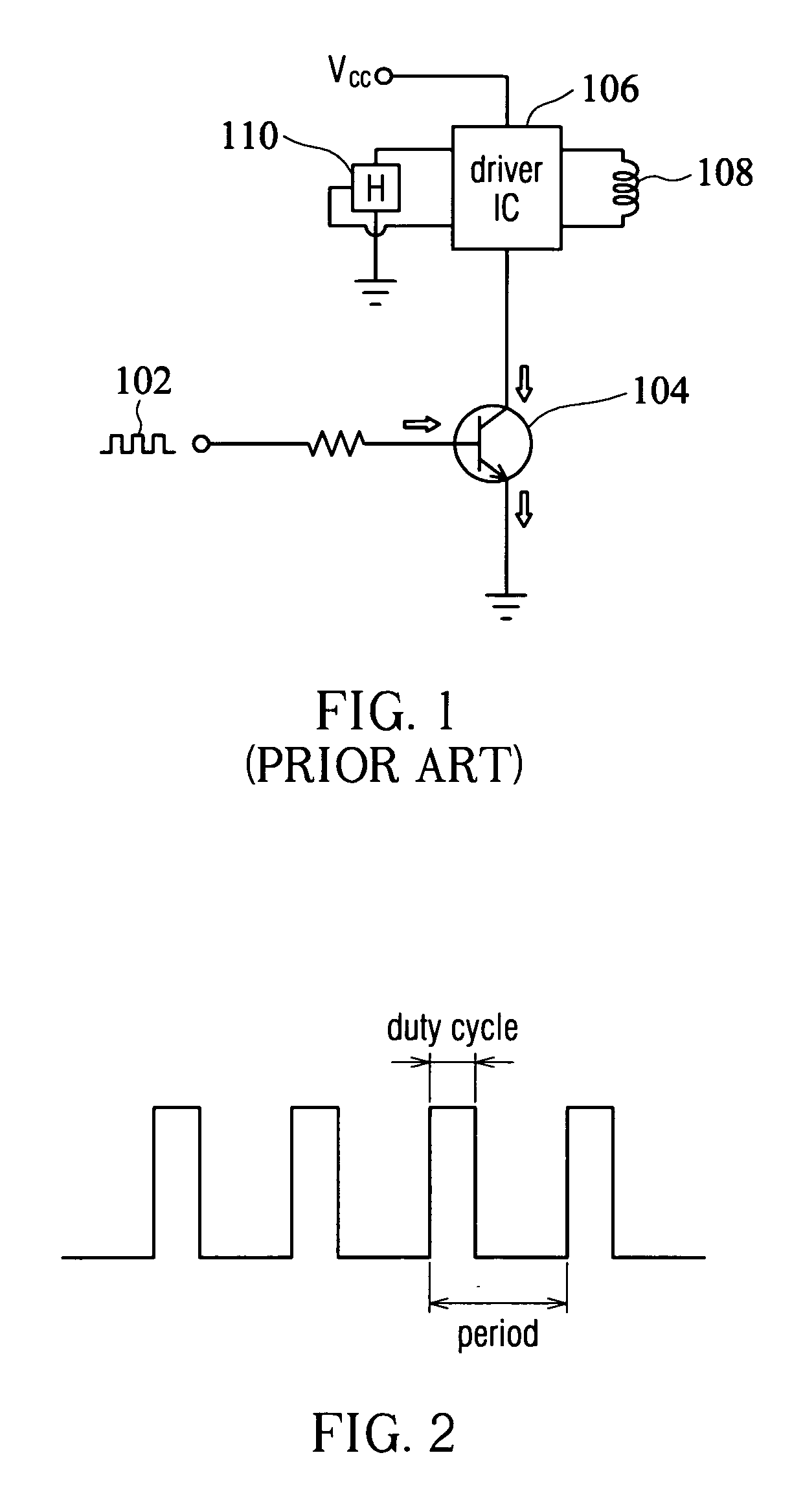

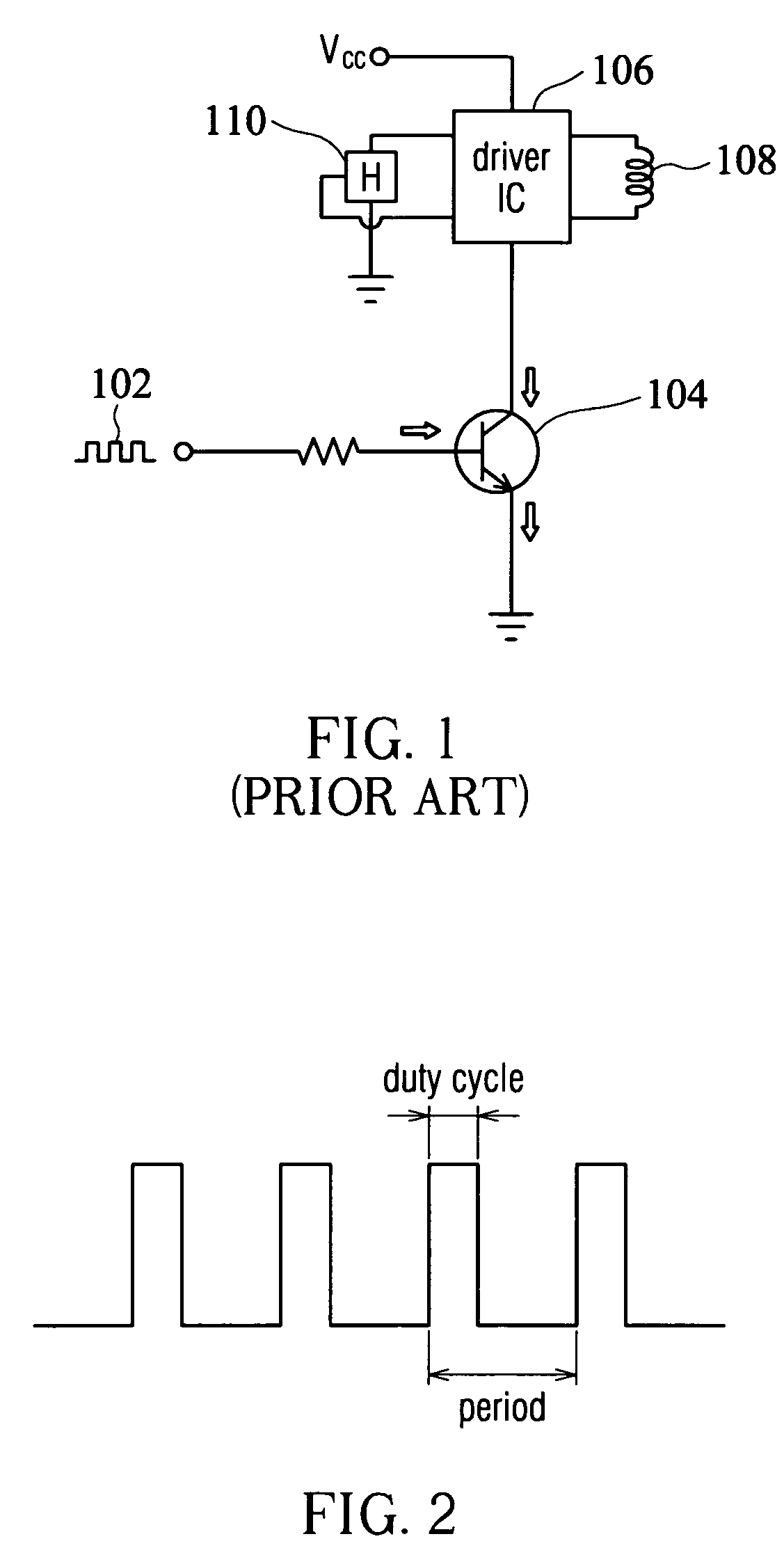

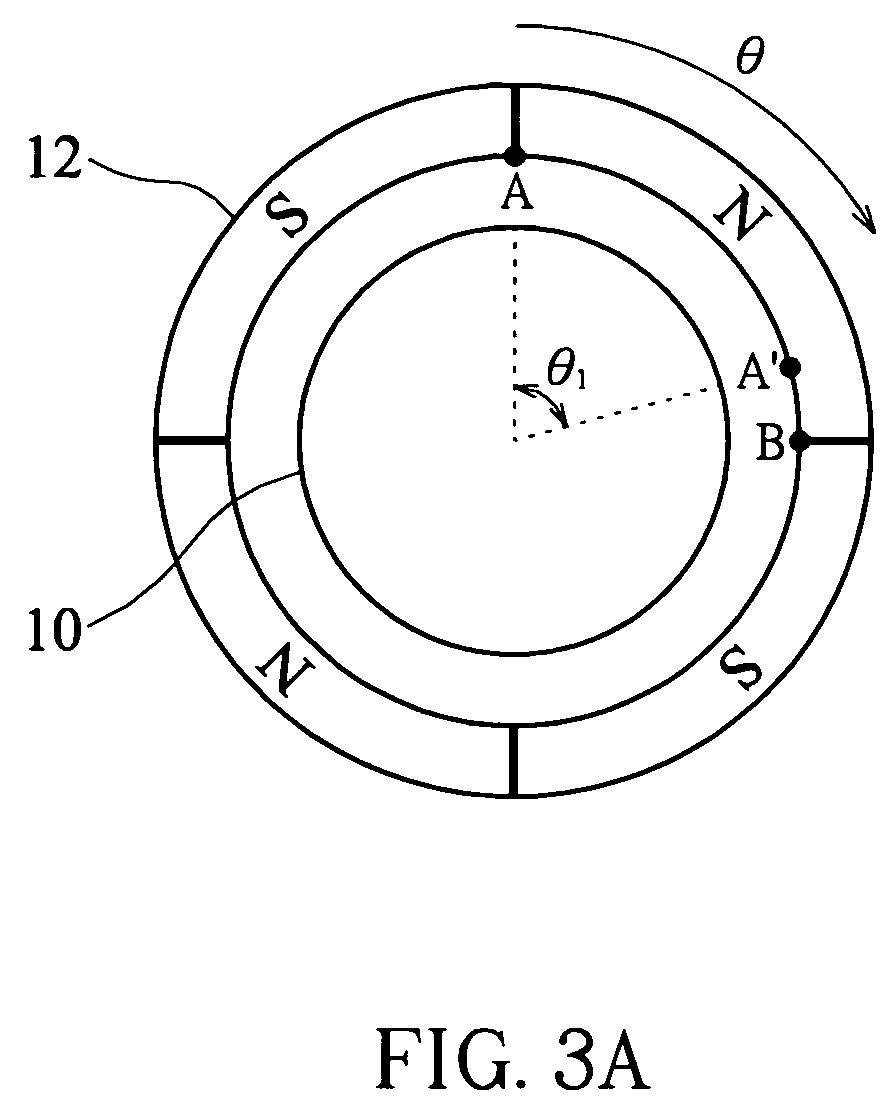

Fan speed control circuit

ActiveUS7233121B2Effectively reducing vibrationEffective noise reductionMotor/generator/converter stoppersAC motor controlControl signalElectromotive force

A fan speed control circuit includes a pulse width modulation (PWM) signal generating circuit, a driving circuit and a phase compensation unit. The PWM signal generating circuit generates a PWM control signal with a sequence of alternating on-time and off-time, and the driving circuit outputs a driving signal according to the PWM control signal to a fan motor. The phase compensation unit is connected to the fan motor for delaying or advancing the PWM control signal by a phase angle to synchronize the acting period of the back electromotive force formed by the magnetic flux variation with the off-time of the PWM control signal. The present invention further provides a bi-power motor driving system including a motor rotating by receiving a first power from a first power generator, and a driving circuit for driving the motor according to a second power from a second power generator.

Owner:DELTA ELECTRONICS INC

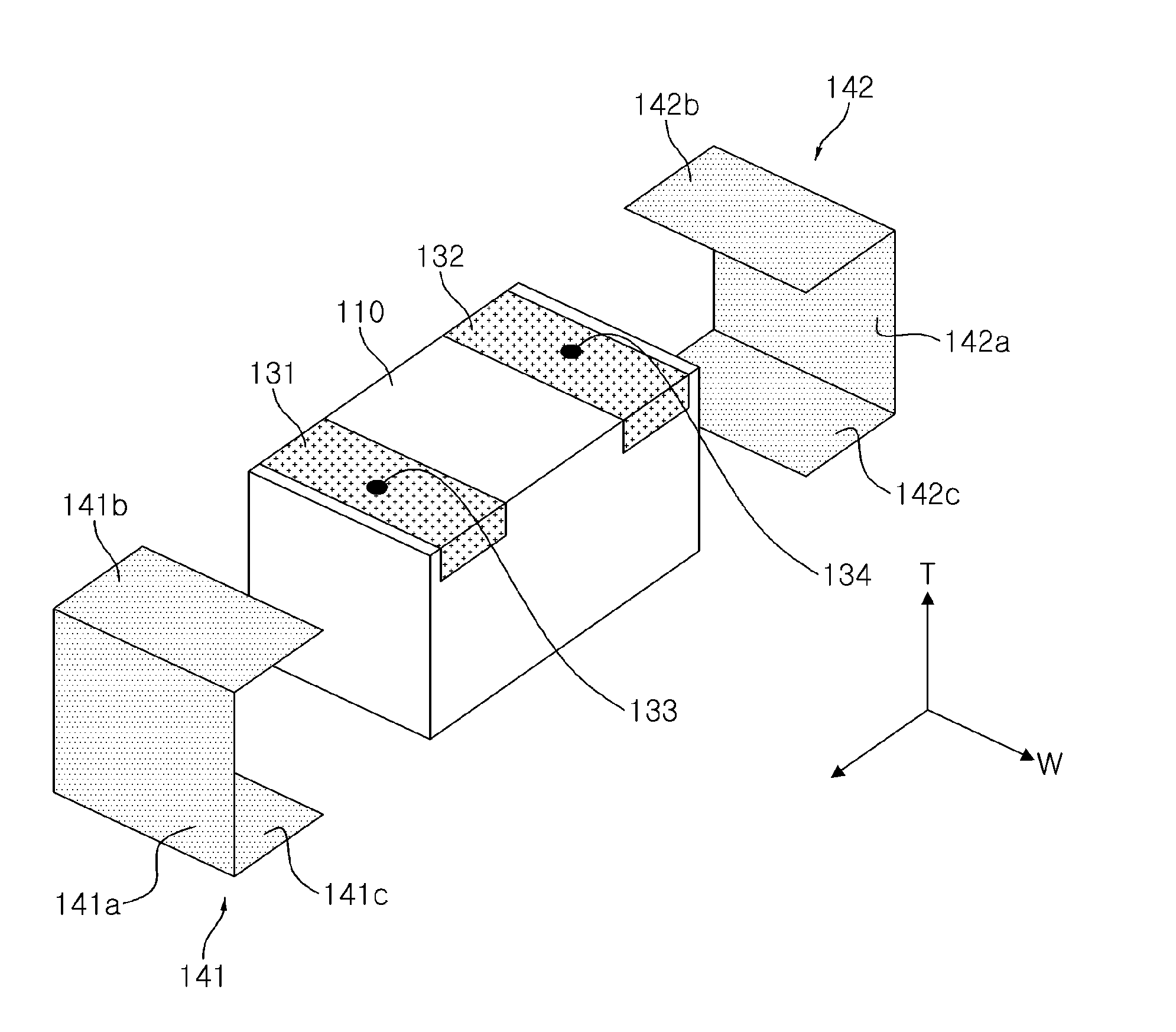

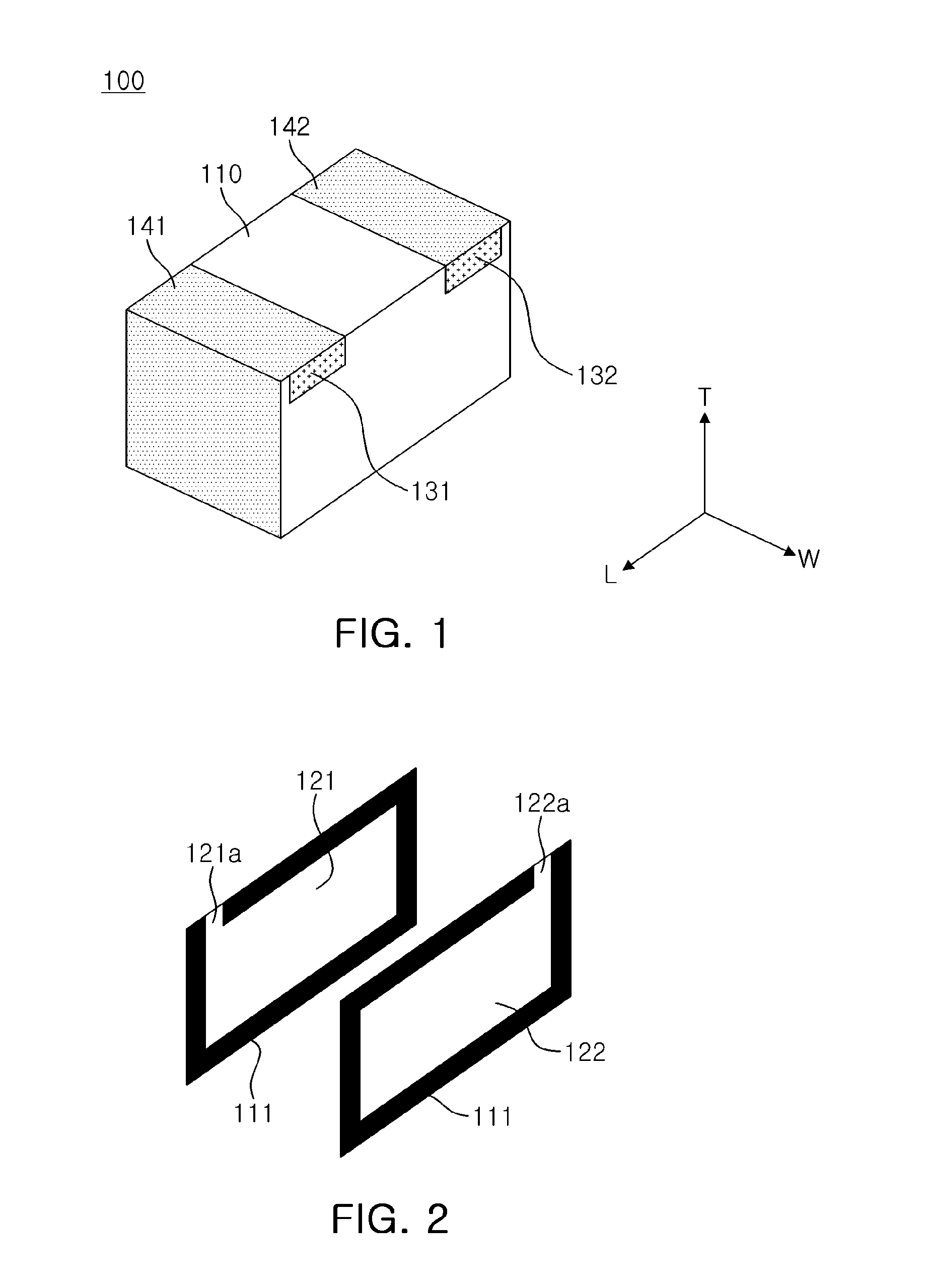

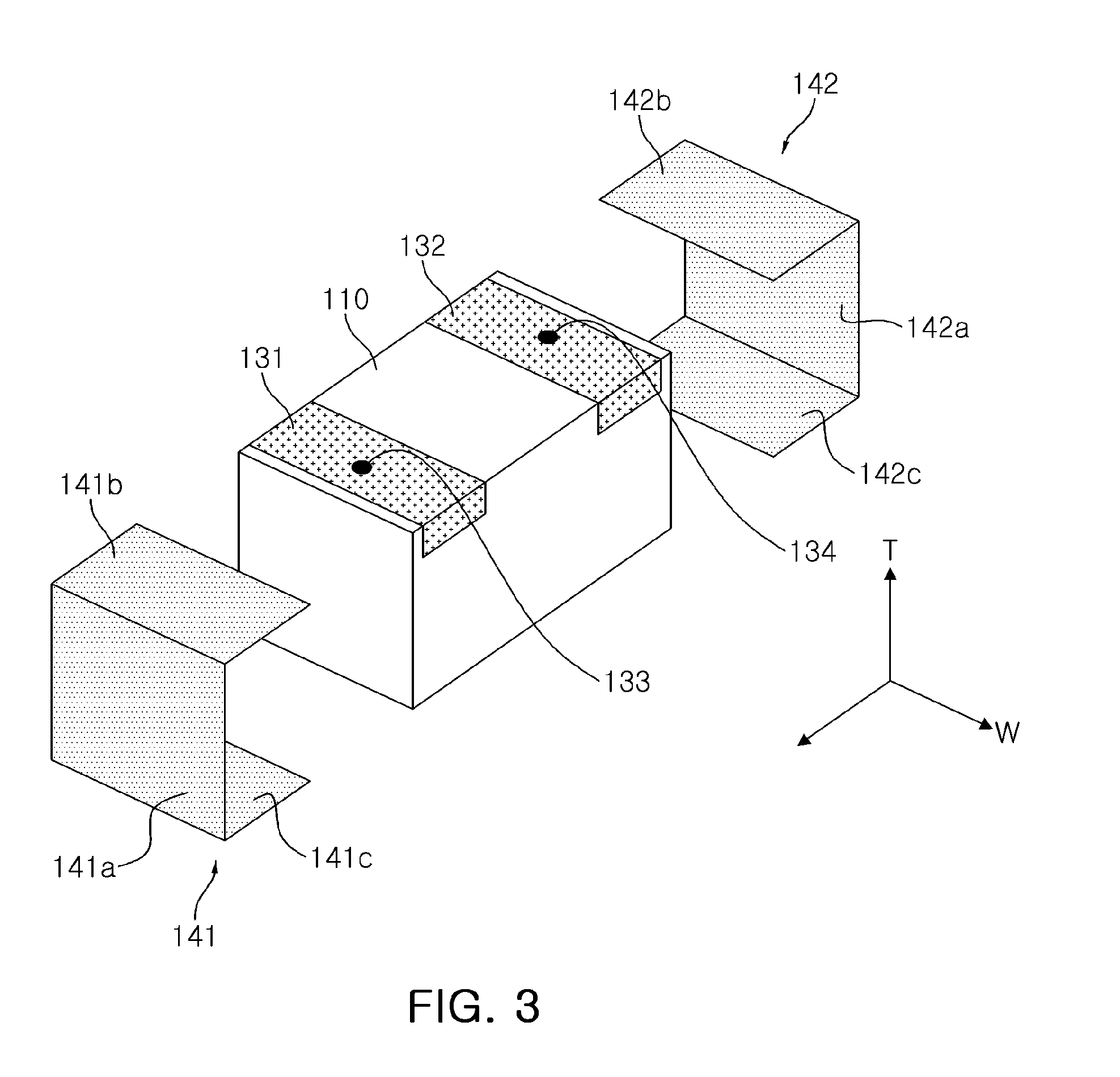

Multilayer ceramic capacitor and mounting circuit board therefor

ActiveUS20150014038A1Effectively reducing acoustic noiseReduce the overall heightFixed capacitor electrodesFinal product manufactureMetallurgyCeramic capacitor

There is provided a multilayer ceramic capacitor including: a ceramic body; first and second internal electrodes disposed to face each other within a ceramic body, and having respective lead portions exposed to an upper surface of the ceramic body; first and second external electrodes formed on the upper surface of the ceramic body and connected to the lead portions, respectively; and first and second terminal frames each including a vertical portion facing end surfaces of the ceramic body and upper and lower horizontal portions facing upper and lower surfaces of the ceramic body, respectively, wherein the upper horizontal portions are connected to the first and second external electrodes, respectively, and adhesive layers are provided between the upper horizontal portions and the first and second external electrodes, respectively.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

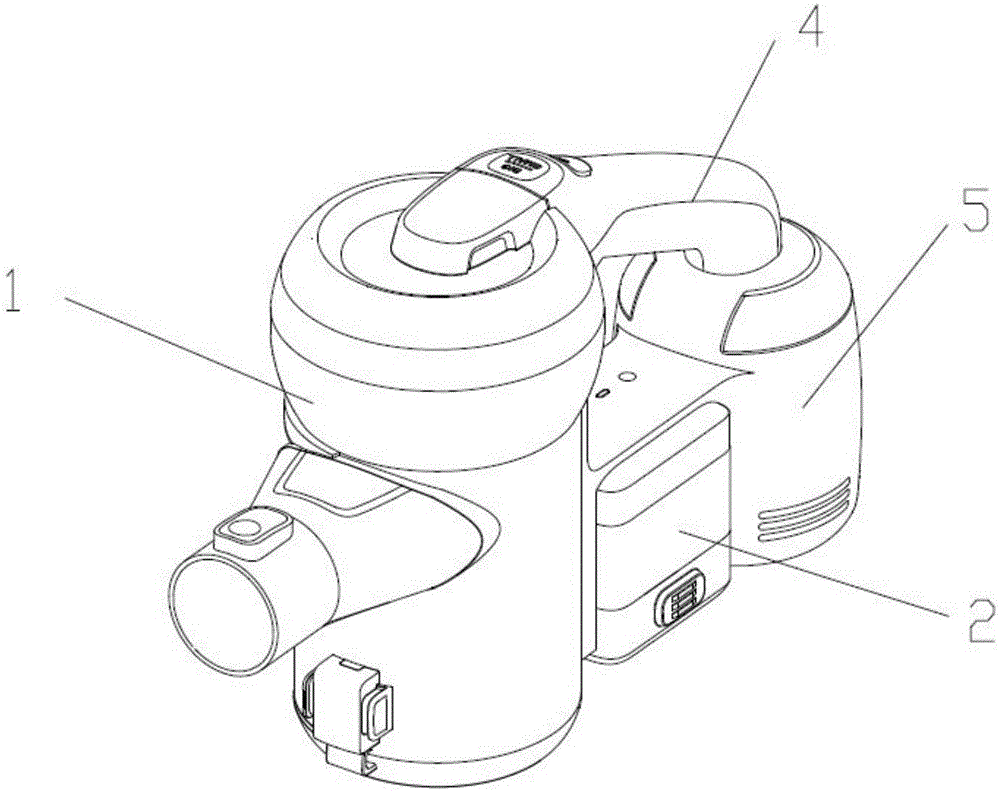

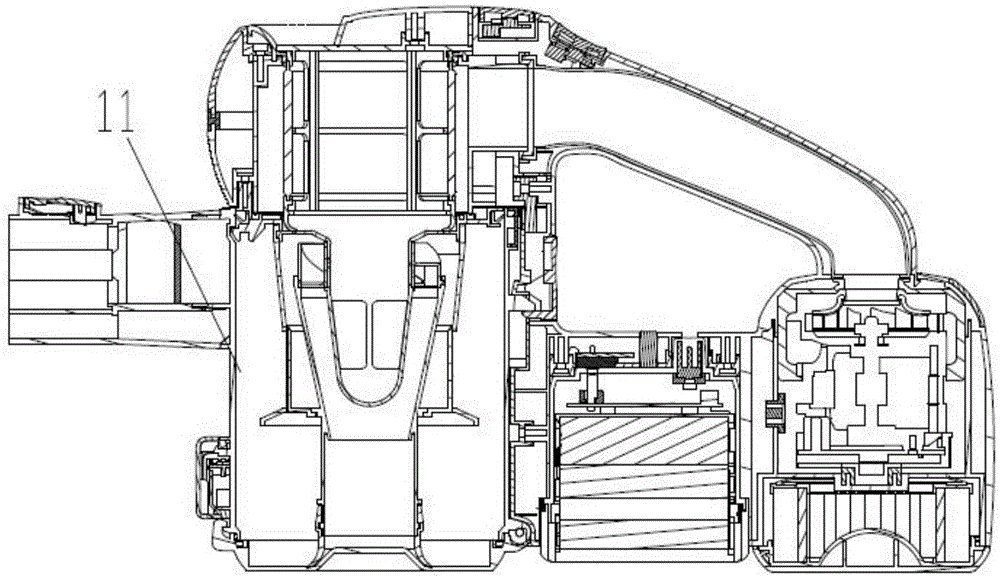

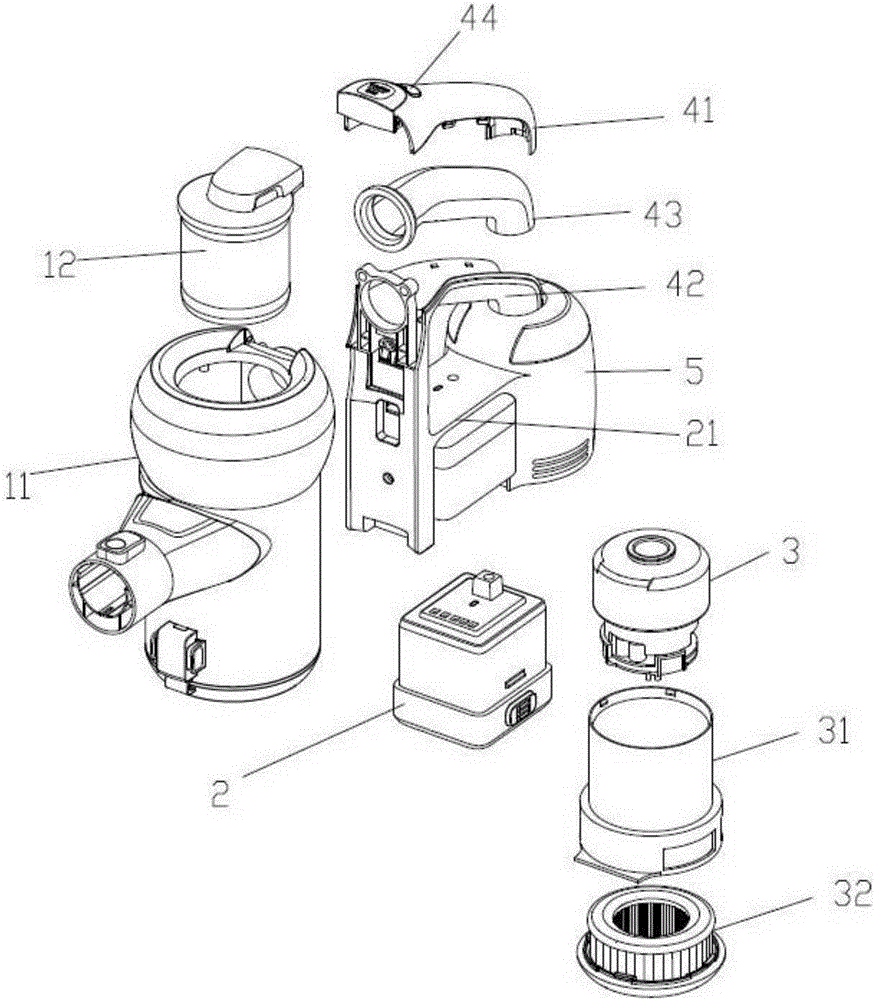

Handheld type vacuum cleaner

InactiveCN106343919AReduce the burden onEasy to operateSuction filtersSuction handlesAir separationAerospace engineering

The invention discloses a handheld type vacuum cleaner. The handheld type vacuum cleaner comprises a cyclone dust and air separation device, a motor, a battery and a handle, wherein the battery is positioned between the cyclone dust and air separation device and the motor; the handle is positioned above the motor and the battery. The handheld type vacuum cleaner has theadvantage that the center of gravity of the whole vacuum cleaner is positioned under the holding part, so that the arrangement is compact, and the burden of a user is reduced.

