Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

287 results about "Heated glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heated glass is a resistance heater created when a transparent, electrically conductive coating is applied to float glass and then subjected to an electric current. The electric current in the coating creates heat energy, which warms the glass until the glass radiates heat.

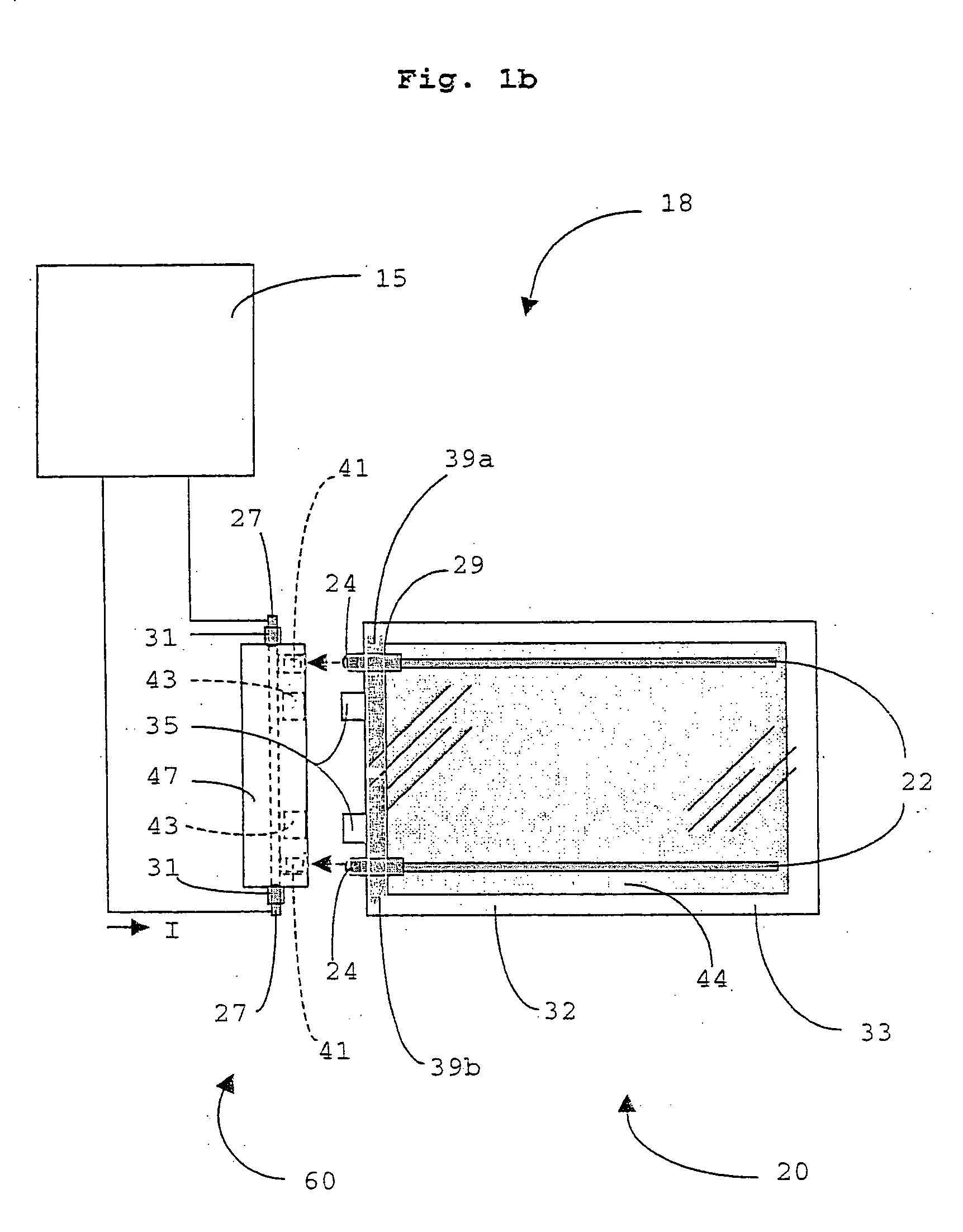

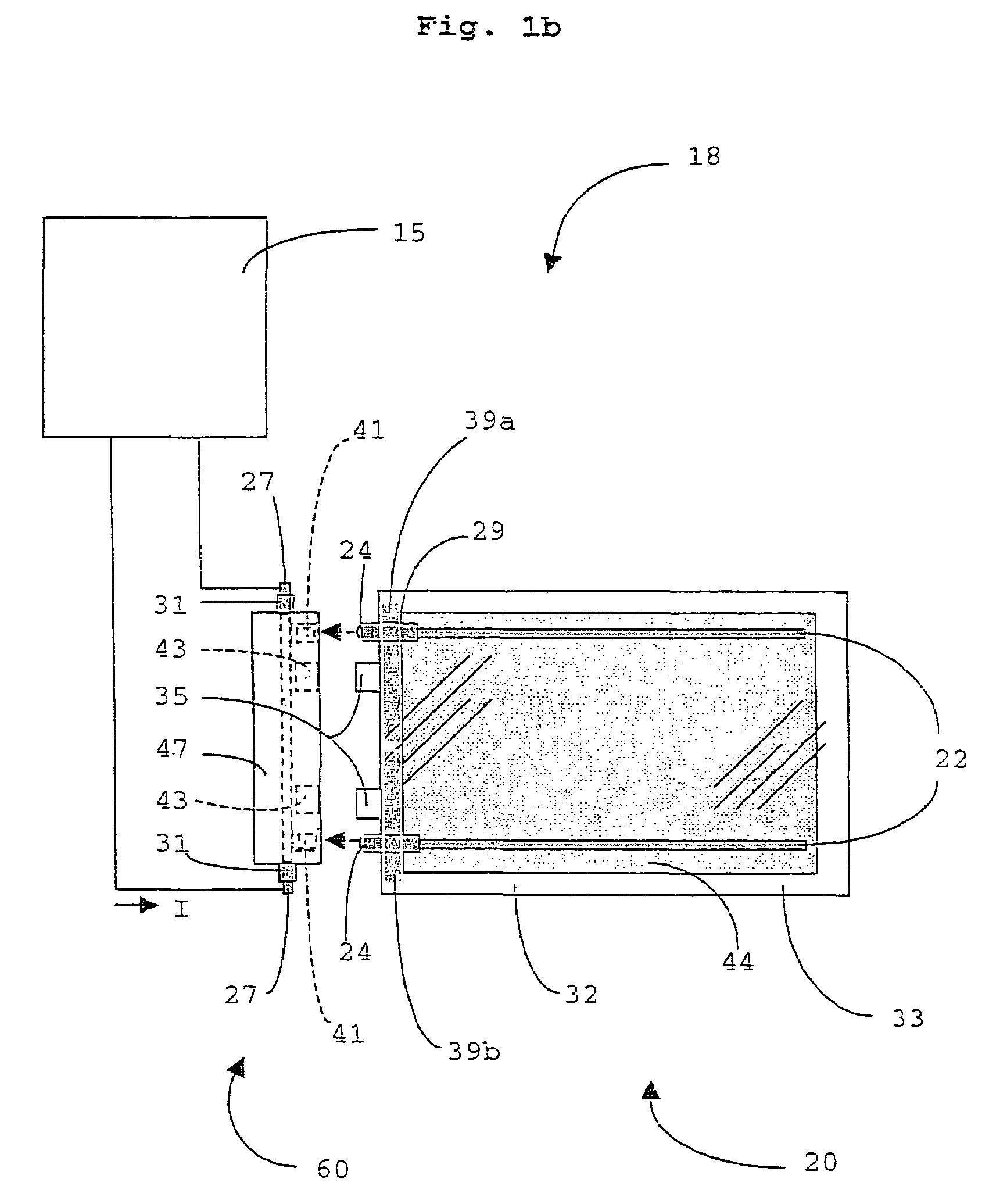

Heated glass panels and methods for making electrical contact with electro-conductive films

InactiveUS7362491B2Lighting and heating apparatusSemiconductor/solid-state device detailsElectrical conductorEngineering

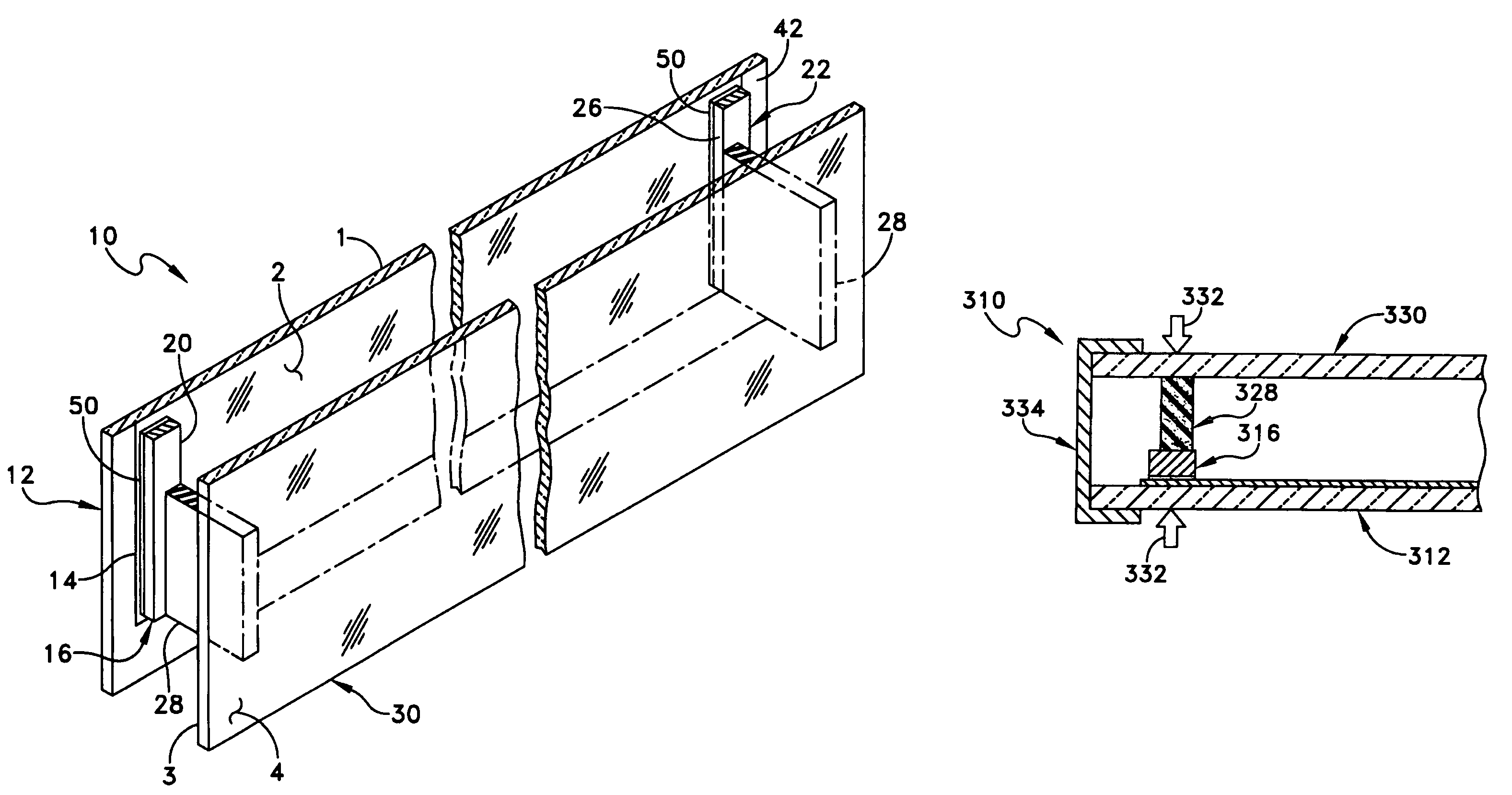

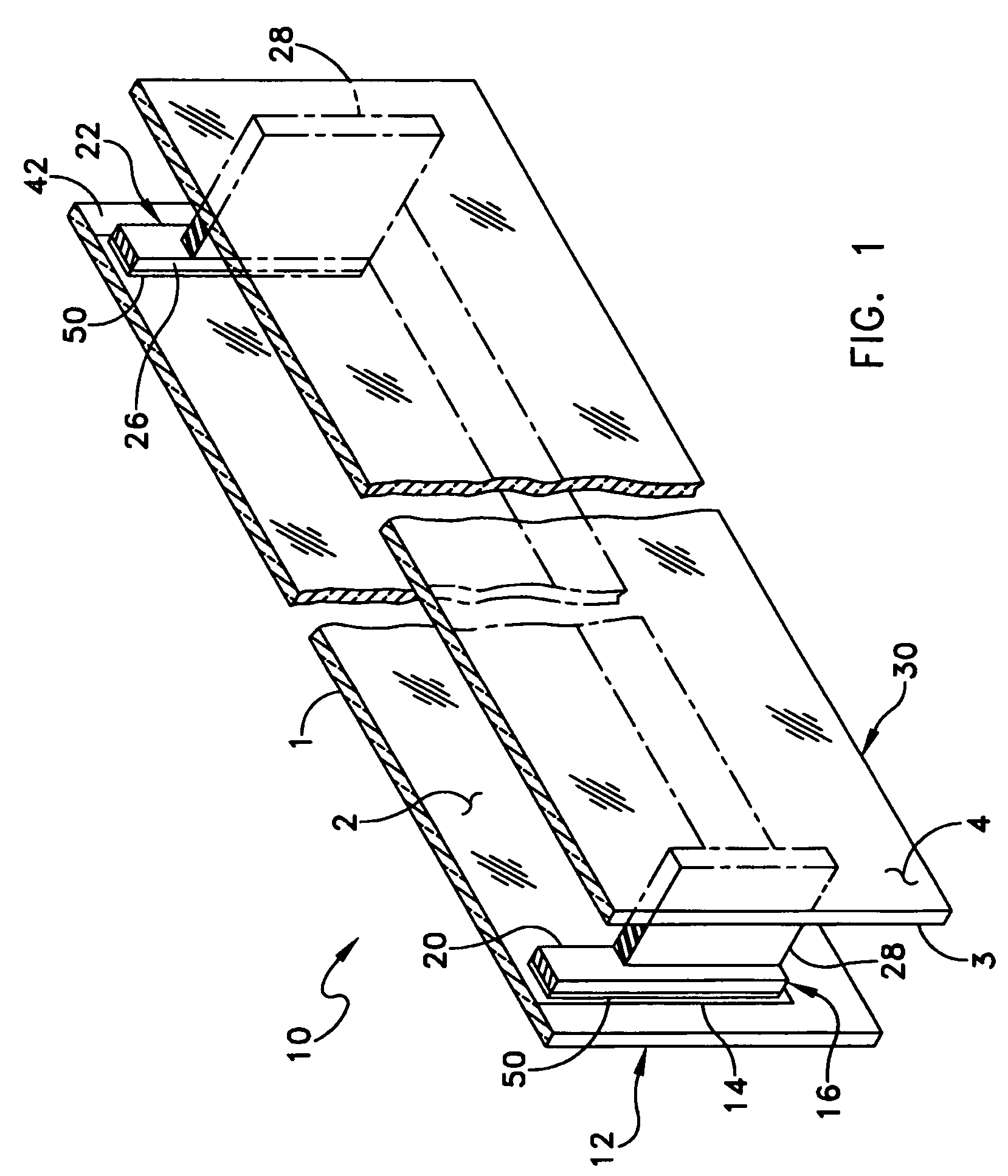

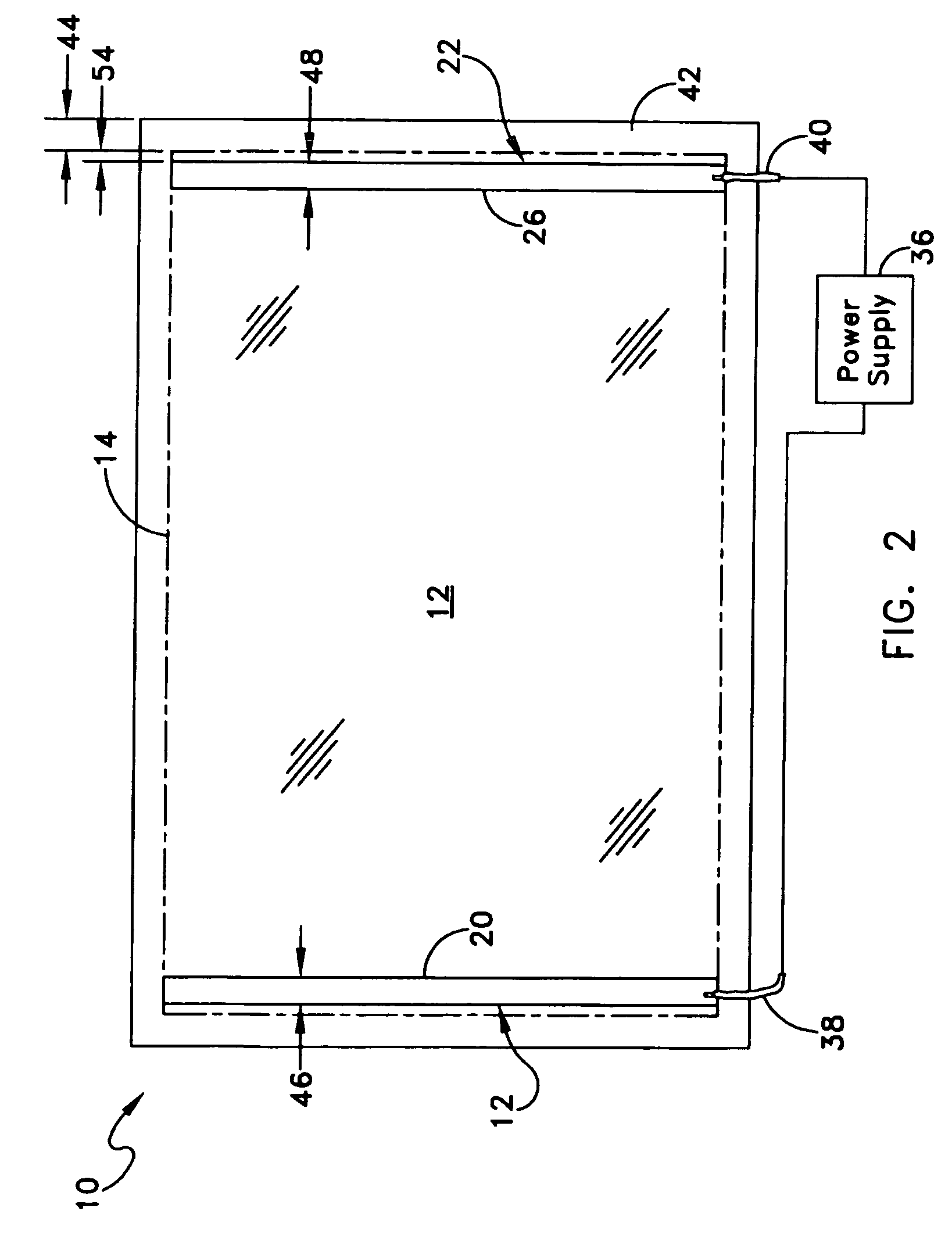

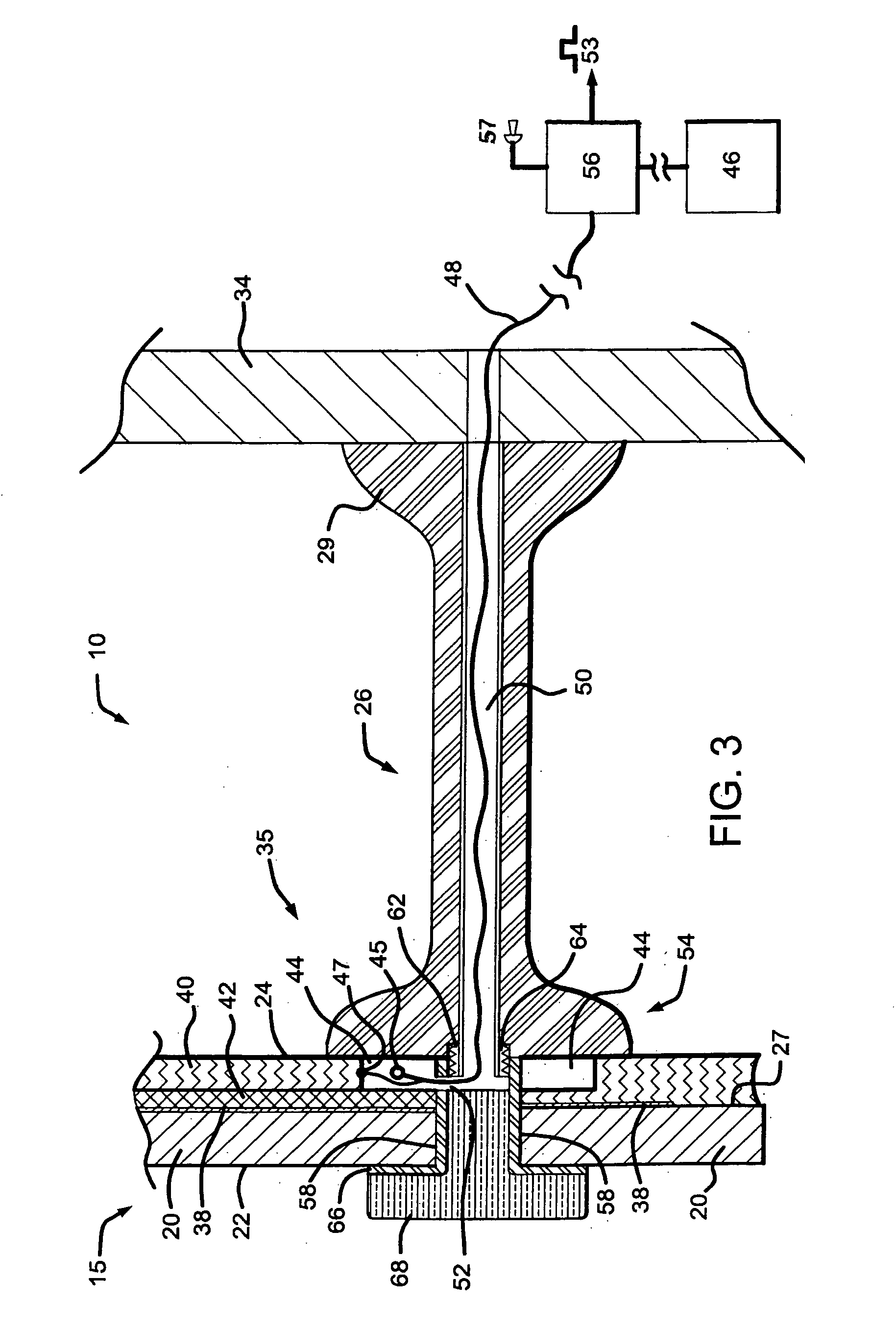

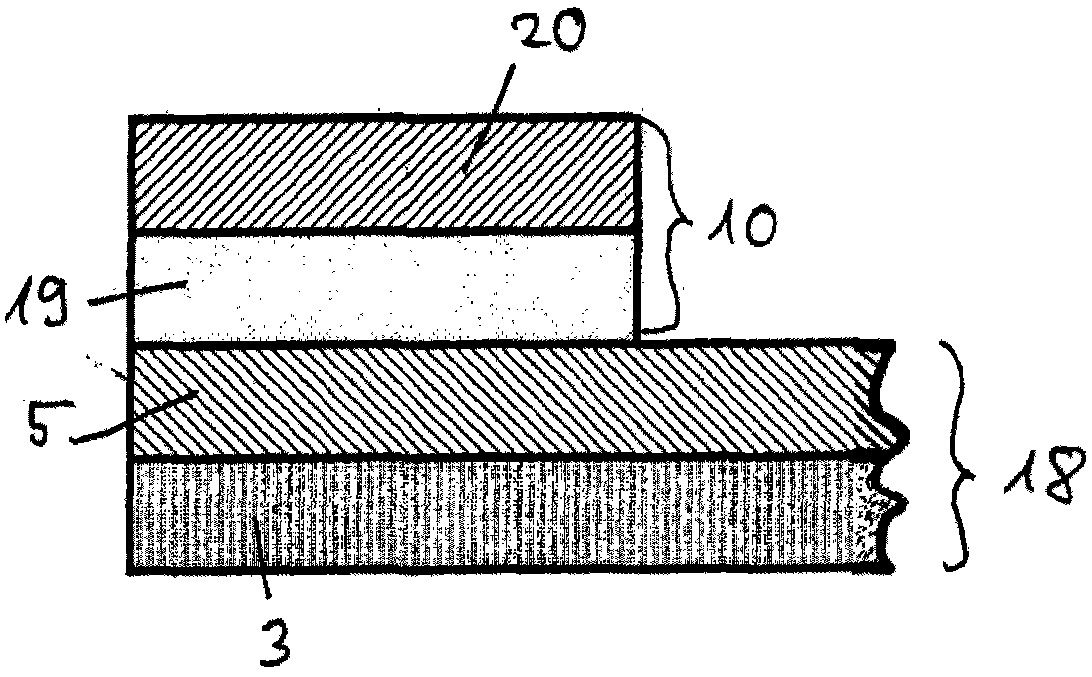

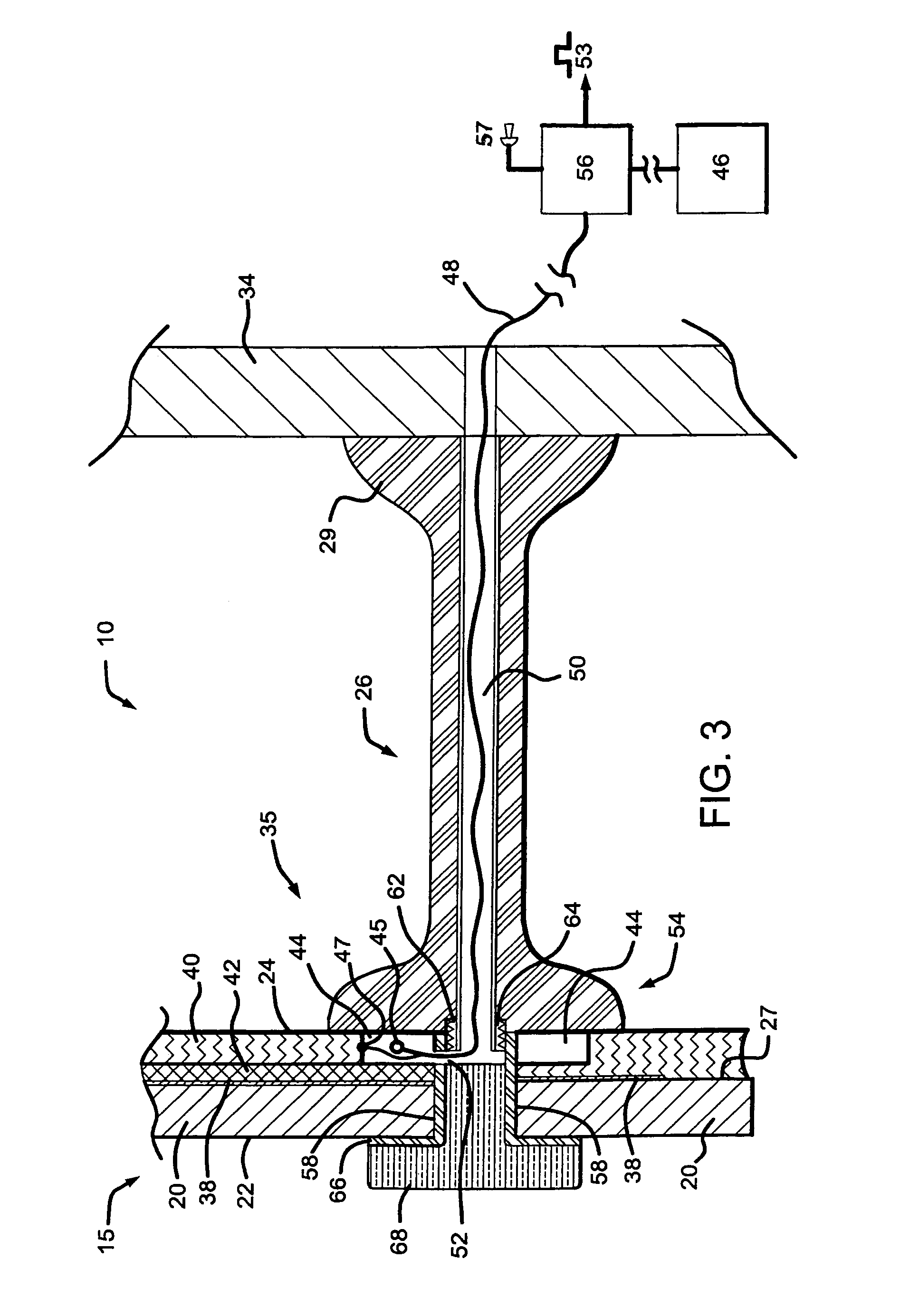

A heated glass panel assembly according to one embodiment of the invention may include a substrate having an electro-conductive film provided thereon. A conductor is positioned in contact with the electro-conductive film. A resilient material is positioned in contact with the conductor so that at least a portion of the conductor is located between the resilient material and the electro-conductive film. A retainer is positioned in contact with the resilient material so that at least a portion of the resilient material and at least a portion of the conductor are located between the retainer and the electro-conductive film. The retainer applies a compressive pressure to the resilient material which transfers at least a portion of the compressive pressure to the conductor to hold the conductor in contact with the electro-conductive film.

