Built-in perforated plate type Helmholtz resonator and low-frequency broadband sound absorbing structure based on Helmholtz resonator

A resonator and perforated plate technology, applied in the field of low-frequency broadband sound-absorbing structures to achieve effective noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

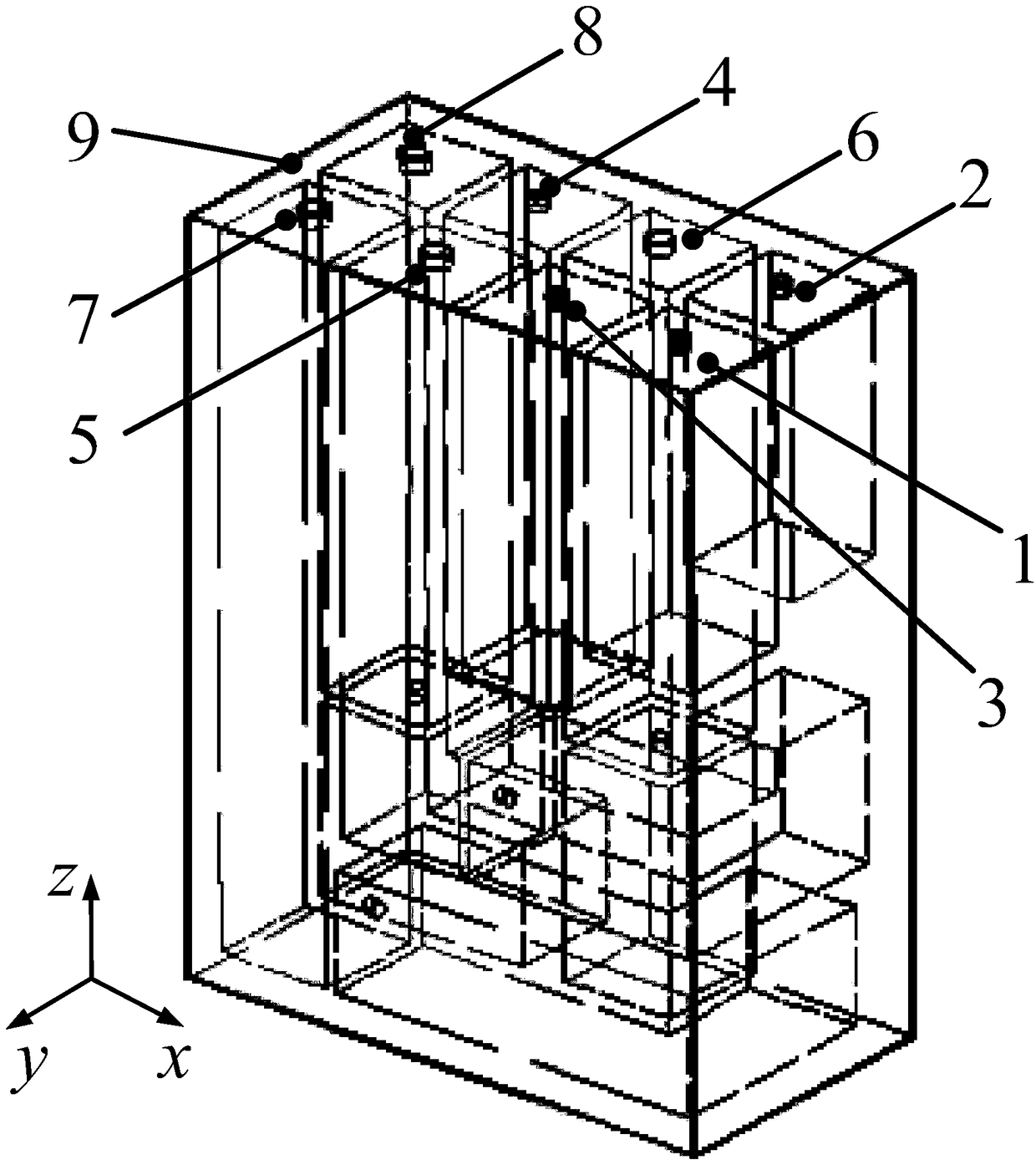

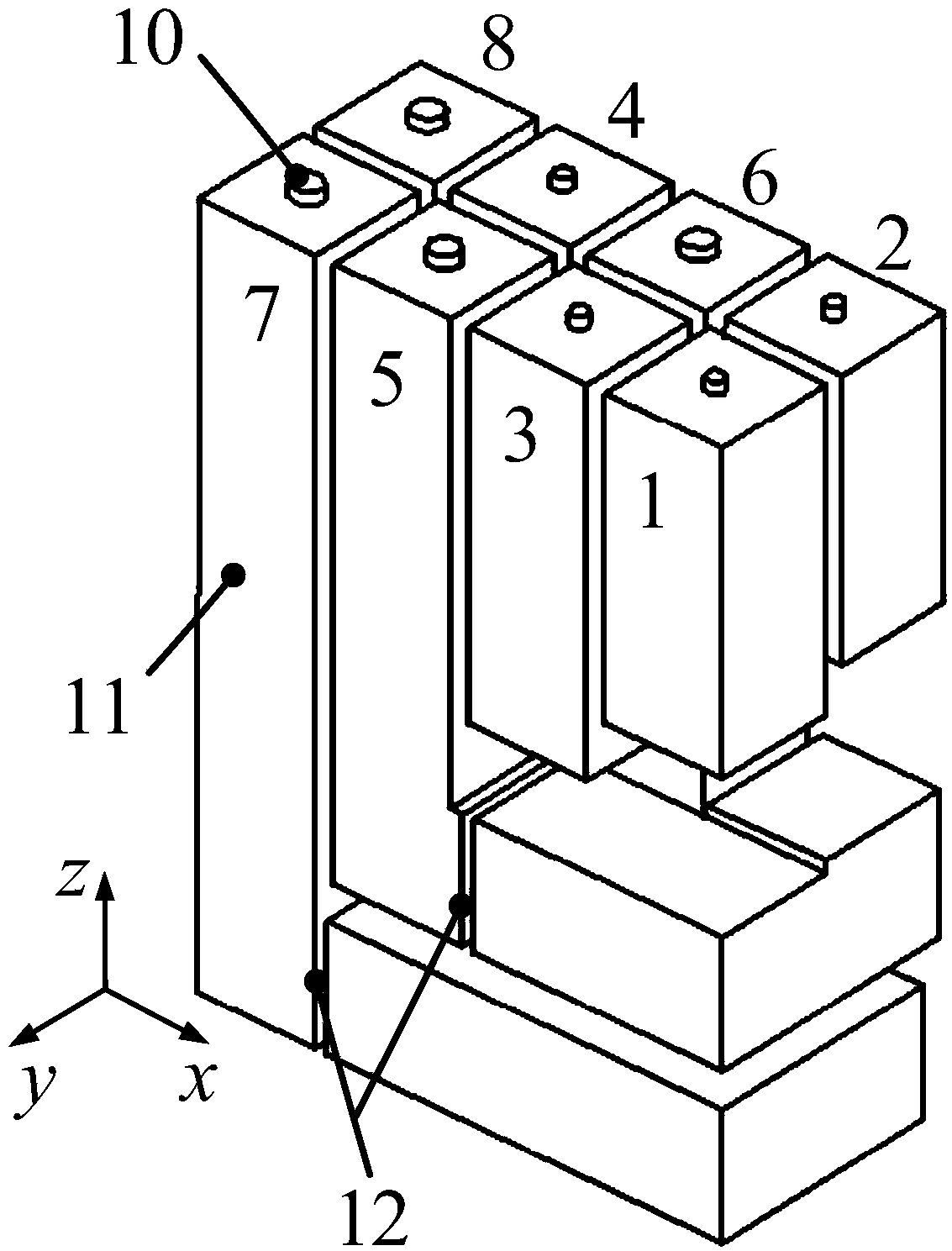

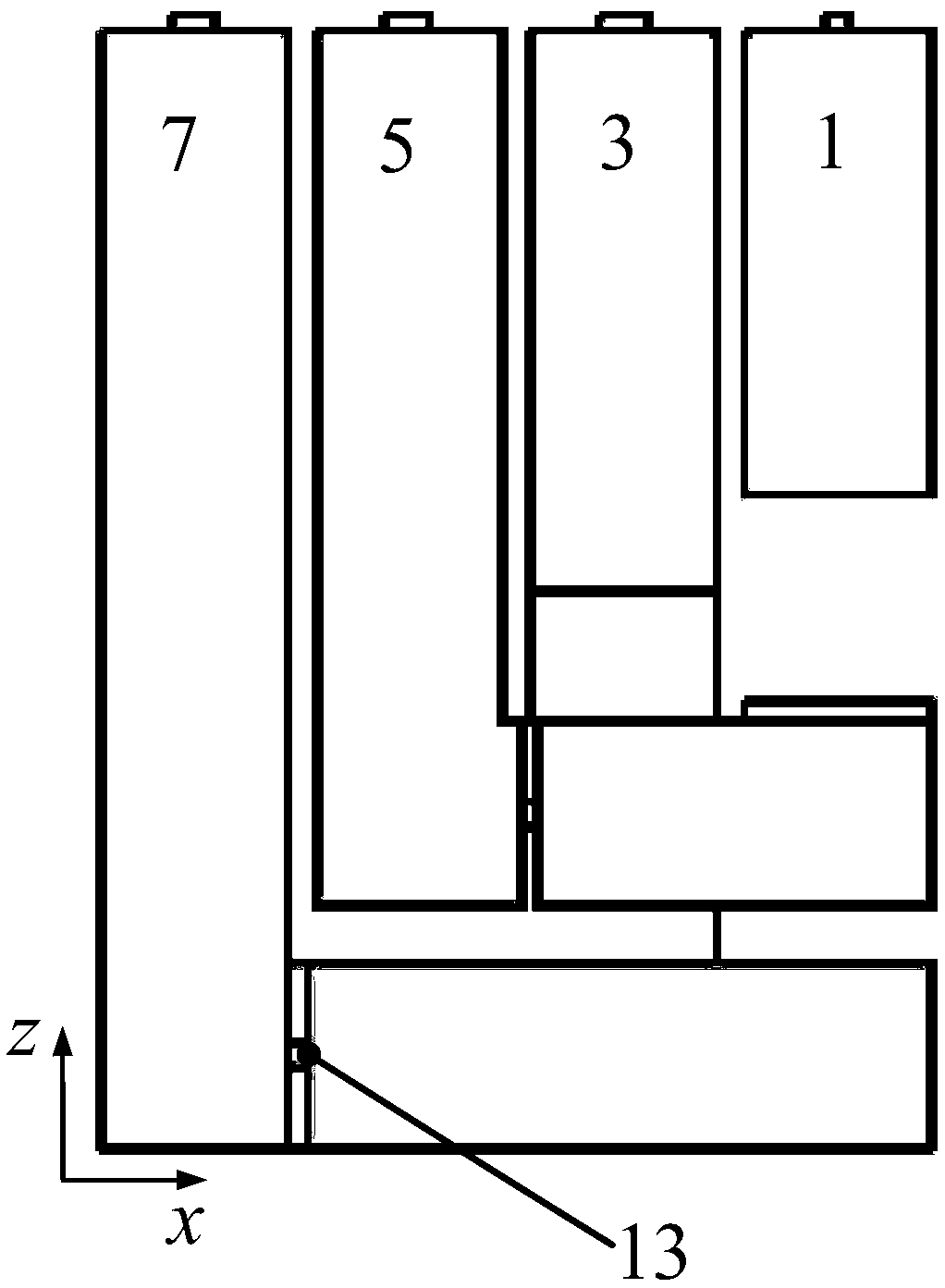

[0032] Such as Figure 1 ~ Figure 4 As shown, in the low-frequency broadband sound-absorbing structure based on the built-in perforated plate Helmholtz resonator in this embodiment, eight cavity resonators are arranged in the frame 9, and four of the eight cavity resonators are Helmholtz resonators. Helmholtz resonators, and the rest are built-in perforated plate Helmholtz resonators; the four Helmholtz resonators are respectively denoted as the first Helmholtz resonator 1, the second Helmholtz resonator 2, and the third Helmholtz resonator. Helmholtz resonator 3 and fourth Helmholtz resonator 4; first Helmholtz resonator 1, second Helmholtz resonator 2, third Helmholtz resonator 3 and fourth Helmholtz resonator The diameters of the small holes 10 on the surface of the Holtz resonator 4 are 1.5mm, 1.4mm, 1.4mm and 1.4mm respectively, and the thicknesses are 41mm, 30mm, 25mm and 21mm respectively; the four built-in perforated plate Helmholtz resonators are all A partition 12 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com