Owner:KINGCLEAN ELECTRIC

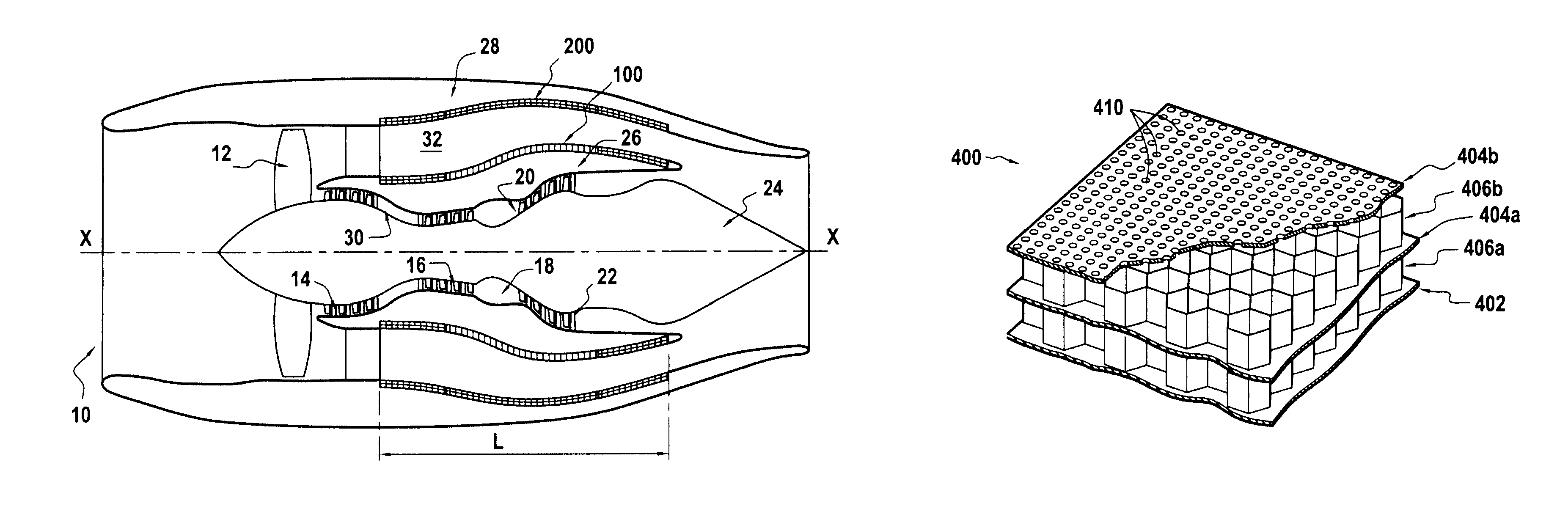

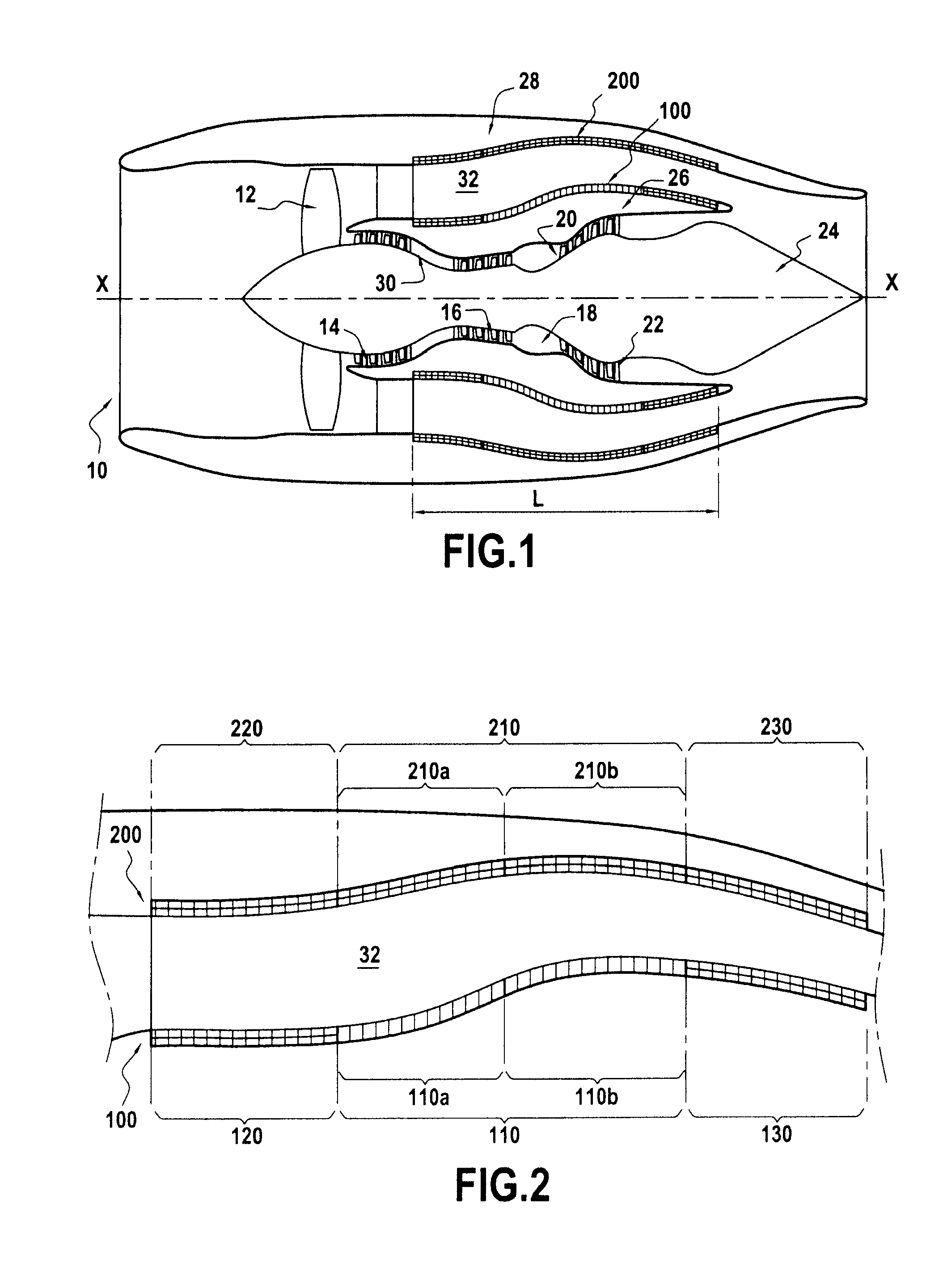

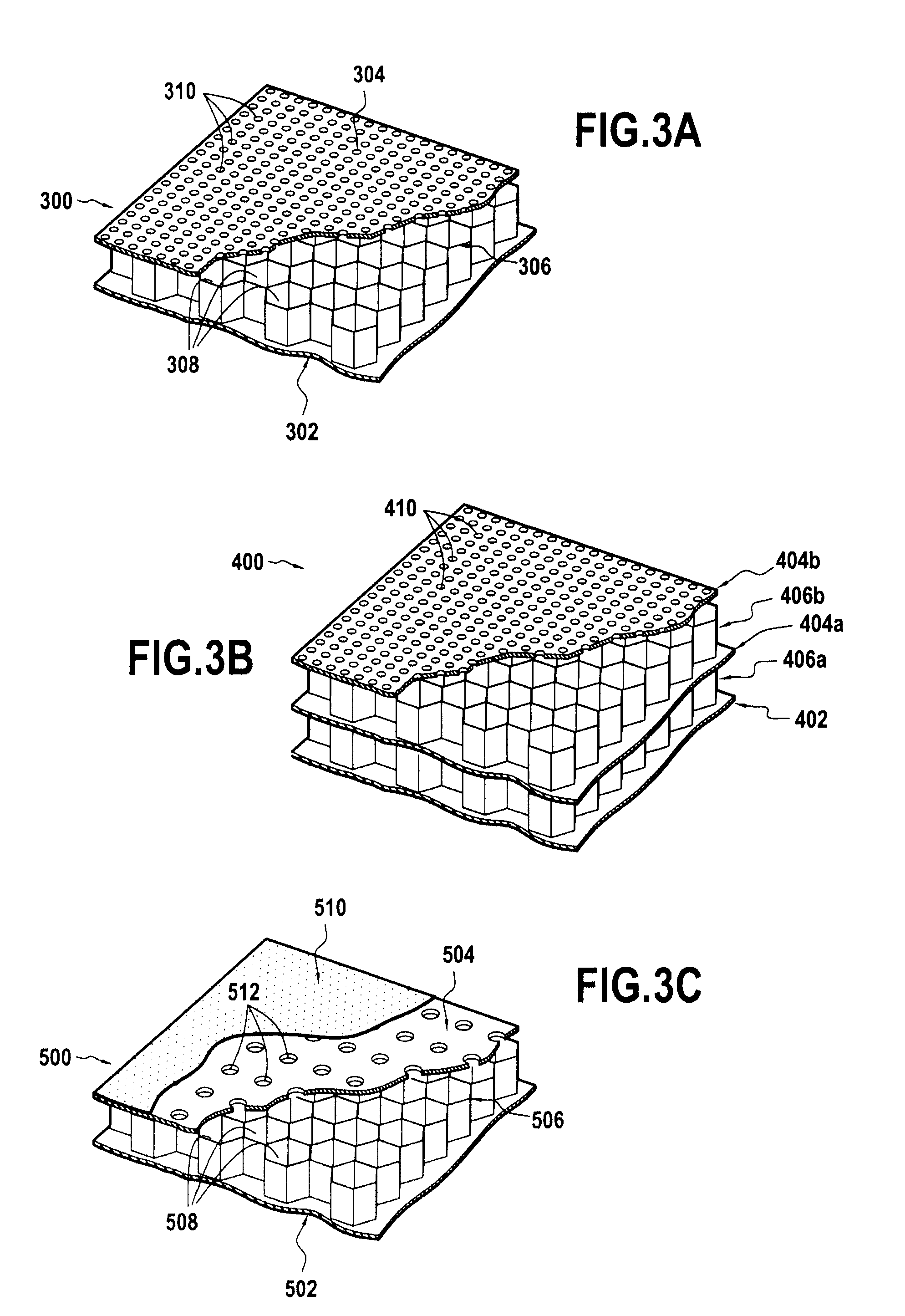

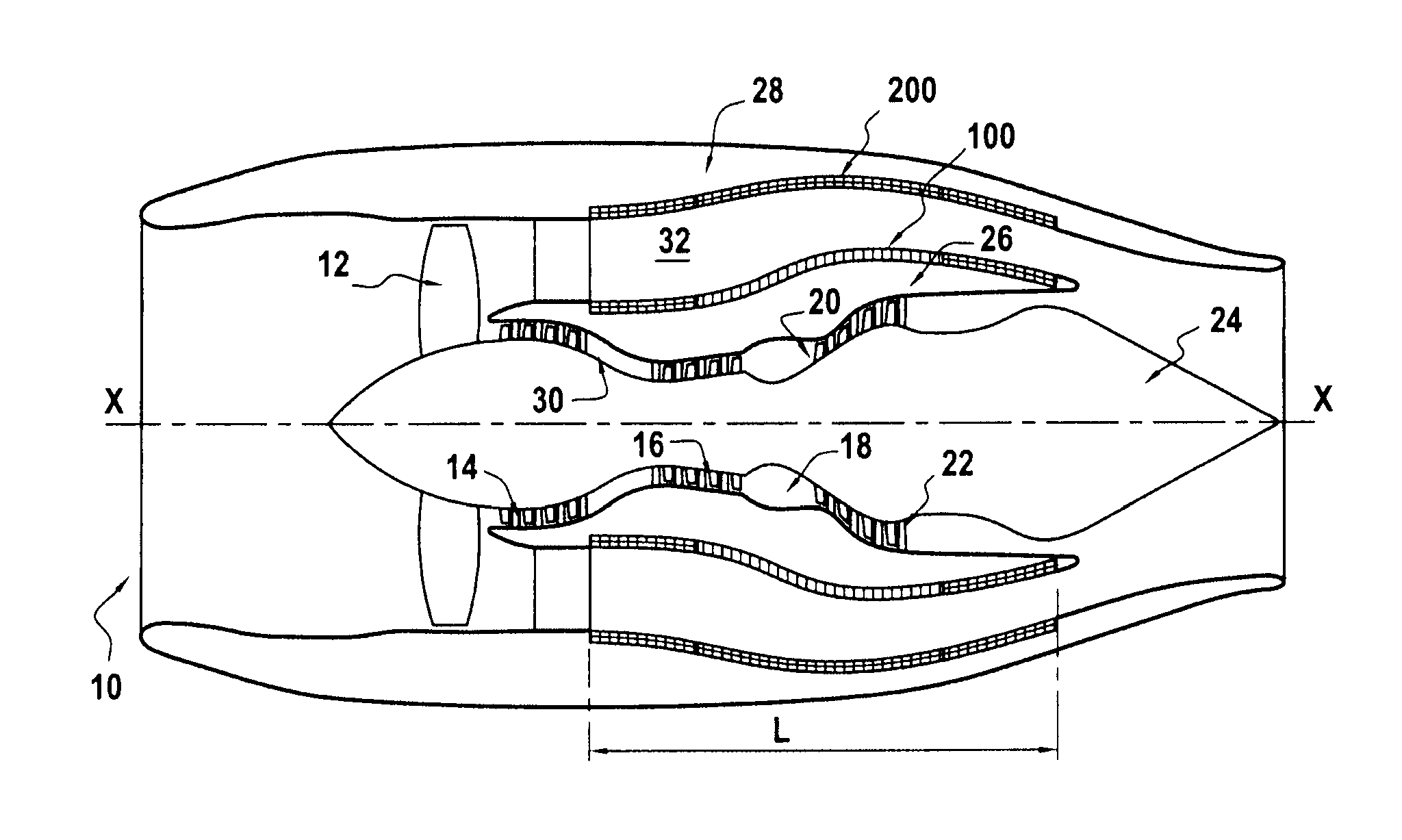

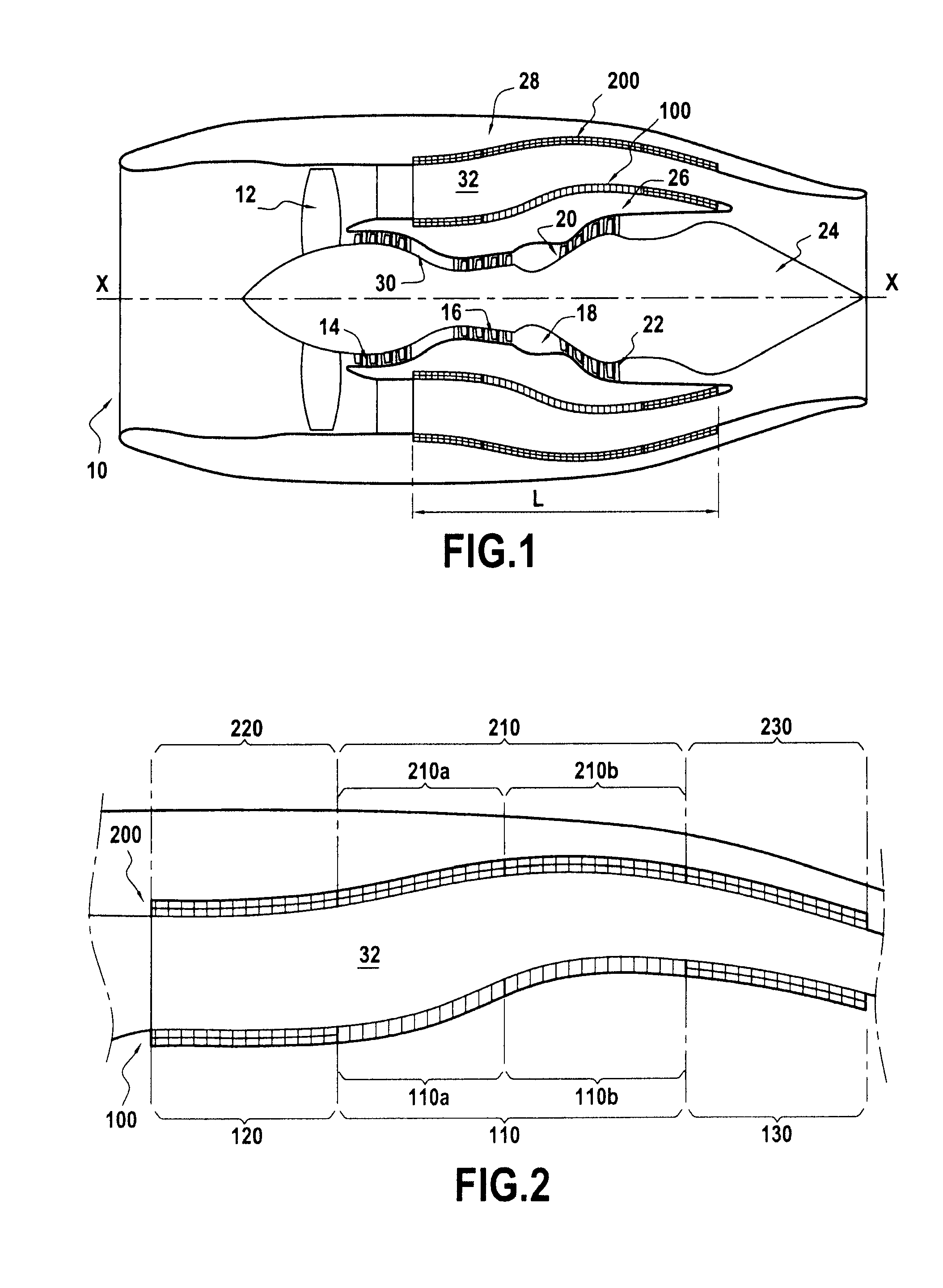

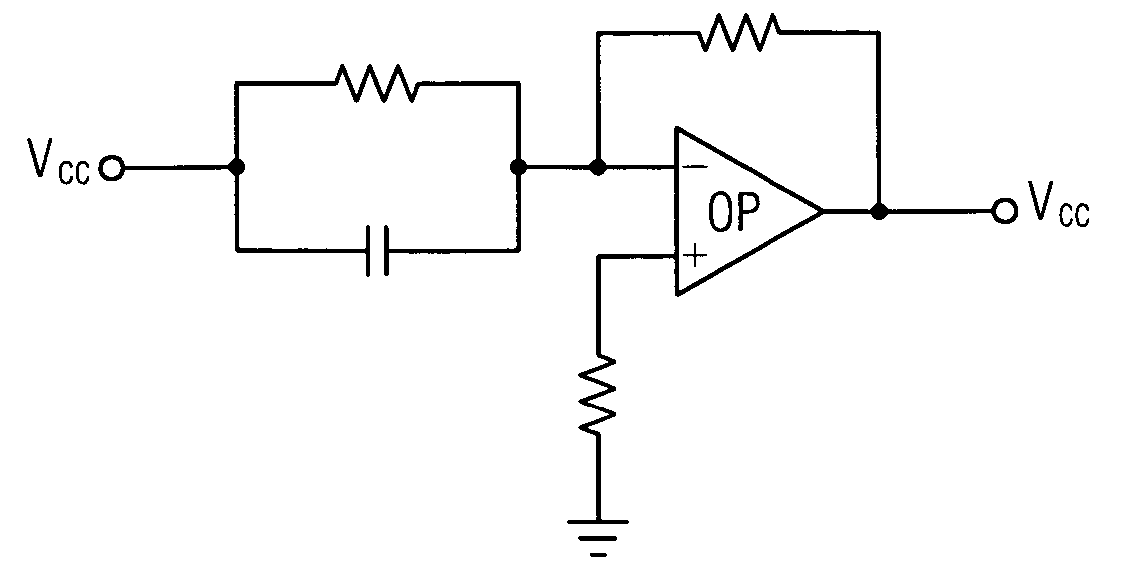

Device for acoustic treatment of the noise emitted by a turbojet

ActiveUS8579225B2Mitigate such drawbackEffective noise reductionGas turbine plantsFuselage insulationJet engineEngineering

The invention provides a device for acoustical treatment of the noise emitted by a bypass turbojet comprising a primary cowl having in an outer surface an inner annular acoustic treatment panel and a secondary cowl including in an inner surface an outer annular acoustic treatment panel arranged facing the inner panel. The inner and outer panels include respective central panel portions facing each other and extending axially over a common predetermined length, the length of the central panel portions lying in the range one-fifth to four-fifths of the total length of the panels, and the ratio between the acoustic resistances of the central panel portions being not less than 2.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