Owner:RADIANT GLASS INDS

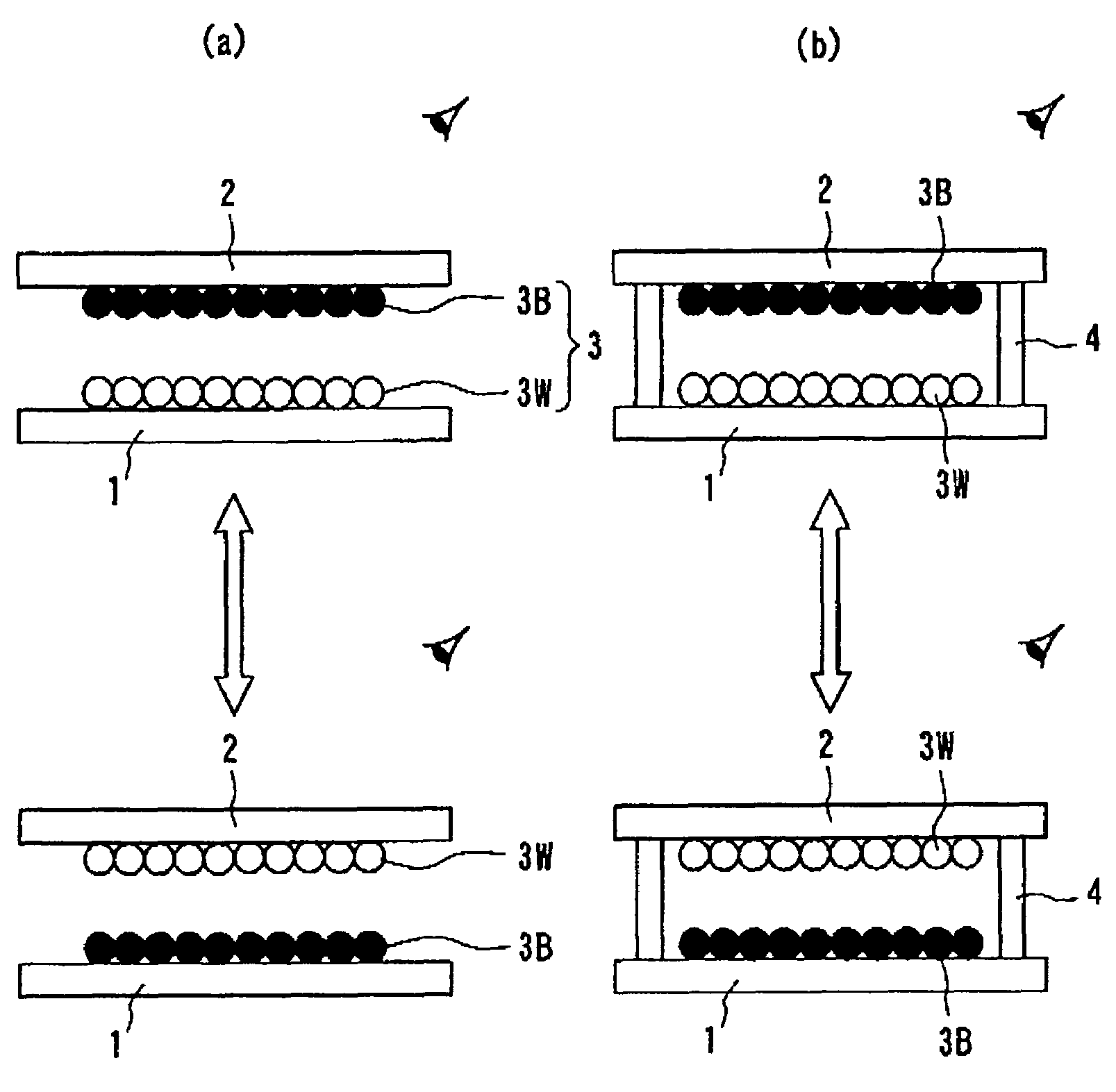

White color particles for display media and information display device utilizing them

InactiveUS7639417B2Improve reflectivityIncrease contrastStatic indicating devicesNon-linear opticsHeat resistanceTitanium oxide

Owner:BRIDGESTONE CORP

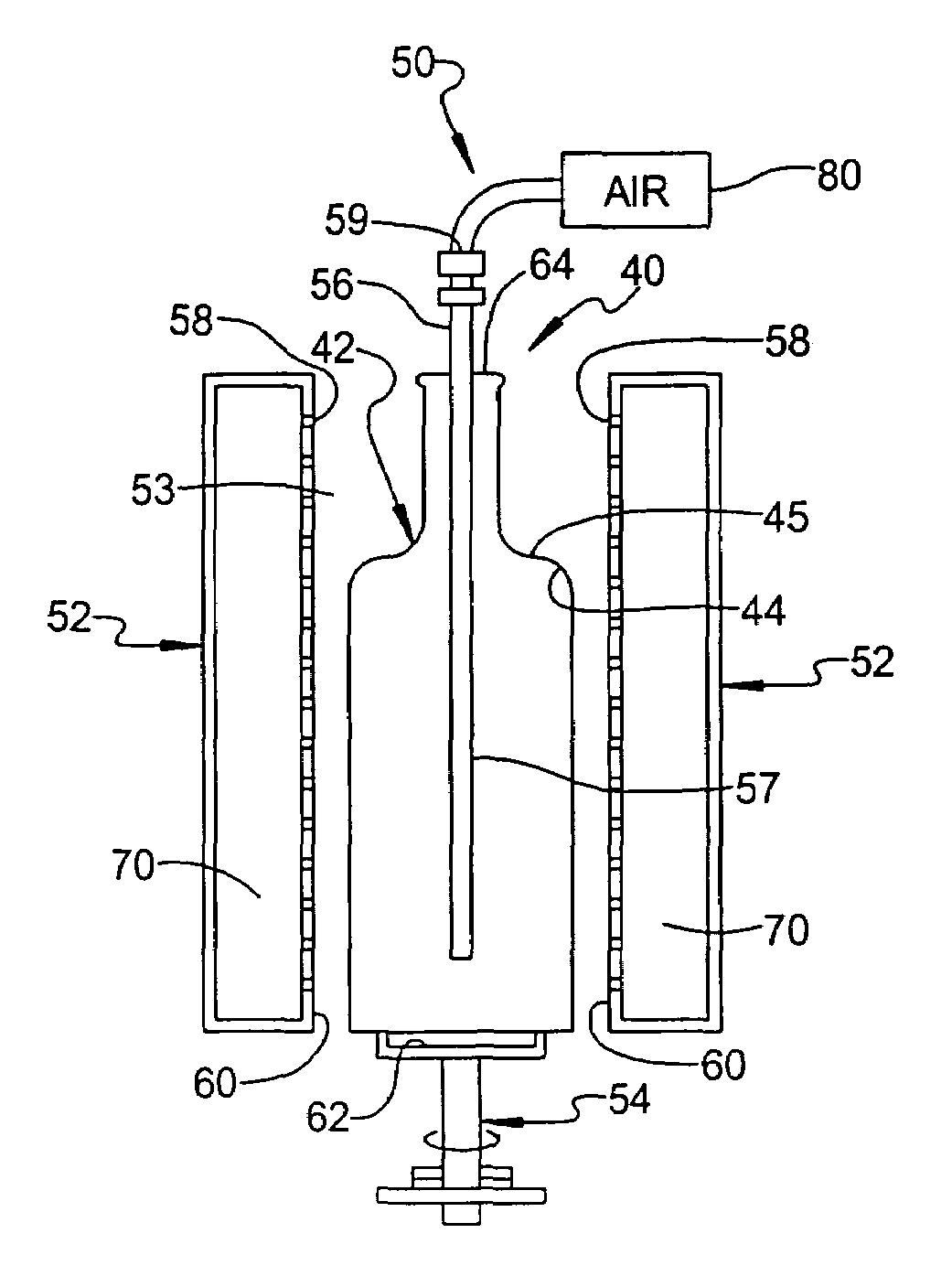

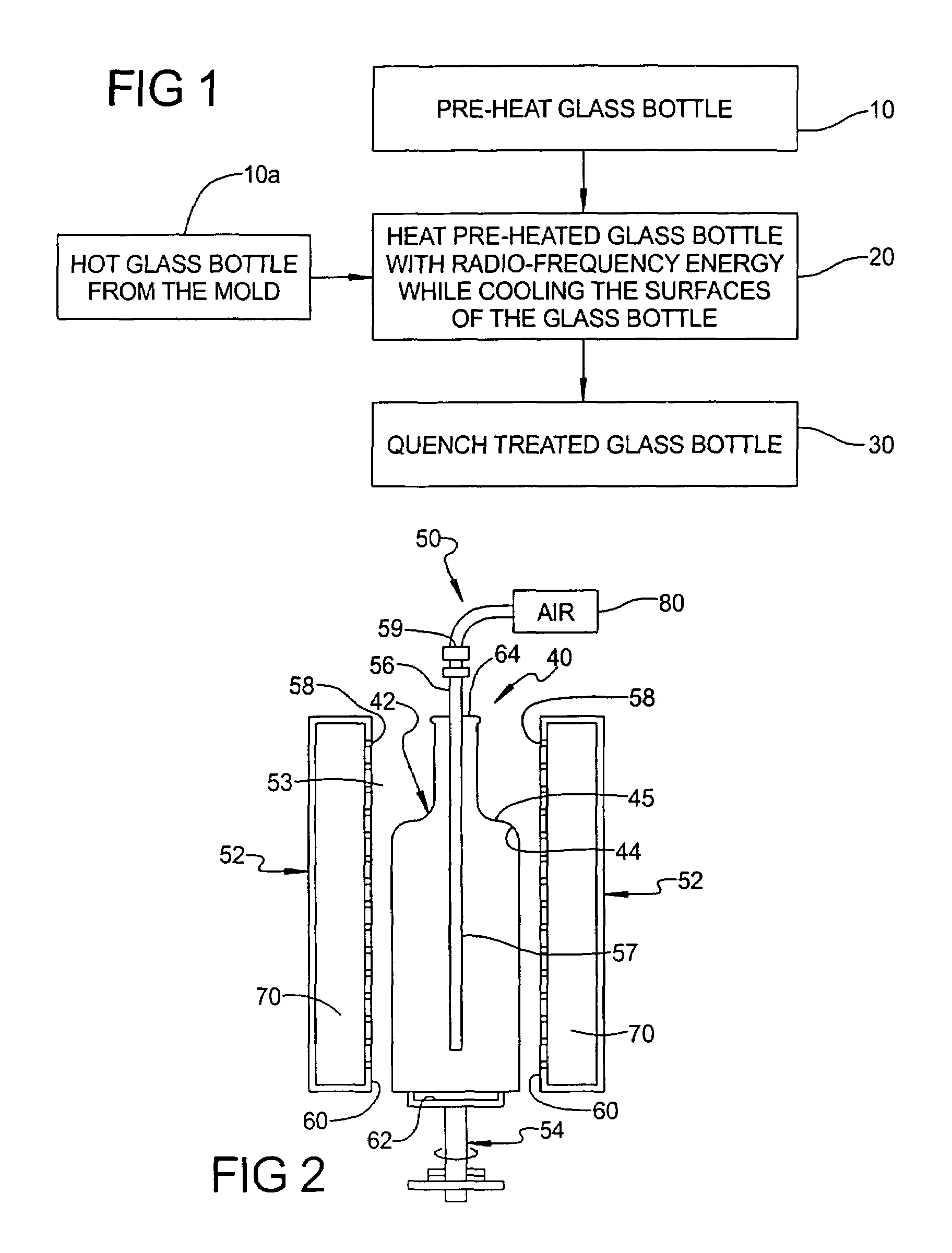

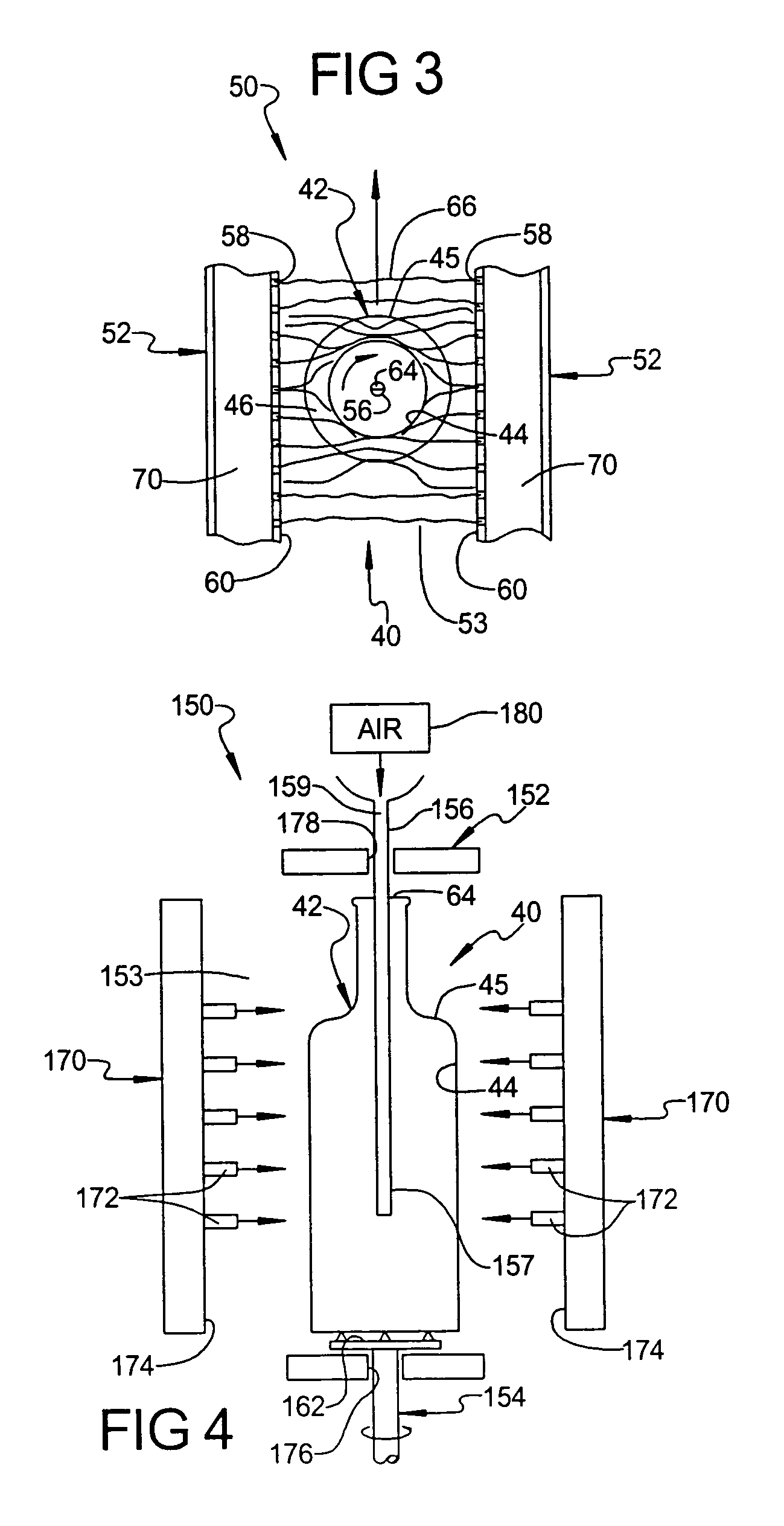

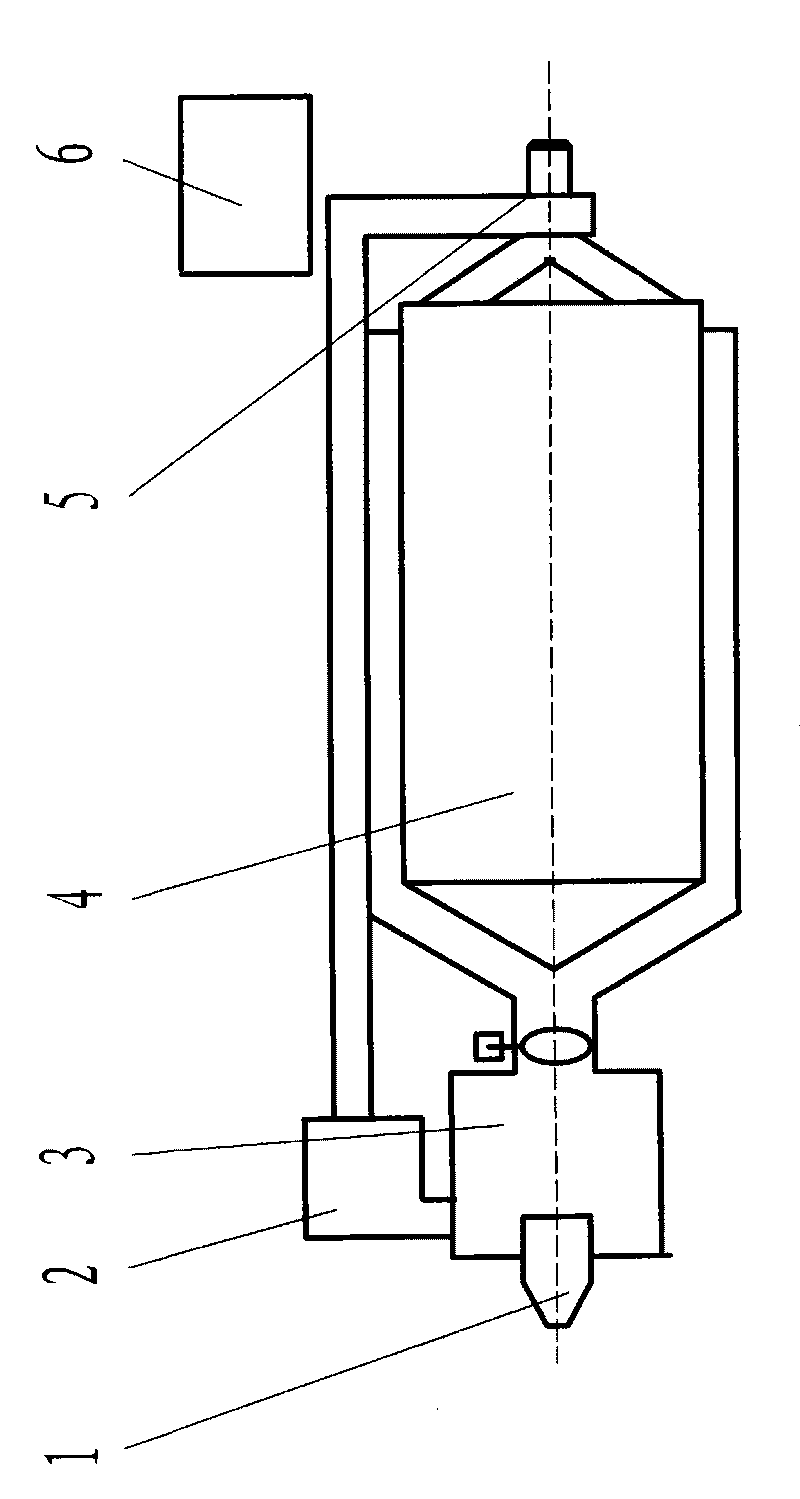

System and method for tempering glass containers

InactiveUS7694532B1Save energySave raw materialsInduction heatingFurnace typesRadio frequency energyEngineering

A system and method is provided for tempering a glass container. The method includes the steps of pre-heating the glass container to a first predetermined temperature. The method also includes the steps of applying radio-frequency energy to the pre-heated glass container to heat the glass container to a second predetermined temperature and, after a predetermined amount of time, simultaneously cooling at least one surface of the heated glass container to a third predetermined temperature to treat the glass container. The method further includes the steps of, after a predetermined amount of time, quenching the treated glass container to a fourth predetermined temperature to produce a tempered glass container.

Owner:BOAZ PREMAKARAN T

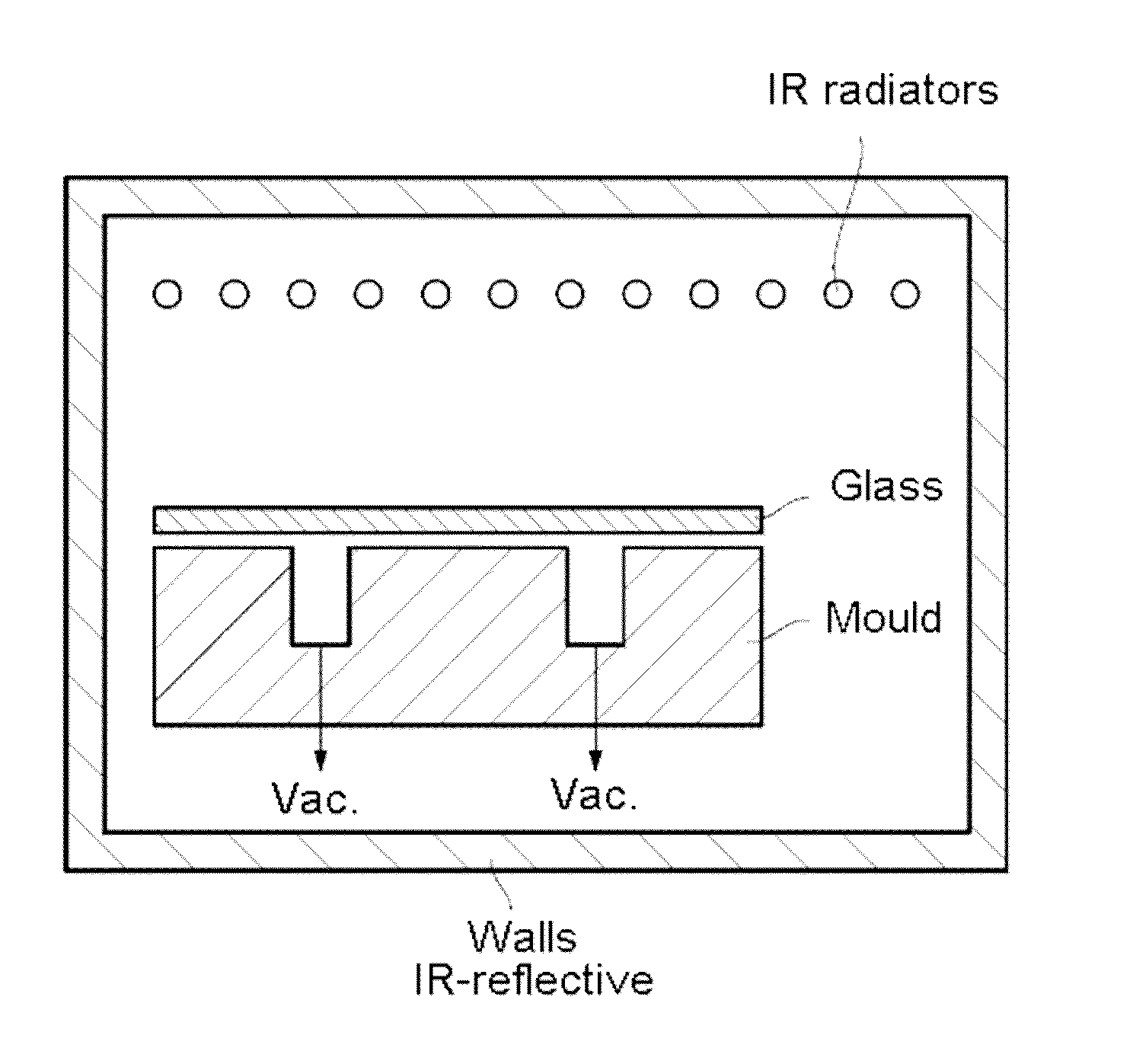

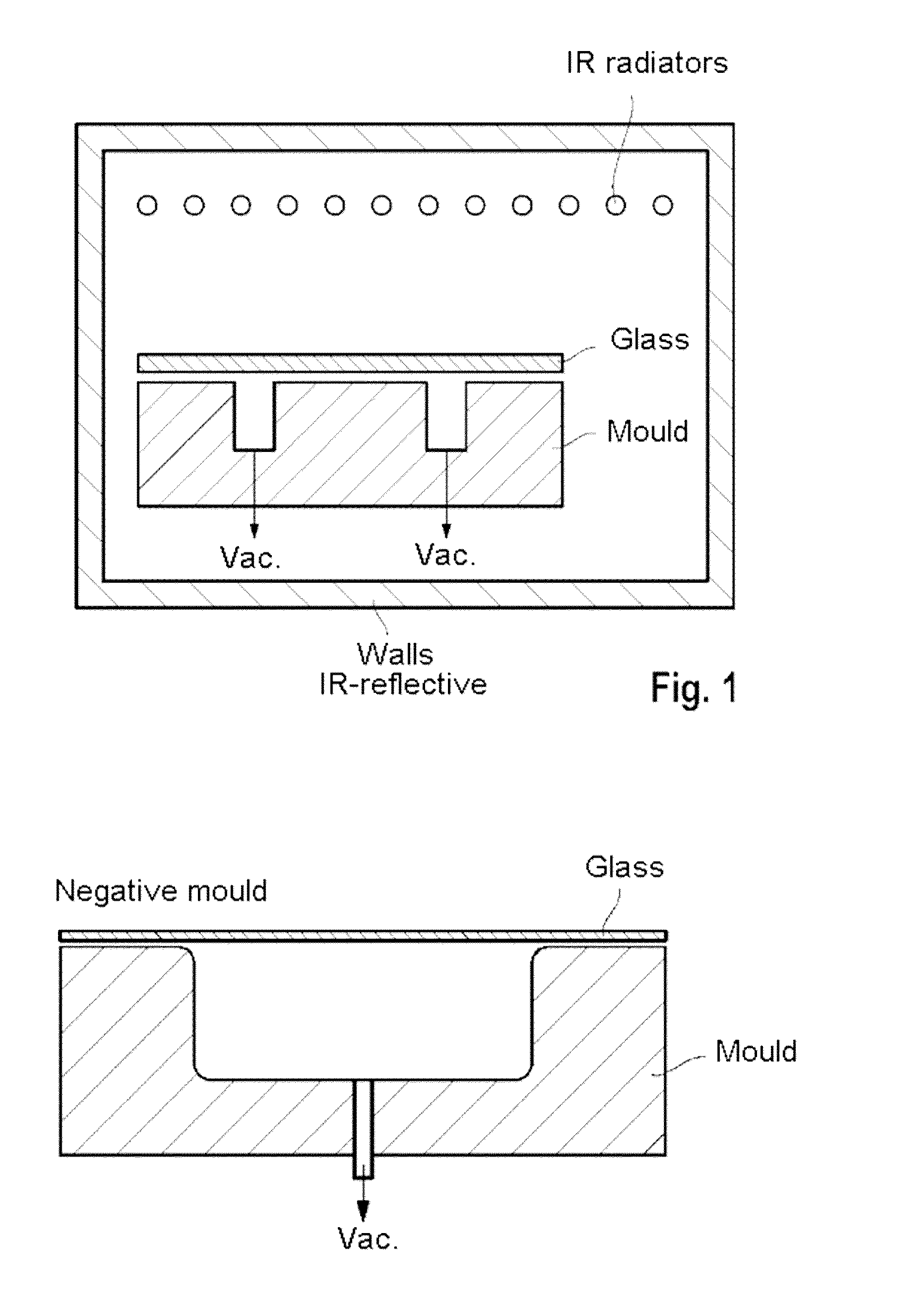

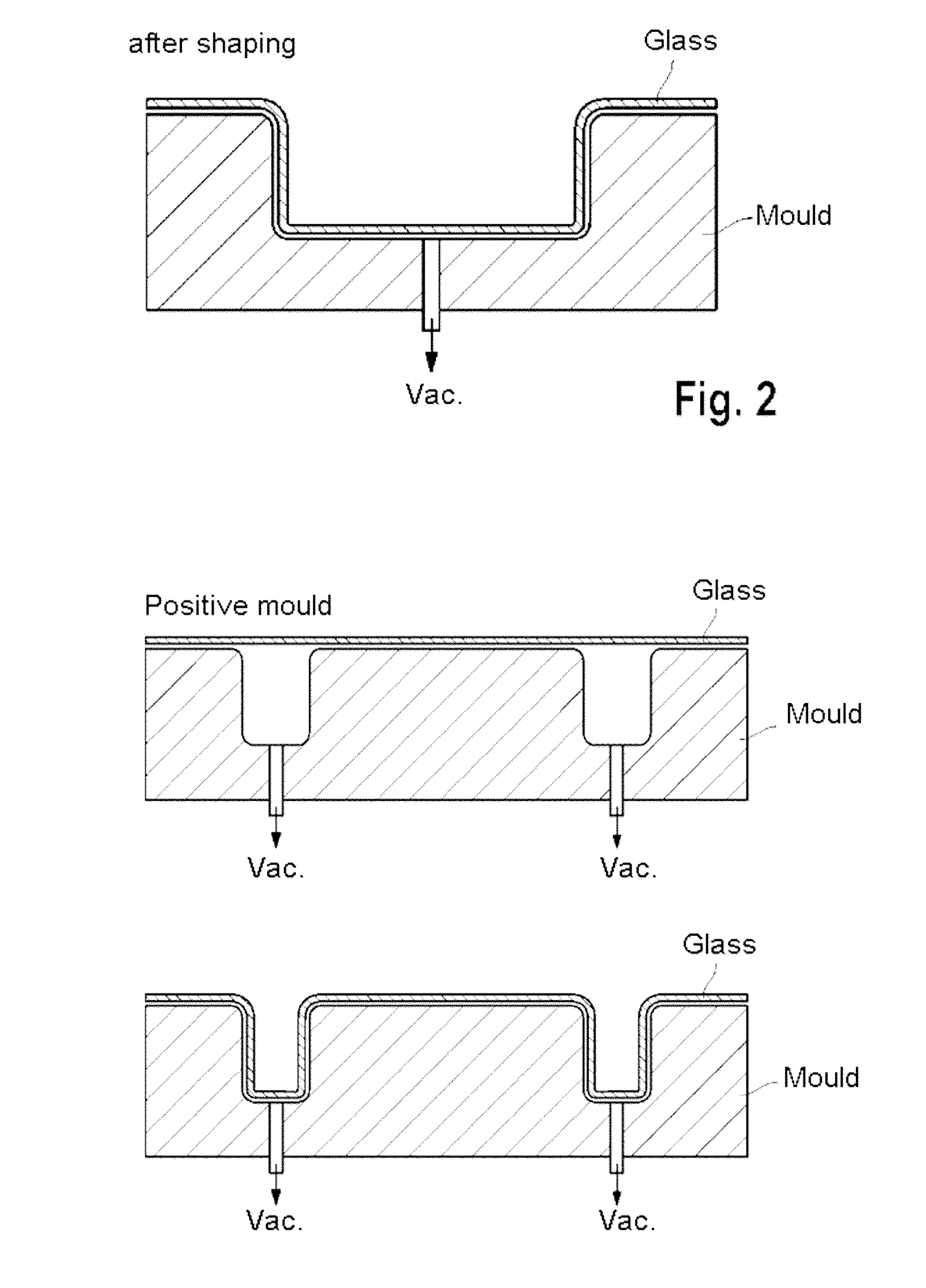

Method for manufacturing molded glass articles, and use of the glass articles manufactured according to the method

ActiveUS20130298608A1Fast heatingMaintain temperatureGlass reforming apparatusGlass severing apparatusMetallurgyPositive pressure

Processes for producing shaped glass articles with a defined geometry are provided. In some embodiment, the process includes arranging a glass pane on a mould, heating the glass pane by infrared radiation, deforming the heated glass pane over the mould by gravity, negative pressure, and / or positive pressure, and cooling the shaped glass pane to obtain the shaped glass article with a defined geometry.