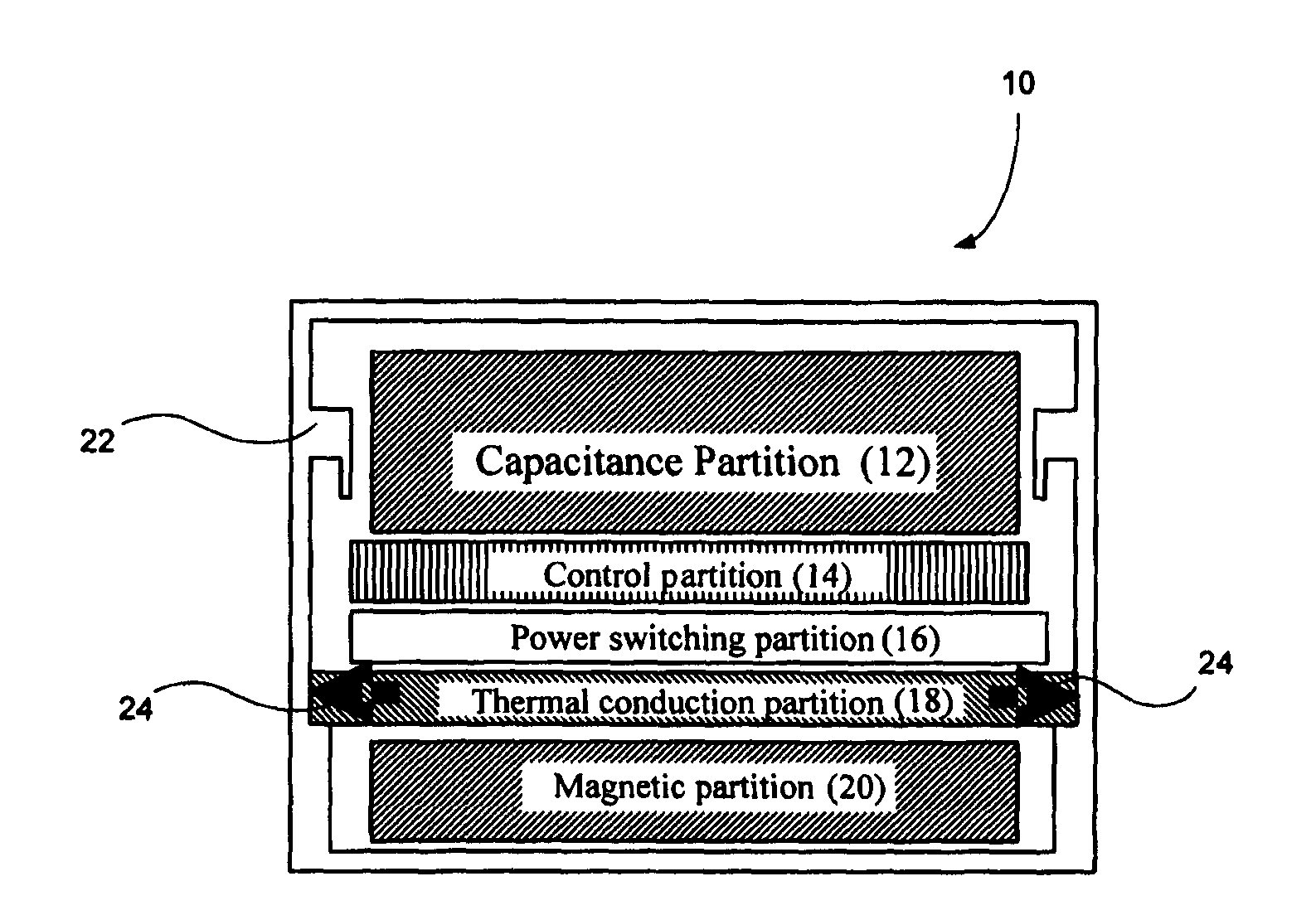

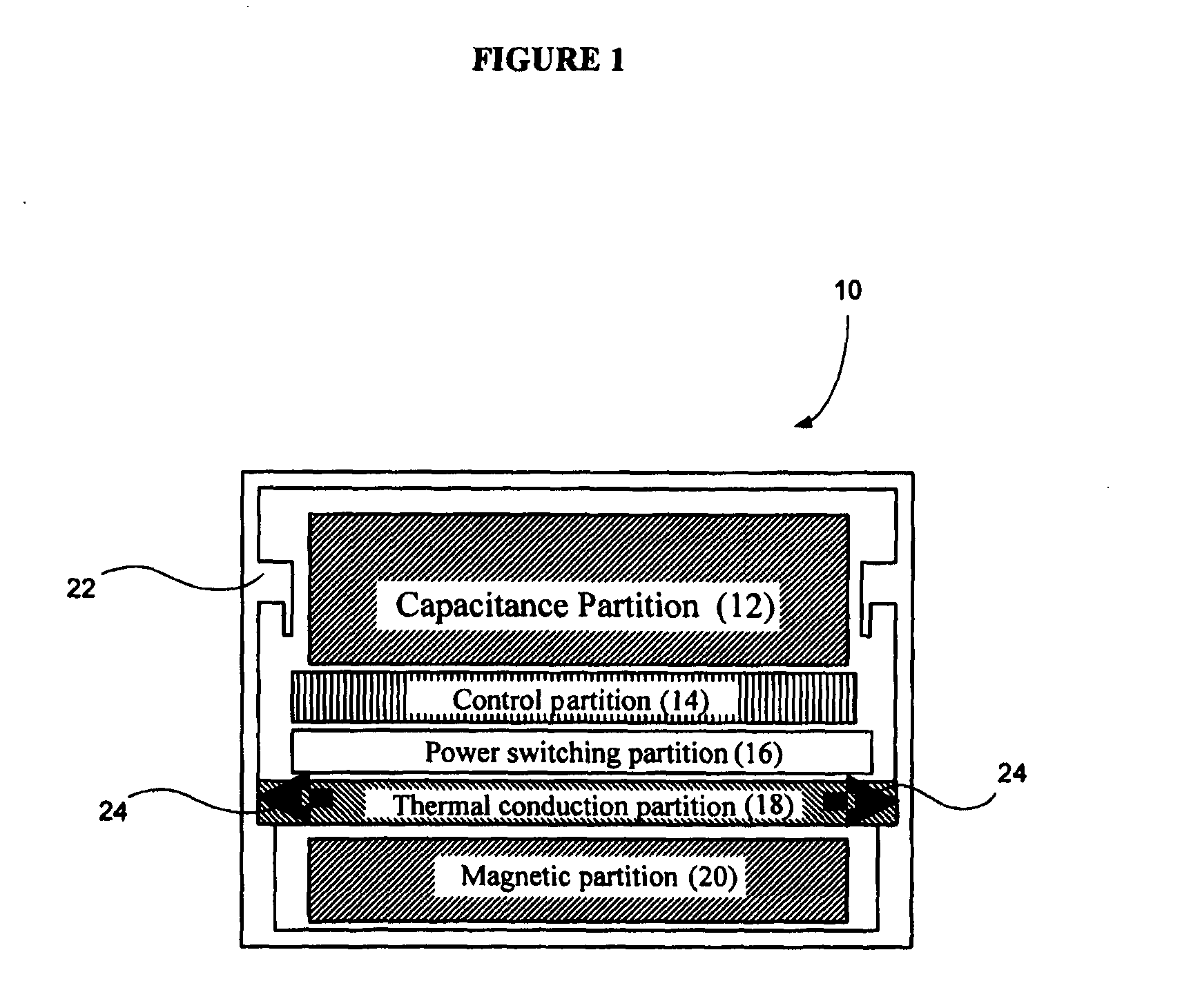

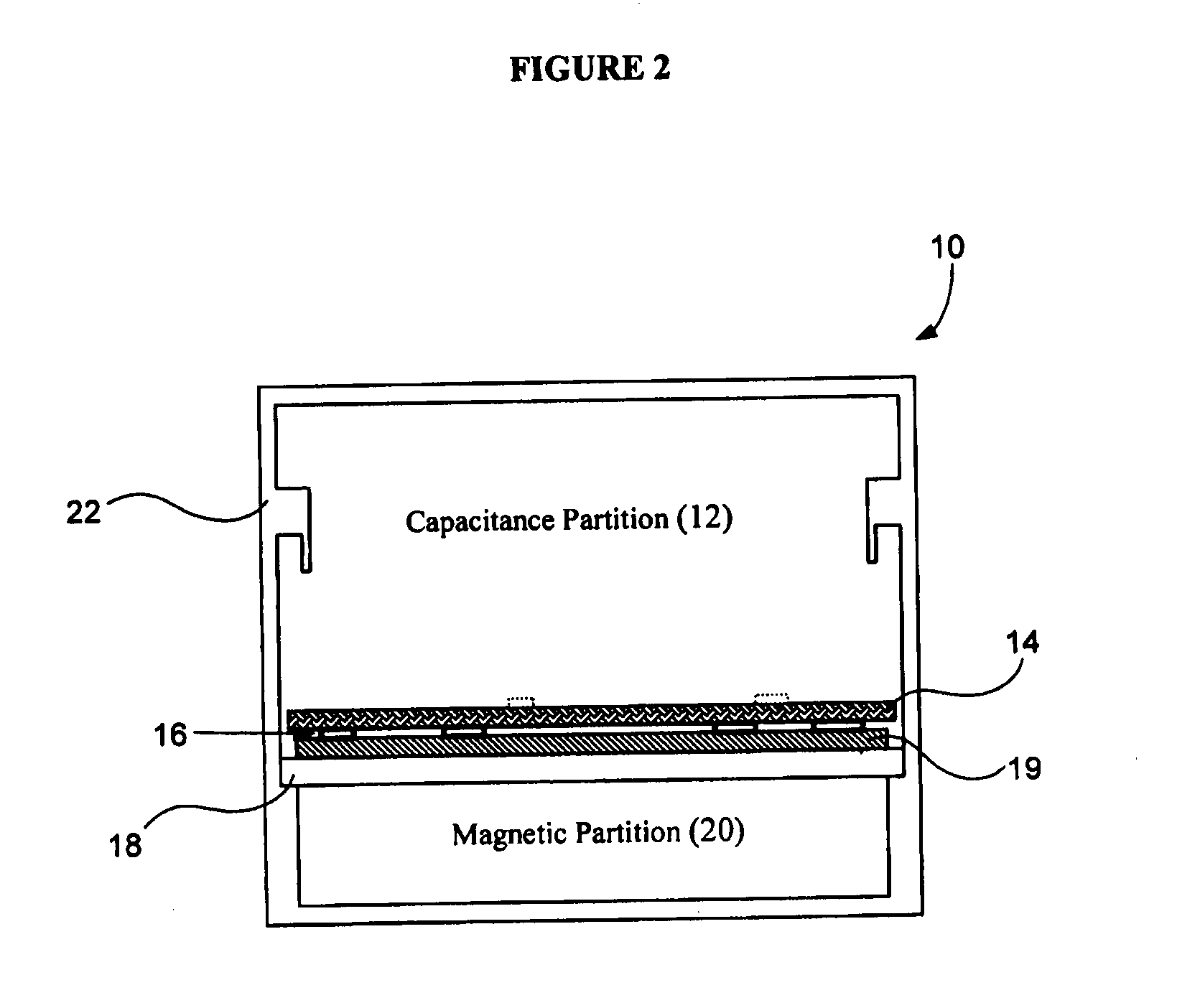

Power supply device and components thereof

ActiveUS20140369006A1Effective noise reductionPrognosis calculationPrinted circuit assemblingElectronic circuit testingElectricityCapacitance

A power supply device including a capacitance partition, a control partition, a power switching partition, a thermal conduction partition, a magnetic partition. The thermal conduction partition includes electrical connections to connect other partitions. The thermal conduction partition provides for magnetic shielding of the magnetic partition and thermal dissipation in a substantially orthogonal direction to the electrical connections. The layering arrangement allows automated production and / or testing.

Owner:SPECTRALWATT PTY LTD

Device for acoustic treatment of the noise emitted by a turbojet

ActiveUS20120085861A1Mitigate such drawbackEffective noise reductionGas turbine plantsFuselage insulationAcoustic processingEngineering

The invention provides a device for acoustical treatment of the noise emitted by a bypass turbojet comprising a primary cowl having in an outer surface an inner annular acoustic treatment panel and a secondary cowl including in an inner surface an outer annular acoustic treatment panel arranged facing the inner panel. The inner and outer panels include respective central panel portions facing each other and extending axially over a common predetermined length, the length of the central panel portions lying in the range one-fifth to four-fifths of the total length of the panels, and the ratio between the acoustic resistances of the central panel portions being not less than 2.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

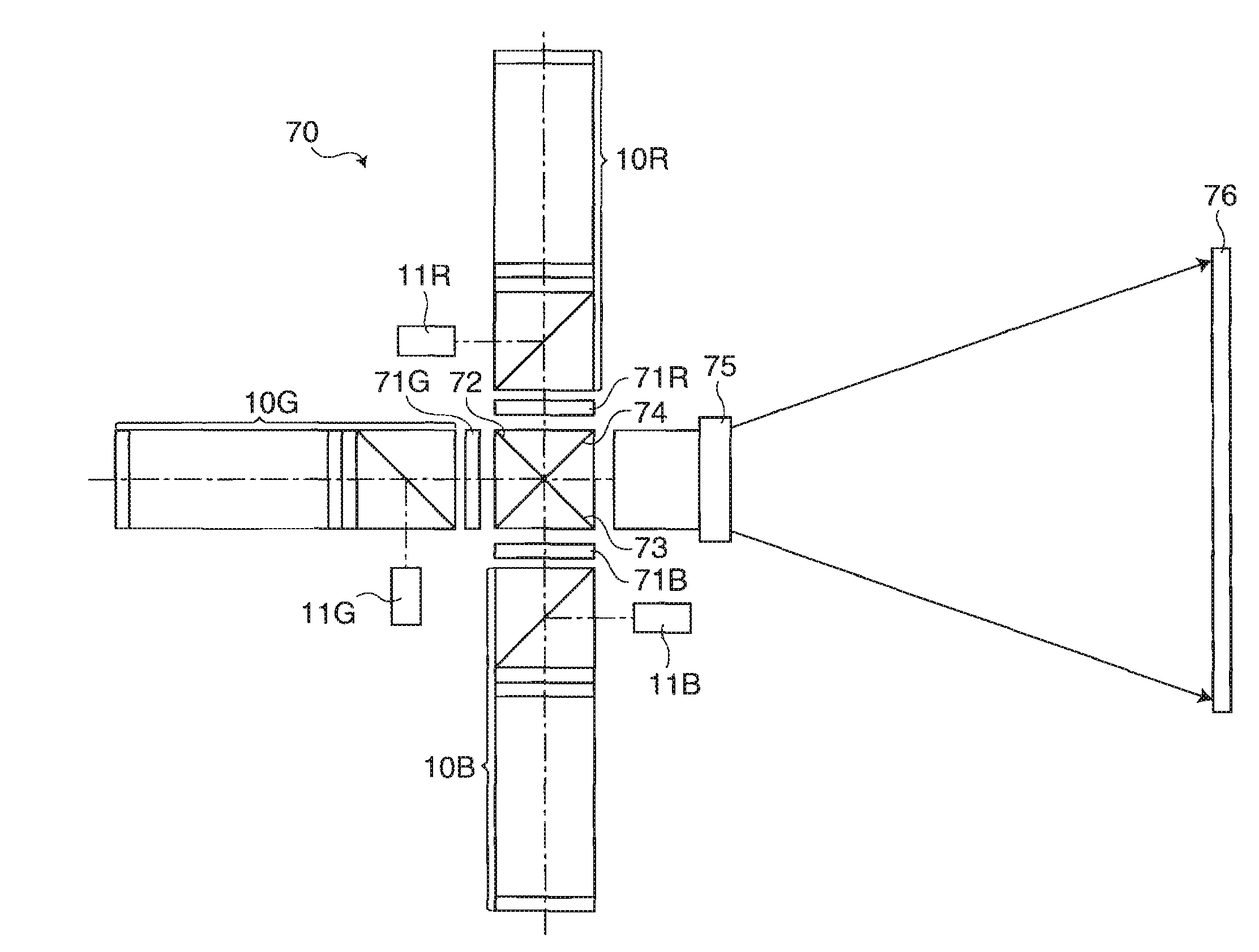

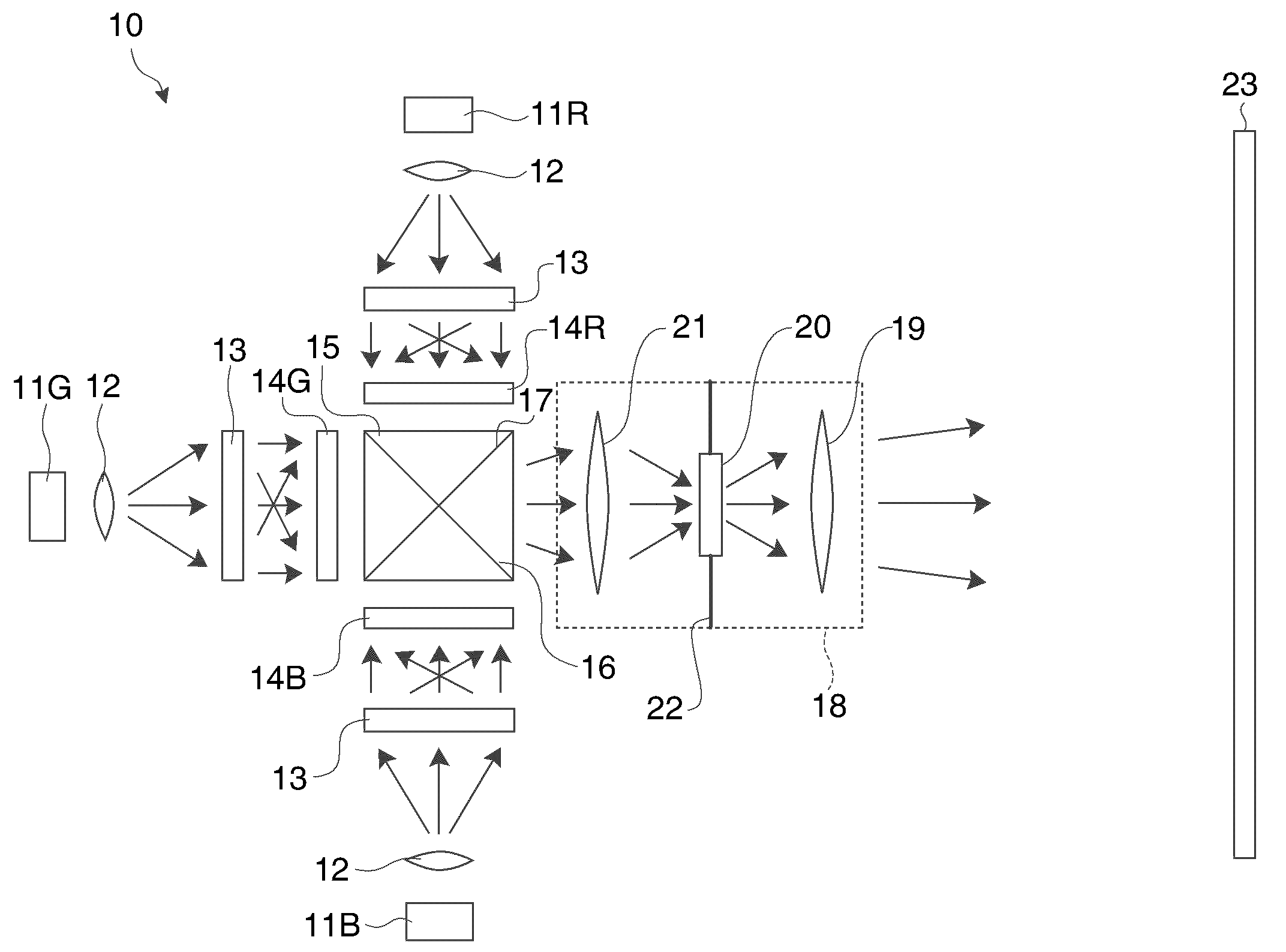

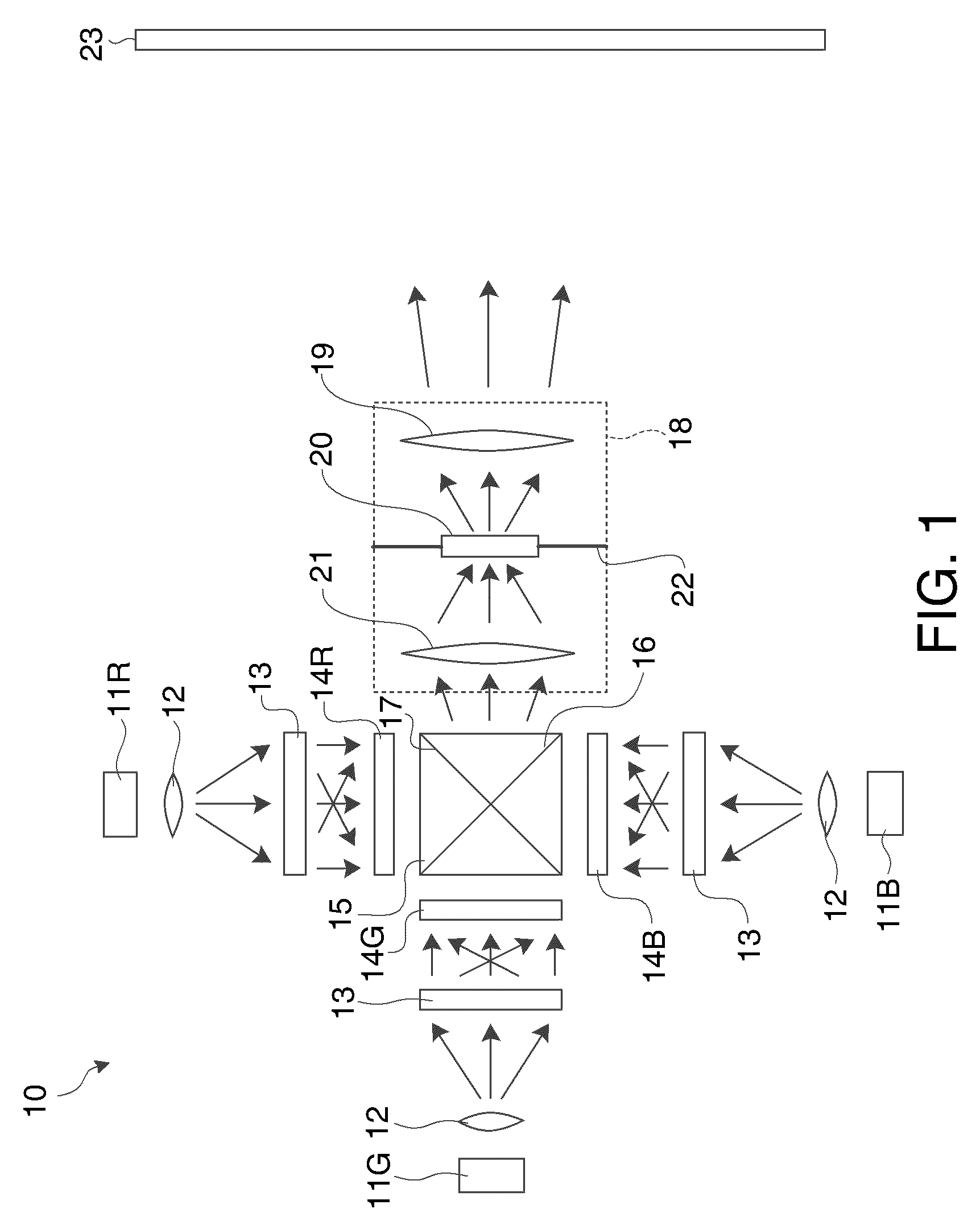

Lighting device and projector

InactiveUS20080123056A1Reduce speckle noiseReduce light lossPoint-like light sourceProjectorsLight equipmentEffect light

A lighting device includes: a light source unit which supplies coherent light; a polarized light splitting unit which reflects first polarized light having first oscillation direction and transmits second polarized light having second oscillation direction substantially orthogonal to the first oscillation direction to split the first polarized light from the second polarized light; a reflection unit which reflects light advancing in a direction other than the lighting direction from the polarized light splitting unit; a partial reflection unit disposed between the polarized light splitting unit and the reflection unit to transmit a part of entering light and reflect the other part of the entering light; and a wavelength plate disposed between the polarized light splitting unit and the partial reflection unit no vary polarization condition of entering light. The partial reflection unit and the reflection unit produce optical path difference between light which passes through the partial reflection unit and the polarized light splitting unit to be released in the lighting direction and light which sequentially passes through the partial reflection unit, the reflection unit, the partial reflection unit, and the polarized light splitting unit to be released in the lighting direction.

Owner:COLUMBIA PEAK VENTURES LLC

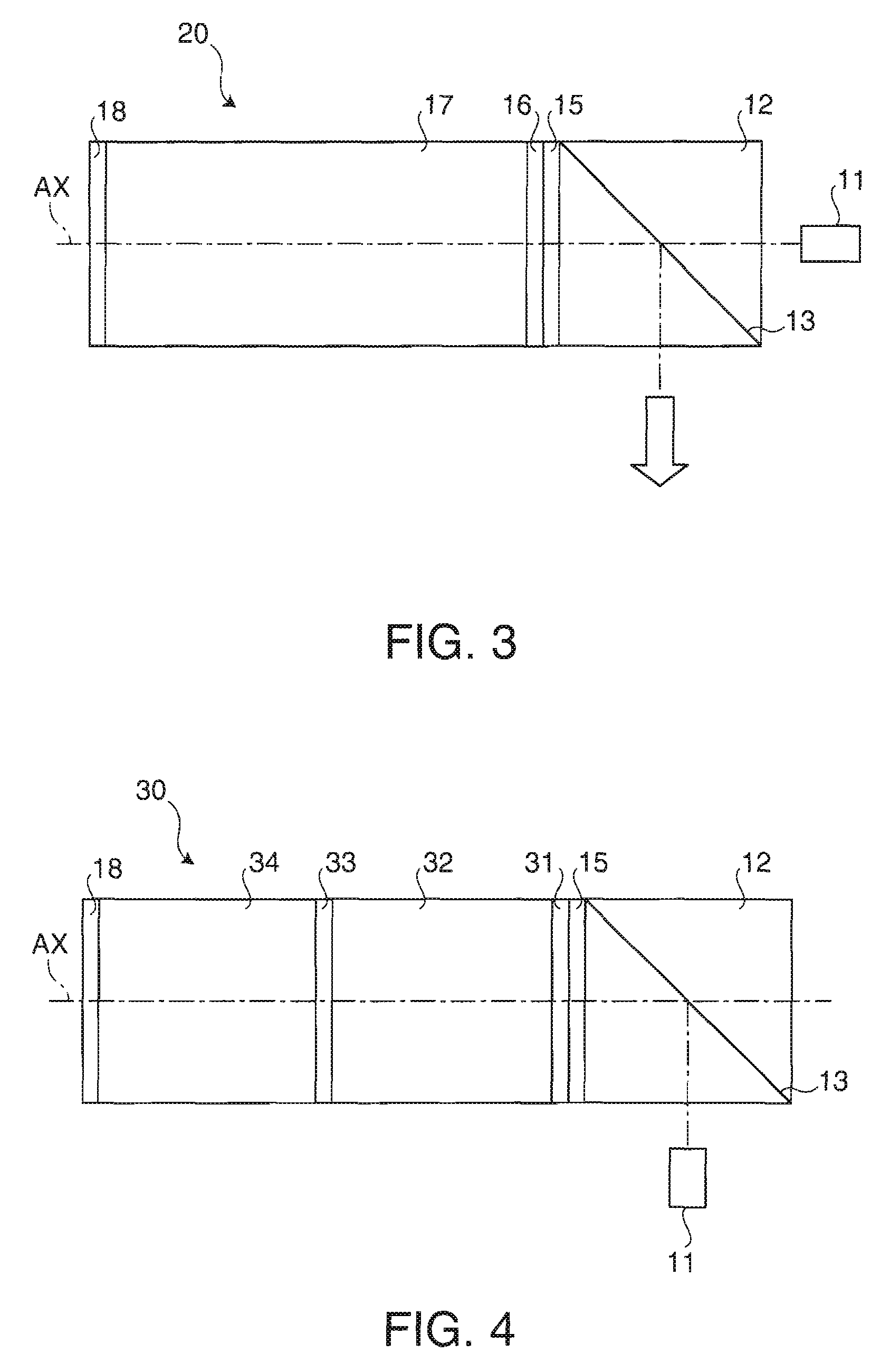

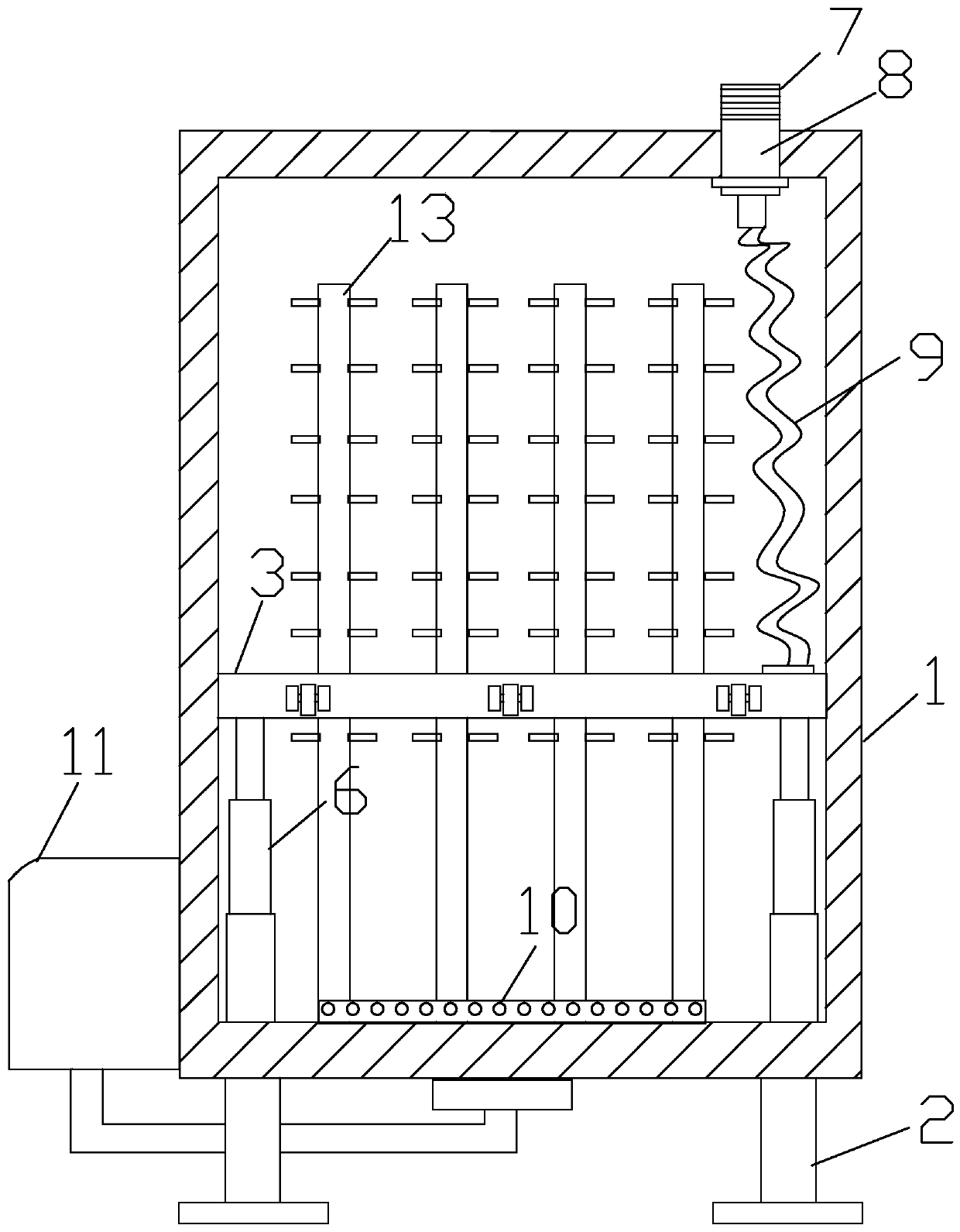

Environment-friendly processing equipment for straw

The invention discloses environment-friendly processing equipment for straw. The equipment comprises a crushing bin, crushing knives, a discharging hopper, a conveying belt, a packaging box and a base; the crushing bin is fixed above the base through a rack; a feeding hopper is arranged on the right side of the top of the crushing bin; a magnetic ring is arranged on the feeding hopper; a group of feeding rollers are further arranged inside the feeding hopper; the top of the crushing bin communicates with a dust suction pipe; the dust suction pipe is connected with a dust collector; two rotating shafts are arranged inside the crushing bin and are connected with motors; knife rests are arranged on the rotating shafts; the crushing knives are arranged on the knife rests; a screen is arranged at the bottom of the crushing bin and is in driving connection with a vibration motor; the discharging hopper is arranged below the screen; a valve is arranged below the discharging hopper; the conveying belt is arranged below the discharging hopper and is fixed above the base through a supporting frame; the right end of the conveying belt directly faces the left end of a downward pressing plate of the packaging box; and the lower side of the downward pressing plate is connected with a gas cylinder. The equipment is simple in structure, good in stability, convenient to maintain, good in packaging effect and high in working efficiency.