Owner:SCHOTT AG

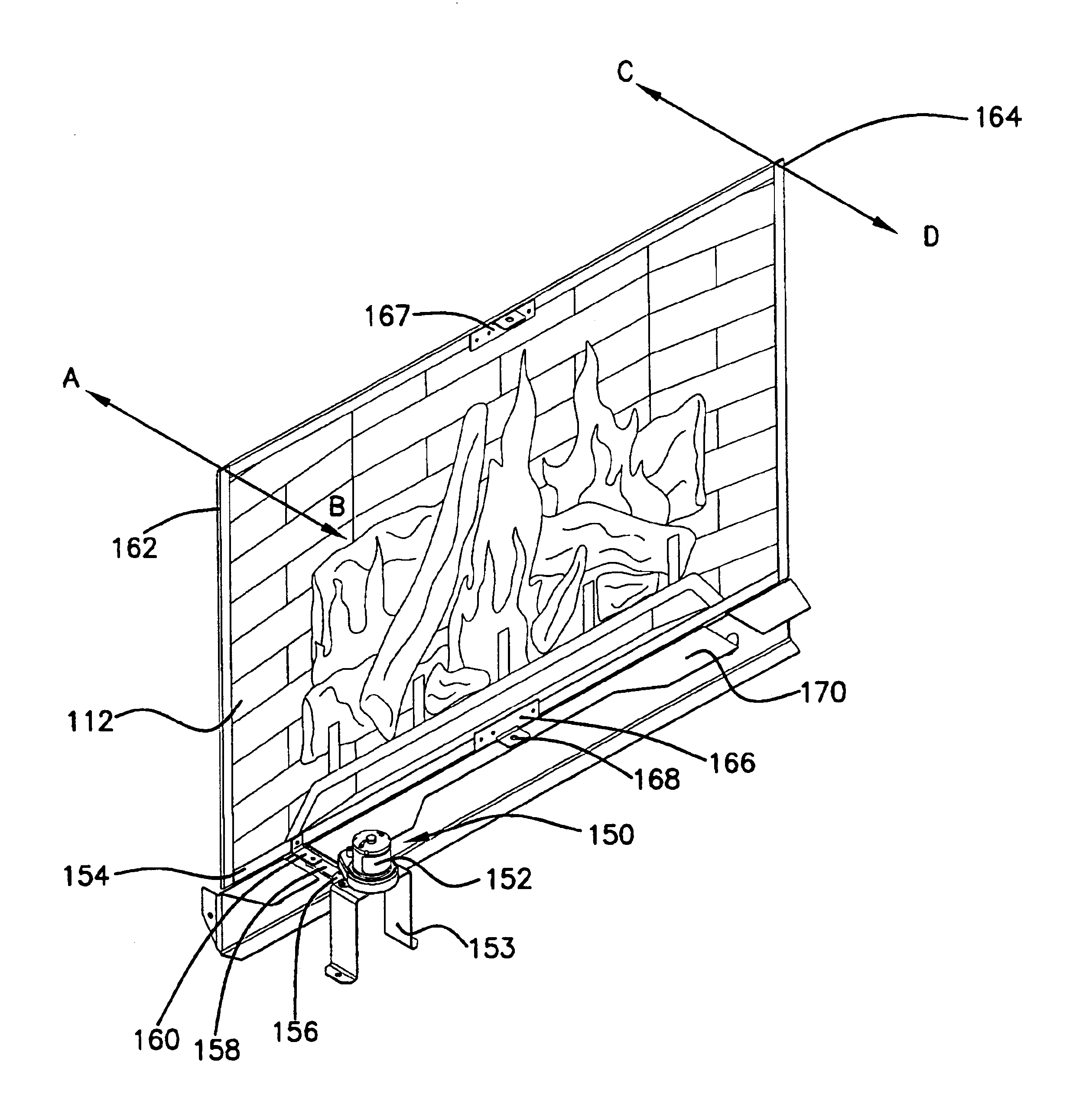

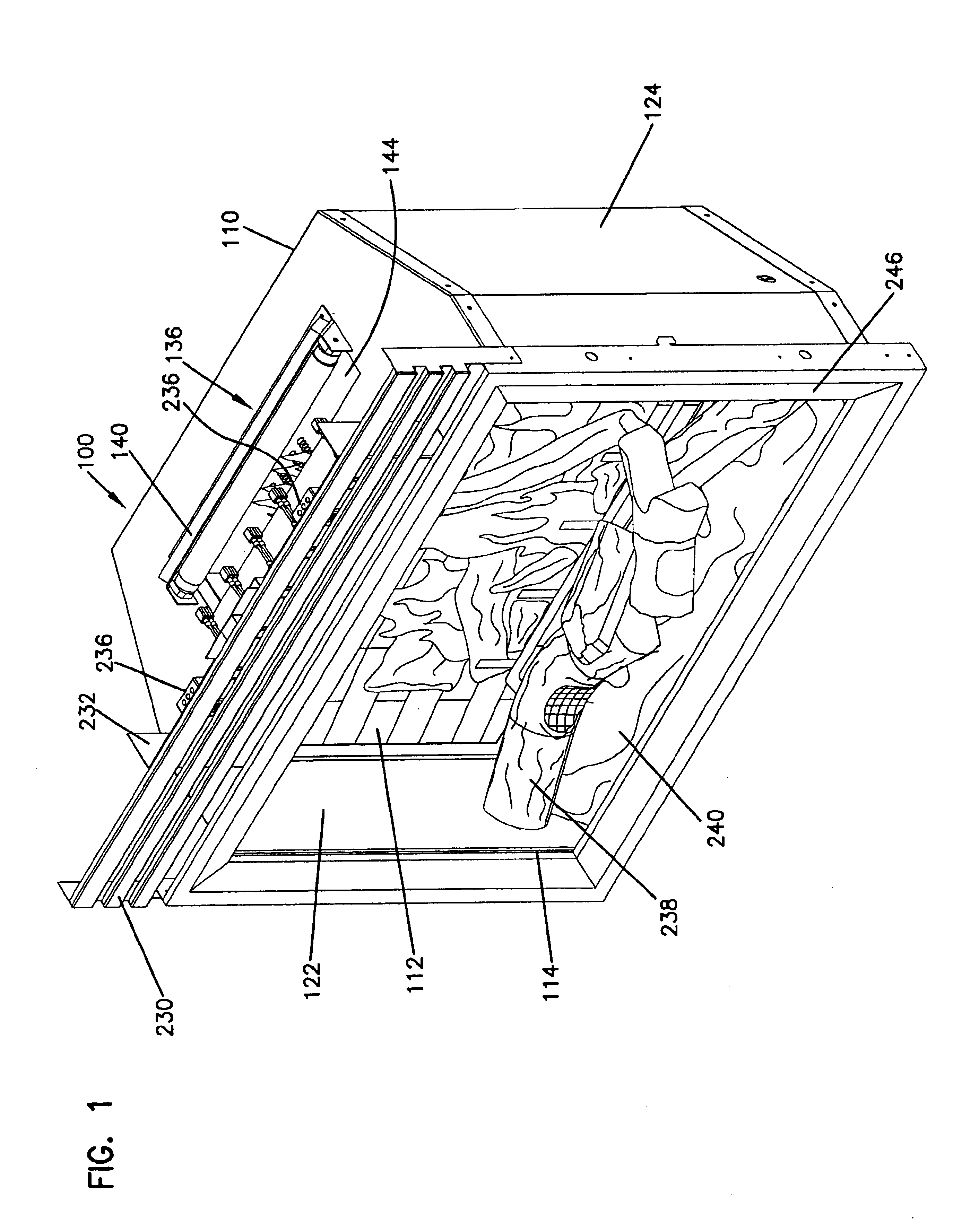

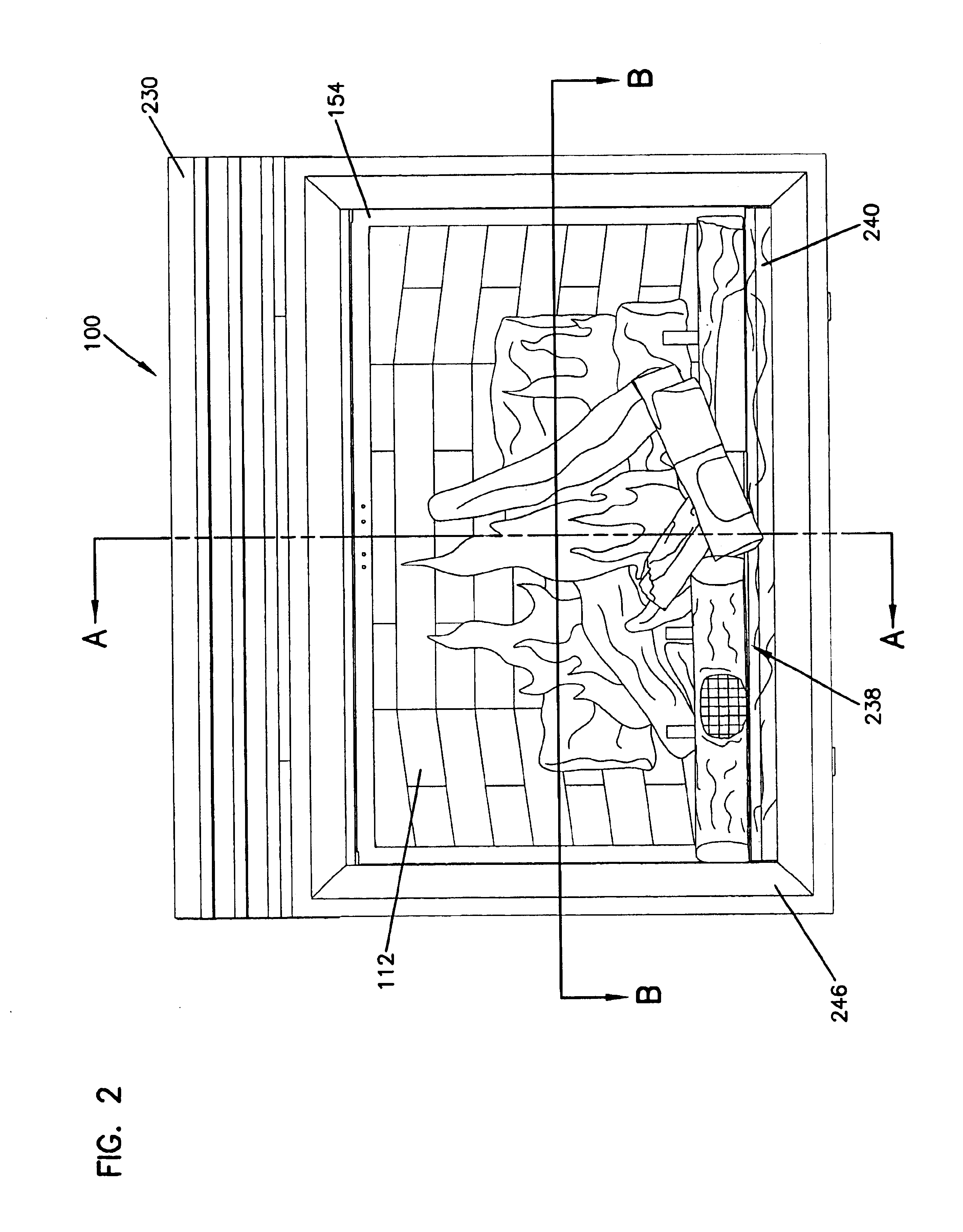

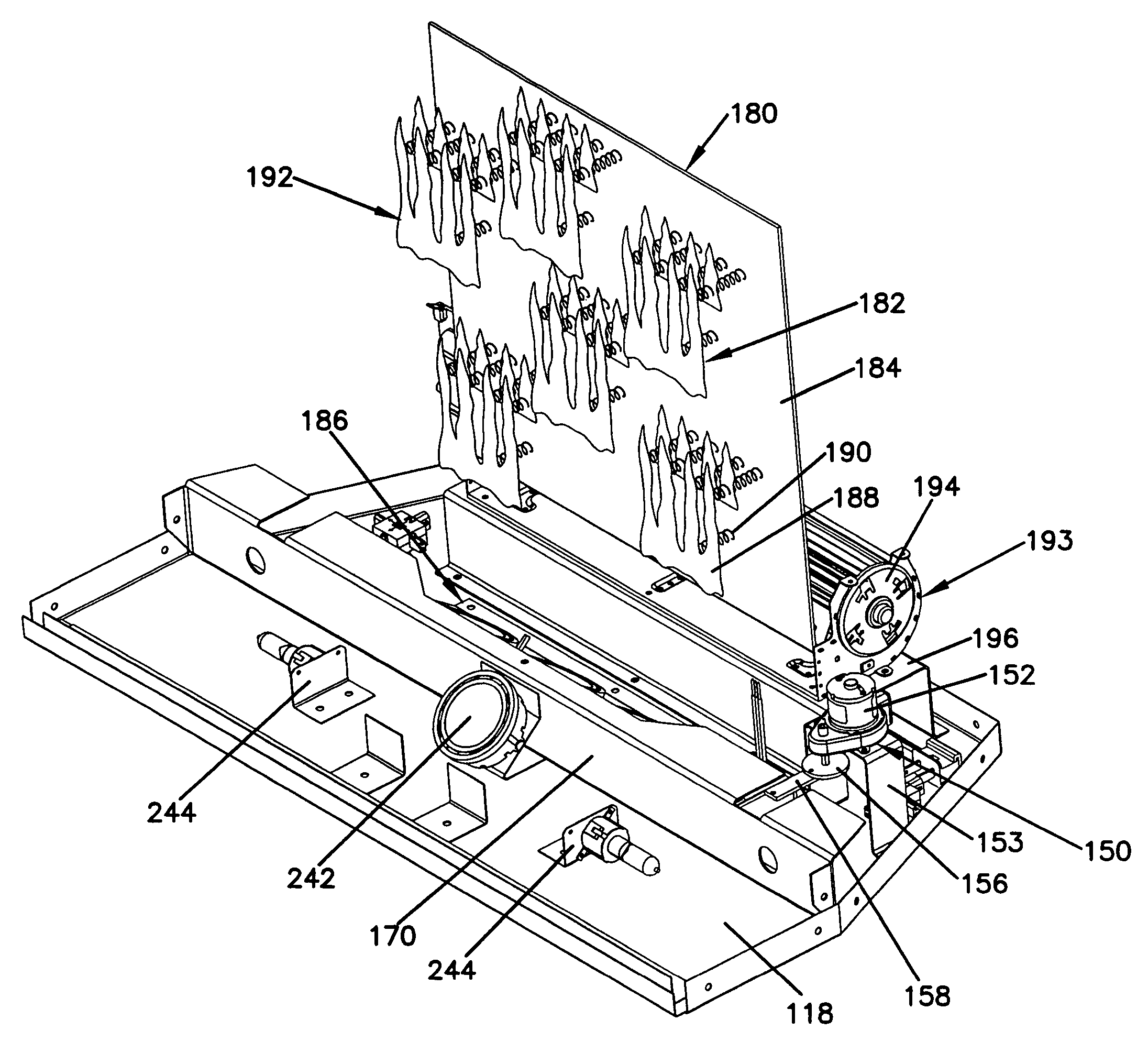

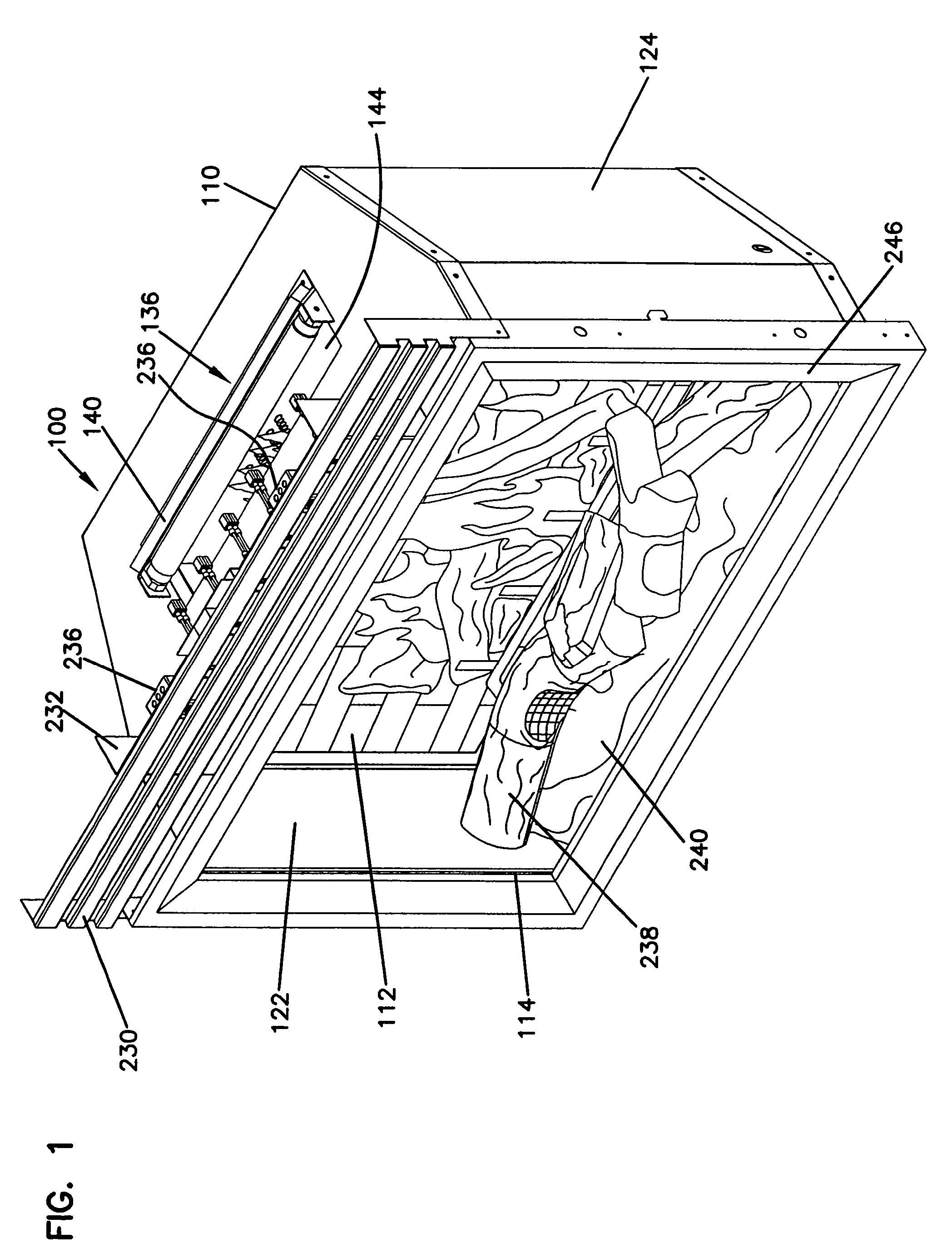

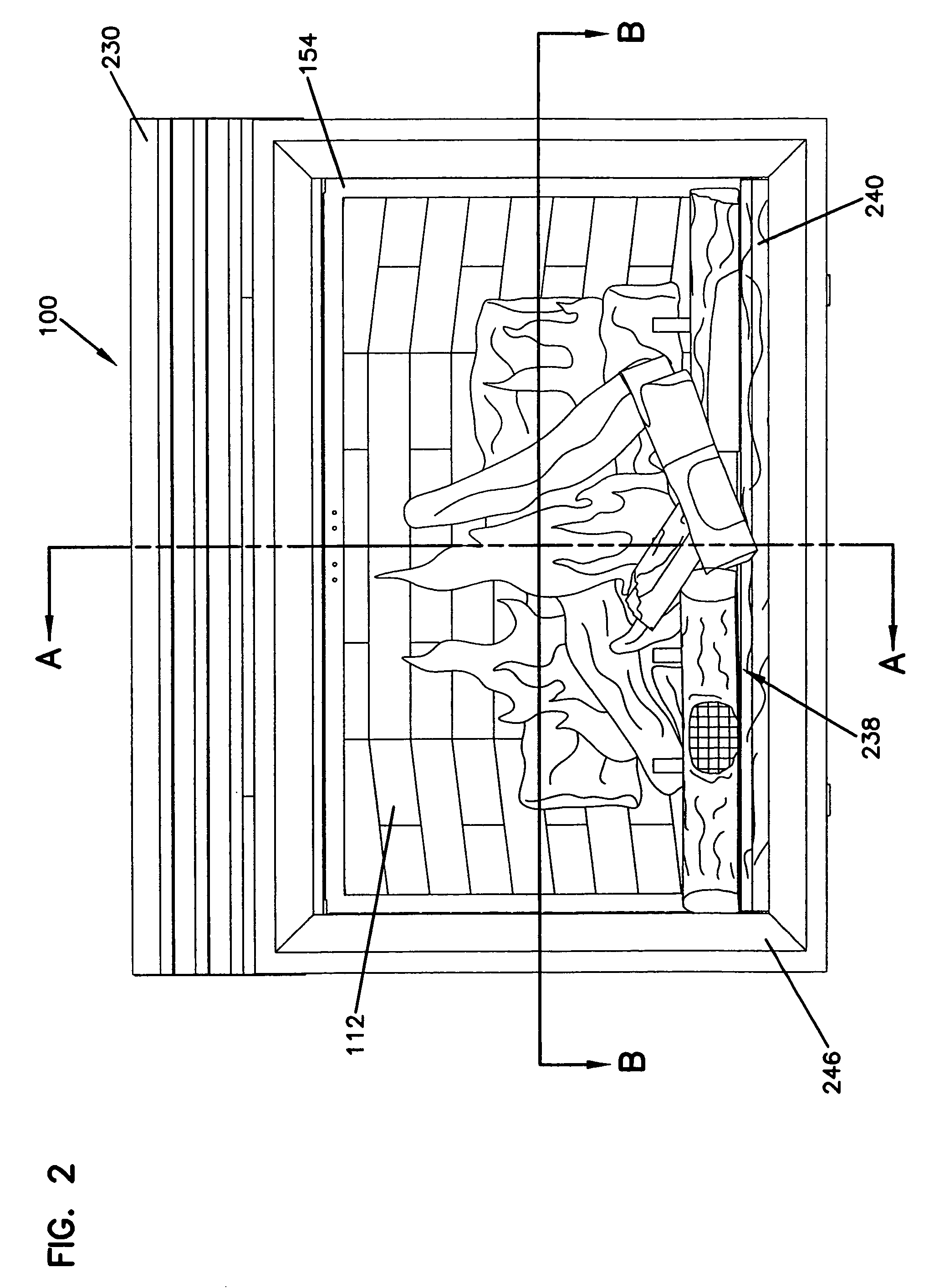

Lenticular fireplace

InactiveUS6880275B2Domestic stoves or rangesElectrical heating fuelLenticular lensPhase-change material

A lenticular fireplace and methods for simulating a fire within a fireplace are disclosed. In one respect, a fire is simulated with a lenticular screen. The lenticular screen includes a lenticular lens layer and an image layer, wherein the image layer comprises one or more images of a fire. A device is coupled to the lenticular screen that moves the lenticular screen to alter a viewed image of the fire. In another respect, the lenticular screen is disposed within a fireplace enclosure. In another respect, a fireplace includes a convertible heated glass apparatus. The apparatus is used in a front wall of an enclosure. The front wall includes an electrically conductive panel coupled to a phase change material. Electrical terminals are operatively connected to the electrically conductive panel for applying a voltage across the electrically conductive panel to heat the front wall and convert the phase change material from an opaque solid to a less opaque liquid to allow viewing through the front wall. In another respect, a flame simulation apparatus simulates a flickering flame effect on a translucent screen. The flame simulation apparatus includes the translucent screen having a front surface and a back surface, a bobble-flame, a device to move the bobble-flame, and a light source to reflect light off of the bobble-flame and onto the translucent screen. In another respect, a fireplace includes the lenticular screen, the convertible heated glass apparatus, and the flame simulation apparatus.