Owner:GUANGXI UNIV

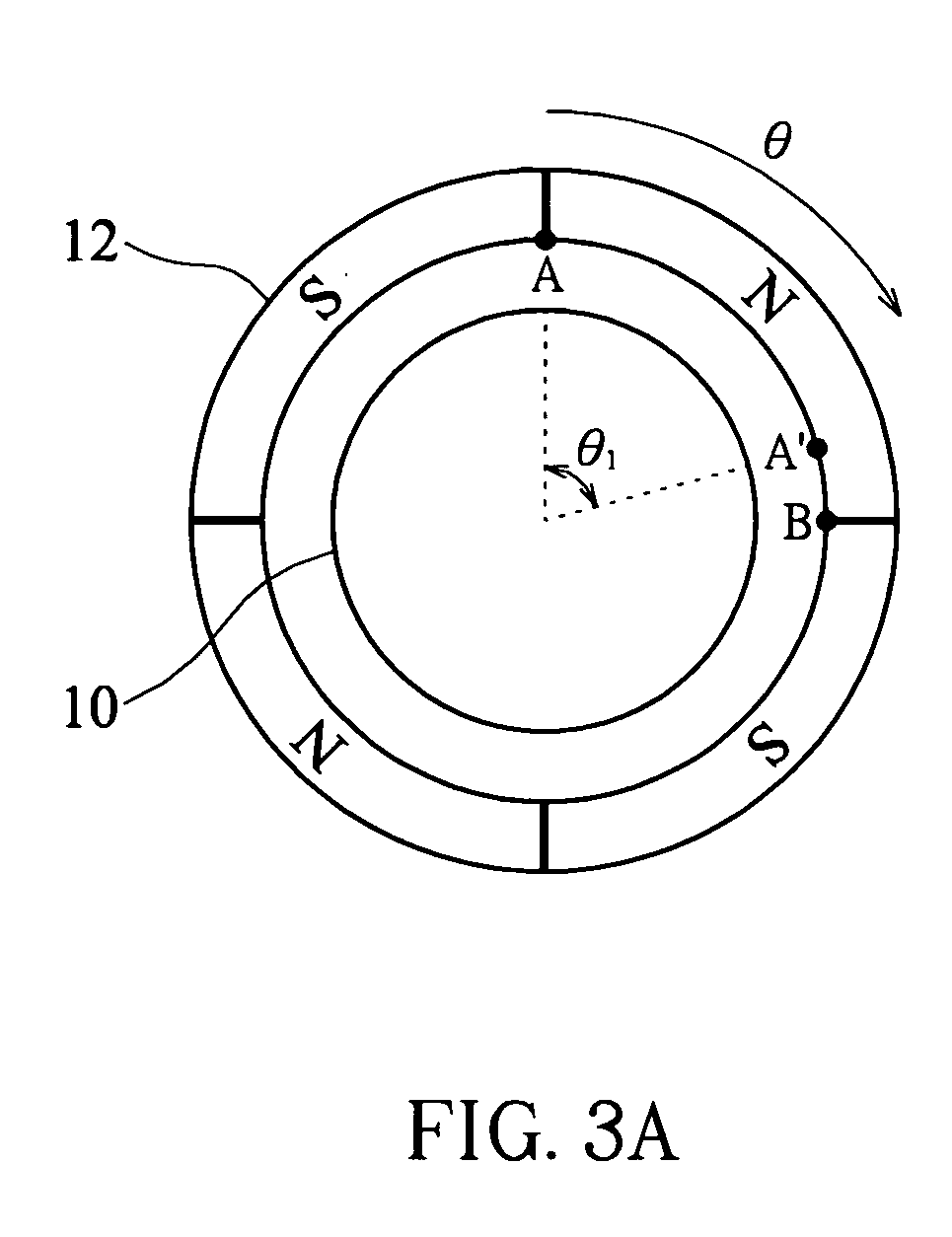

Fan speed control circuit

ActiveUS20060056823A1Reducing and even eliminating electric noiseEffectively reducing vibrationMotor/generator/converter stoppersAC motor controlControl signalEngineering

A fan speed control circuit includes a pulse width modulation (PWM) signal generating circuit, a driving circuit and a phase compensation unit. The PWM signal generating circuit generates a PWM control signal with a sequence of alternating on-time and off-time, and the driving circuit outputs a driving signal according to the PWM control signal to a fan motor. The phase compensation unit is connected to the fan motor for delaying or advancing the PWM control signal by a phase angle to synchronize the acting period of the back electromotive force formed by the magnetic flux variation with the off-time of the PWM control signal. The present invention further provides a bi-power motor driving system including a motor rotating by receiving a first power from a first power generator, and a driving circuit for driving the motor according to a second power from a second power generator.

Owner:DELTA ELECTRONICS INC

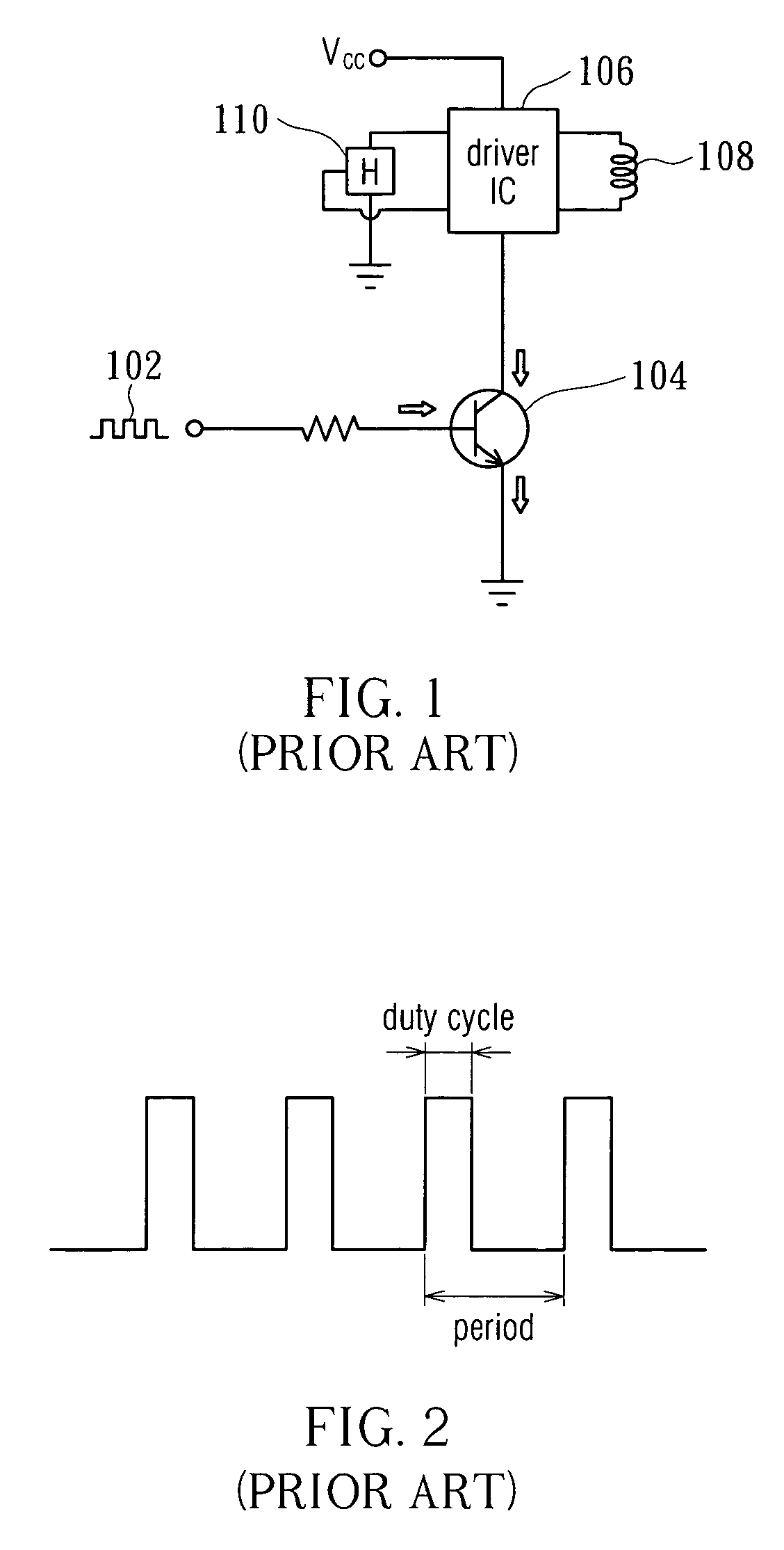

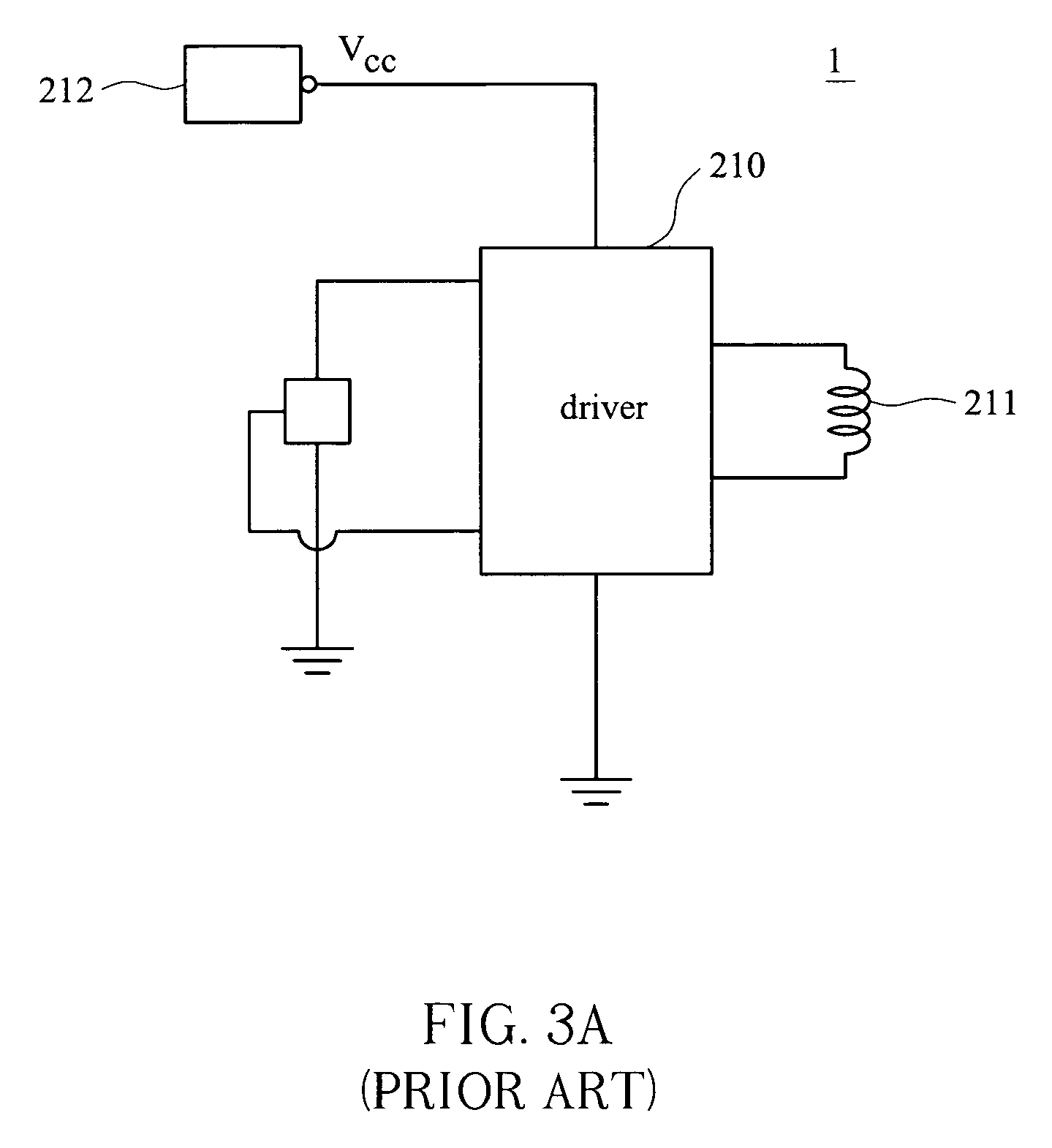

Fan speed control circuit

ActiveUS20050002657A1Reduce noiseReduce vibrationElectronic commutation motor controlMotor/generator/converter stoppersControl signalElectromotive force

A fan speed control circuit includes a pulse width modulation (PWM) signal generating circuit, a driving circuit and a phase compensation unit. The PWM signal generating circuit generates a PWM control signal with a sequence of alternating on-time and off-time, and the driving circuit outputs a driving signal according to the PWM control signal to a fan motor. The phase compensation unit is connected to the fan motor for delaying or advancing the PWM control signal by a phase angle to synchronize the acting period of the back electromotive force formed by the magnetic flux variation with the off-time of the PWM control signal.

Owner:DELTA ELECTRONICS INC

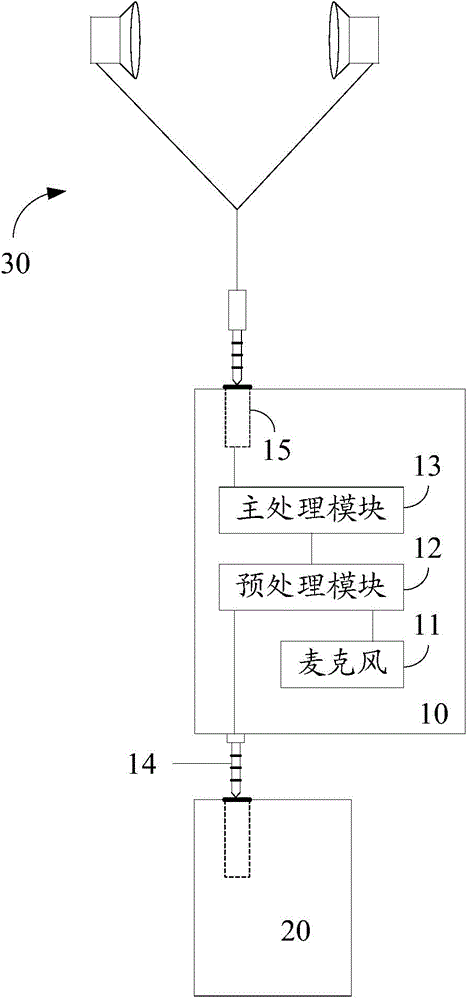

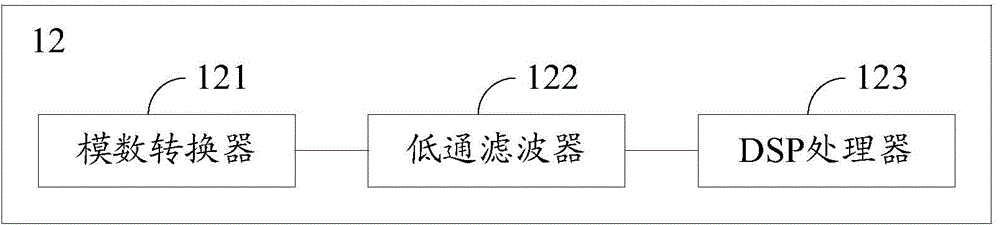

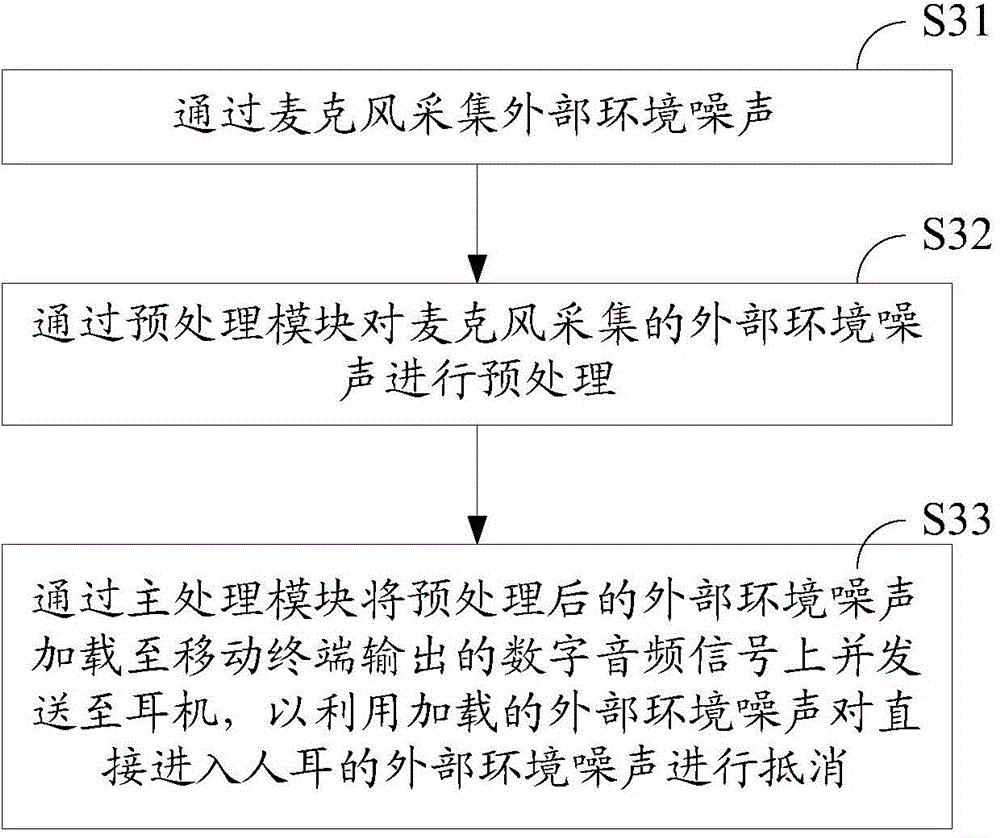

External noise reduction device for mobile terminal and noise reduction method of external noise reduction device

ActiveCN104602162AEffective noise reductionImprove user experienceEarpiece/earphone attachmentsTransducer circuitsEnvironmental noiseComputer module

The invention provides an external noise reduction device for a mobile terminal and a noise reduction method of the external noise reduction device. The external noise reduction device is used for externally connecting between the mobile terminal and a headset and comprises a microphone, a preprocessing module and a main processing module, the microphone is used for acquiring external environmental noise, the preprocessing module is used for preprocessing the external environmental noise, the main processing module is used for loading the preprocessed external environmental noise to digital audio signals outputted by the mobile terminal and transmitting the preprocessed external environmental noise to the headset, and the external environmental noise directly entering ears is eliminated by the aid of the loaded external environmental noise. Effective noise reduction can be performed for audio signals directly entering the ears, and the external noise reduction device is low in cost and high in transportability.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

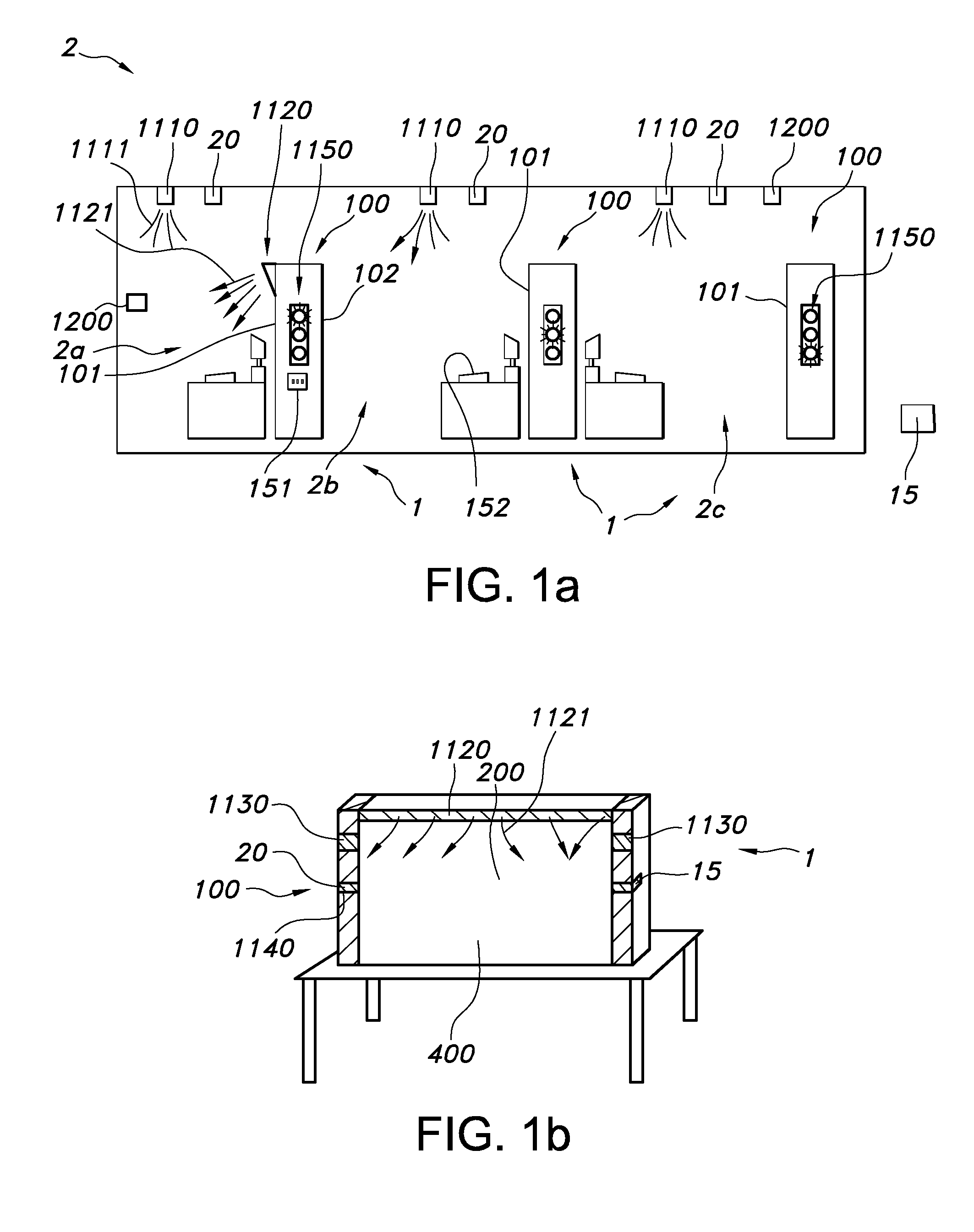

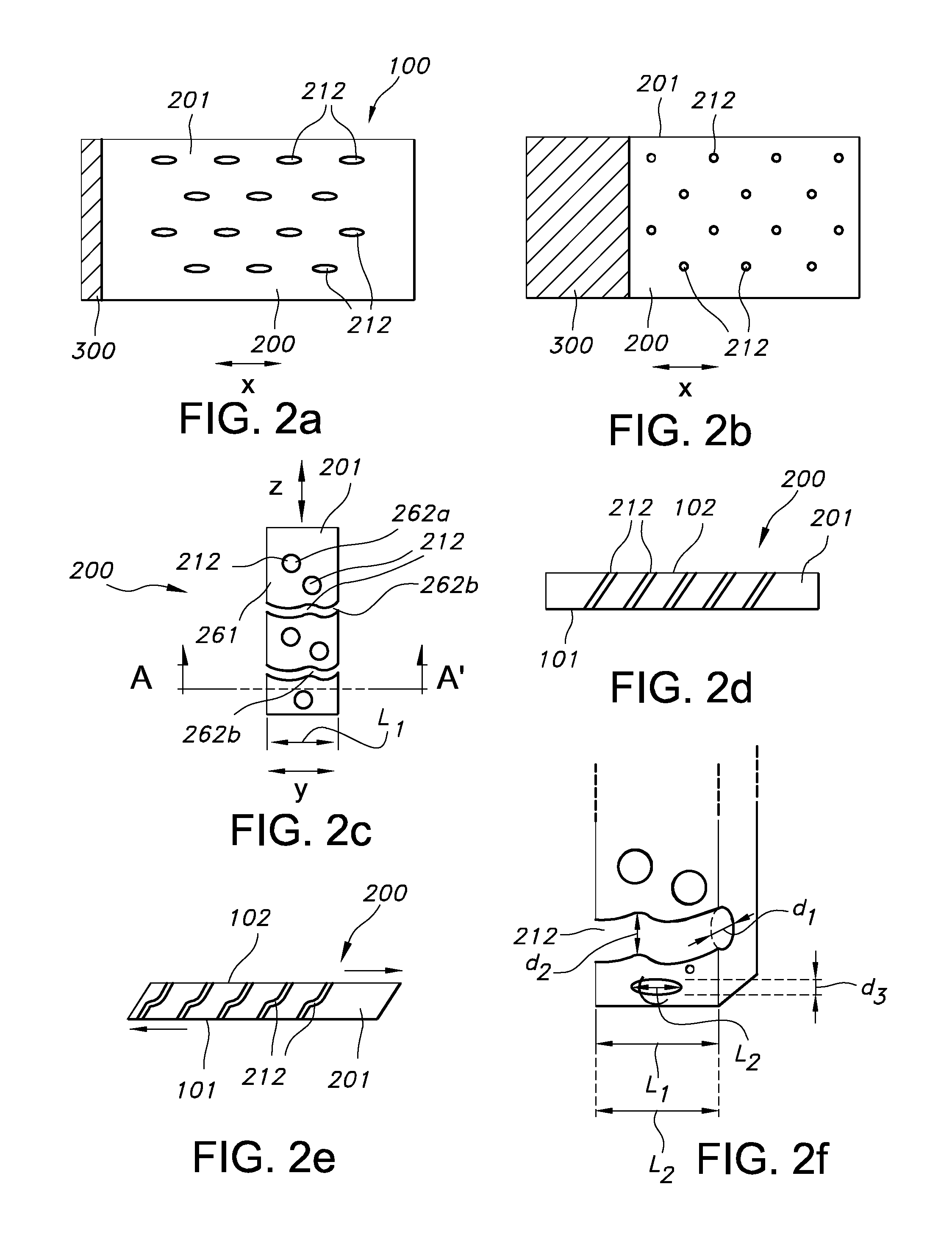

System comprising a sound attenuating panel

InactiveUS20160163302A1Crate privacyLow transparencyVibration measurement in fluidElectrical apparatusControl cellEngineering

The invention provides a system (1) comprising a sound attenuating panel (100), a control unit (15), and a sound sensor (20), wherein the sound sensor (20) is configured to measure sound in a space wherein the sound attenuating panel (100) is applied and is configured to provide a corresponding sound sensor signal, wherein the control unit (15) is configured to control controllable devices as function of the sound sensor signal, wherein the controllable devices are a sound attenuating panel (100) having controllable properties and another device having controllable properties, said another device being selected from the group consisting of (i) a light source not embedded in the sound attenuating panel and (ii) a sound attenuating panel with a light source embedded therein.

Owner:SIGNIFY HLDG BV

Projector

ActiveUS20090207380A1Efficient reductionHigh quality imagingProjectorsNon-linear opticsOptoelectronicsImage signal

A projector includes a light source unit that emits coherent light, a spatial light modulation unit that modulates the coherent light emitted from the light source unit in accordance with an image signal, and a polarized light modulation unit having a plurality of modulating areas, each of which changing the polarization state of light. The plurality of modulating areas temporally and spatially change the polarization state of the light outputted from the spatial light modulation unit.