Owner:HNI TECH INC

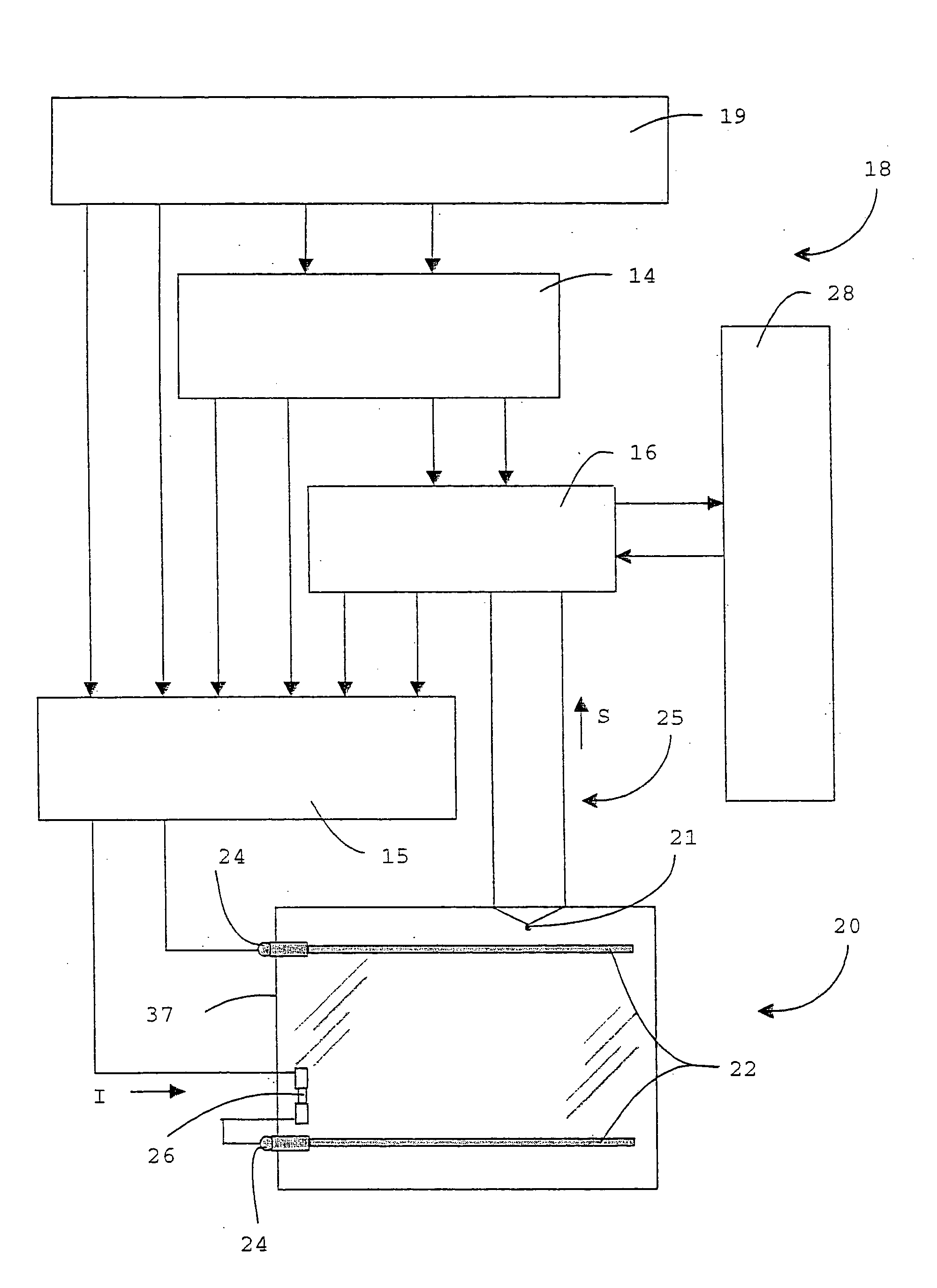

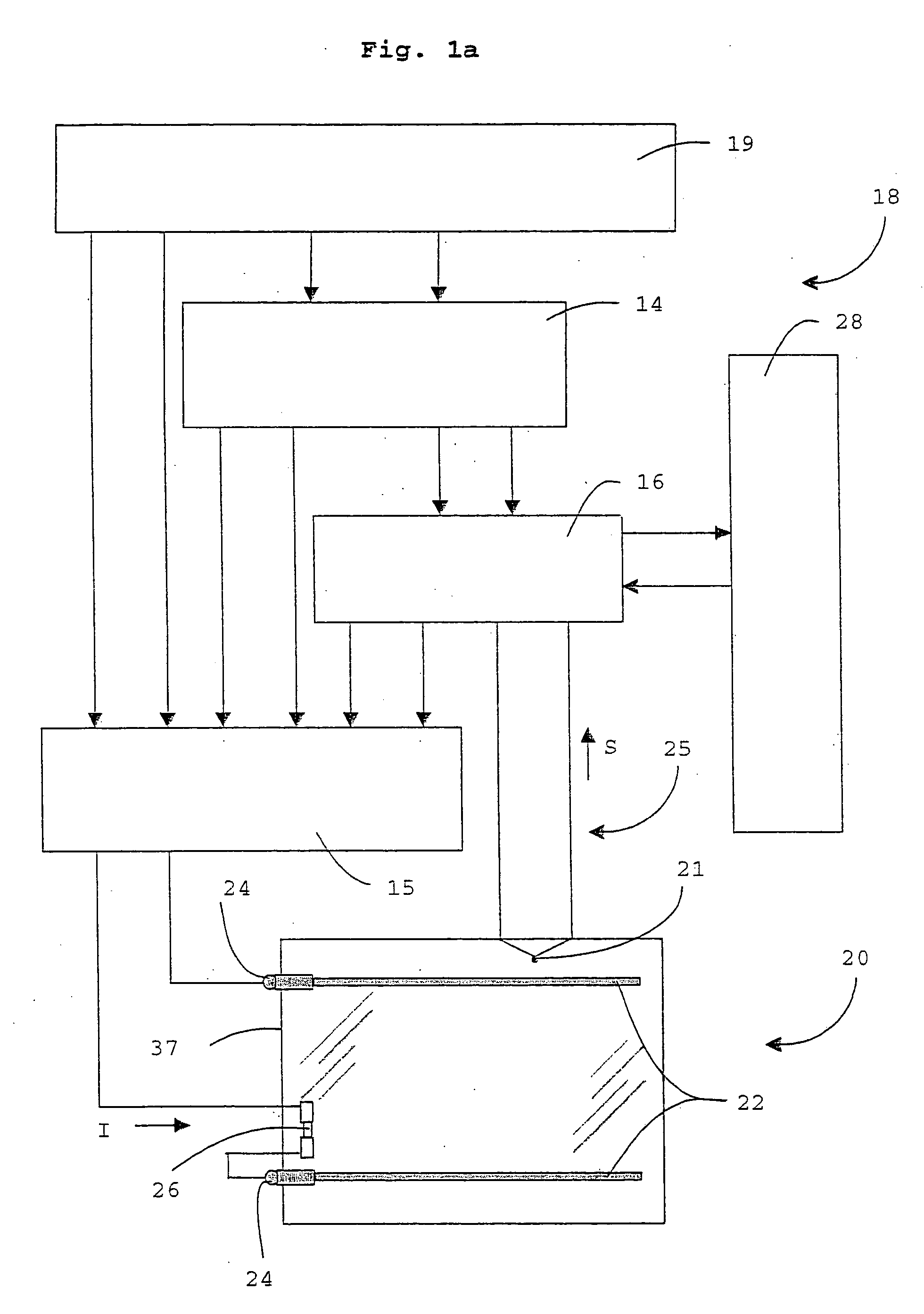

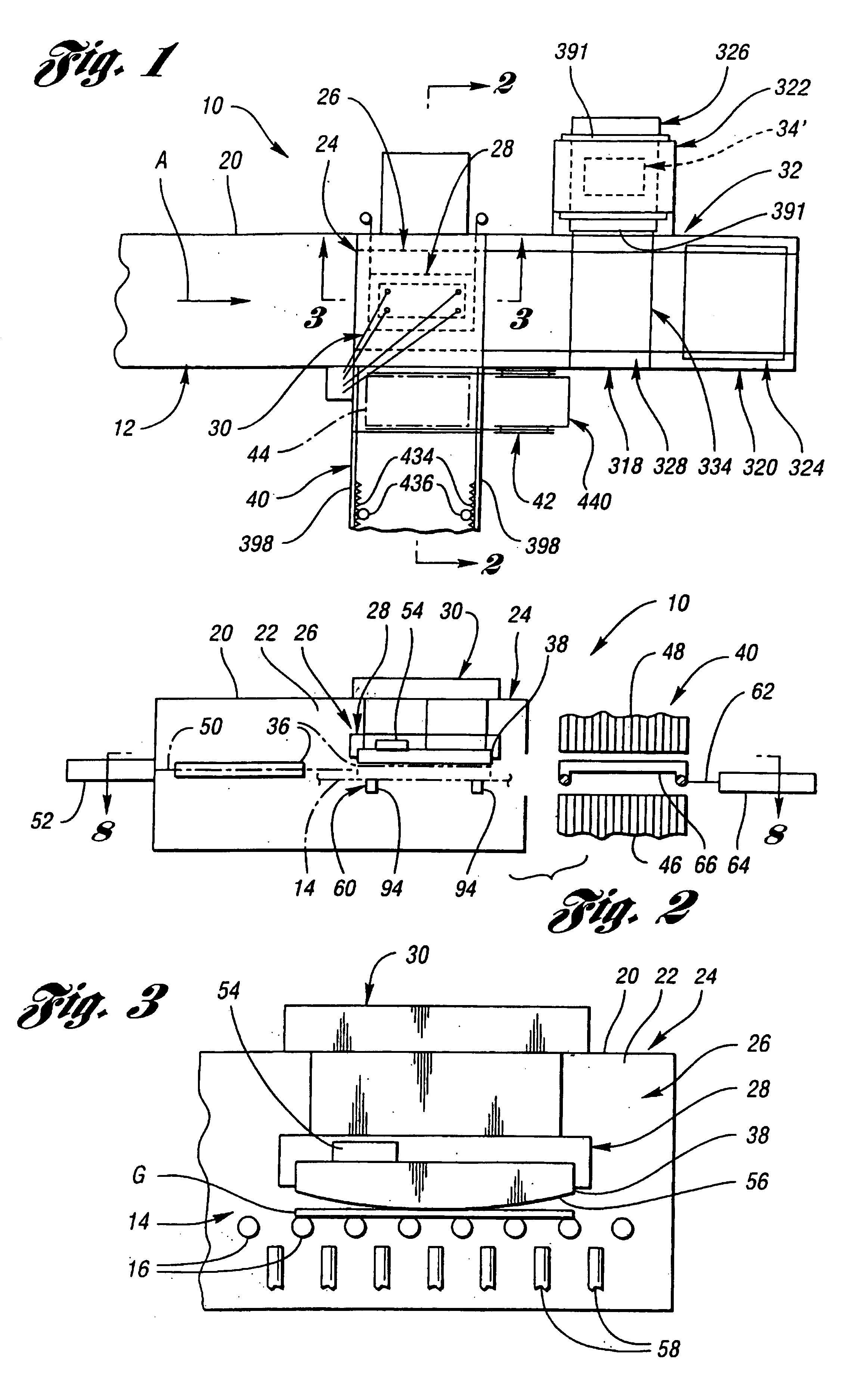

Method for forming heated glass panels

InactiveUS20050115954A1Robust external electrical connectionRailway vehiclesSemiconductor/solid-state device manufacturingDielectricConductive coating

Methods for forming electrically conductive heated dielectric panels are provided. The panels are utilized for warming objects and / or insuring unobstructed viewing through the panels by removing moisture. The methods include depositing electrically conductive metal bus bars onto the dielectric panel, onto which panel a conductive coating has previously been disposed. The conductive metal bus bars are deposited onto the coated dielectric panel through the use of a circularly rotating or an inline heating head and mask apparatus, in combination with an oxyacetylene or a plasma device. A metallic tab, which extends from the panel peripheral edge, is brought into electrical contact with each conductive metal bus bar for external electrical connectivity.