Owner:SEIKO EPSON CORP

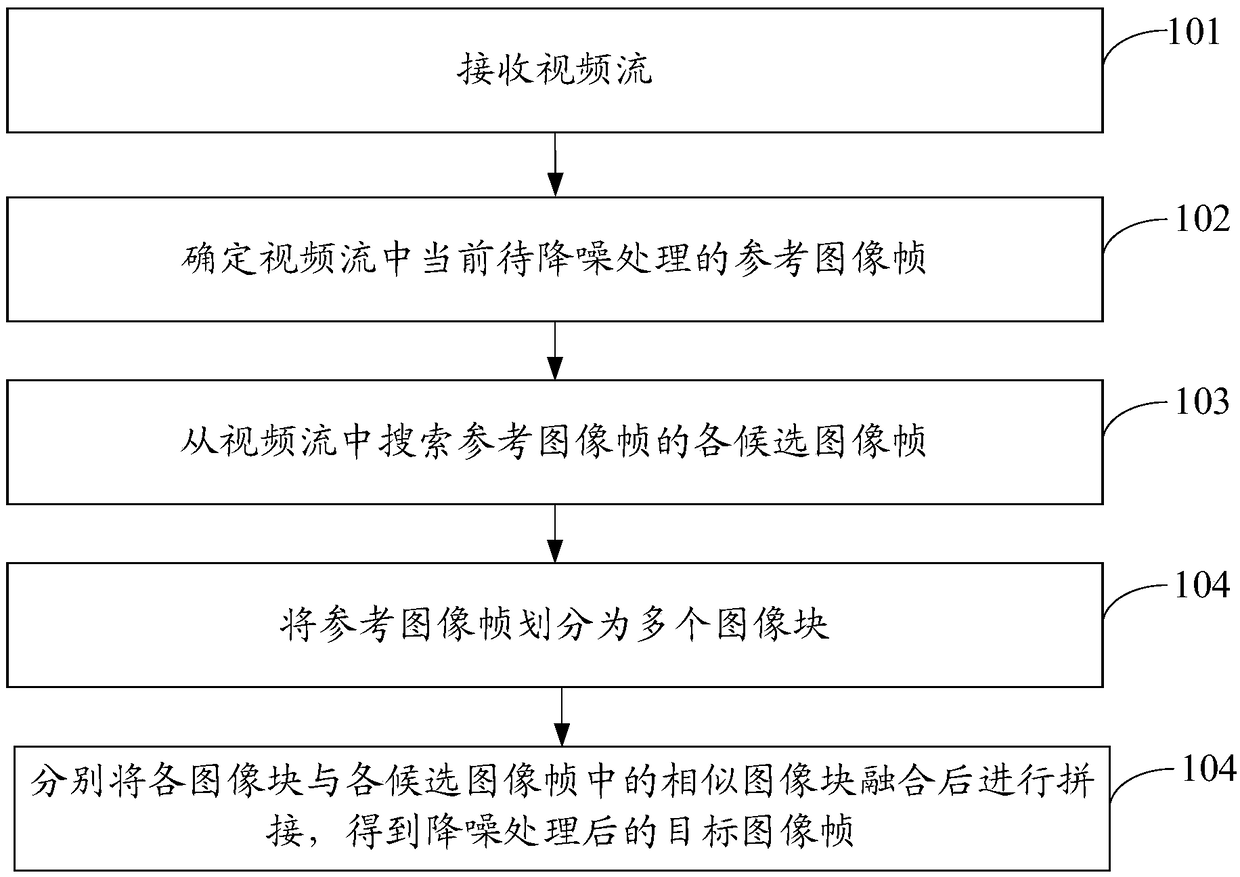

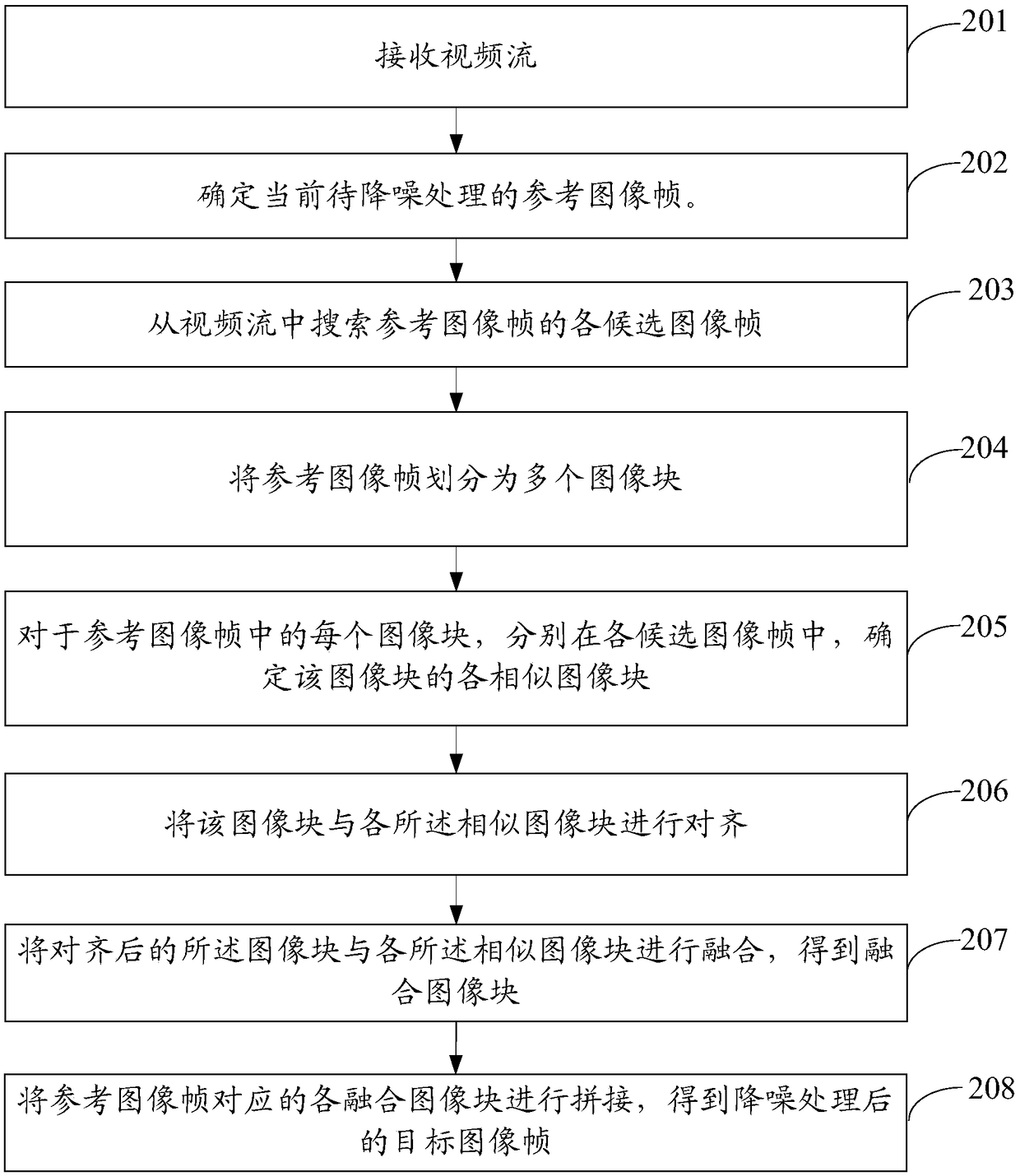

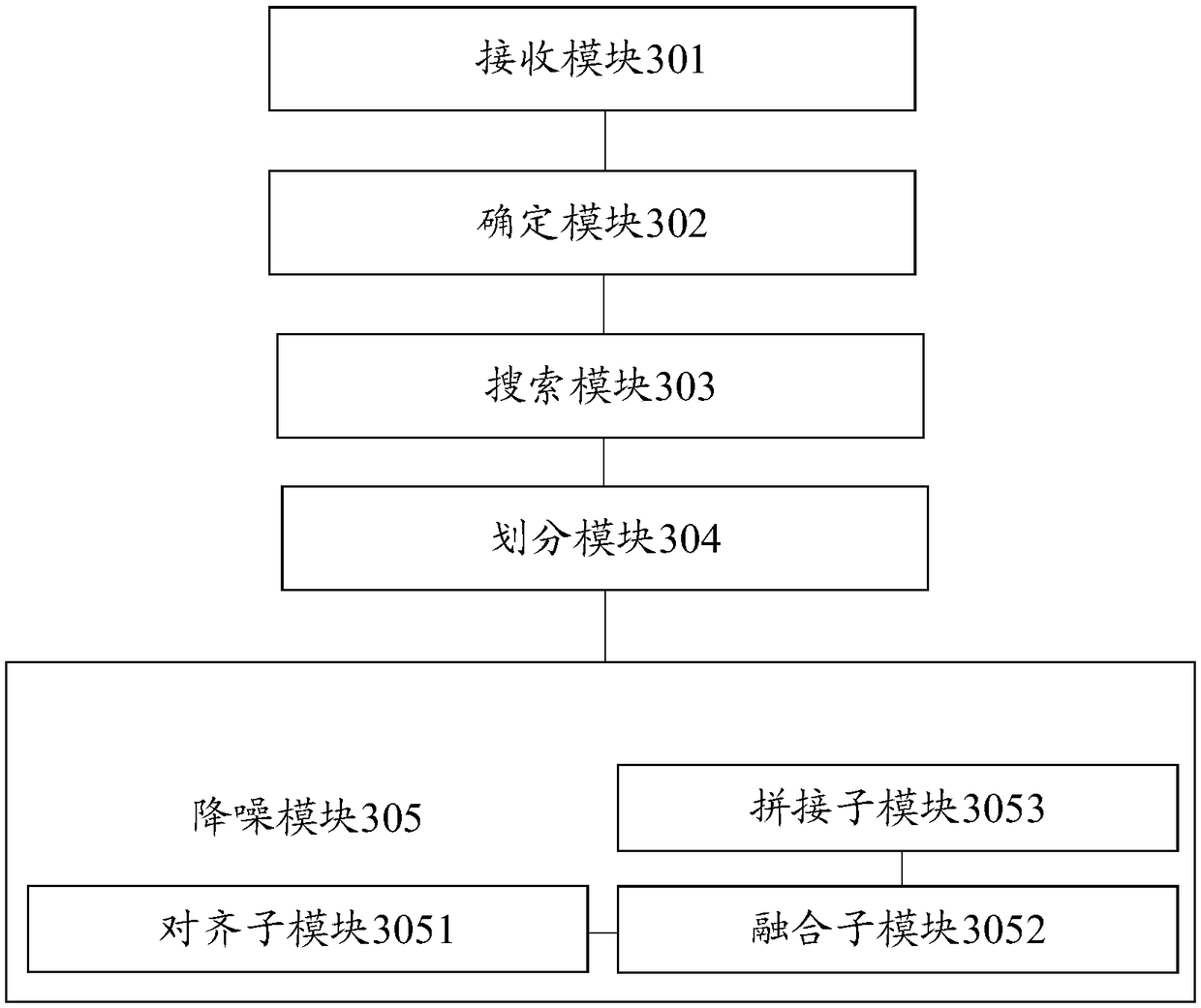

Video stream noise reduction method and device, electronic device and storage medium

InactiveCN109246332AEffective noise reductionImprove signal-to-noise ratioTelevision system detailsColor television detailsReference imageNoise reduction

The invention relates to a video stream noise reduction method and device, an electronic device and a storage medium. The method includes the steps: receiving a video stream, wherein the video streamincludes a plurality of image frames; determining a current to-be-denoised reference image frame of the current video stream; searching for all candidate image frames of the reference image frame fromthe video stream; dividing the reference image frame into a plurality of image blocks; respectively merging and splicing each of the image blocks with similar image blocks in each of the candidate image frames to obtain a target image frame after noise reduction processing. The method provided by the present invention can achieve the effective noise reduction of the video stream, and enables thevideo stream to display a clear video image.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Fan speed control circuit

ActiveUS7218846B2Effectively reducing vibrationEffective noise reductionElectronic commutation motor controlMotor/generator/converter stoppersControl signalElectromotive force

A fan speed control circuit includes a pulse width modulation (PWM) signal generating circuit, a driving circuit and a phase compensation unit. The PWM signal generating circuit generates a PWM control signal with a sequence of alternating on-time and off-time, and the driving circuit outputs a driving signal according to the PWM control signal to a fan motor. The phase compensation unit is connected to the fan motor for delaying or advancing the PWM control signal by a phase angle to synchronize the acting period of the back electromotive force formed by the magnetic flux variation with the off-time of the PWM control signal.

Owner:DELTA ELECTRONICS INC

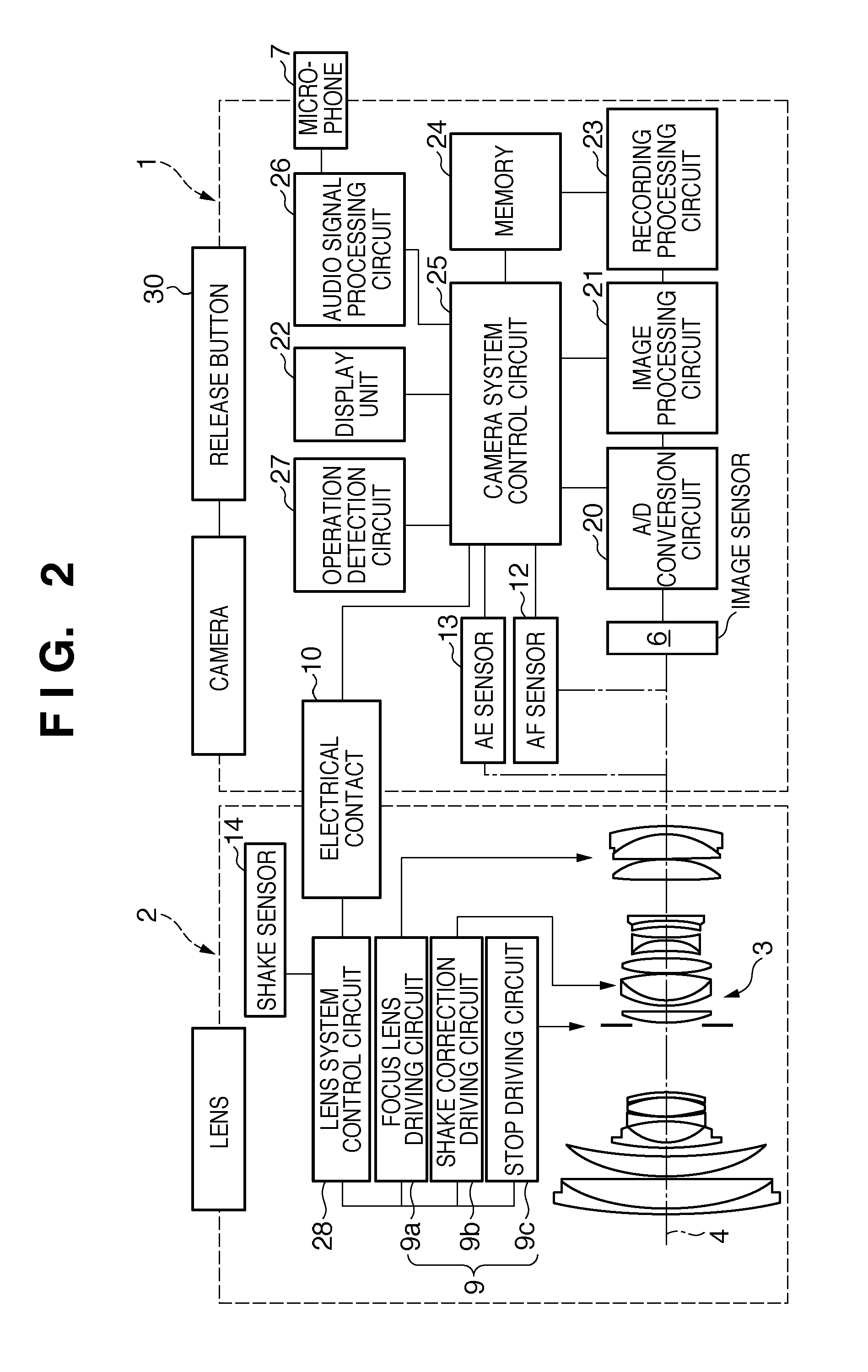

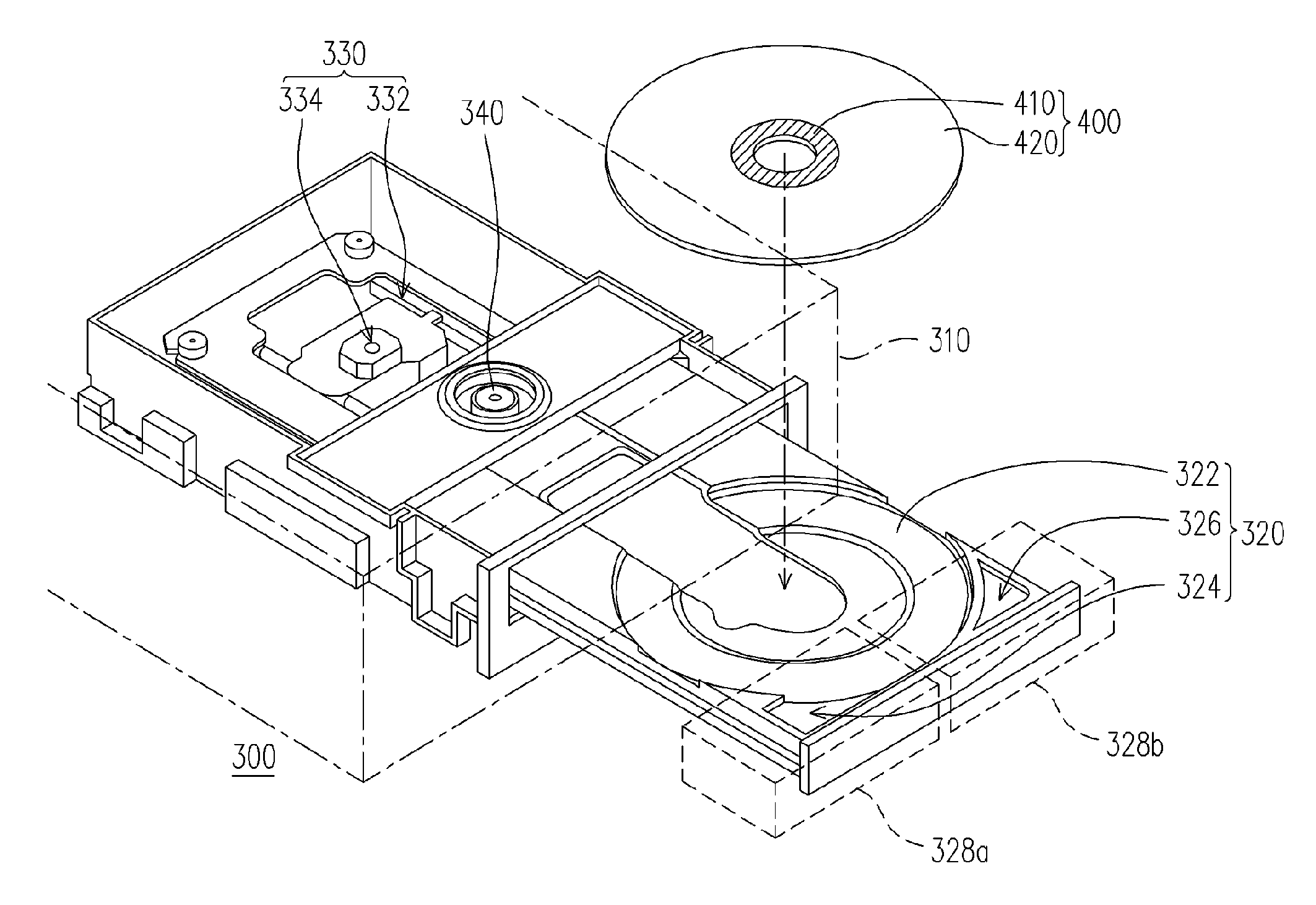

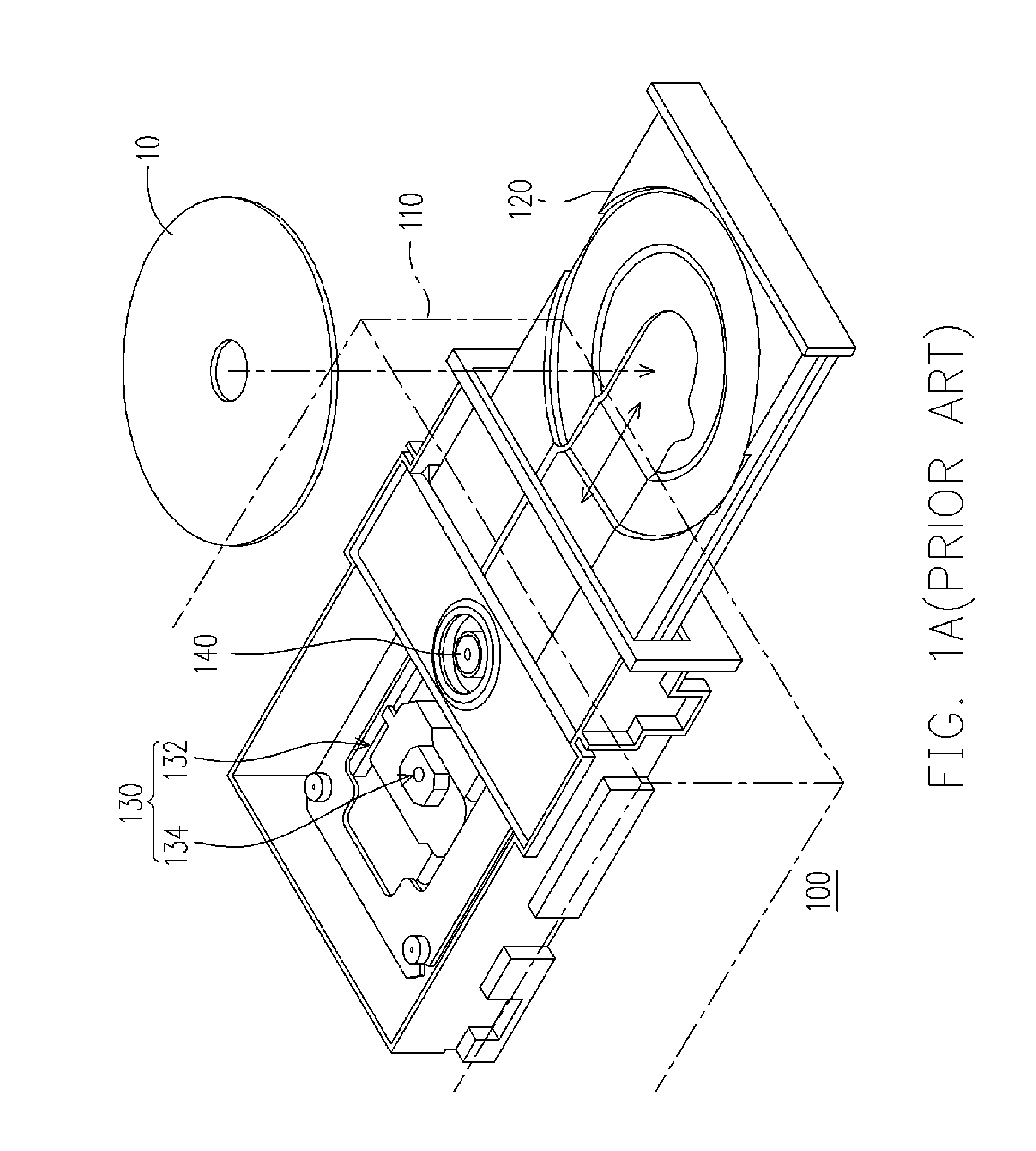

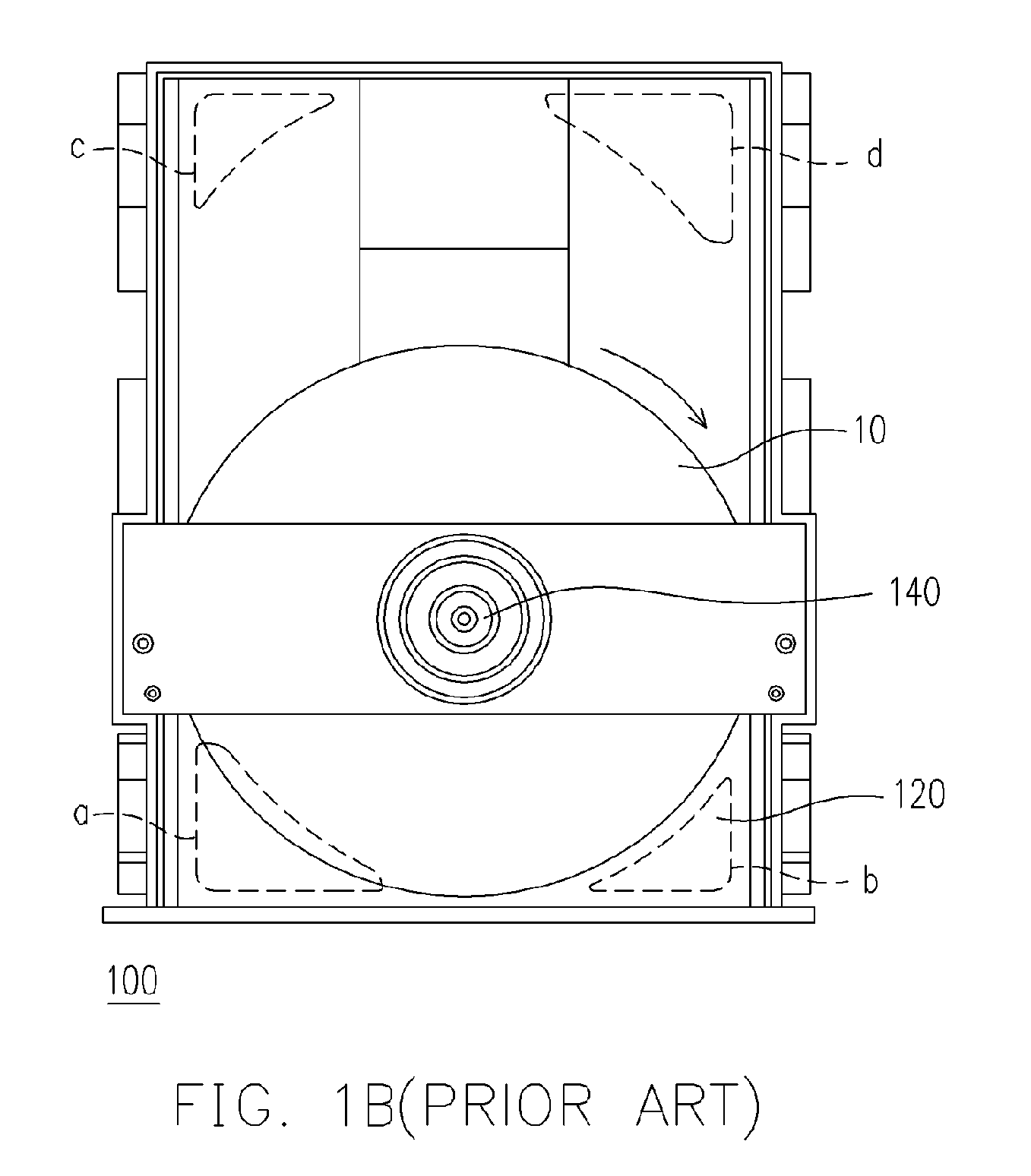

Disk recording/reading apparatus

InactiveUS20070006241A1Reduce noise and vibrationEffectively reducing vibrationReducing temperature influence on carrierUndesired vibrations/sounds insulation/absorptionOptical pickupAirflow

A disk recording / reading apparatus for recording / reading a disk is provided. The disk recording / reading apparatus includes a case, a tray, a turntable and an optical pickup unit. The tray is inside the case and has a concave trough and a concave trough extension portion. The concave trough is used for accommodating a disk, and the concave trough extension portion stretches from the concave trough to a side of the tray front end and has an opening passing through the tray. The turntable is disposed below the tray for driving the disk. Wherein, at least a spinning airflow below the disk is suitable for being expelled from the opening of the concave trough extension portion to reduce the noise caused by air turbulence and the vibration during disk spin.