Owner:ENGINEERED GLASS PRODS

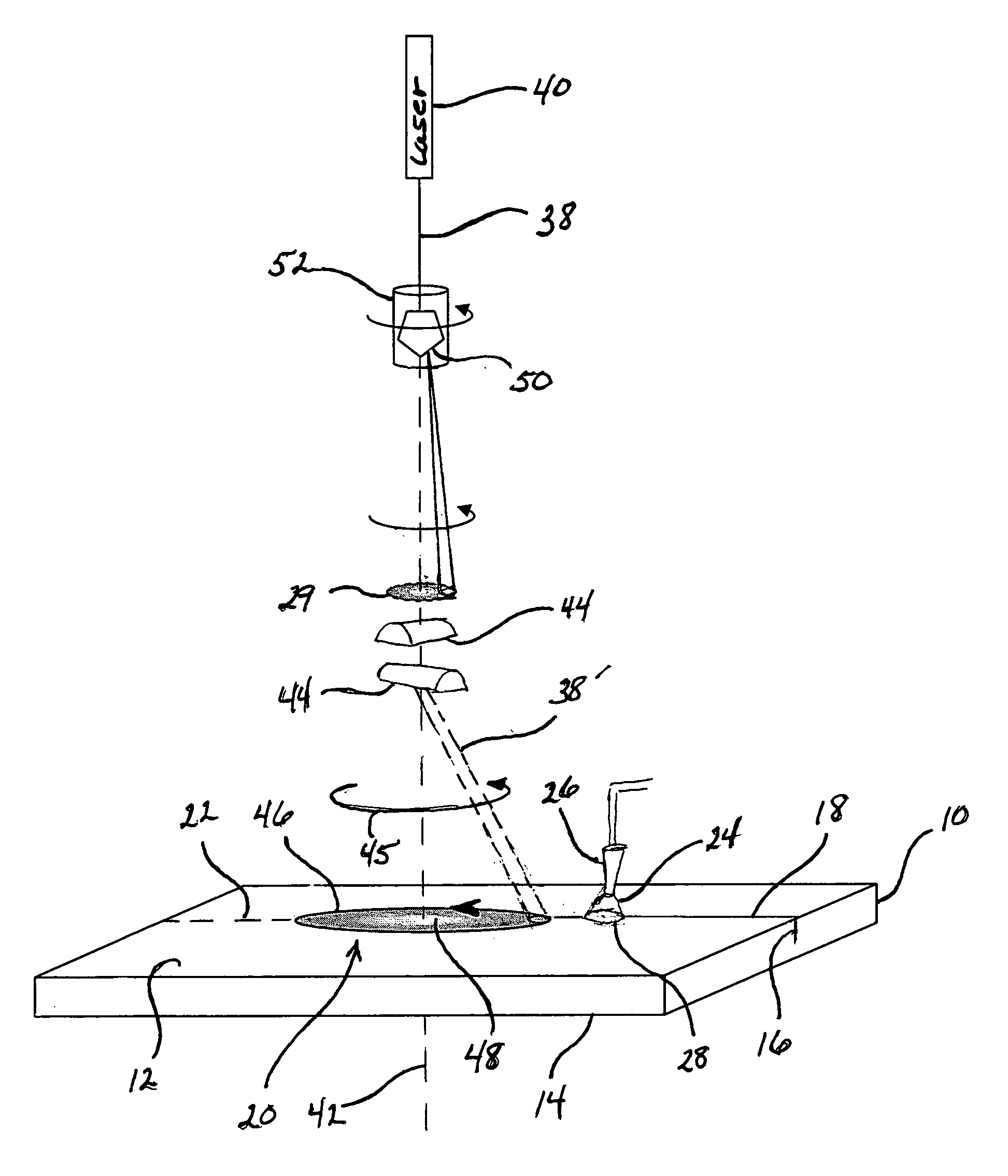

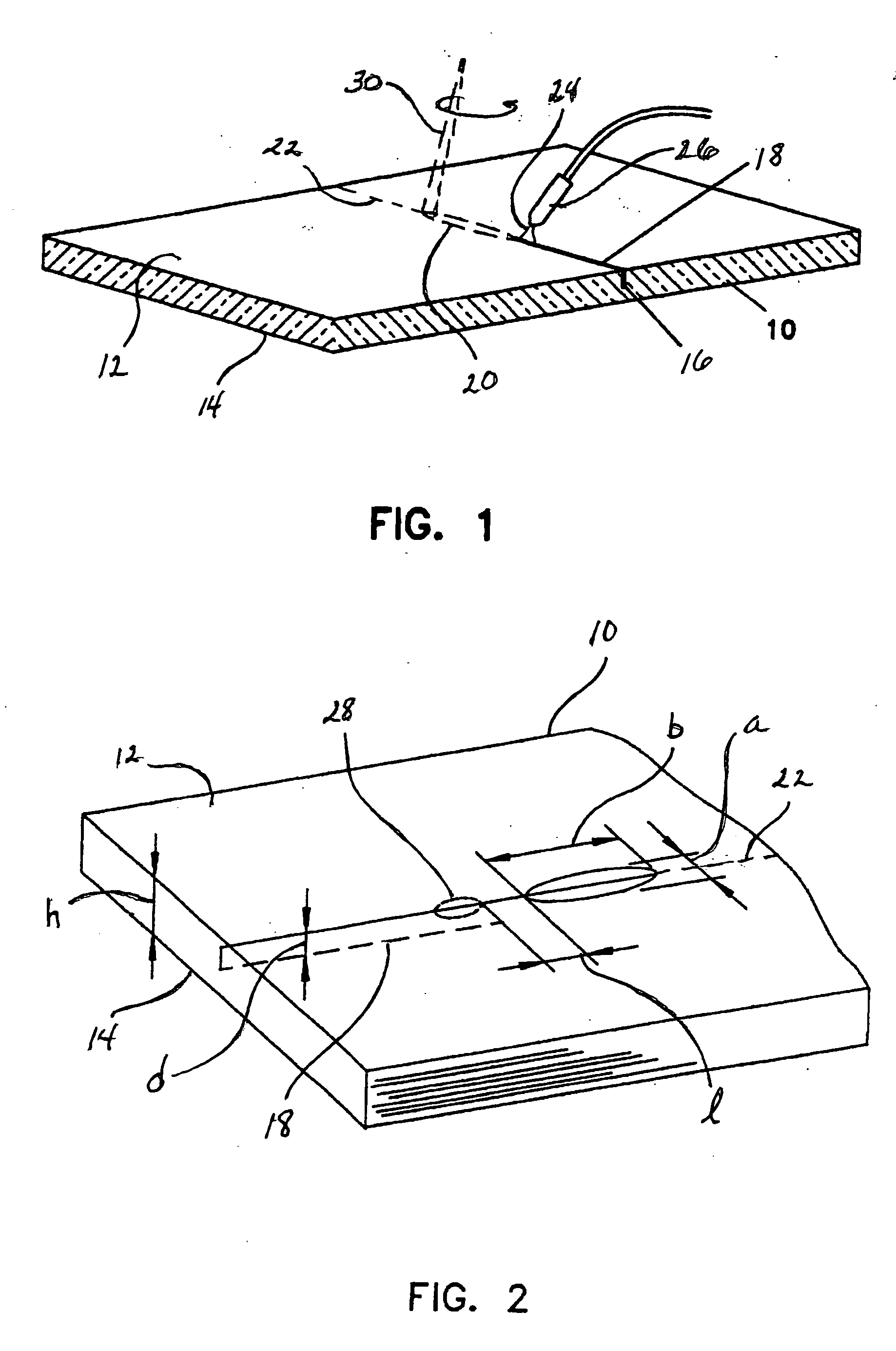

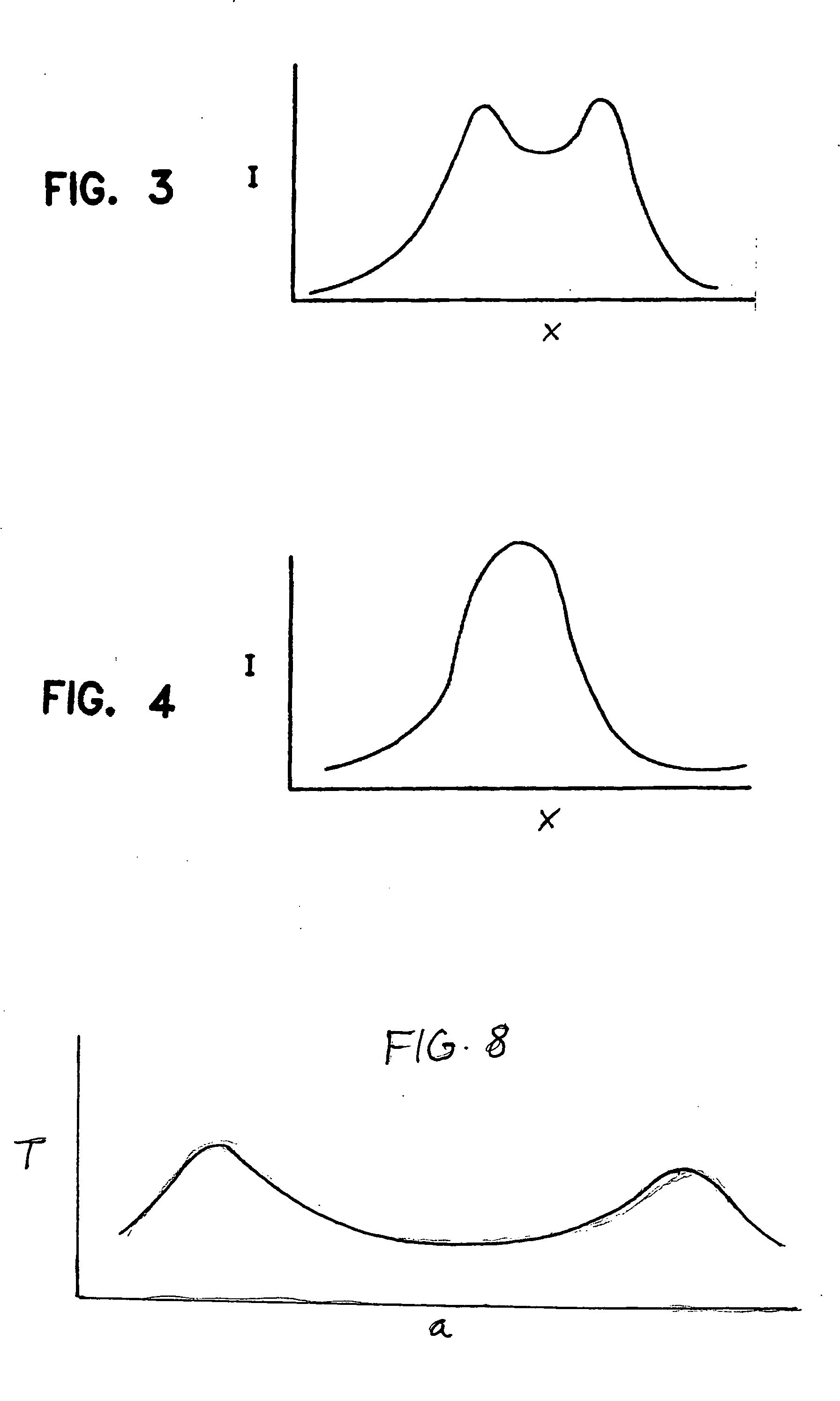

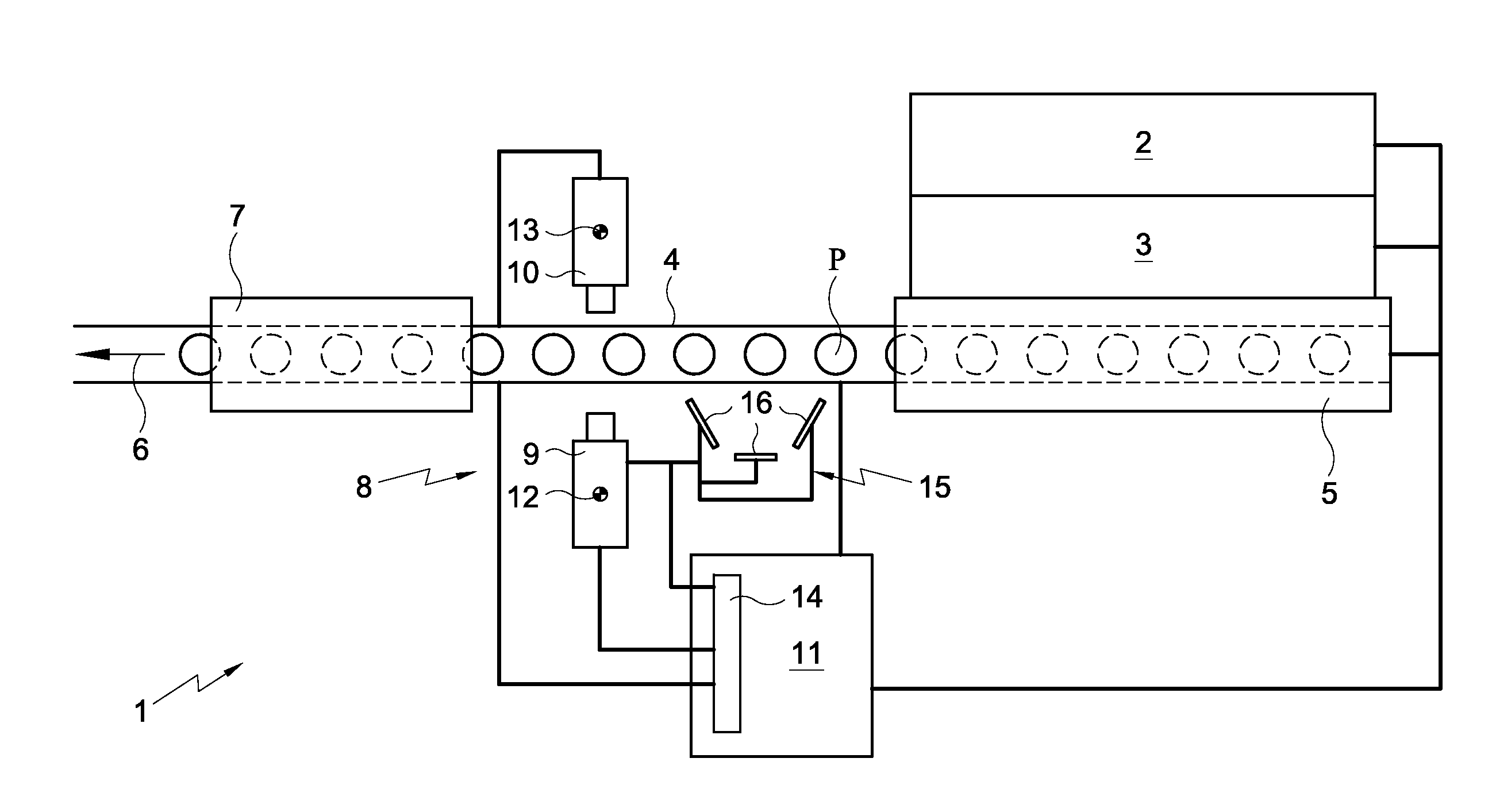

Process and apparatus for scoring a brittle material

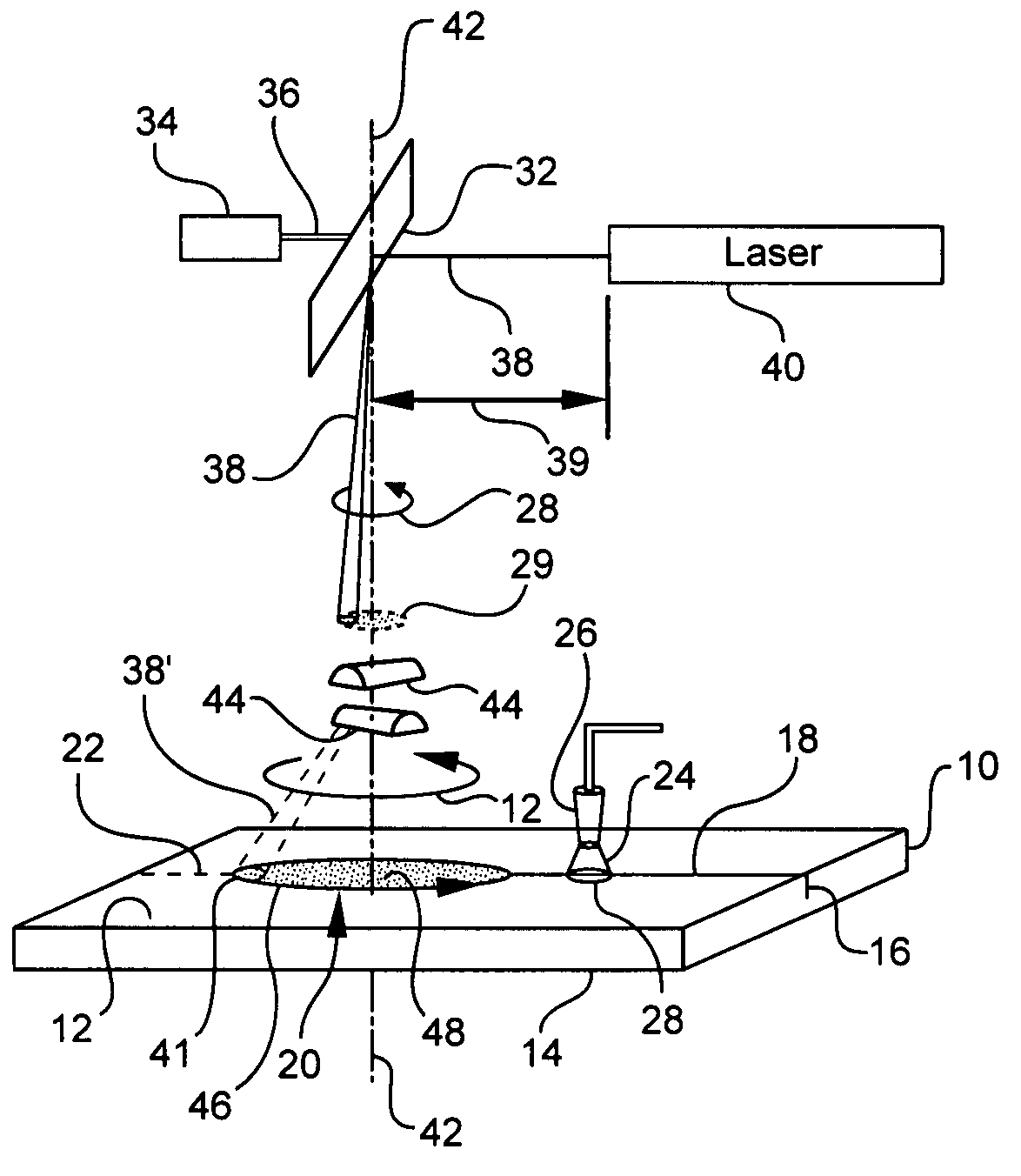

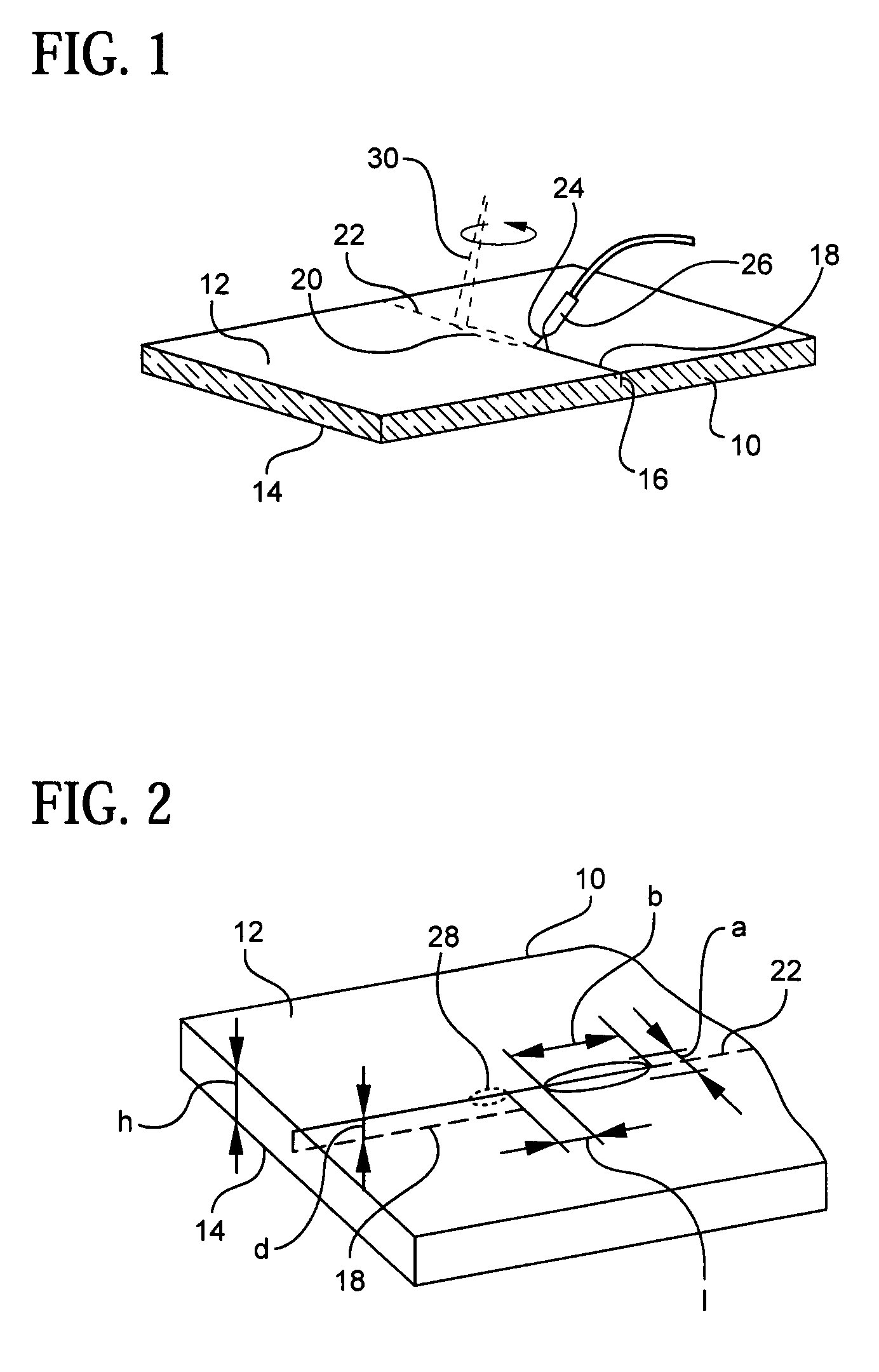

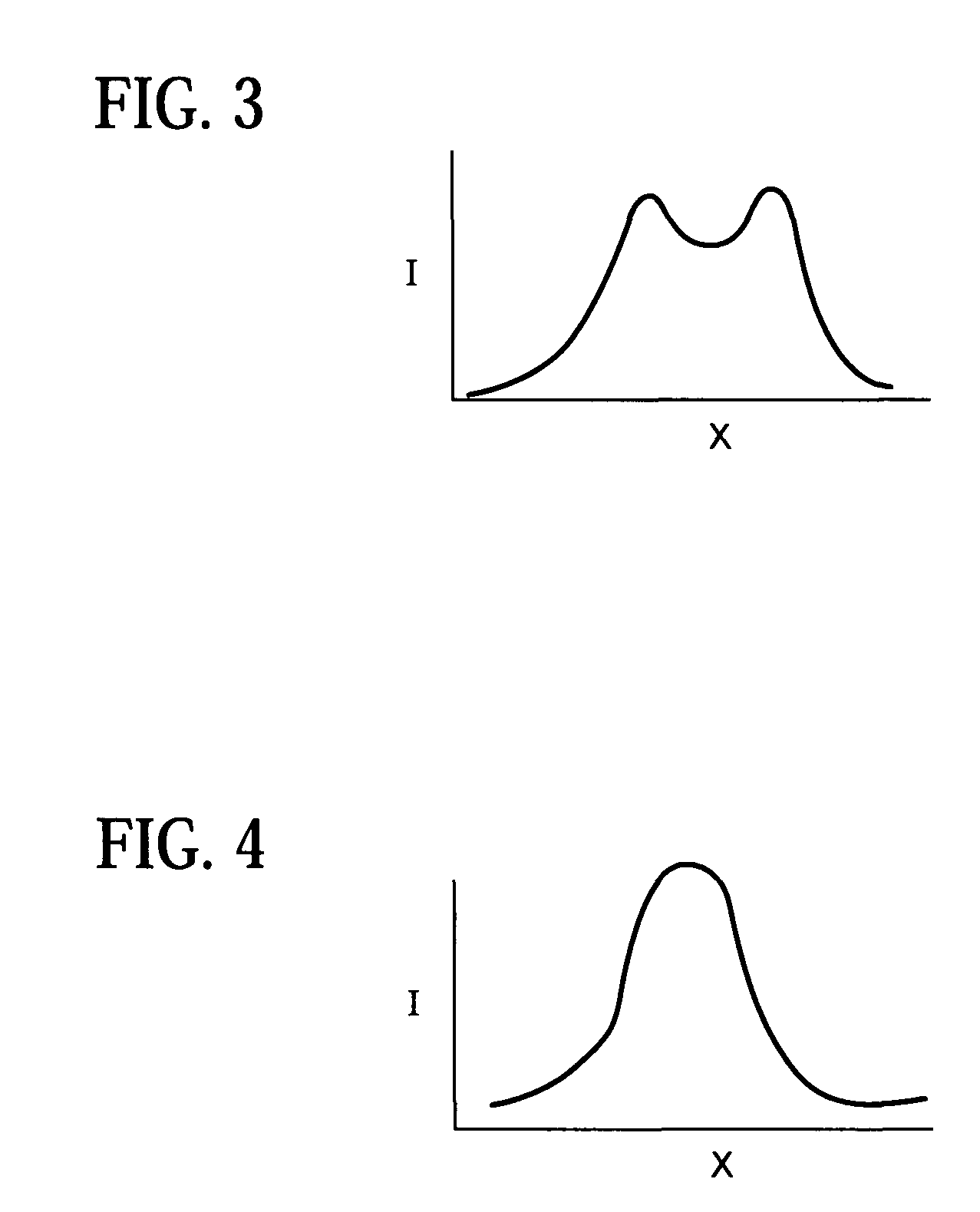

The present invention relates to a process for laser scoring of flat glass sheets. The process comprises manipulating a laser beam having a substantially Gaussian intensity profile to produce an elongated heating zone on the glass sheet to be scored, the elongated heating zone having a central portion with a lower temperature than a temperature of an outer portion of the heating zone. An initial crack is made in the glass sheet, the elongated heating zone is traversed across the glass sheet coincident with the initial crack, and the heated glass is thermally shocked by directing a cooled liquid against the heated glass, thus propagating the crack. The scored glass sheet may thereafter be broken by applying bending techniques as are known in the art.

Owner:CORNING INC

Method for forming heated glass sheets

Owner:GLASSTECH

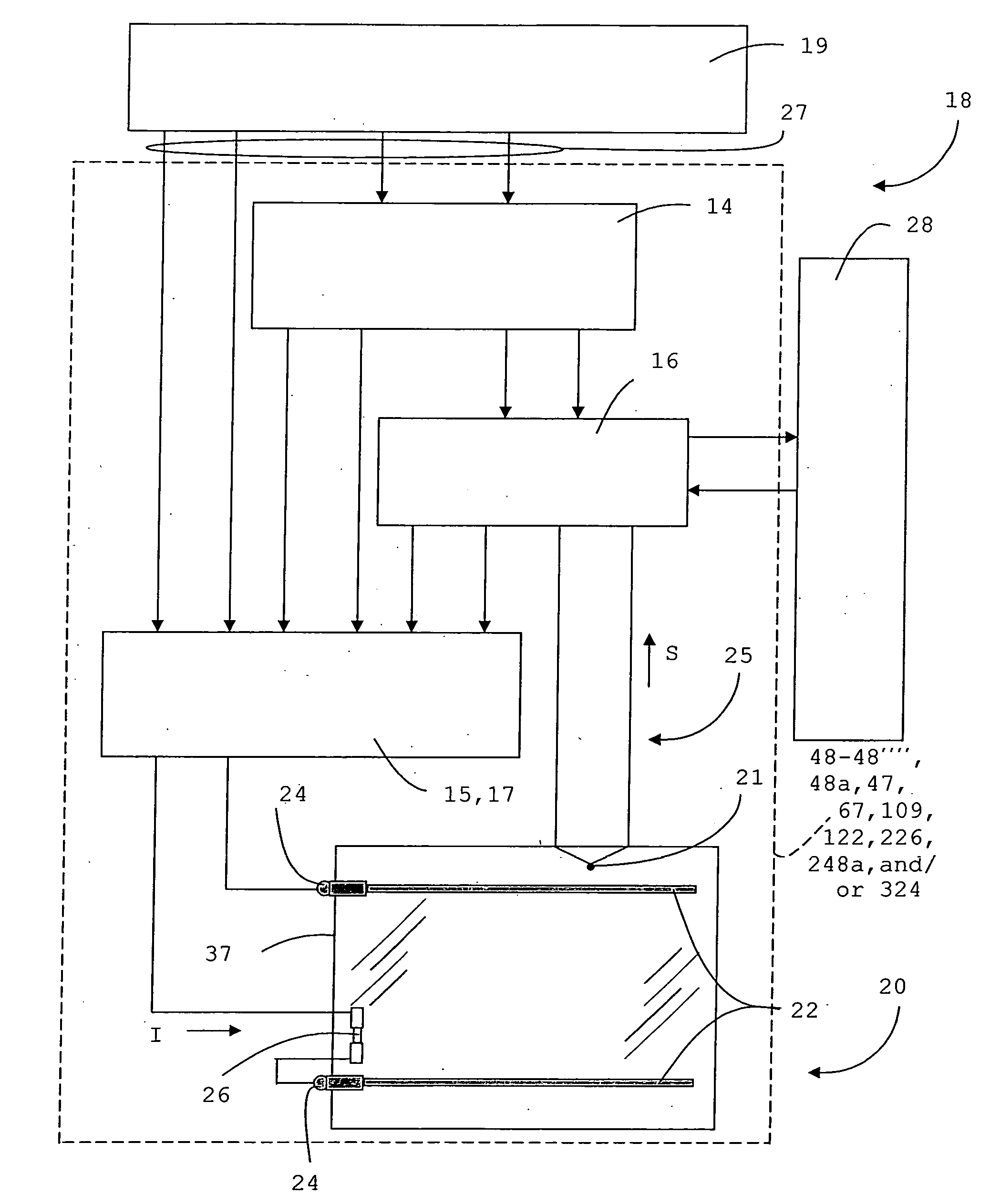

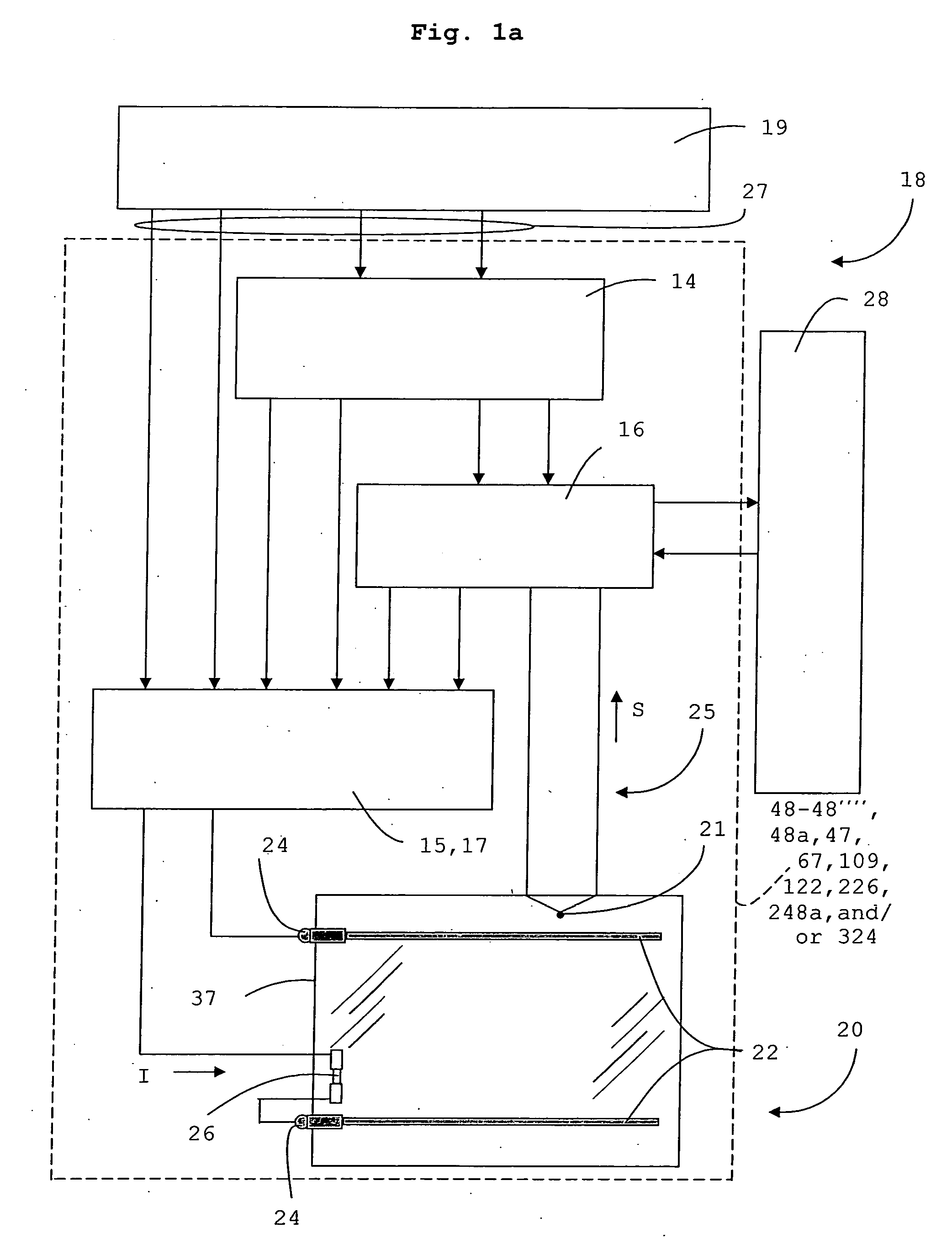

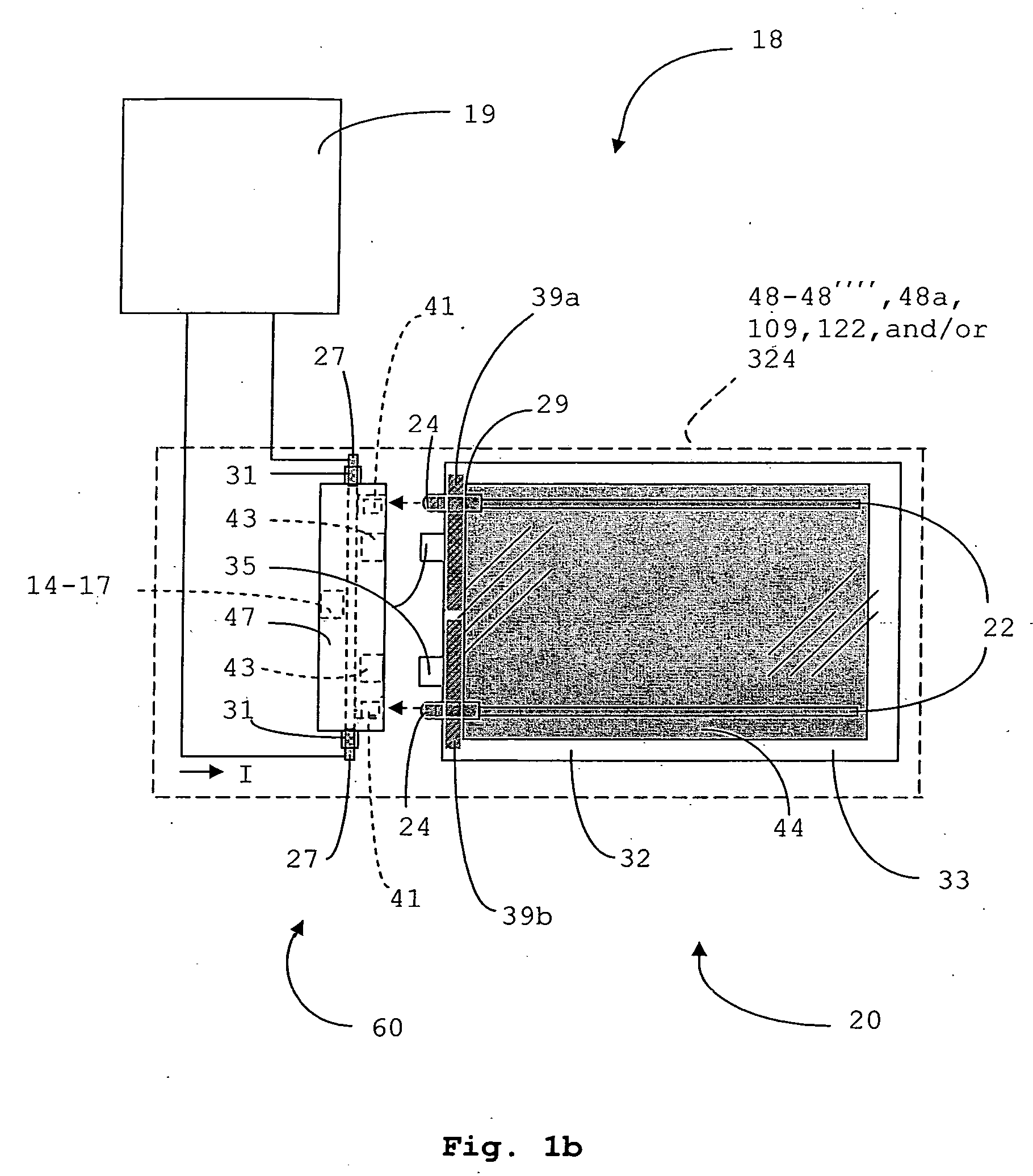

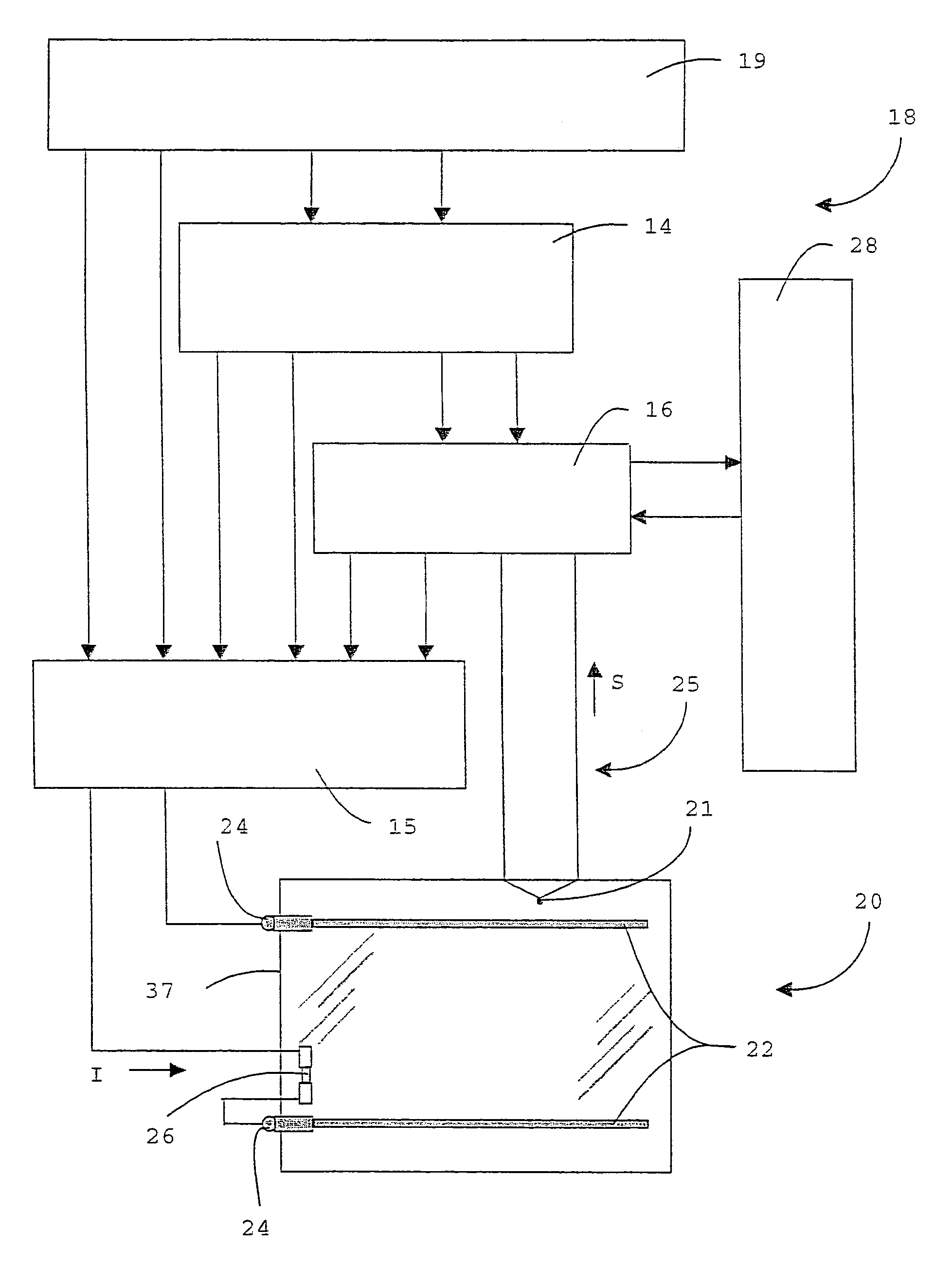

Heated glass panel frame with electronic controller and triac

The present invention places an electronic controller and / or a triac in a frame, a cover, a chase, or a mounting member of a heated glass panel assembly, where the panel has a conductive coating dispose on it. By placing the controller in the panel frame, the cover, the chase, or the mounting member, field wiring of the panel assembly is greatly reduced, wire lengths are standardized, production glazing, wiring, and pre-testing are facilitated, and installation time and complexity are minimized. By placing the triac in thermal contact with the panel frame, the cover, the chase, or the mounting member, the heat from the triac may be used to complement the heat supplied by the assembly.

Owner:ENGINEERED GLASS PRODS

Process and apparatus for scoring a brittle material

InactiveUS20060022008A1Easy to understandGlass severing apparatusWelding/soldering/cutting articlesFlat glassLaser beams

The present invention relates to a process for laser scoring of flat glass sheets. The process comprises manipulating a laser beam having a substantially Gaussian intensity profile to produce an elongated heating zone on the glass sheet to be scored, the elongated heating zone having a central portion with a lower temperature than a temperature of an outer portion of the heating zone. An initial crack is made in the glass sheet, the elongated heating zone is traversed across the glass sheet coincident with the initial crack, and the heated glass is thermally shocked by directing a cooled liquid against the heated glass, thus propagating the crack. The scored glass sheet may thereafter be broken by applying bending techniques as are known in the art.

Owner:CORNING INC

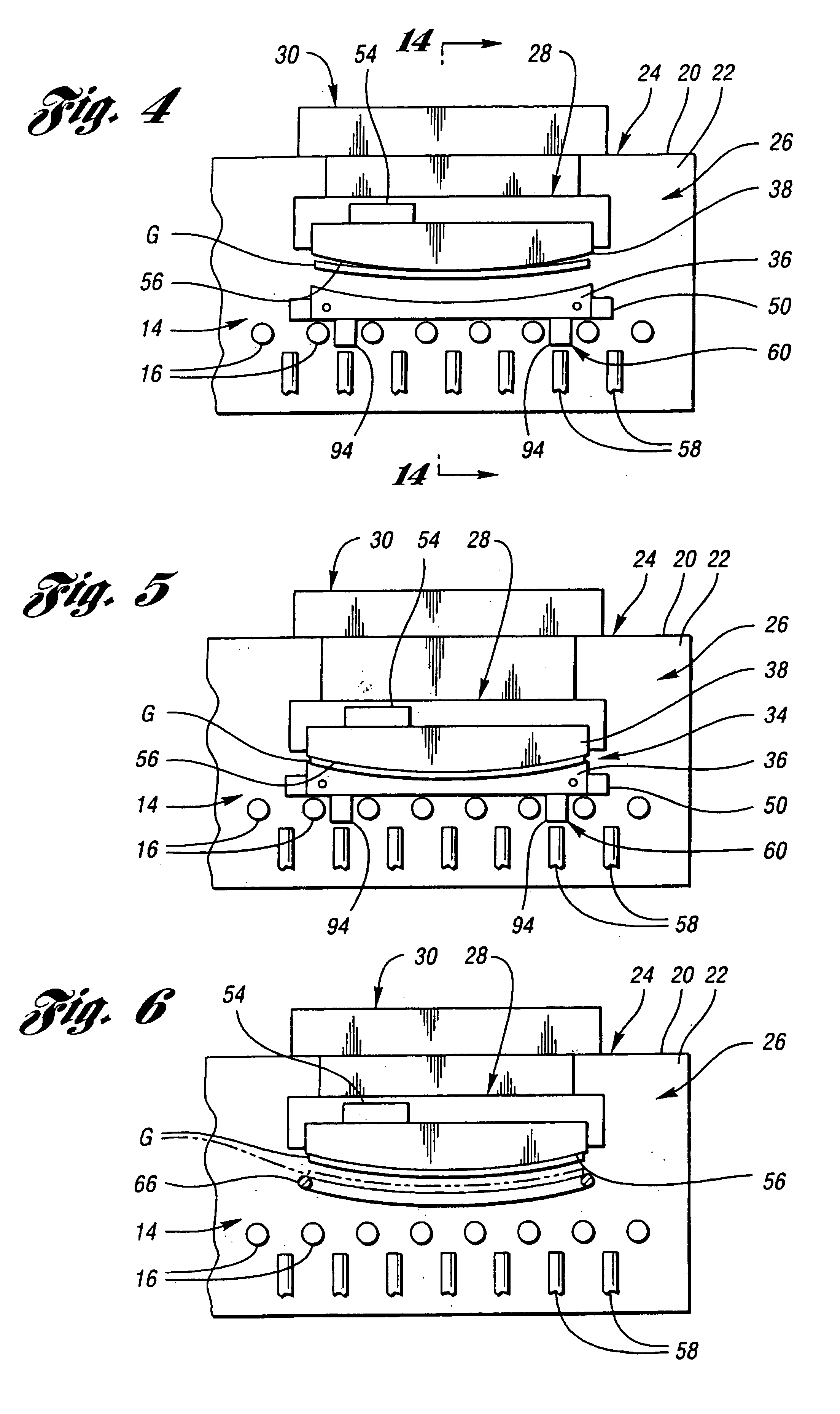

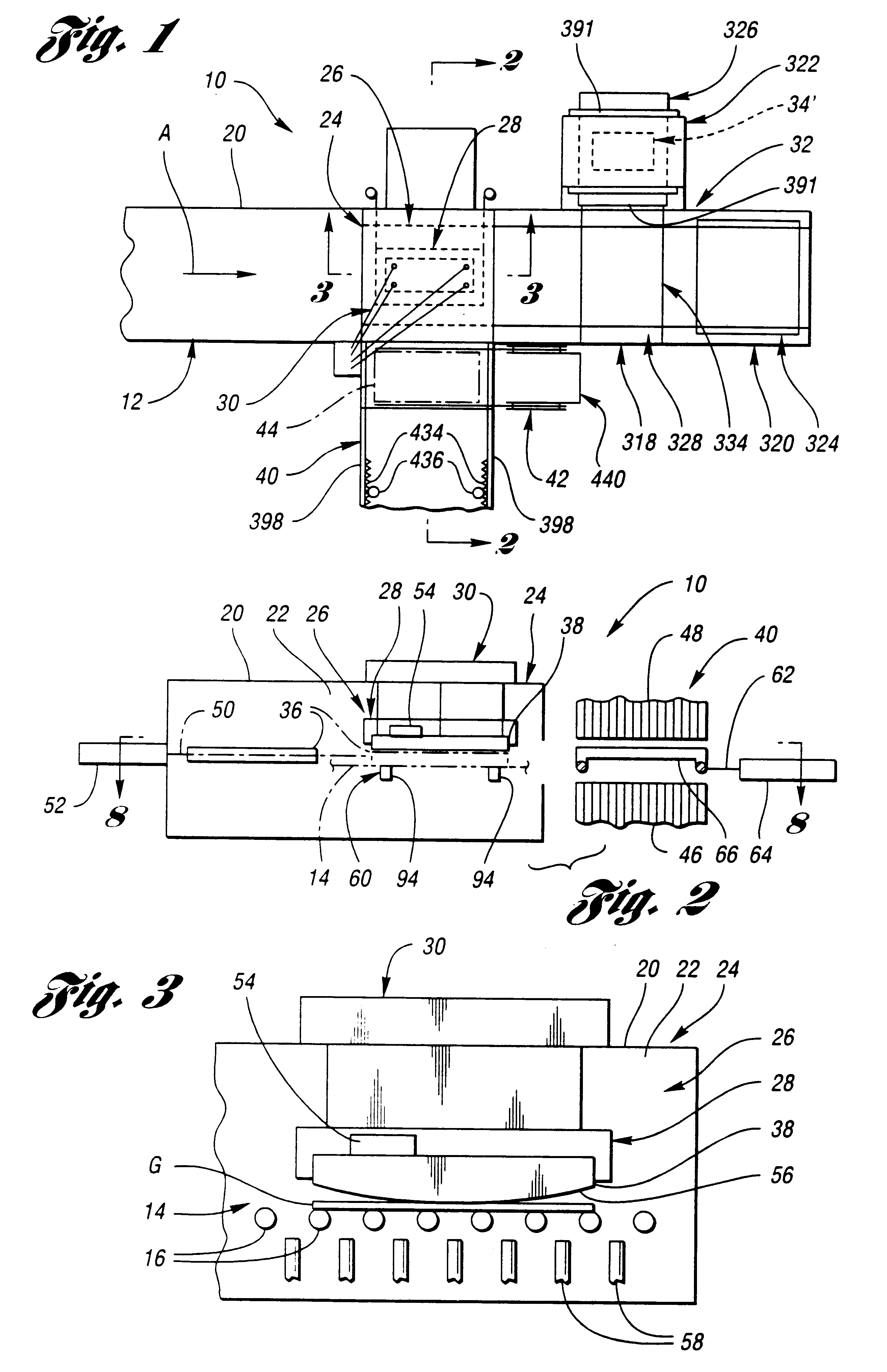

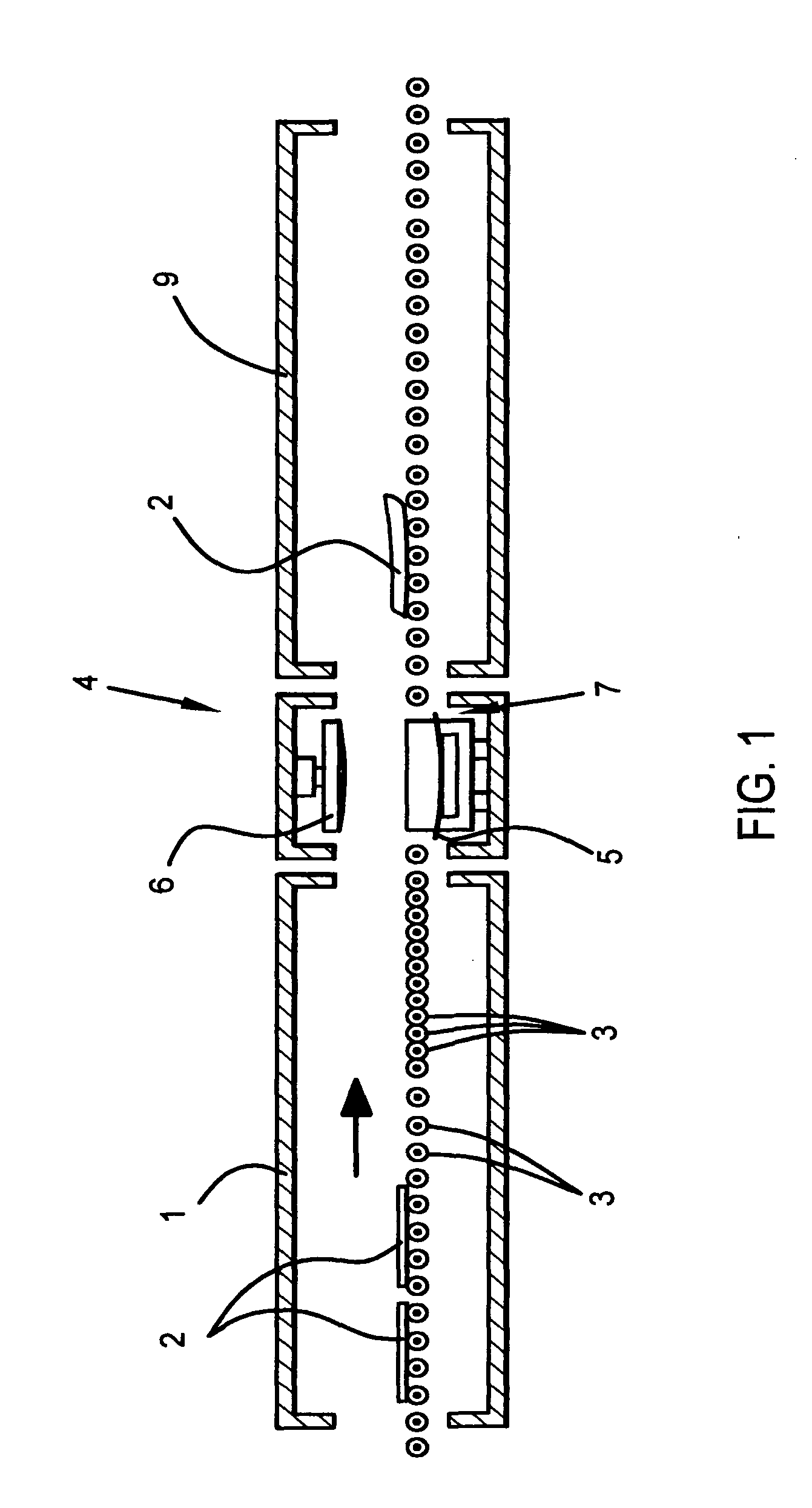

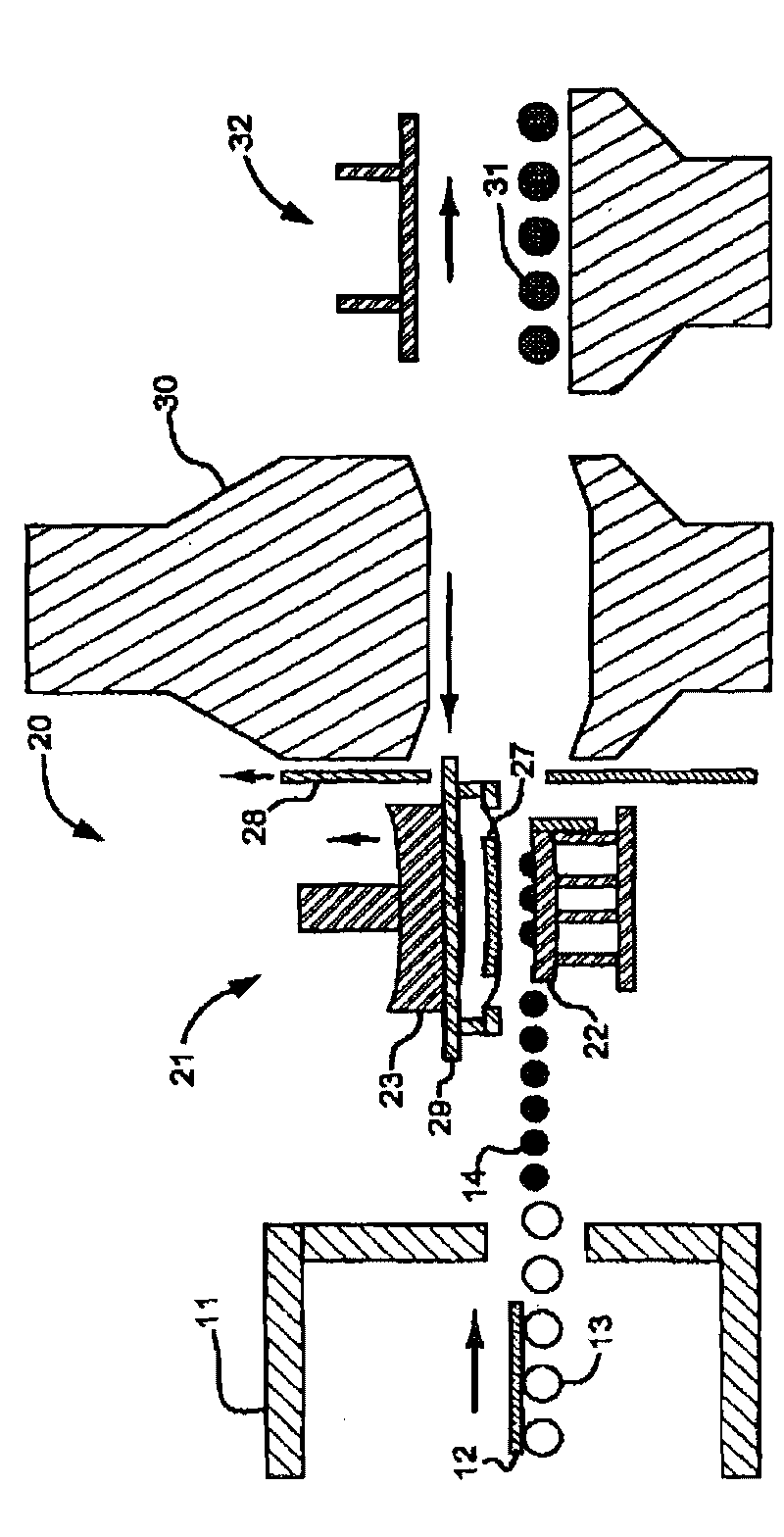

Apparatus for vacuum impulse forming of heated glass sheets

InactiveUS6227008B1Reduced optical distortionIncrease vacuumGripping headsGlass reforming apparatusGlass sheetMaterials science

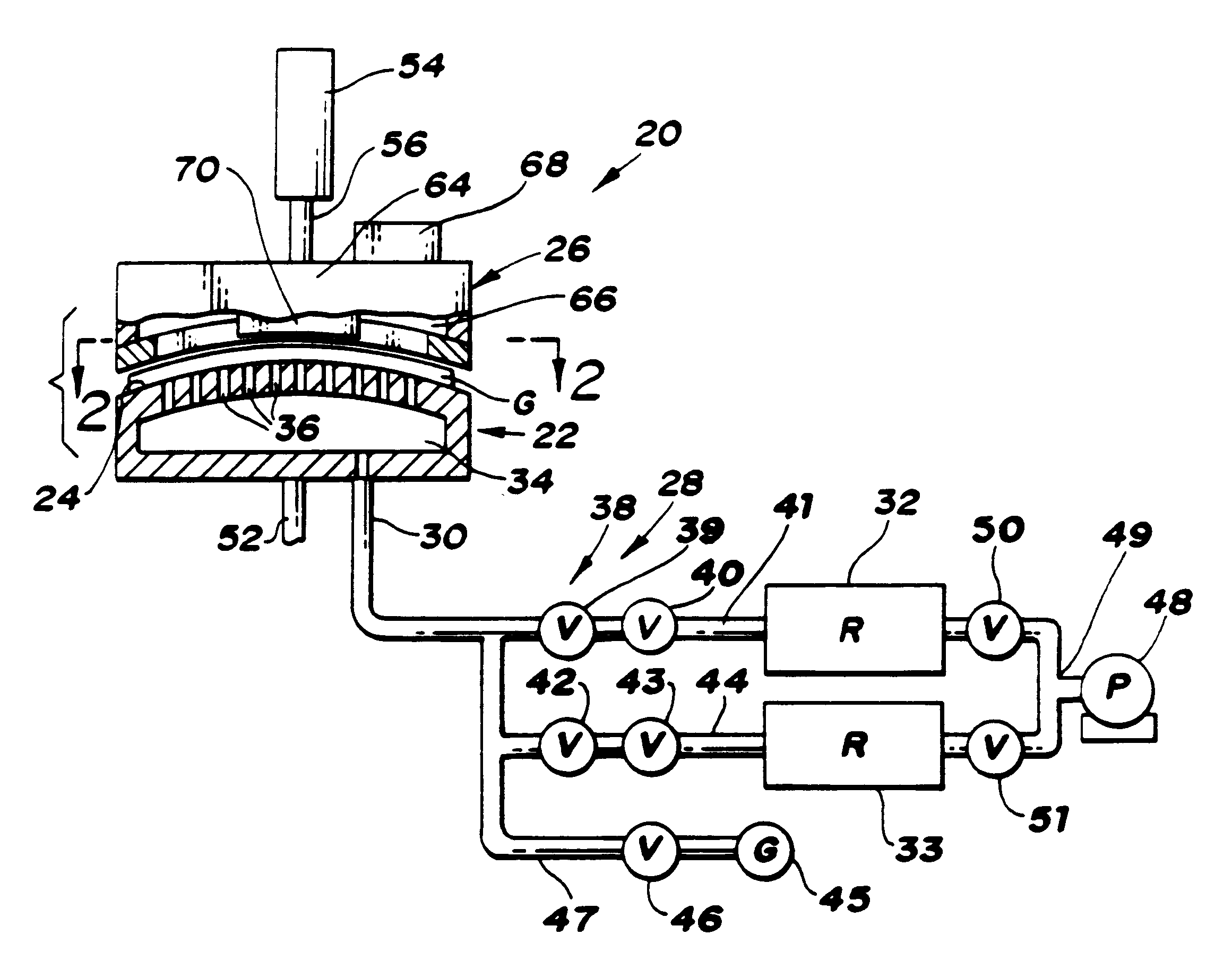

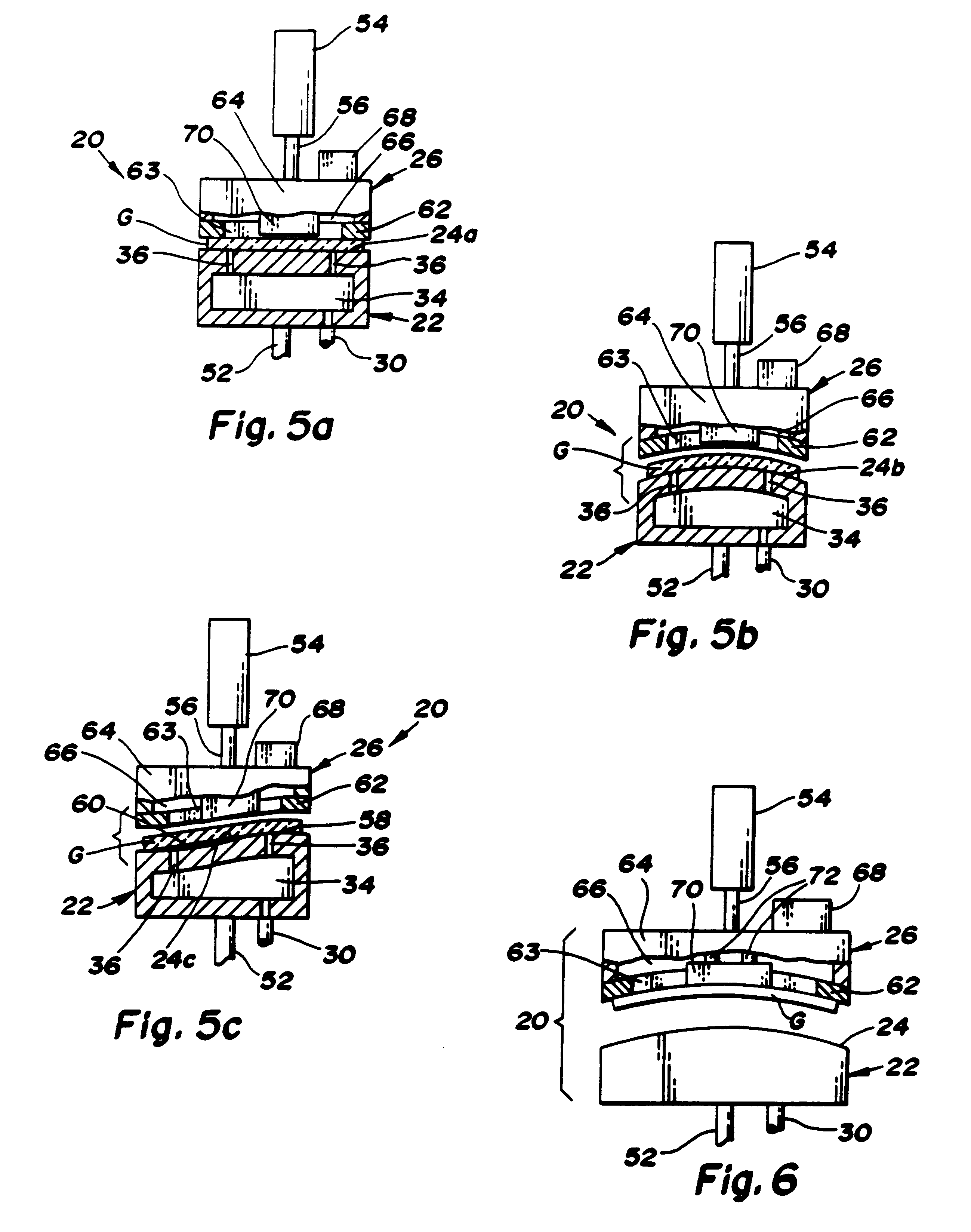

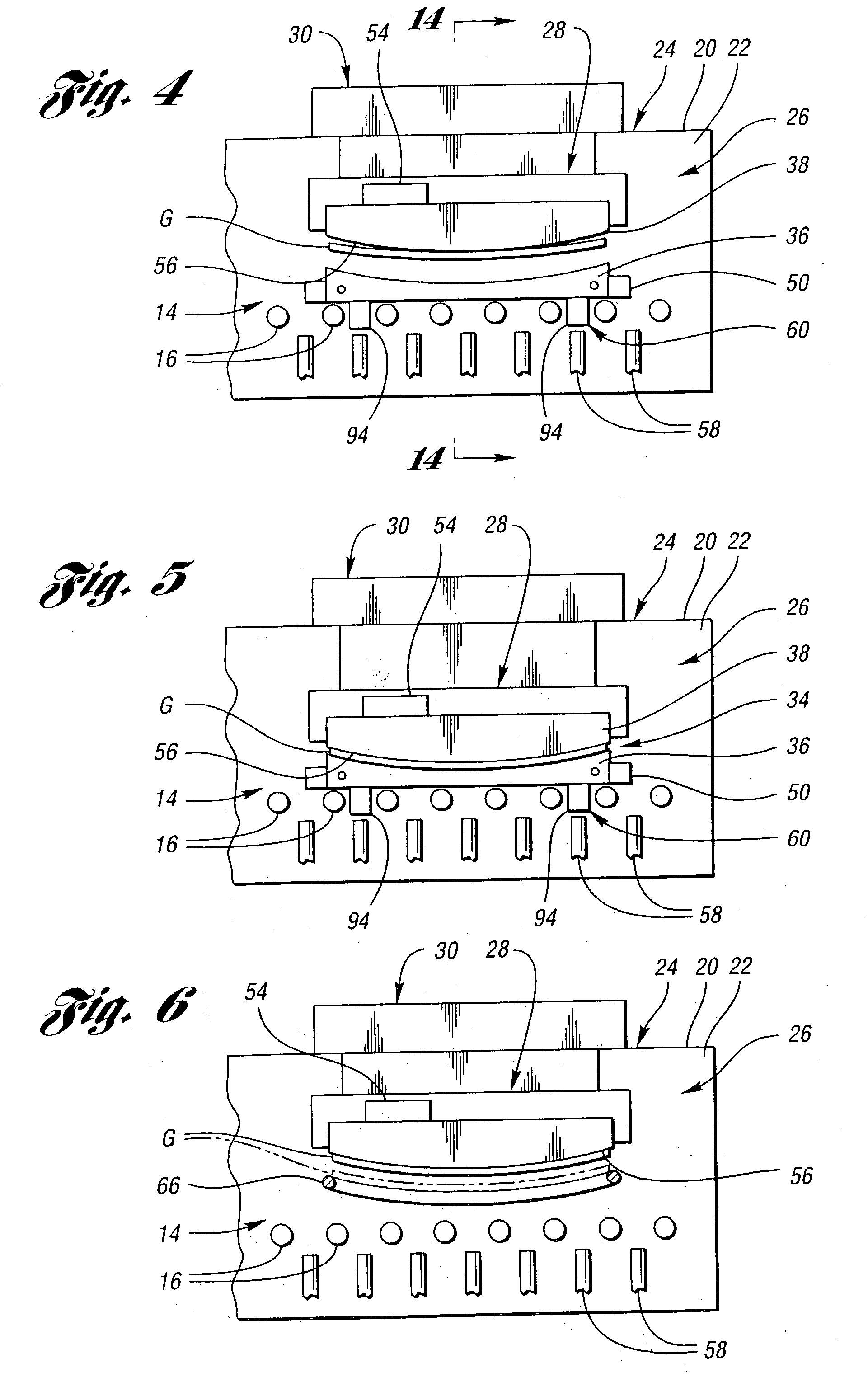

Apparatus (20,120) for forming a heated glass sheet G is disclosed as including a vacuum mold (22,22a,122,122a) having a full surface (24,24a,124,124a) against which a peripheral mold (26,26a,126,126a) presses the glass sheet periphery and with which at least one vacuum reservoir (32,33) is communicated within the interior of the sealed glass sheet periphery to form the glass sheet to the shape of the vacuum mold surface. Valving (38) of a vacuum system (28) is preferably operable to provide the vacuum impulse in two stages with an initial limited extent of vacuum and a subsequent greater extent of vacuum by communication first with one vacuum reservoir (32) and subsequently with another vacuum reservoir (33). Different embodiments of the vacuum mold have the vacuum mold surface facing upwardly and downwardly with convex and concave shapes. Glass sheet shapes including straight line elements such as cylindrical and conical bends as well as shapes including curvatures in transverse directions and inverse curvatures can be effectively provided by this vacuum impulse forming.