Owner:LITE ON IT

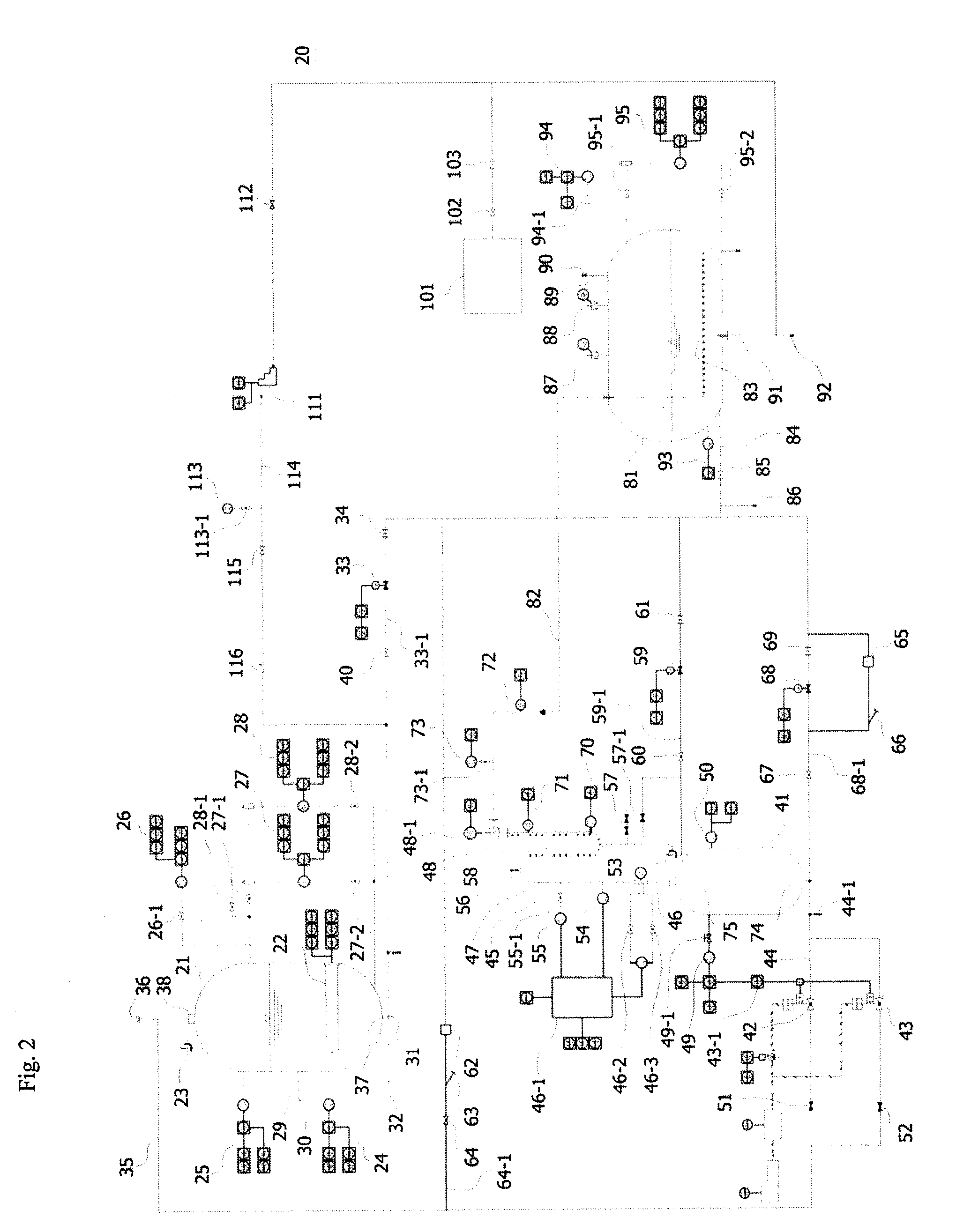

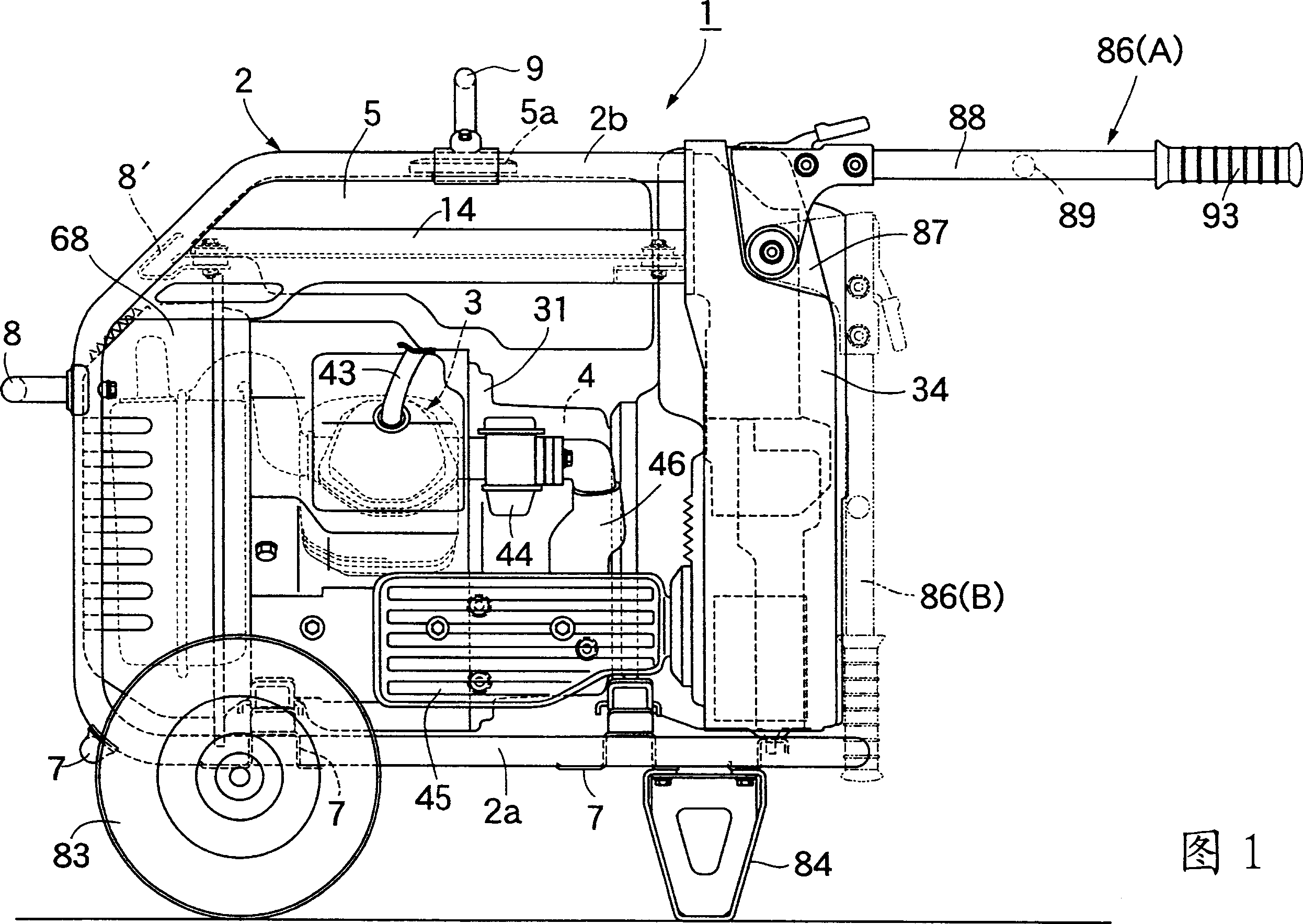

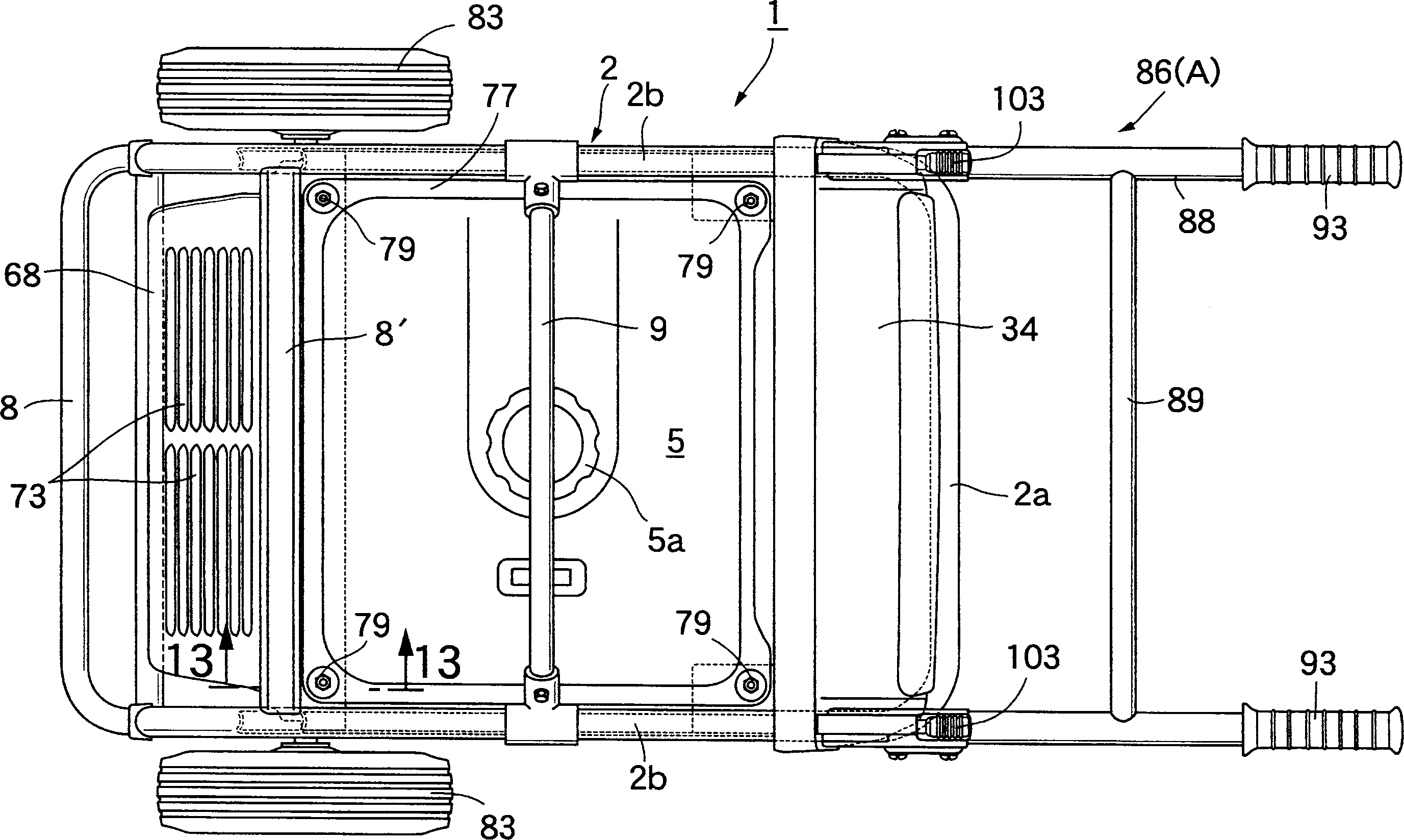

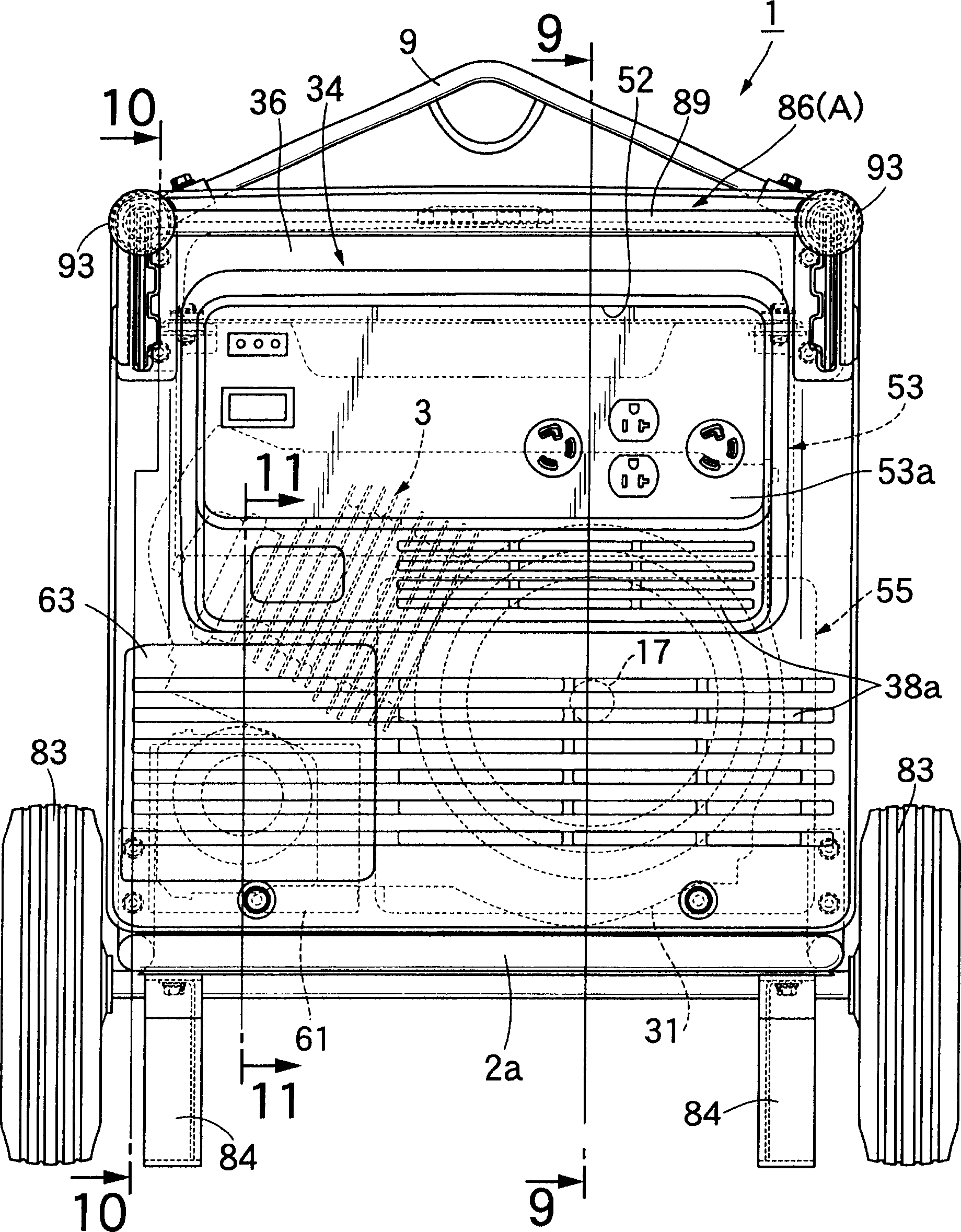

Engine-driven electric generator

InactiveCN1823216ASimple structureReduce weightEngine controllersMachines/enginesEngineeringElectric generator

An engine-driven generator is provided that is formed by supporting on a frame (2) an engine (3) and a generator (4) driven by the engine (3), wherein the frame is formed by integrally connecting via a cross member (7) lower side sections of a pair of left and right side frames (2b, 2b) formed by bending a steel pipe into a U-shape, a control box (34) housing and holding an electrical component (53, 55) is mounted on open end parts of the two side frames (2b, 2b) in order to reinforce the frame (2) by connecting the open end parts to each other, and an assembly of the engine (3) and generator (4) is resiliently supported on the cross member (7). The structure of the frame of the engine-driven generator can thereby be simplified, the frame can be reinforced by the control box that houses and supports the electrical component, and the frame can be made lightweight.

Owner:HONDA MOTOR CO LTD

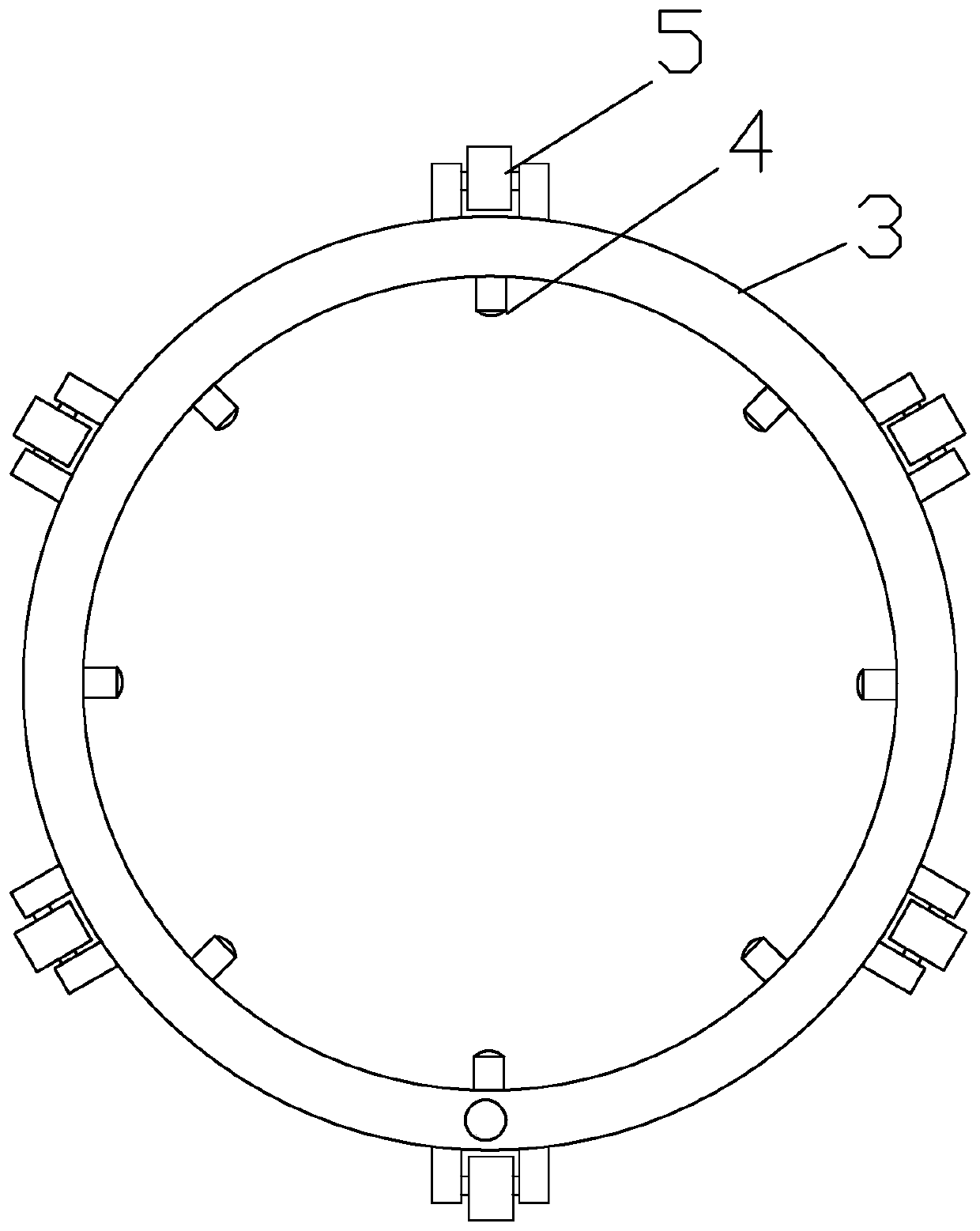

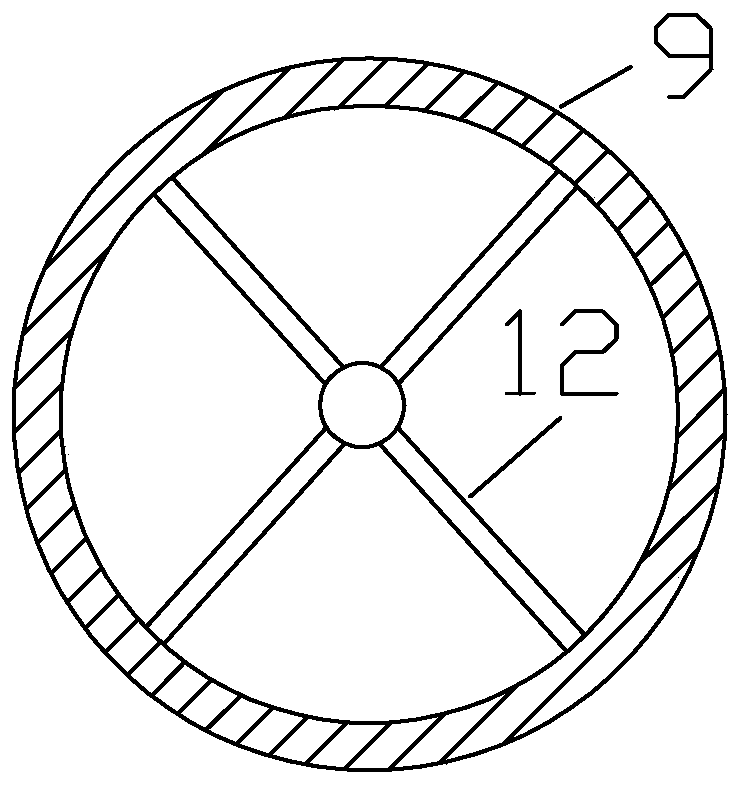

Built-in perforated plate type Helmholtz resonator and low-frequency broadband sound absorbing structure based on Helmholtz resonator

PendingCN109346051APeak unchangedEffective noise reductionSound producing devicesLow frequency vibrationEngineering

The invention belongs to the field of low-frequency vibration and noise reduction and relates to a built-in perforated plate type Helmholtz resonator and a low-frequency broadband sound absorbing structure based on the Helmholtz resonator. Each unit has a sound absorption peak of a specific frequency; and after a plurality of units are coupled in parallel, the structure can have a continuous low-frequency perfect sound absorption broadband. According to the built-in perforated plate type Helmholtz resonator, one or more separation plates are adopted, so that two or more peaks can be provided,and thus the sound absorption band can be further widened; and the built-in perforated plate type Helmholtz resonator can be used in combination with ordinary Helmholtz resonators in a matched manner,so that peak positions can be adjusted more flexibly; the parameters and peak positions of the units are strictly adjusted, so that a 100% continuous sound absorption broadband is almost obtained ina range of 450Hz to 1360Hz when the thickness of the structure is 60mm (1 / 60 wavelength); and therefore, the structure has great advantages and engineering application potentials compared with currentmature structures.