Owner:GLASSTECH

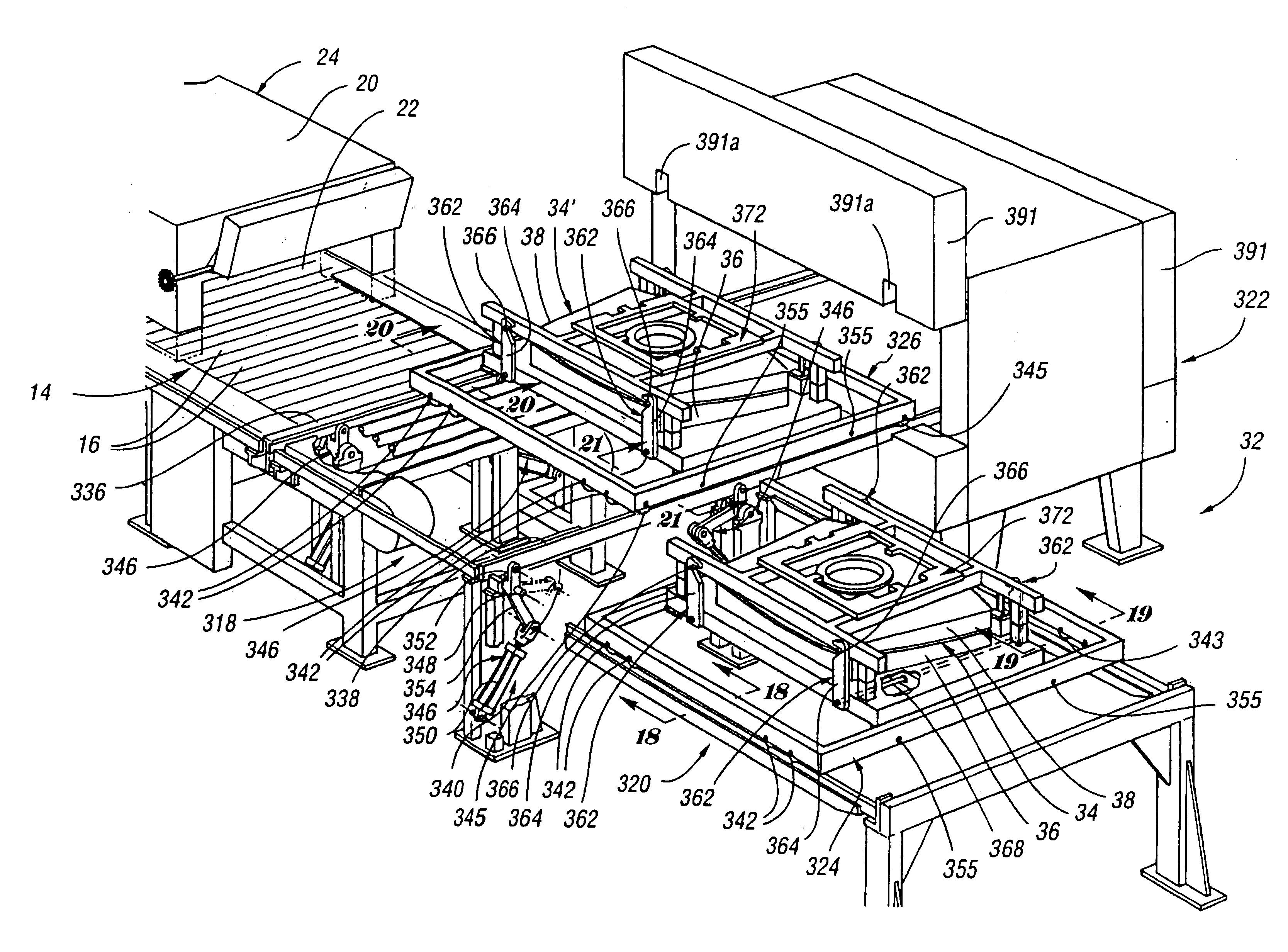

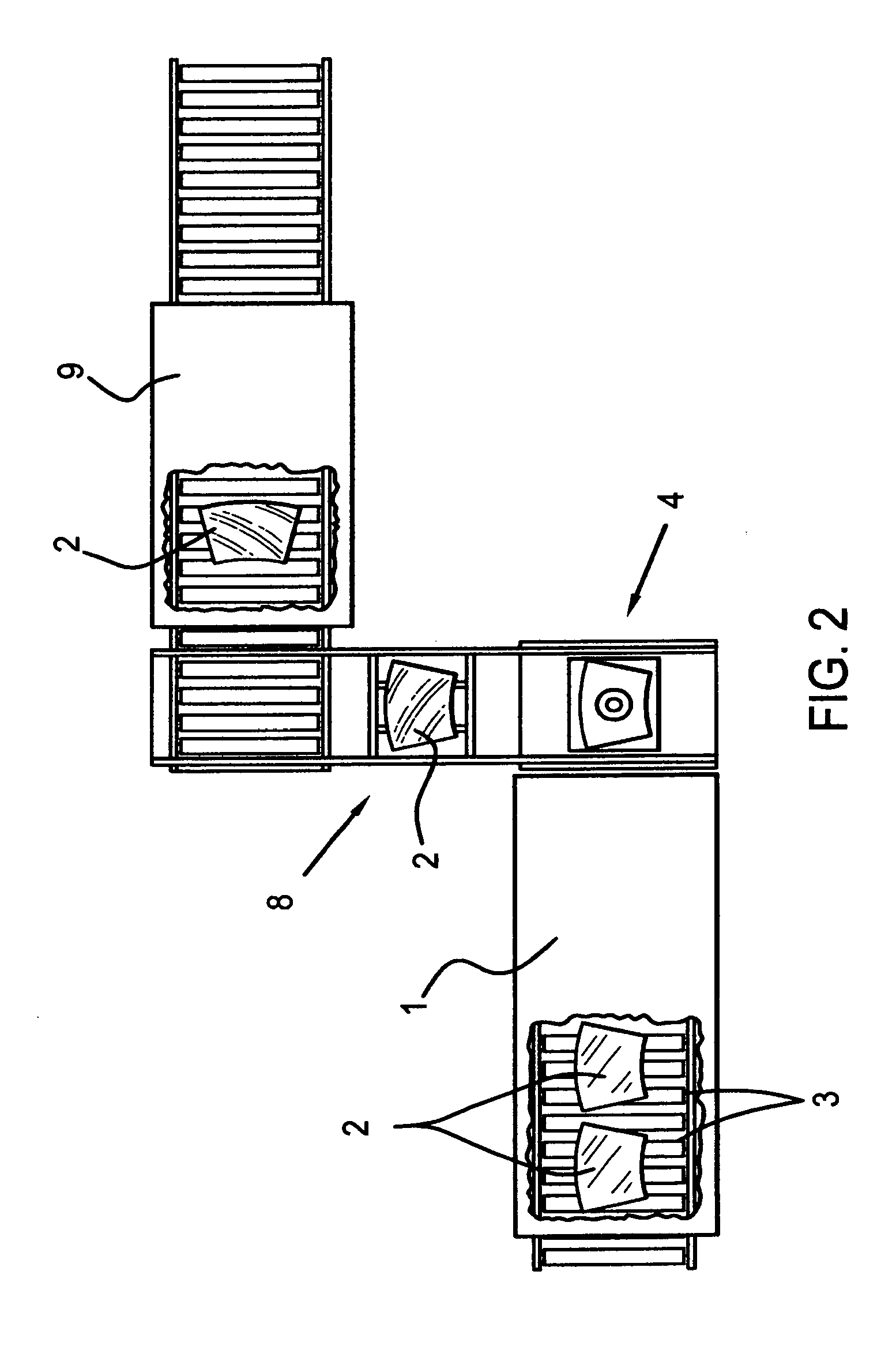

Method for forming heated glass sheets

InactiveUS20030106340A1Blowing machine gearingsGlass drawing apparatusMechanical engineeringGlass sheet

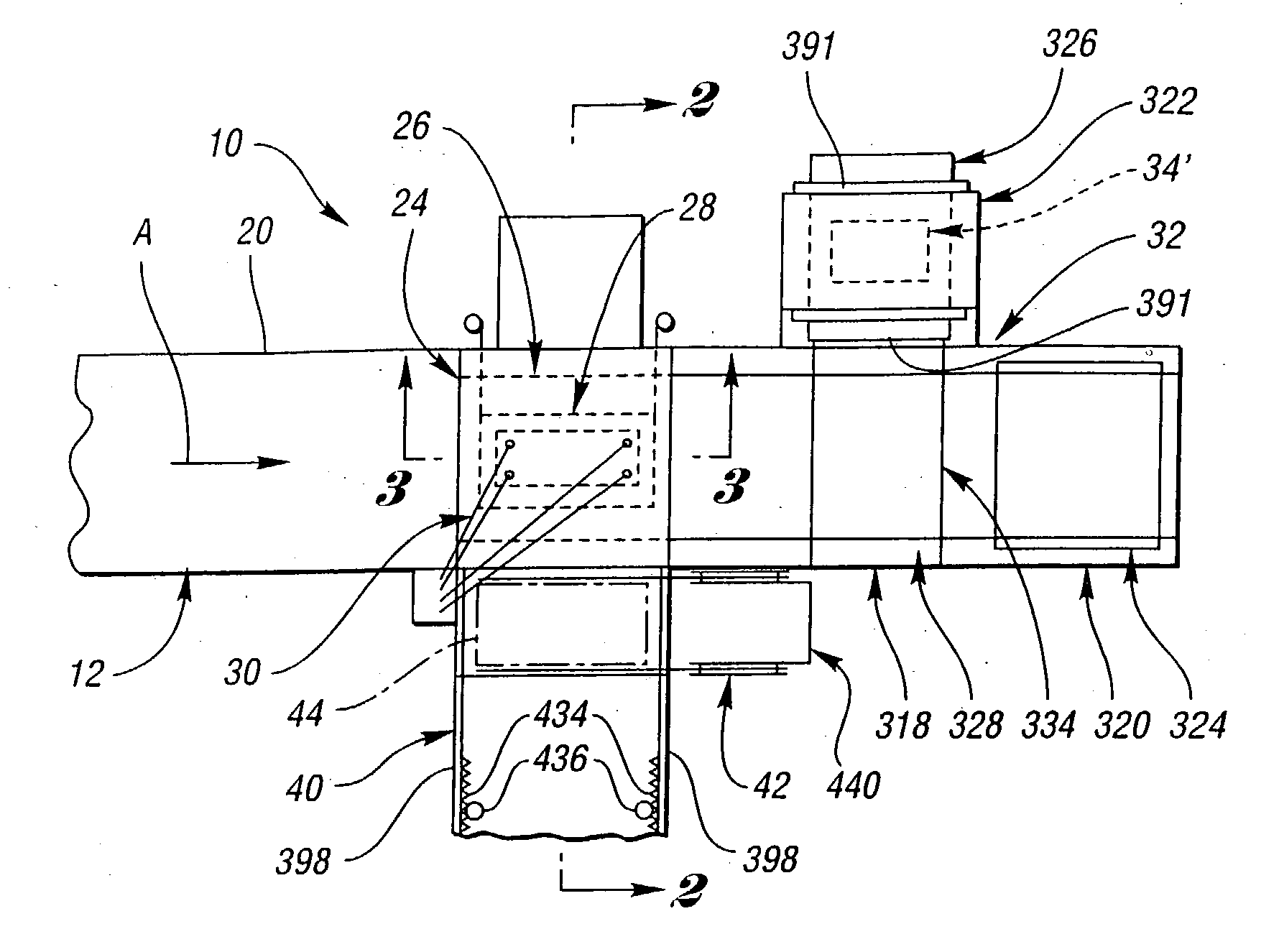

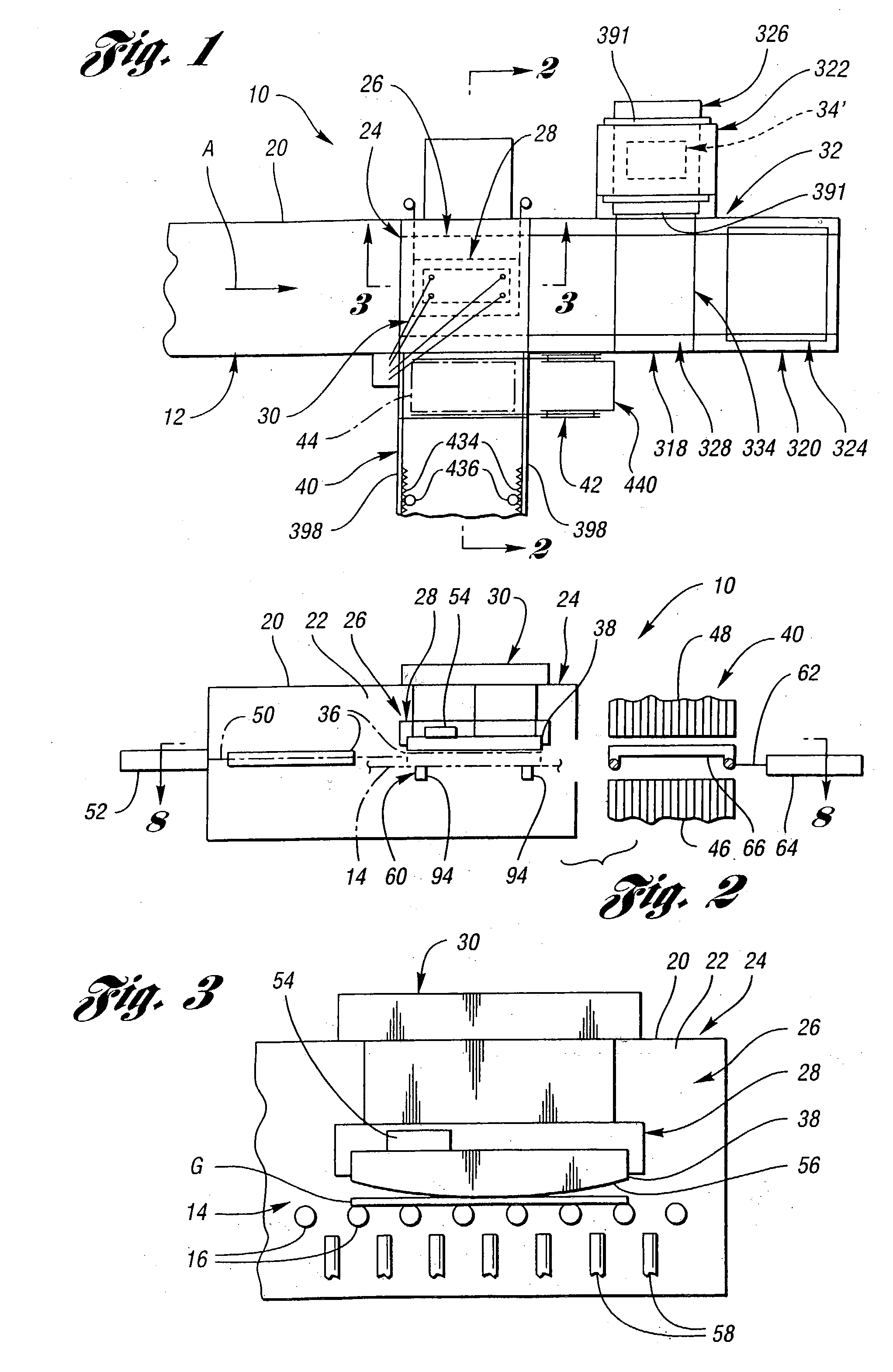

Apparatus (26) and a method for forming heated glass sheets in a heated chamber (22) of a housing (20) includes an upper mold support assembly (28) for supporting an upper mold (38) within the heated chamber for cyclical vertical movement between upper and lower positions. A lower mold shuttle (50) supports a lower mold (36) for movement between an idle position horizontally spaced from the upper mold and a use position below the lower mold. The apparatus also includes a lower mold support assembly (60) to which the lower mold is transferred from the lower mold shuttle (50) to provide support thereof while permitting horizontal alignment with the upper mold upon each cycle of downward movement to form a heated glass sheet between the molds. The lower mold shuttle (50) is supported by vertically movable rollers (70) to provide the transfer between the lower mold shuttle and the lower mold support assembly (60). A quench station (40) includes a quench shuttle (62) that moves a quench ring (66) to receive the formed glass sheet from the upper mold (38) and to then move the formed glass sheet between lower and upper quench modules (46,48) of the quench station for quenching.

Owner:GLASSTECH

Method of preparing thermoplastics-continuous fiber hybrid composite

ActiveUS8470114B2Good flexibilityKnitting simpleSynthetic resin layered productsLaminationThermoplasticFiber

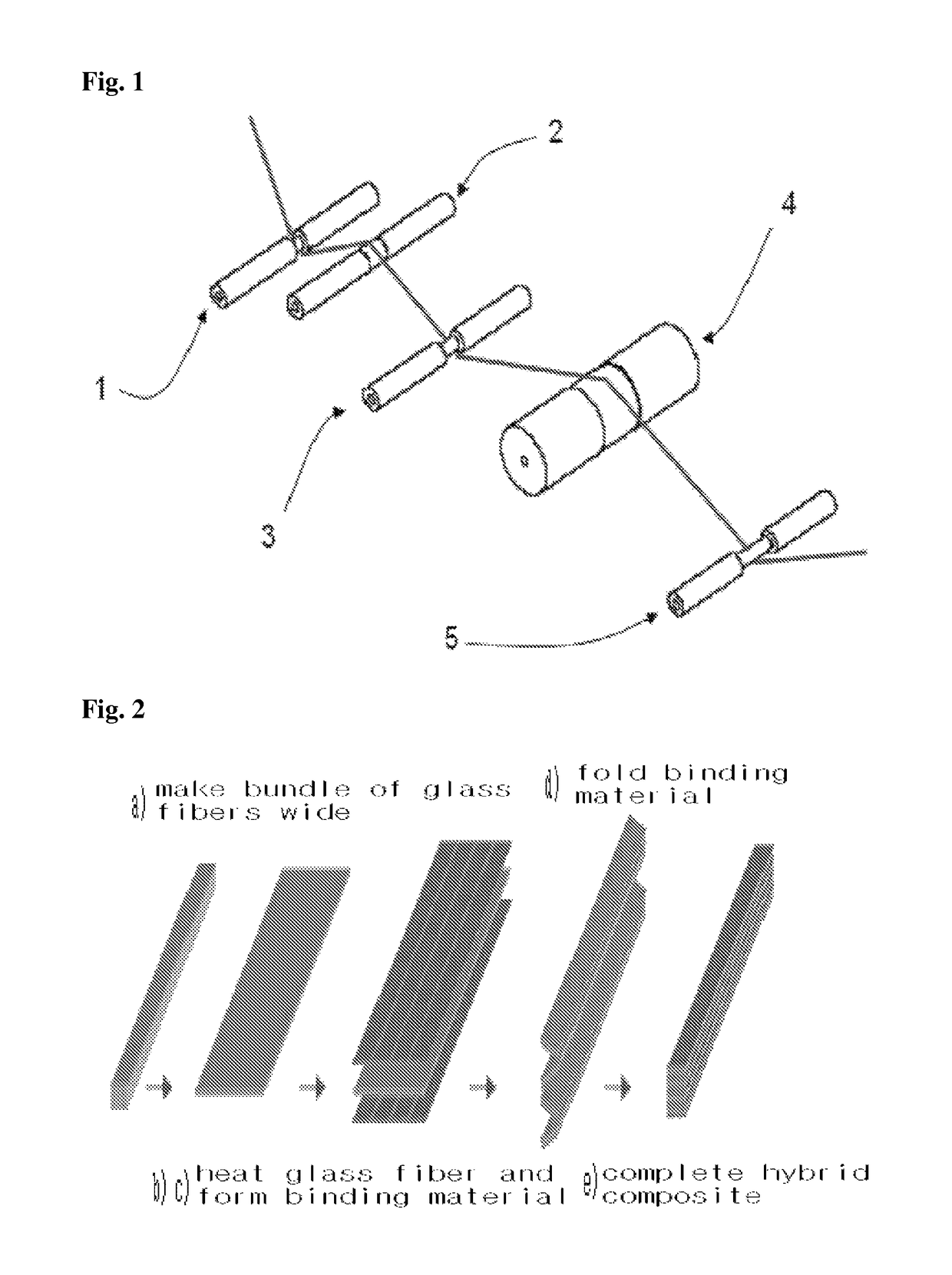

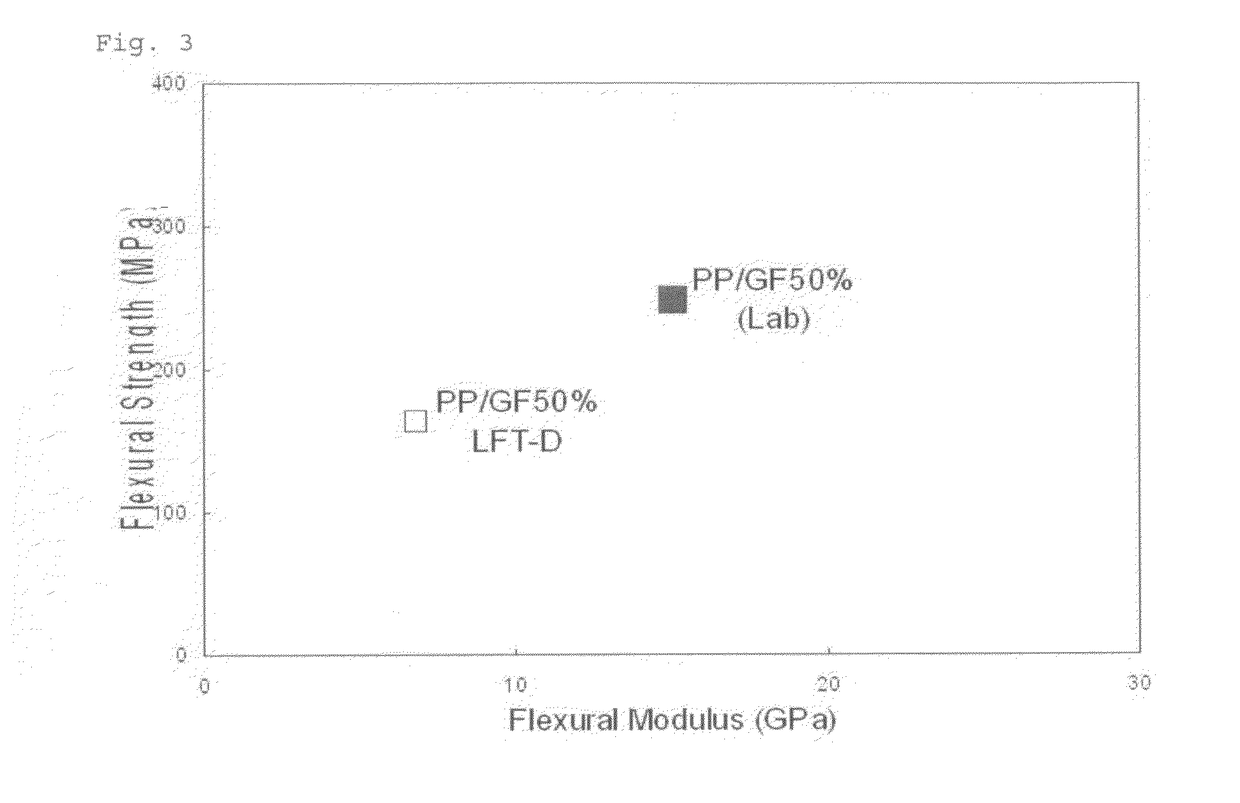

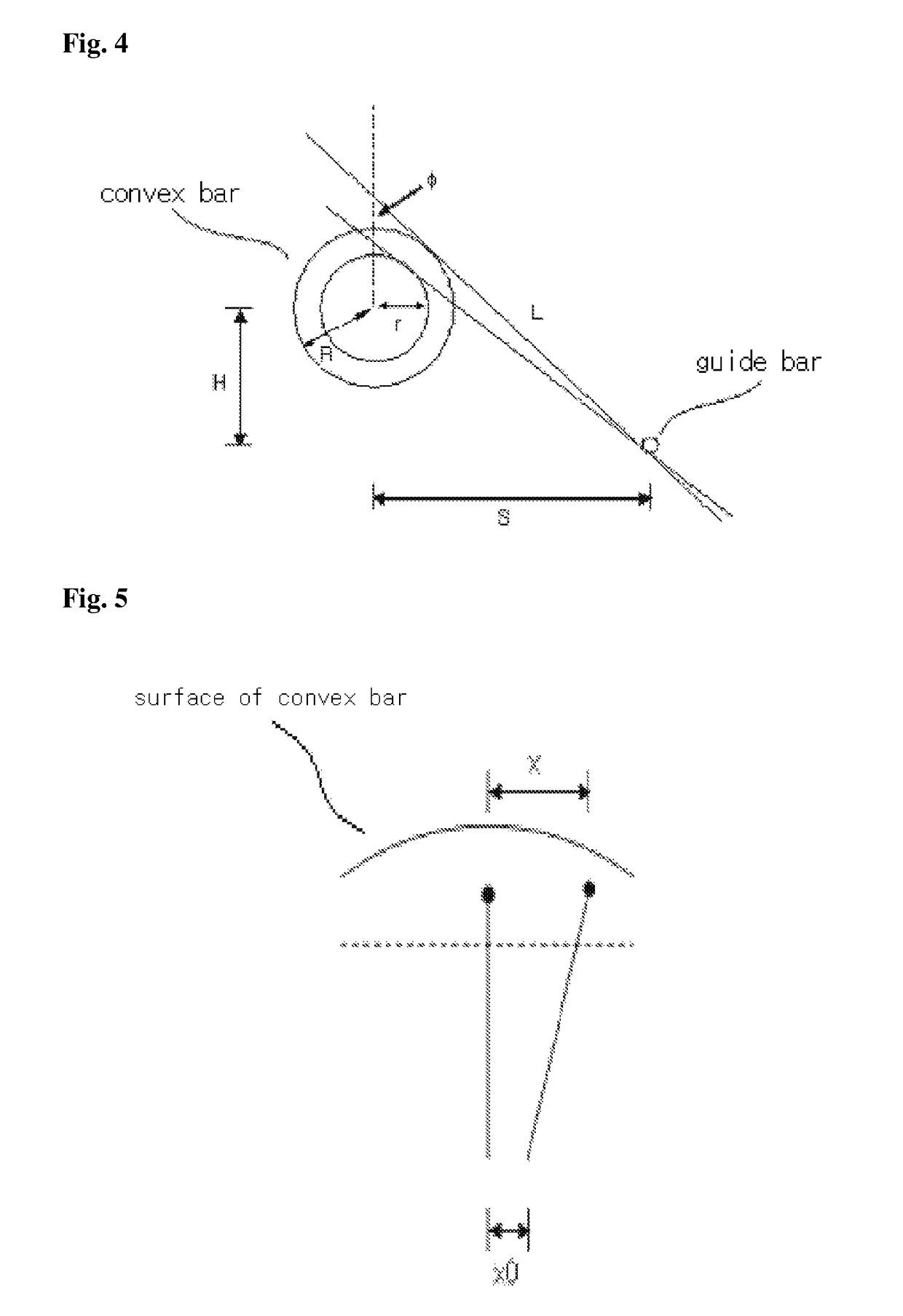

Provided is a method of preparing thermoplastics-continuous fiber hybrid composite, which is easily woven and has excellent uniformity and impregnation at the time of hot melt impregnation after the weaving, including: a) widely and uniformly stretching a bundle of glass fibers; b) heating the stretched glass fibers; c) preparing a thermoplastics-continuous fiber bonding material by binding the heated glass fiber with thermoplastics; d) preparing a multi-layered thermoplastics-continuous fiber bonding material by folding the bonding material in a shape of zigzag; and e) pressing the multi-layered thermoplastics-continuous fiber bonding material.

Owner:LARGE +1

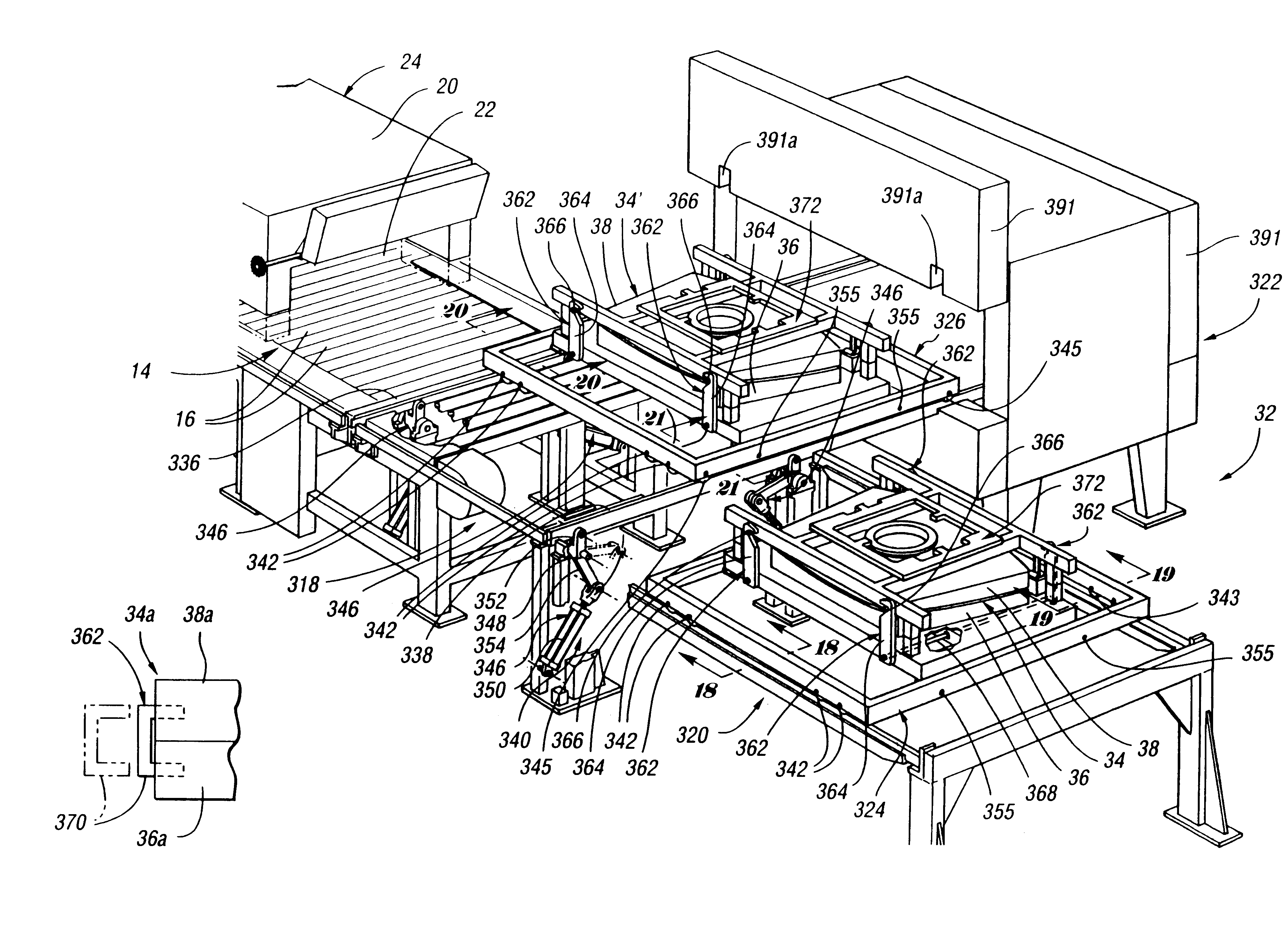

Method for installing mold assembly

InactiveUS6173587B1Simple methodBlowing machine gearingsGlass transportation apparatusGlass sheetMaterials science

A mold assembly (34) for cyclically forming heated glass sheets includes a lower mold (36) having an upwardly oriented mold face (356) and an upper mold face having a downwardly oriented mold face (56) that opposes the upwardly oriented mold face of the lower mold to form a heated glass sheet during movement of the molds toward each other. Alignment guides (122,124) align the molds (36,38) with each other as necessary during movement of the molds toward each other. Detachable connectors (362) detachably connect the molds to each other for installation and are disconnectable to permit the molds to be used for glass sheet forming. In one embodiment, the detachable connectors (362) are latches that include a latch member (364) and a keeper (366), and in another embodiment the detachable connectors are retainers (370) engageable and disengageable from the molds to provide their detachable securement. The upper mold (38) includes a support plate (372) having mounting portions (374,376) and mounting guide portions (378,380,382) for providing alignment during mounting.