Owner:XI AN JIAOTONG UNIV

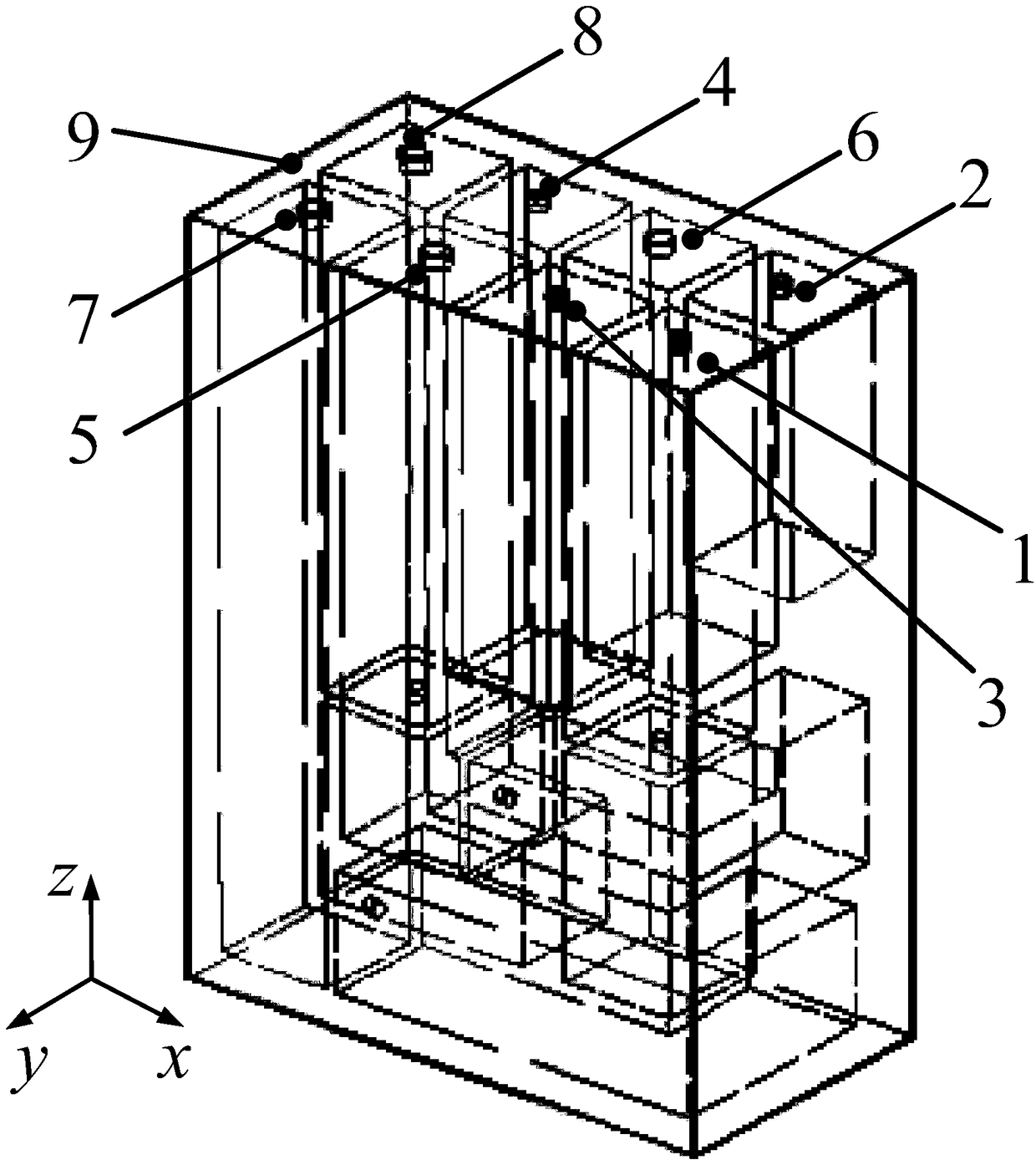

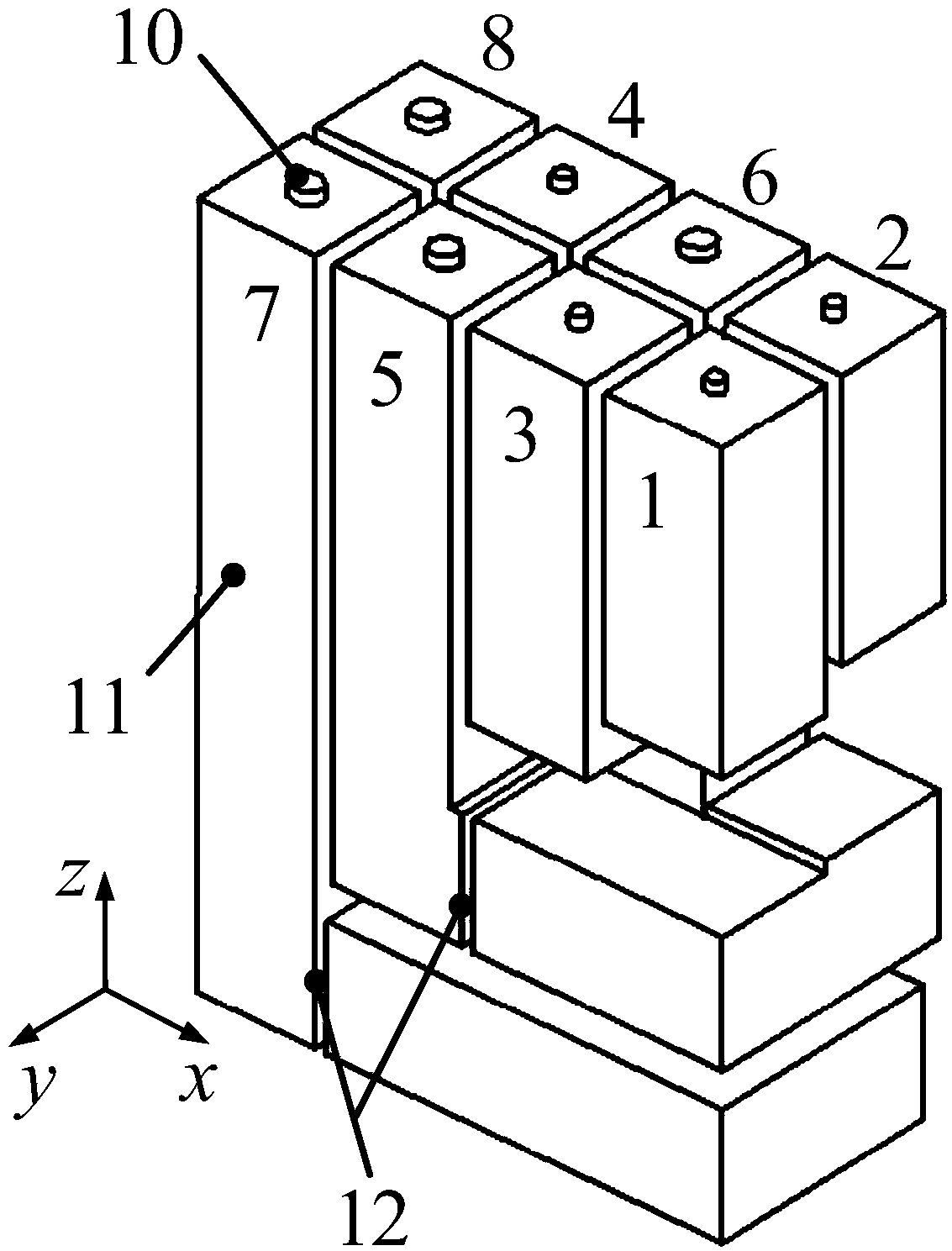

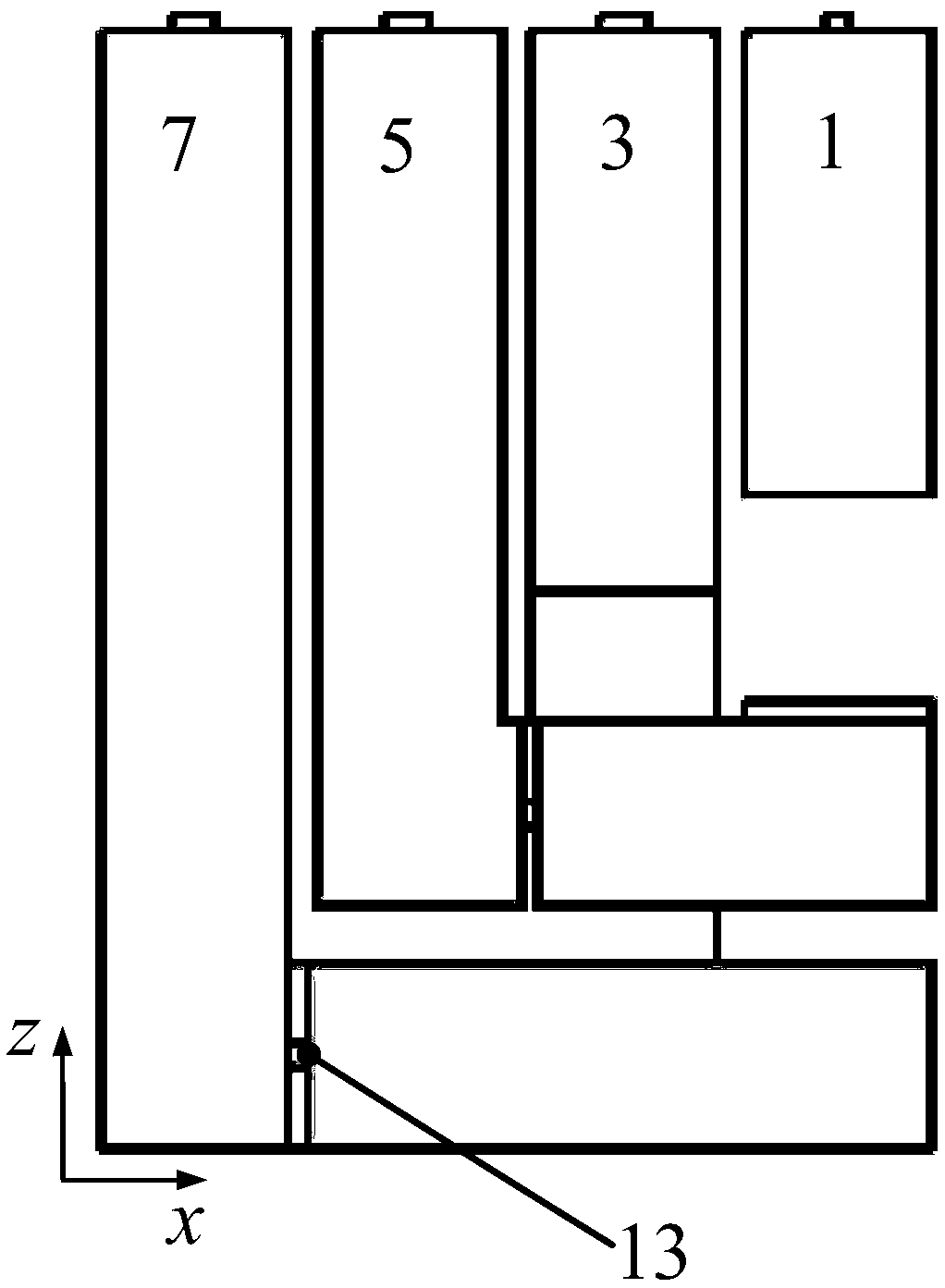

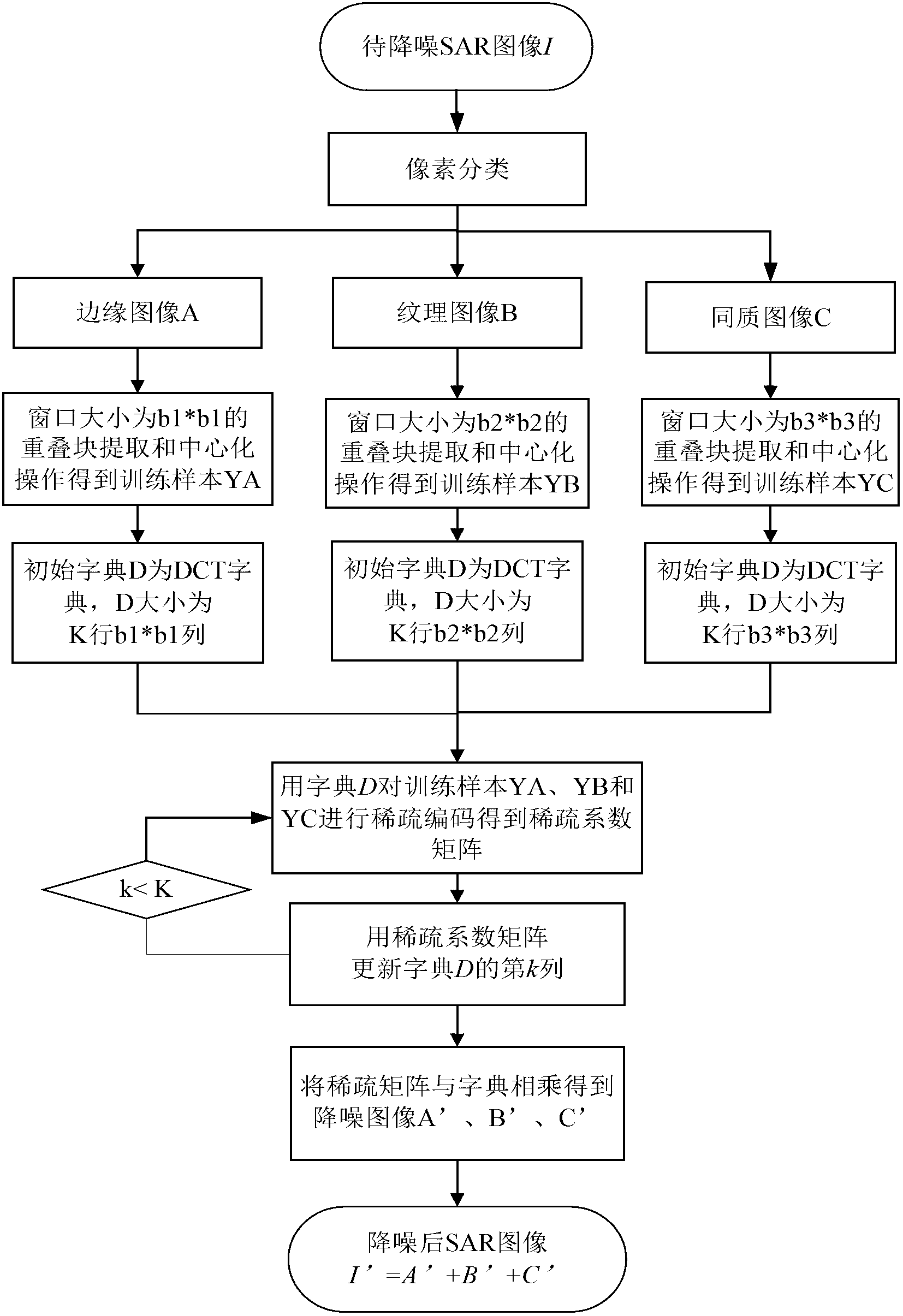

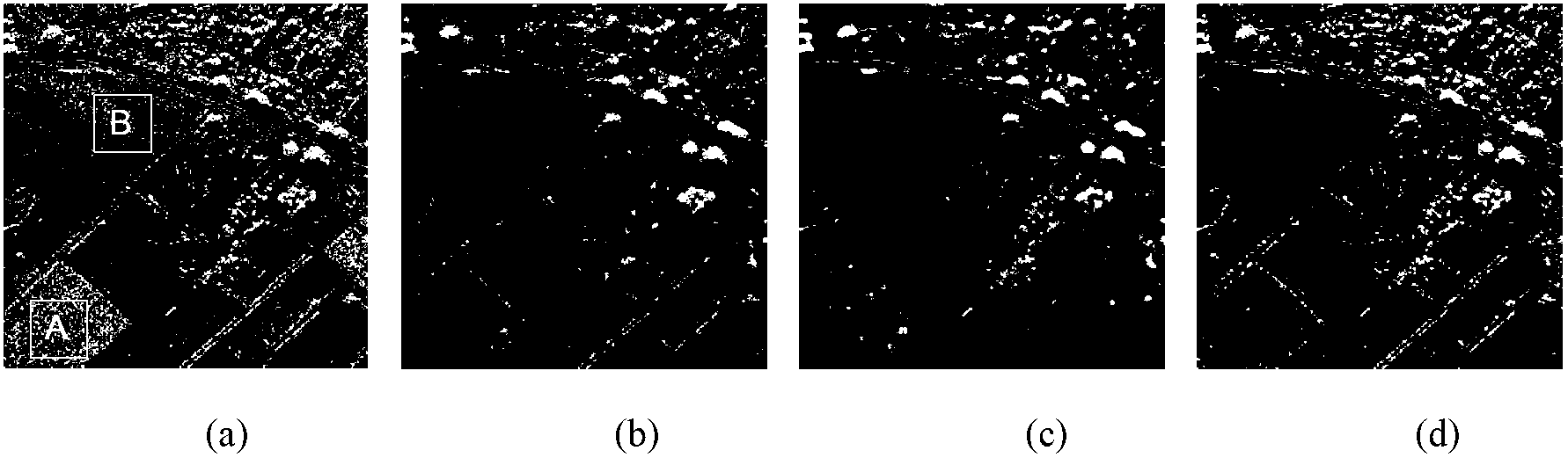

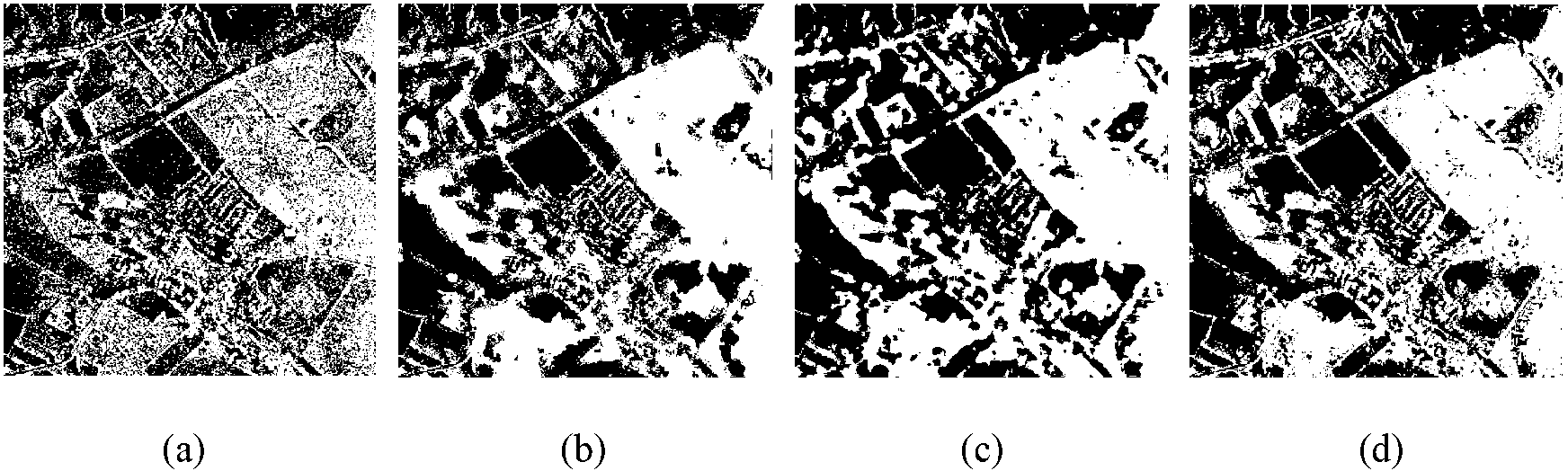

Beta algorithm-based multiscale SAR (Synthetic Aperture Radar) image denoising method

ActiveCN103077507AEasy to keepIntegrity guaranteedImage enhancementDictionary learningImage denoising

The invention discloses a Beta algorithm-based multiscale SAR (Synthetic Aperture Radar) image denoising method, mainly solving the problem that the conventional dictionary learning method is not applicable to SAR image denoising. The Beta algorithm-based multiscale SAR image denoising method comprises the steps of: carrying out pixel classifying on a to-be-denoised SAR image to obtain an edge image A, a texture image B and a homogenous image C; carrying out overlap block extraction and centralization on the images to obtain respective training sample sets; initializing a dictionary into a DCT (Discrete Cosine Transform) dictionary; carrying out sparse coding by using the dictionary to obtain a sparse coefficient matrix; updating kth line of the dictionary by using the sparse coefficient matrix; and repeating the sparse coding step and the dictionary updating step for K times to obtain a final dictionary and a final sparse coefficient matrix, and multiplying to obtain a denoised edge image A', a denoised texture image B' and a denoised homogenous image C', and further obtaining a denoised SAR image of I'=A'+B'+C'. The Beta algorithm-based multiscale SAR image denoising method has the advantages that the noise in the SAR image is effectively removed and texture and edge information of the image can be remained, and the method can be used in SAR image target recognition.

Owner:XIDIAN UNIV

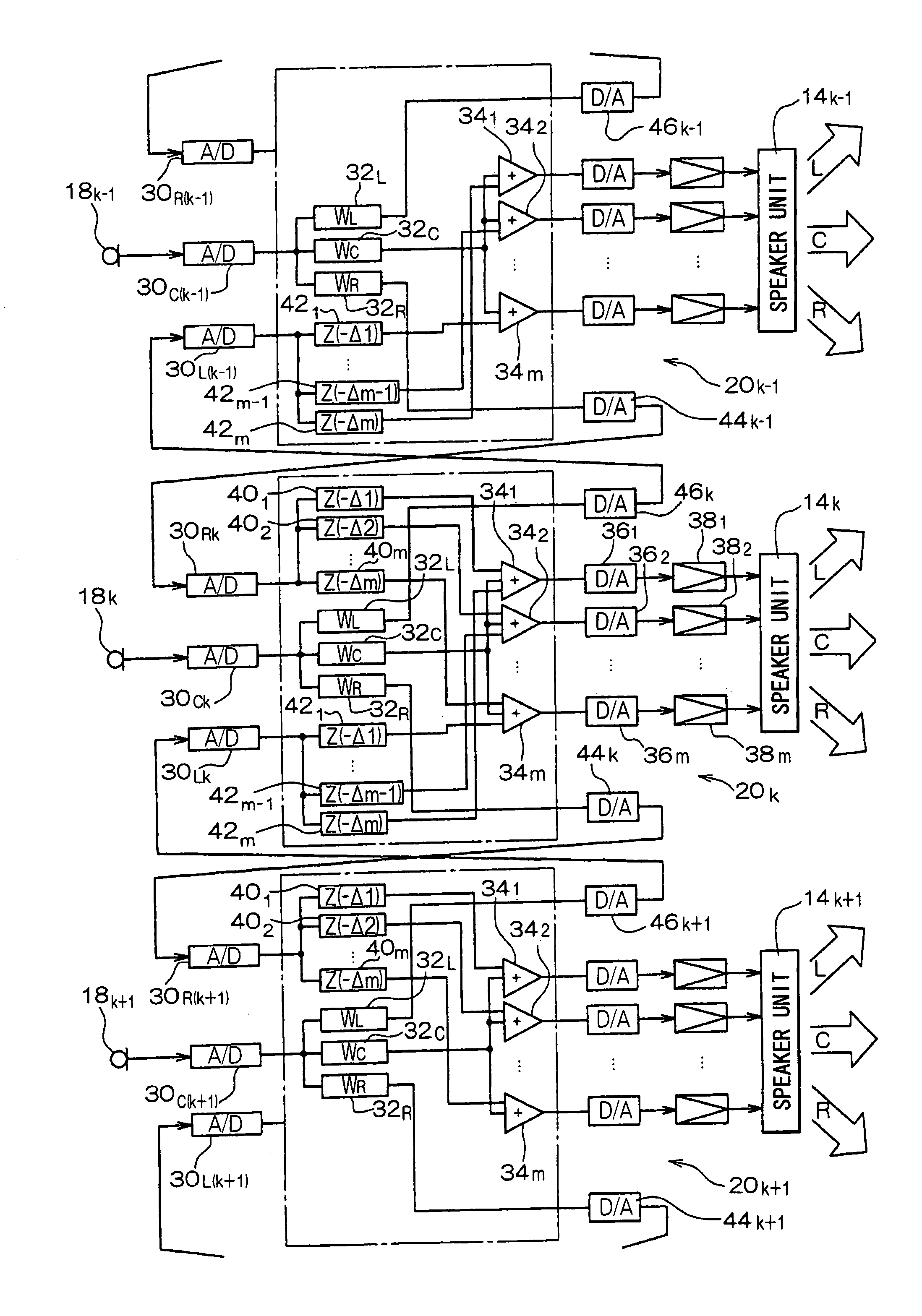

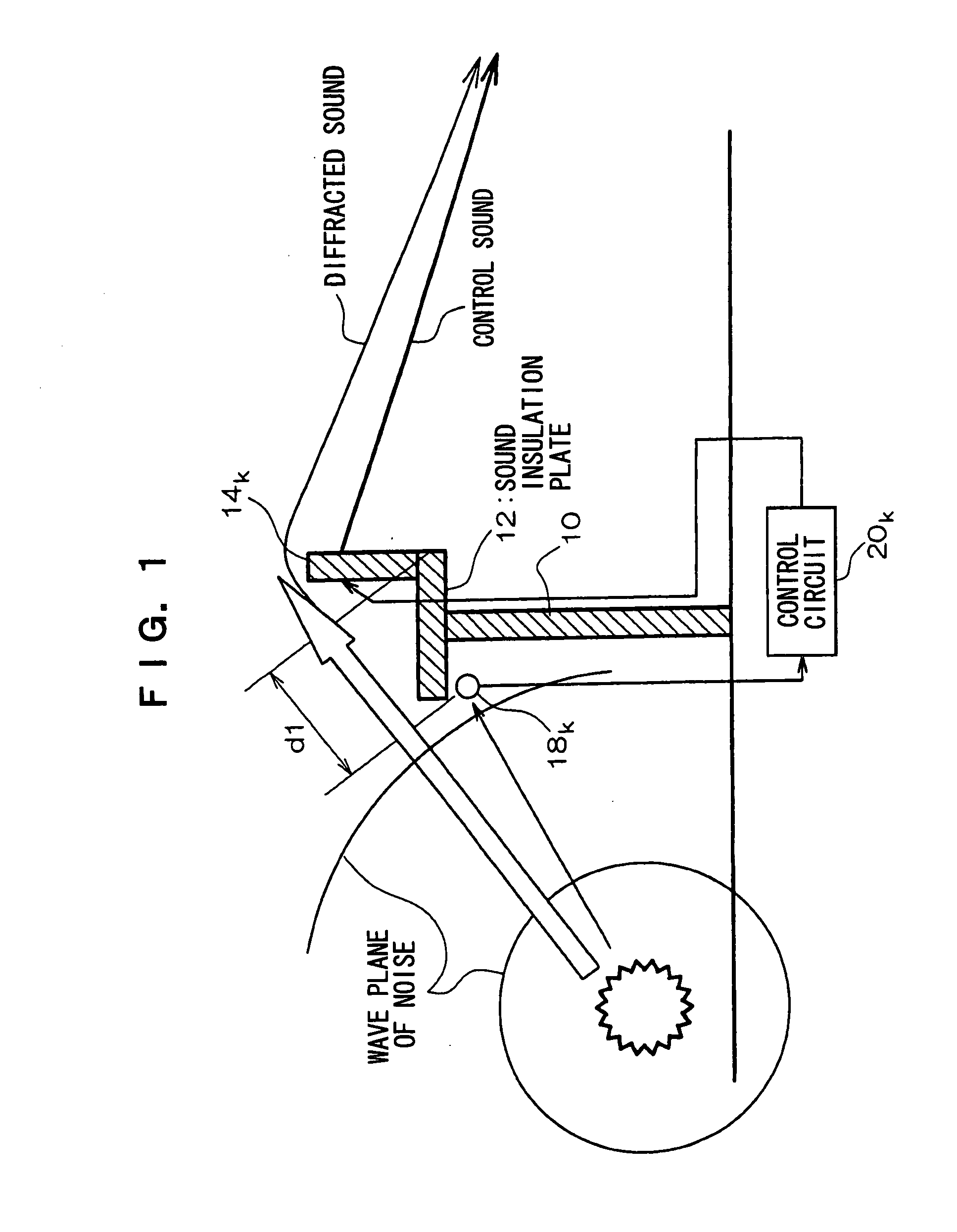

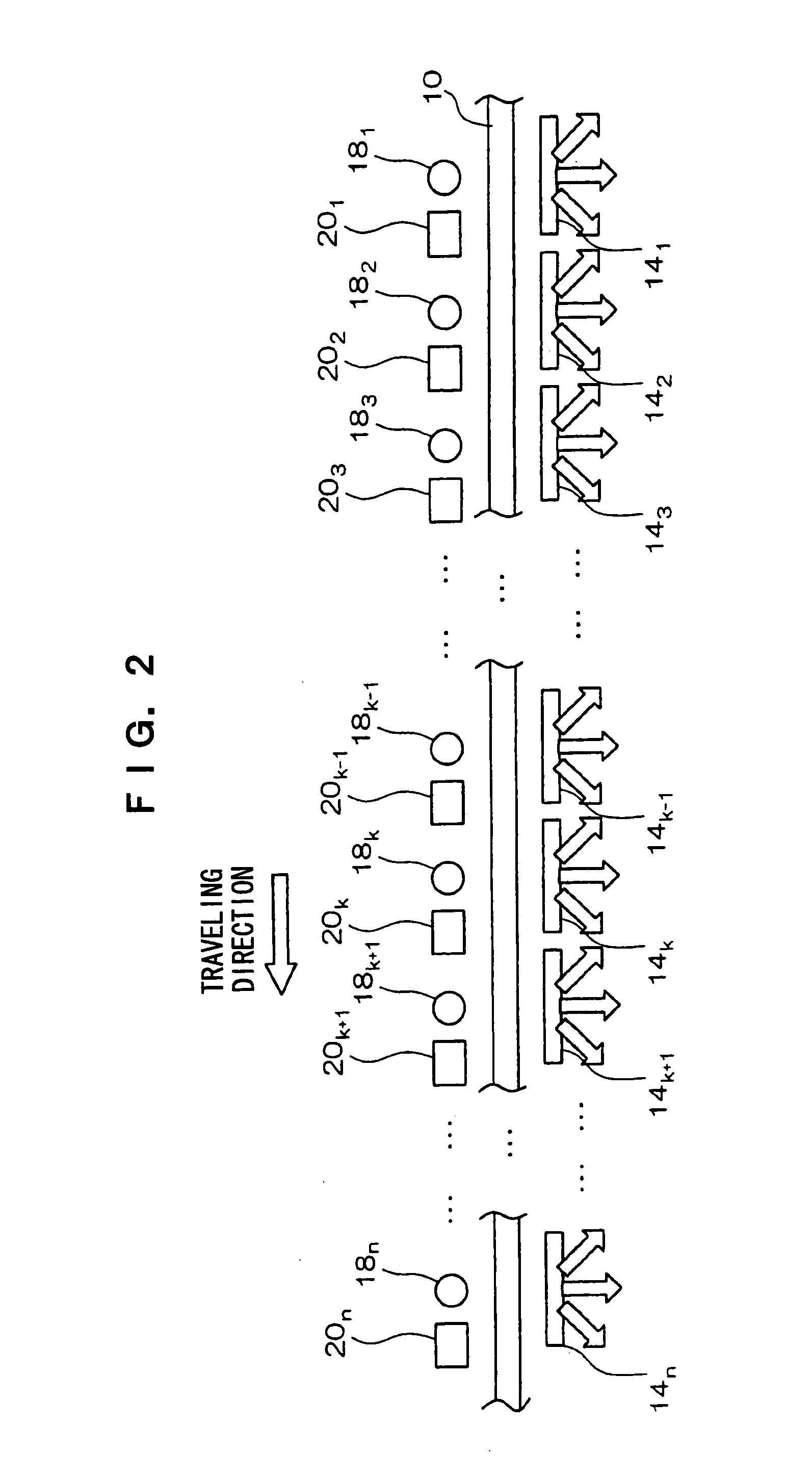

Noise reduction apparatus

InactiveUS20090041258A1Effective noise reductionReduce noiseEar treatmentNoise generationEngineeringNoise reduction

Effective reduction is made of direct sound or diffracted sound of a noise propagating from plural directions. Three microphones (18k−1, 18k, 18k+1) are disposed and: noise is detected by each of the microphones; delay signals are generated by delaying plural times a signal that has been output from 2 of the microphones (18k−1, 18k+1); the output signal from the remaining microphone (18k) is added to 2 of the delayed signals and input to respective speakers of a speaker unit; a control sound is output from the speaker unit in 3 directions (L, C, R); and reduction is made of direct sound or diffracted sound of a noise propagating from each of the directions.

Owner:TAKENAKA KOMUTEN CO LTD

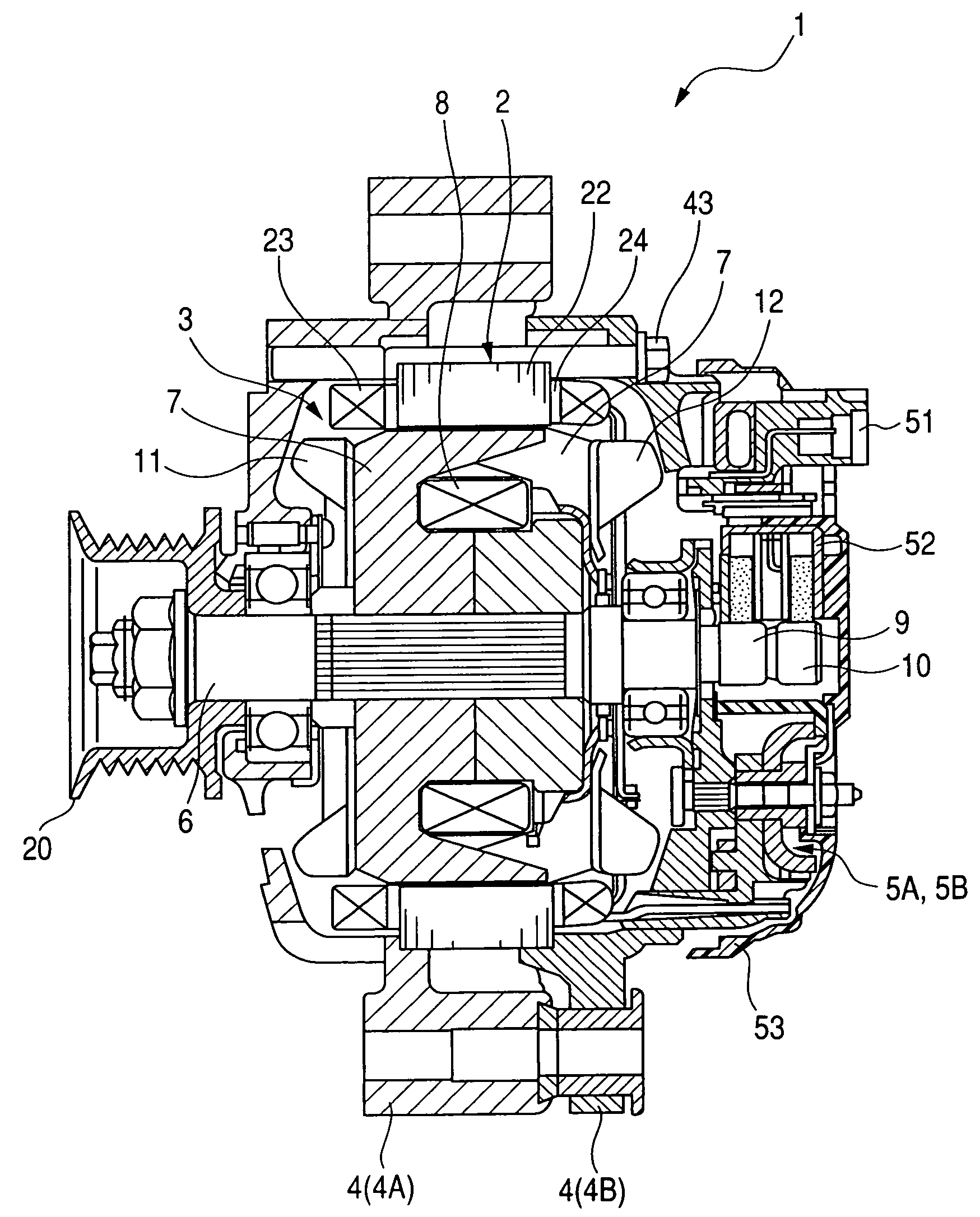

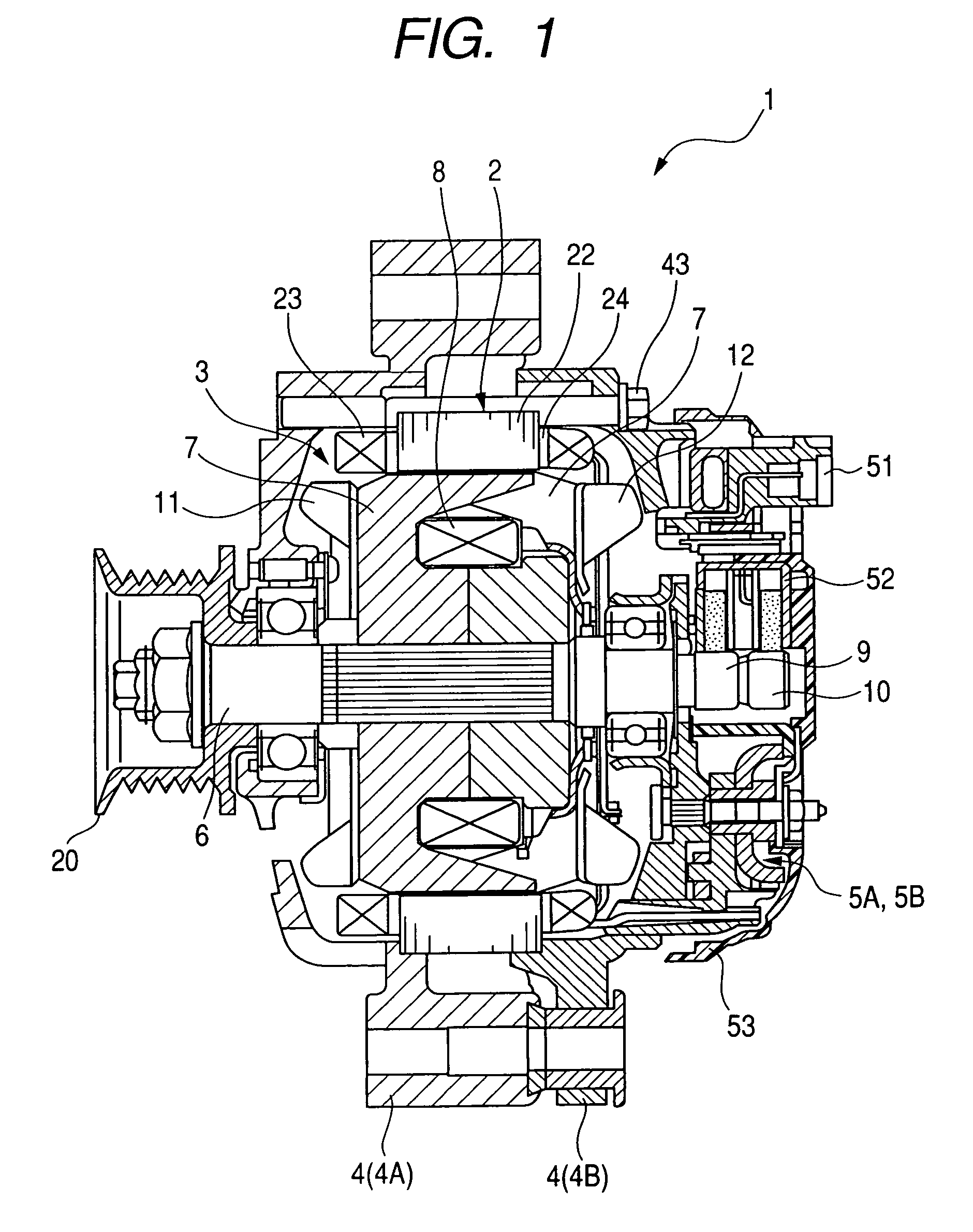

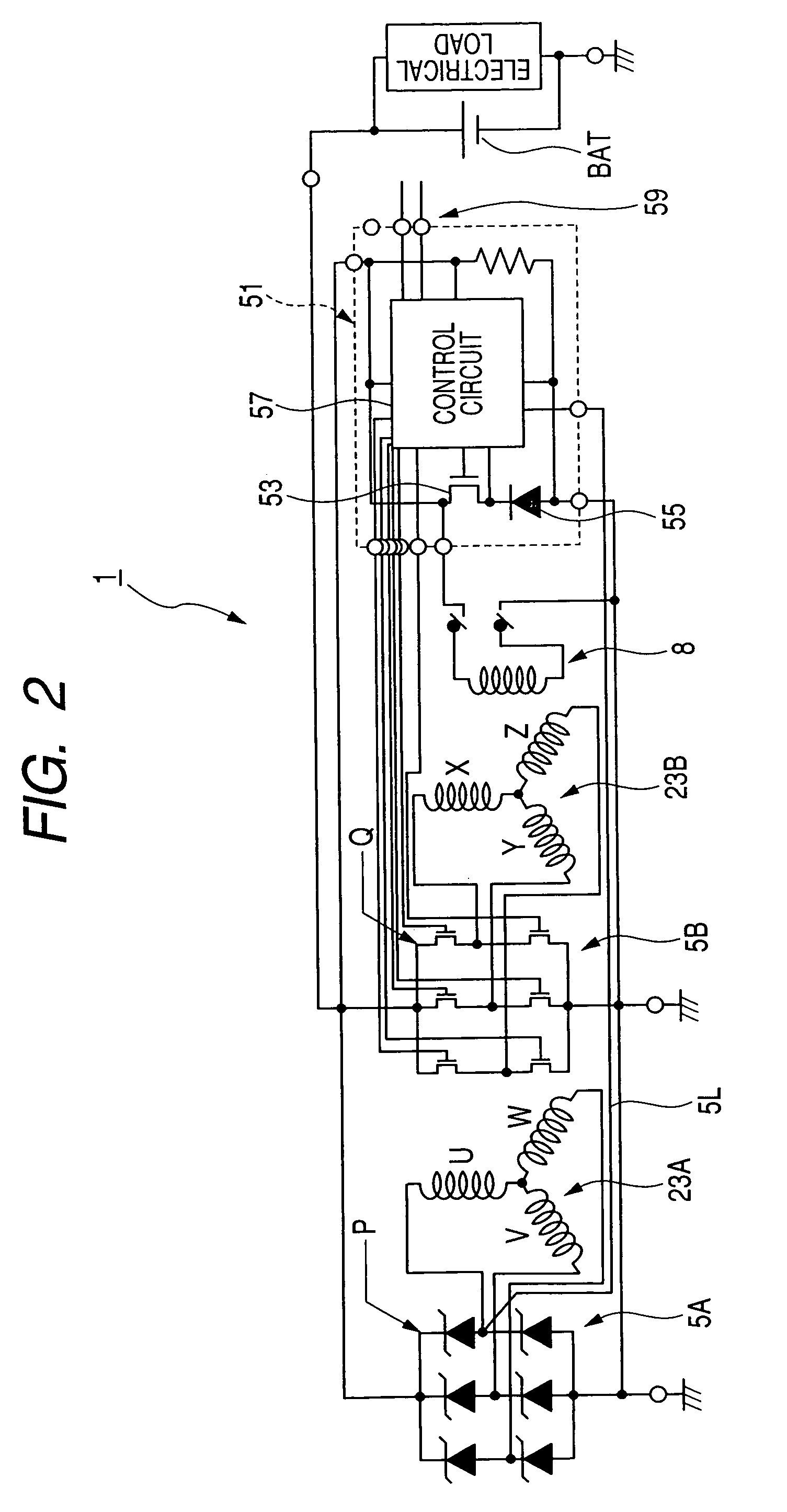

Vehicle-mounted alternator

InactiveUS7541685B2Effective noise reductionMagnetic circuitEmergency protective circuit arrangementsAlternatorPhase angle difference

The stator of the vehicle-mounted alternator includes a stator core formed with a plurality of slots located along a circumferential direction thereof, and first and second multi-phase windings wound in the slots, the first and second multi-phase windings being spaced from each other by a predetermined electrical angle. An output of the first multi-phase winding is rectified by a first rectifier device, and an output of the second multi-phase winding is rectified by a second rectifier device. The second rectifier device is constituted by a plurality of switching devices. The vehicle-mounted alternator includes a control device to perform on / off control on the switching devices such that a phase angle difference between an output of the first rectifier device and an output of the second rectifier device is varied depending on a rotation speed of the stator.

Owner:DENSO CORP

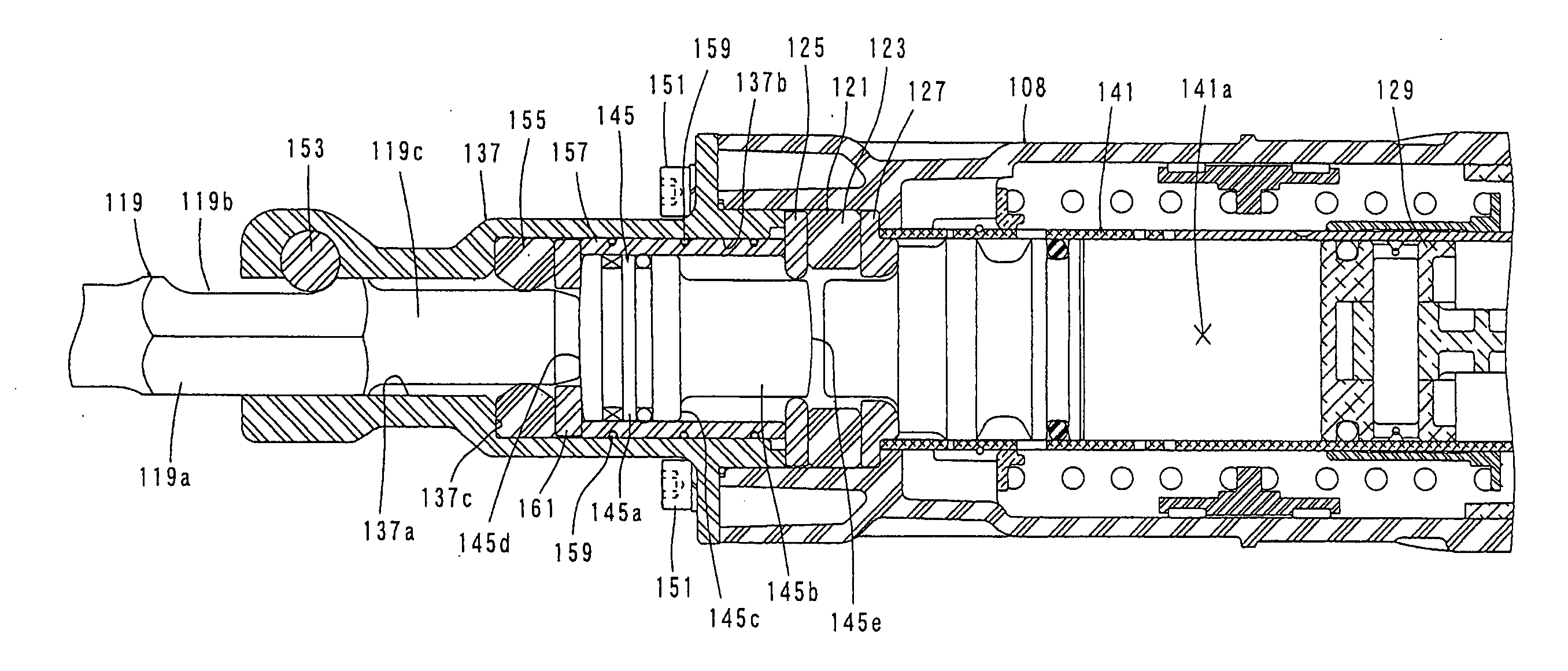

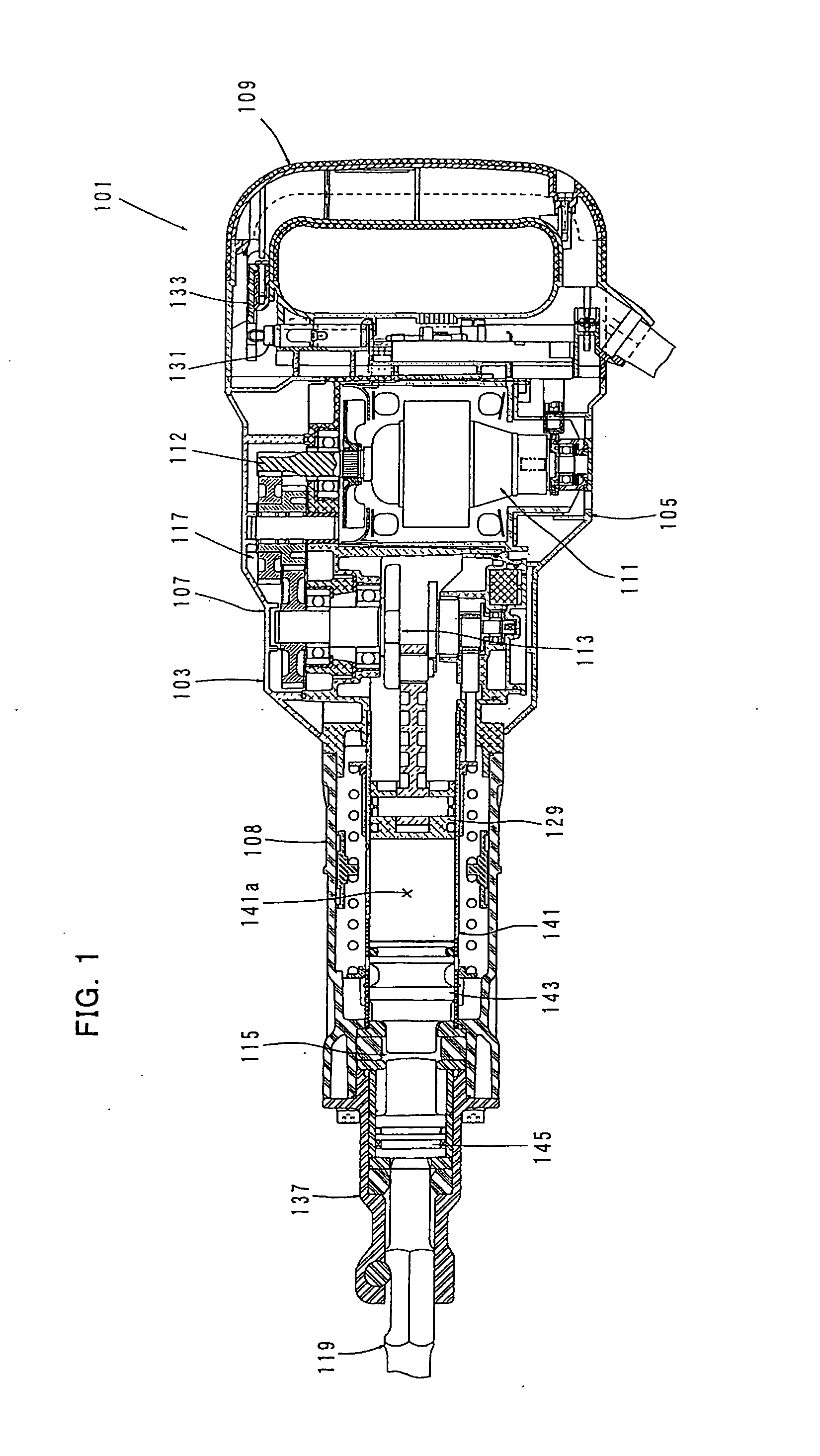

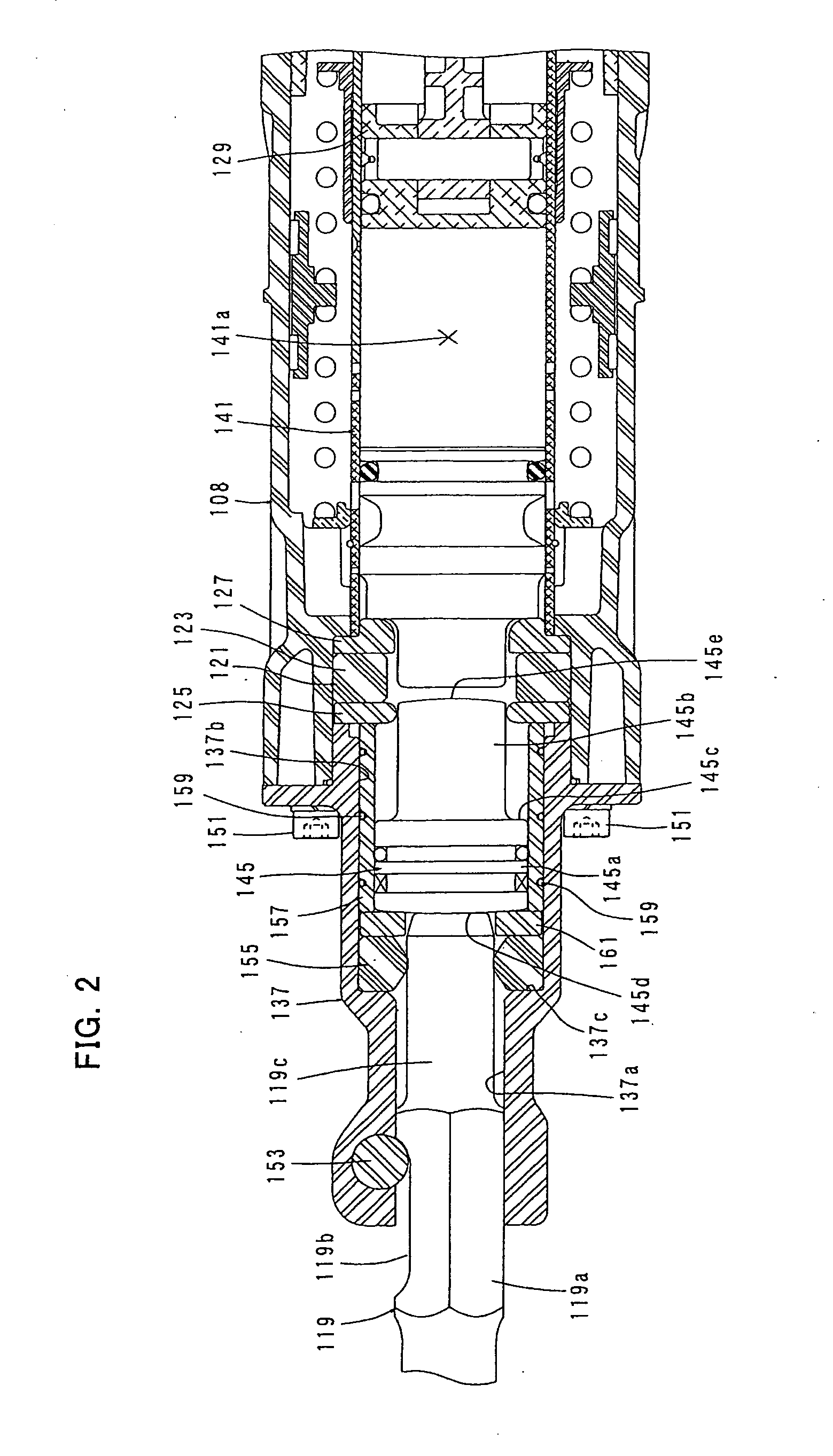

Impact tool

ActiveUS20100155094A1Effective noise reductionReduce noiseReciprocating drilling machinesConstructionsEngineeringPoint contact

It is an object of the invention to reduce noise caused by run-out of a tool bit in an impact tool. The representative impact tool according to the invention includes a tool holder 137 that houses a tool bit 119 in such a manner that the tool bit can linearly move in its axial direction, and a barrel 108 that is integrally connected to the tool holder 137 The impact tool further includes an elastic element 155 that is disposed between an inner circumferential surface of the tool holder 137 and an outer circumferential surface of the tool bit 119 in an end region of the tool bit 119 on the barrel side and connected in close contact with the tool holder 137 and the tool bit 119 over a predetermined length of the tool bit 119 in the axial direction. The elastic element 155 applies a biasing force to prevent a run-out of the tool bit 119 in a direction transverse to the axial direction. Further, an intermediate element 145 comes in point contact with the tool bit 119 on its axial center line.

Owner:MAKITA CORP

PVD vacuum coating process and coating workpiece

ActiveCN110616411AUniform coatingReduce wear and tearVacuum evaporation coatingSputtering coatingMetallurgyMegasonic cleaning

The invention discloses a PVD vacuum coating process. The PVD vacuum coating process comprises the following steps that 1, the surface of a base material is treated, specifically, the surface of the base material is wiped and washed, and degreasing and dedusting treatments are conducted; and the cleanness and dryness of the base material are ensured; 2, prime coating and drying of the base material are conducted, specifically, the surface of the base material is coated with coating oil, then drying is conducted, the drying temperature is 60-70 DEG C, and the drying time is 2 hours; 3, coatingis conducted, specifically, the base material in the step 2 is placed in a vacuum coating furnace, a vacuumizing device vacuumizes the vacuum coating furnace, and after the vacuum degree reaches the requirements, the vacuum coating furnace starts coating; 4, cleaning is conducted, specifically, the coated workpiece is put into an ultrasonic cleaning device for cleaning; and 5, drying is conducted,specifically, the cleaned workpiece is dried, and packaging is conducted.

Owner:海盐鑫中岳电子科技有限公司

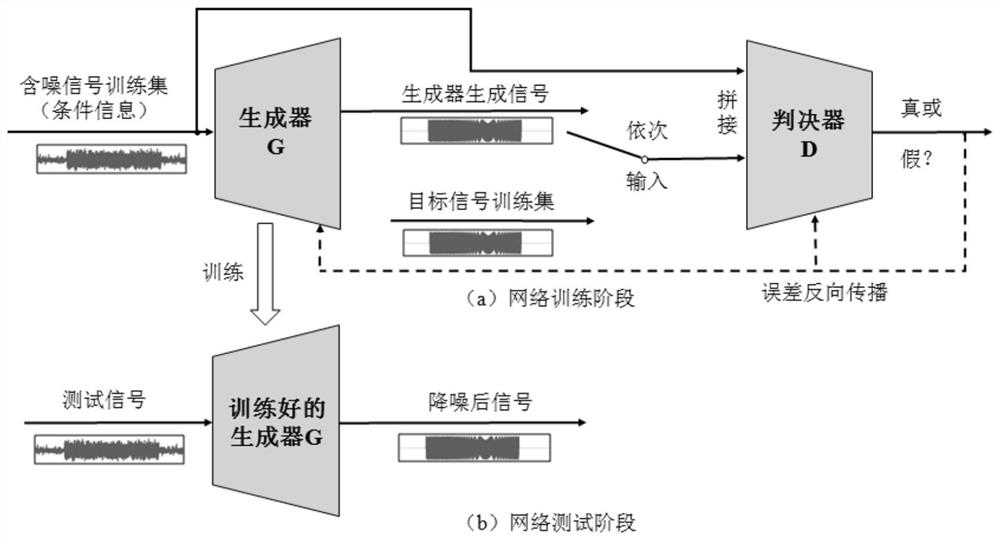

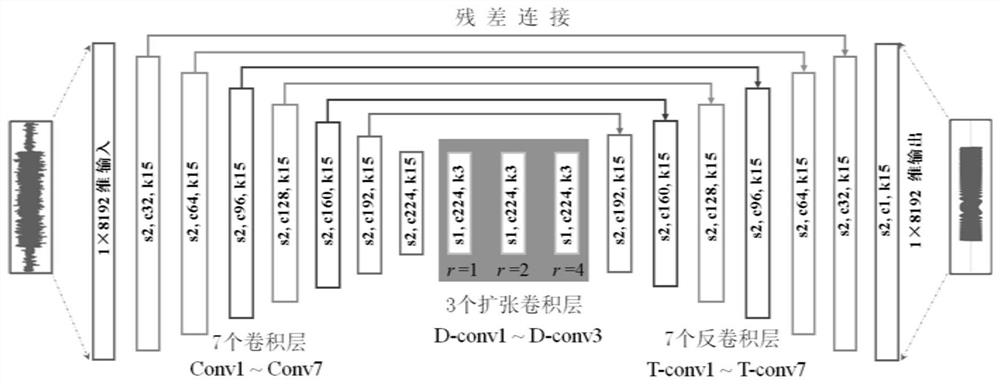

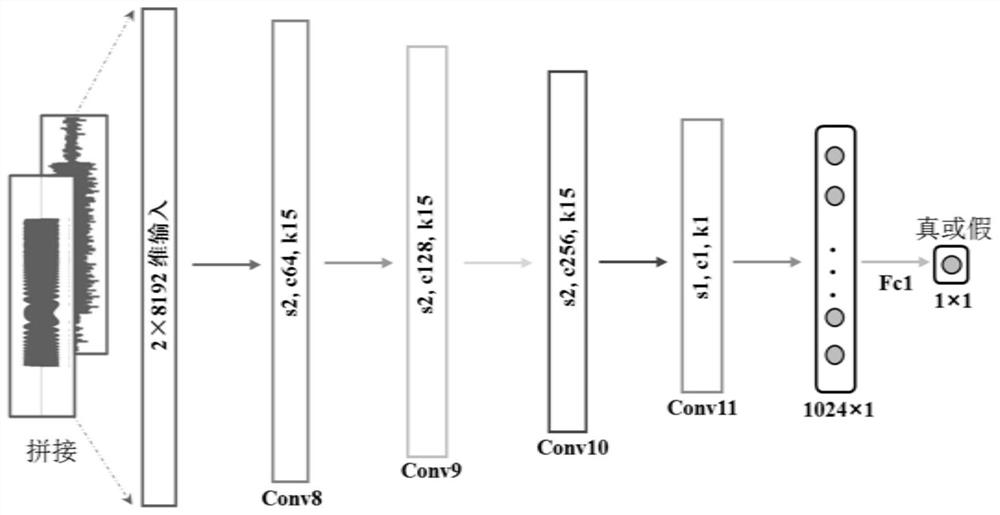

Underwater acoustic signal noise reduction method based on generative adversarial network

PendingCN112466320AImprove noise reductionEffective noise reductionSpeech analysisNeural architecturesPattern recognitionAlgorithm

The invention provides an underwater acoustic signal noise reduction method based on a generative adversarial network. The method comprises a training stage and a testing stage. The training stage comprises the following steps: inputting a noisy signal training set into a generator to obtain a generator generation signal; splicing the generator generation signal and a target signal without noise with a noisy signal respectively, and then inputting the signals into a decision device in sequence; allowing the decision device to take the noisy signal as condition information and performs true andfalse discrimination on another input signal which is input at the same time; and calculating an error between a judgment result and a real label, then updating and optimizing network parameters of the generative adversarial network by utilizing a back propagation algorithm, and obtaining a trained generator model; the testing stage comprises the following steps: inputting a to-be-tested underwater acoustic signal into the trained generator model, and taking the output of the trained generator model as a denoised underwater acoustic signal. The method is suitable for various types of signals,and has a good noise reduction effect on common underwater acoustic communication signals such as MFSK, MPSK, OFDM, LFM and DSSS.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com