Owner:GLASSTECH

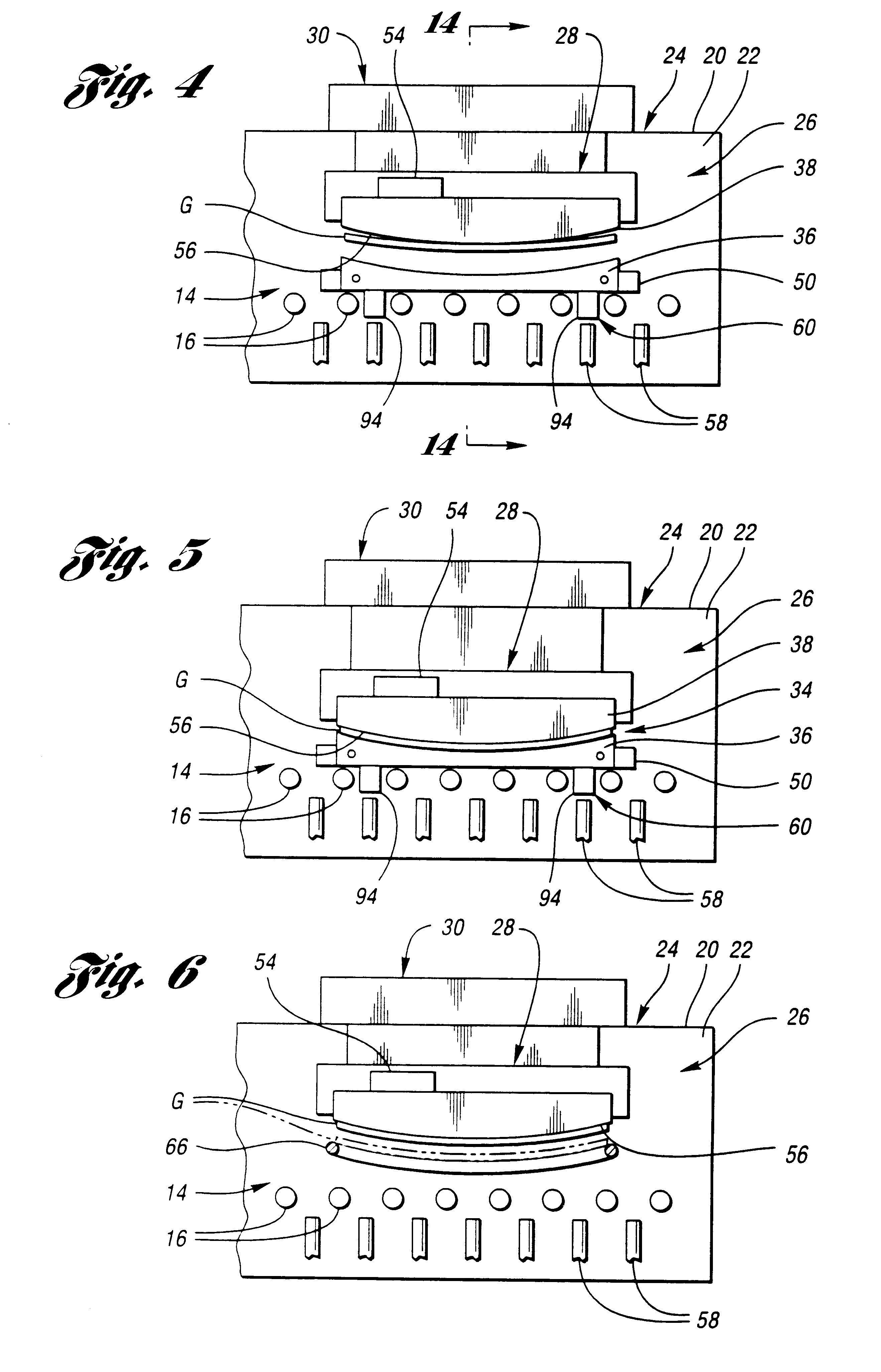

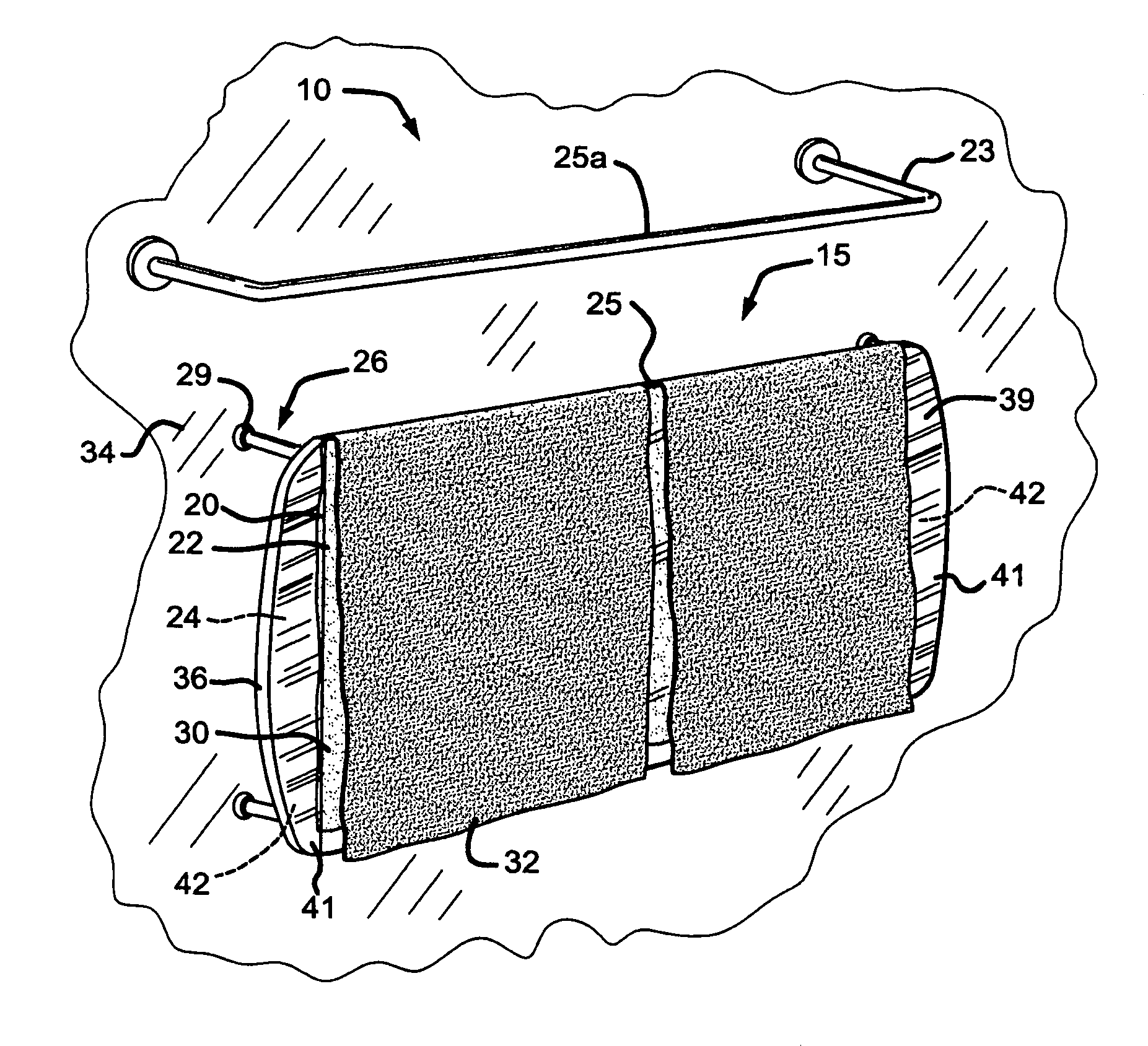

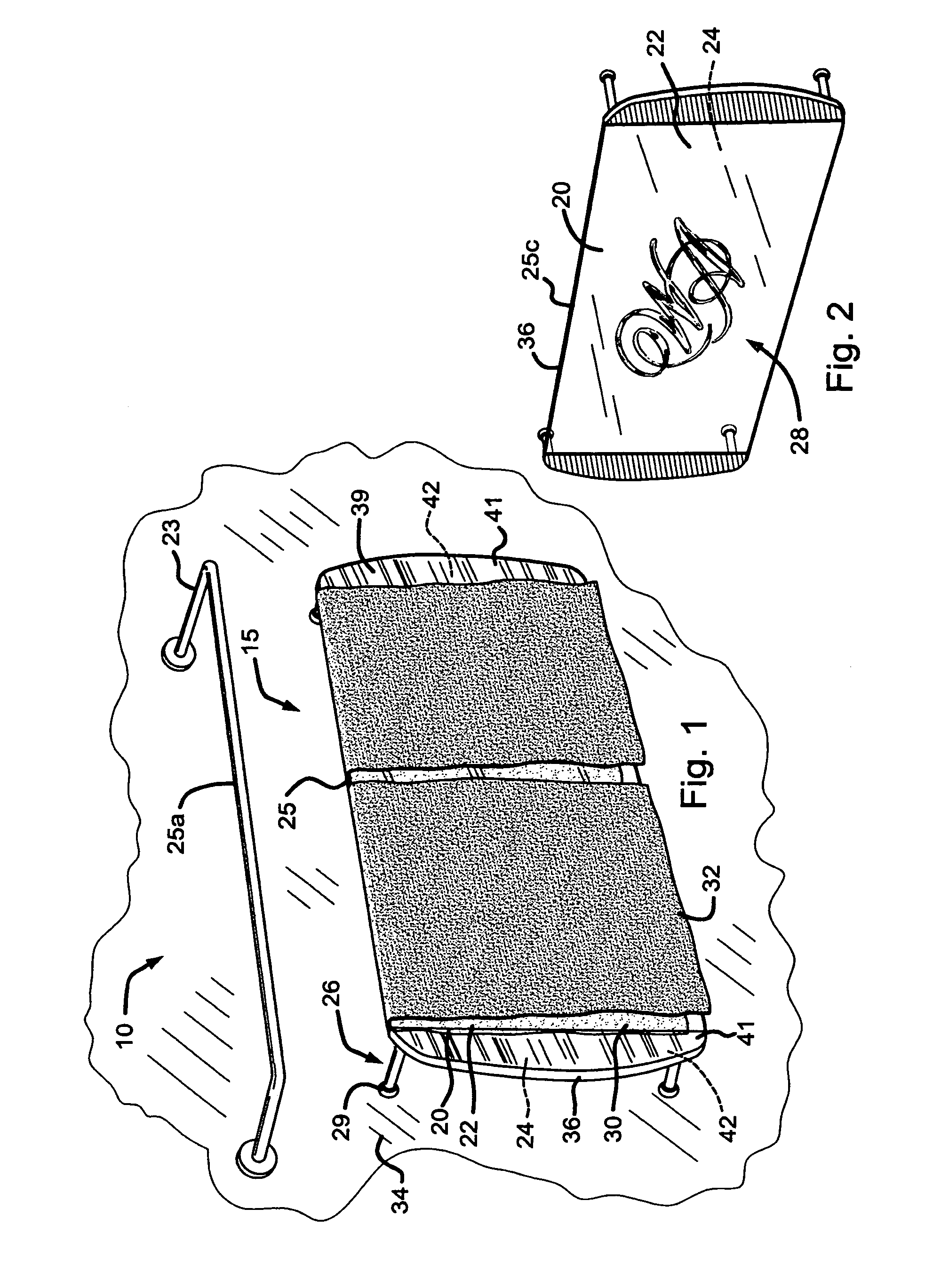

Method and apparatus for a cloth heater

A cloth heater and method for using the heater are provided. The heater utilizes a horizontally disposed surface, a heated glass panel, and support members. The horizontally disposed surface may comprise the top edge or surface of the heated glass panel, or a surface on a separate rack that is above and vertically inline with the top edge of the heated glass panel. The heated glass panel also has two opposing major surfaces. The support members physically support the heated glass panel and have electrical leads that communicate electrical power to the heated glass panel, thus heating the heated glass panel. When a cloth is placed across the horizontally disposed surface, the horizontally disposed surface supports the cloth, and the cloth makes contact with the two opposing major surfaces of the heated glass panel, thus heating the cloth at both opposing major surfaces.

Owner:ENGINEERED GLASS PRODS

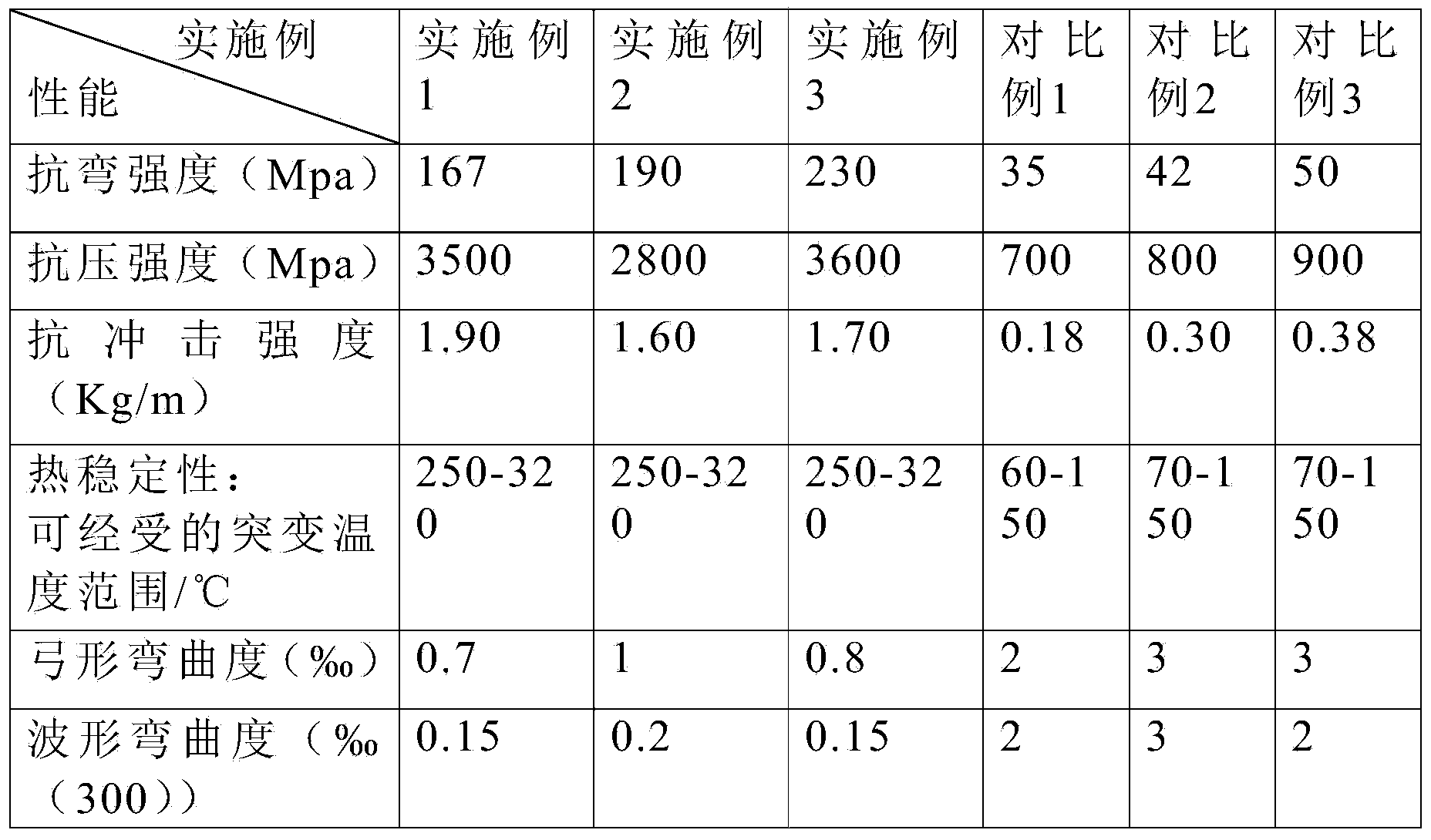

Production process for flat tempered glass

InactiveCN104355530AControl deformationReduce distortionGlass tempering apparatusHeating timeWater cooling

The invention relates to a production process for flat tempered glass, and belongs to the technical field of building materials. The production process comprises the following steps: cutting, edging and cleaning glass; placing the cleaned glass on a roller bed, and conveying the glass into a convection tempering furnace for heating treatment by virtue of the roller bed, wherein heating temperature in a first interval is 450 to 500 DEG C, heating time in the first interval is 100 to 250 seconds, heating temperature in a second interval is 680 to 700 DEG C, and heating time in the second interval is 200 to 300 seconds; discharging the heated glass out of the furnace, feeding the glass into a flat air grid, quenching the glass for 80 to 120 seconds under the air pressure of 0.1 to 4.8KPa by virtue of upper and lower air grids in the flat air grid until the temperature of the surface of the glass is 240 to 260 DEG C, and then quenching the glass to normal temperature to obtain a flat tempered glass finished product. The production process for the flat tempered glass is simple, easy, time-saving and energy-saving, the safety of the tempered glass is remarkably improved, and the bending strength and impact strength of the tempered glass are also remarkably strengthened.

Owner:NINGBO HEXIN GLASS TECH

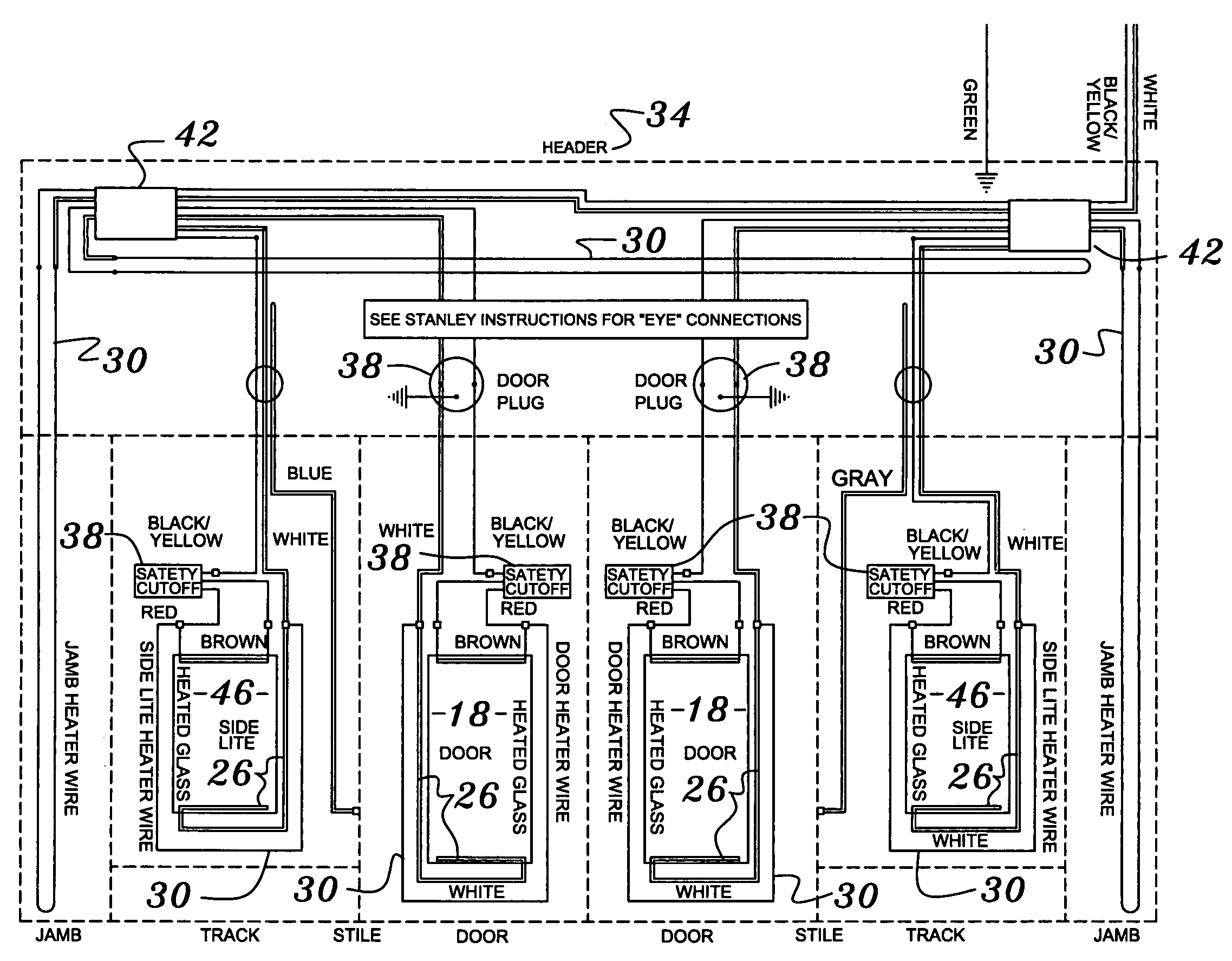

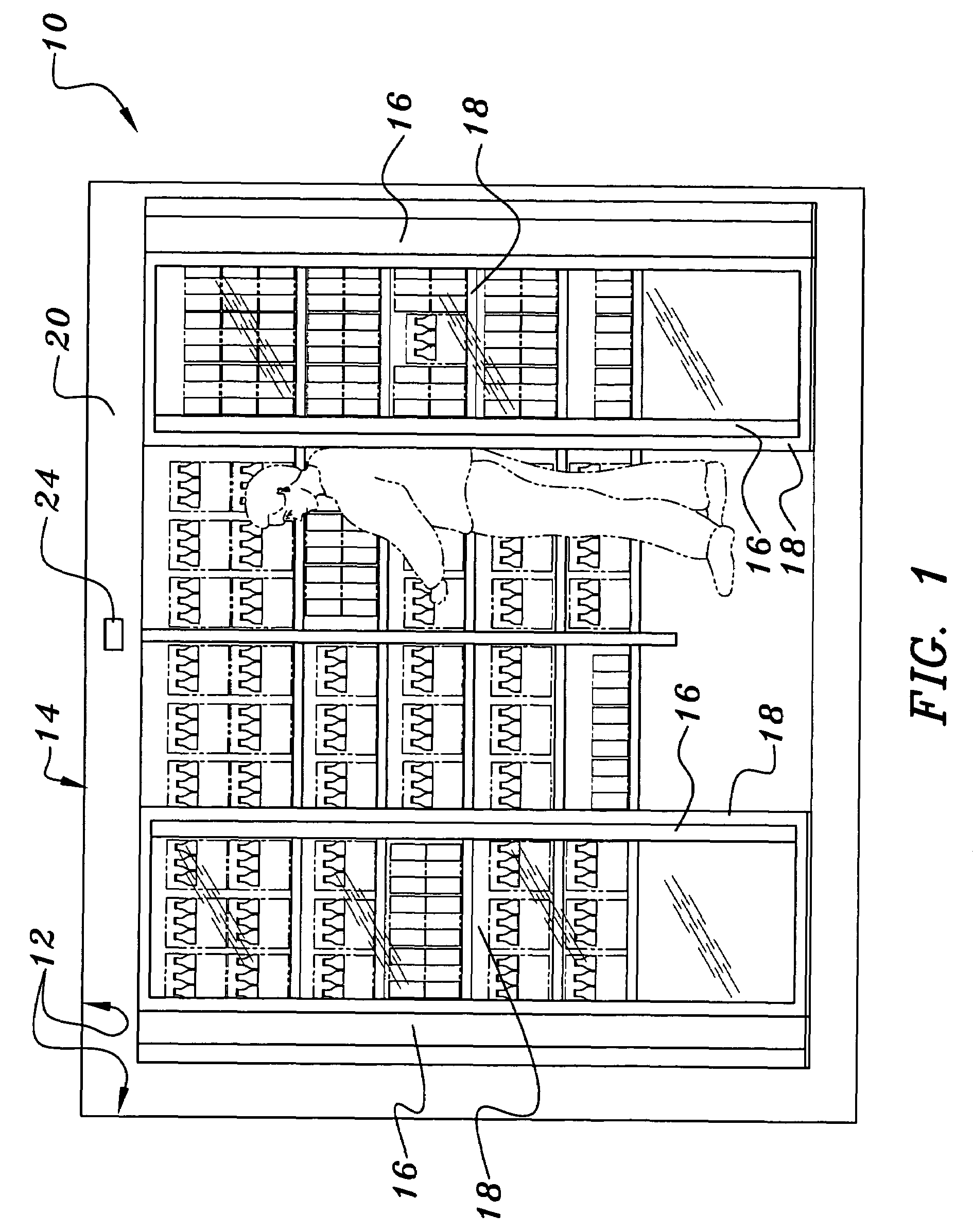

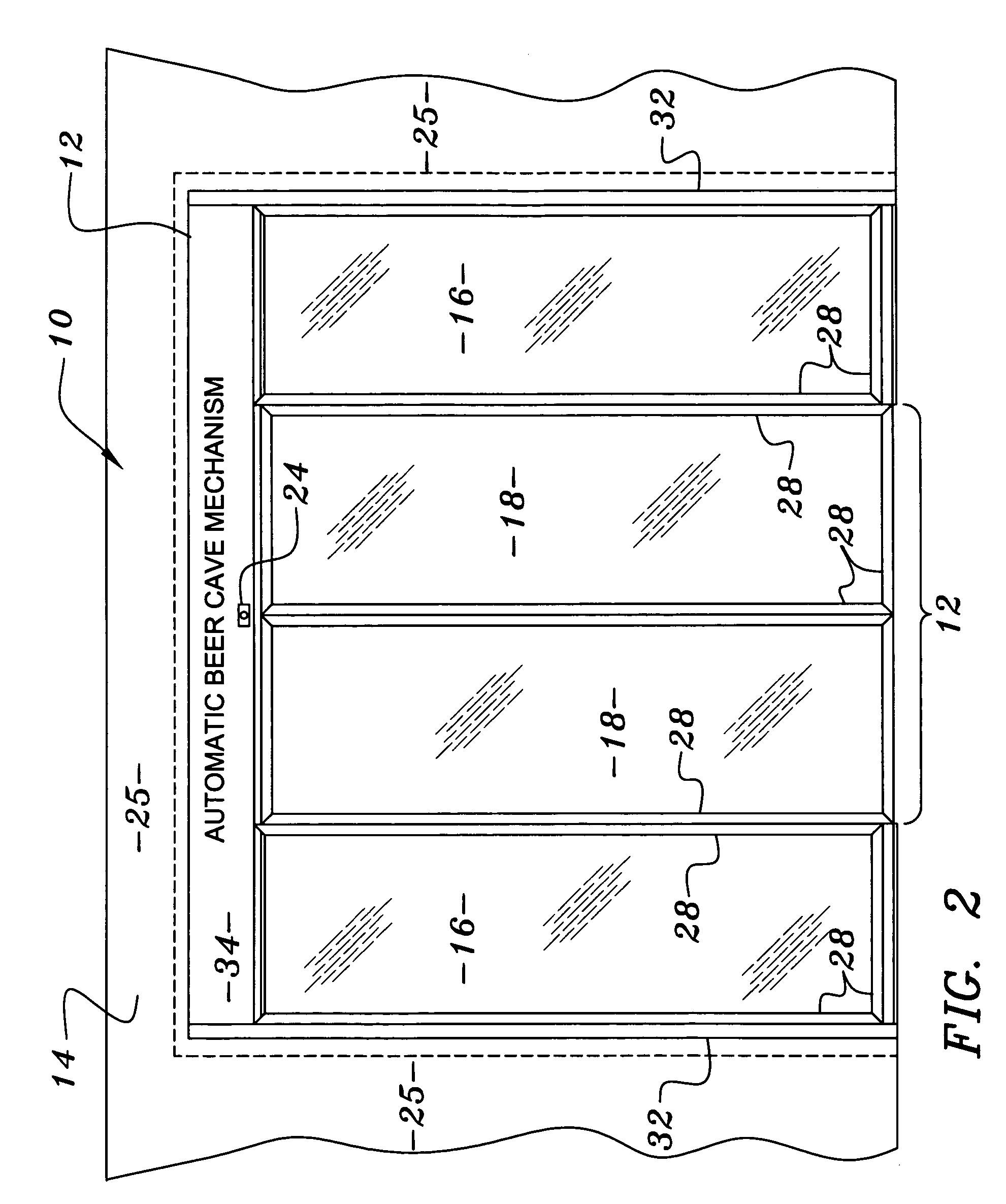

Automated glass entrance door assembly for walk-in coolers

ActiveUS7259359B2Inhibition formationAvoid heatingShow cabinetsDoors/windowsEngineeringMechanical engineering

An automated glass cooler entrance door assembly for an opening in a walk-in cooler comprising at least one fixed, stationary side door that defines a walkway about the opening for ingress and egress into the cooler, at least one opposing sliding door operatively suspended from a concealed drive mechanism above the opening to slide sideways from a closed position across the opening to close-off the cooler to and from an opened position overlapping the fixed stationary side door to allow customer ingress and egress to the cooler via the walkway through the opening and each of the doors comprising heated glass that is electrically connected to electrical power to heat the same.

Owner:HUSSMANN CORP

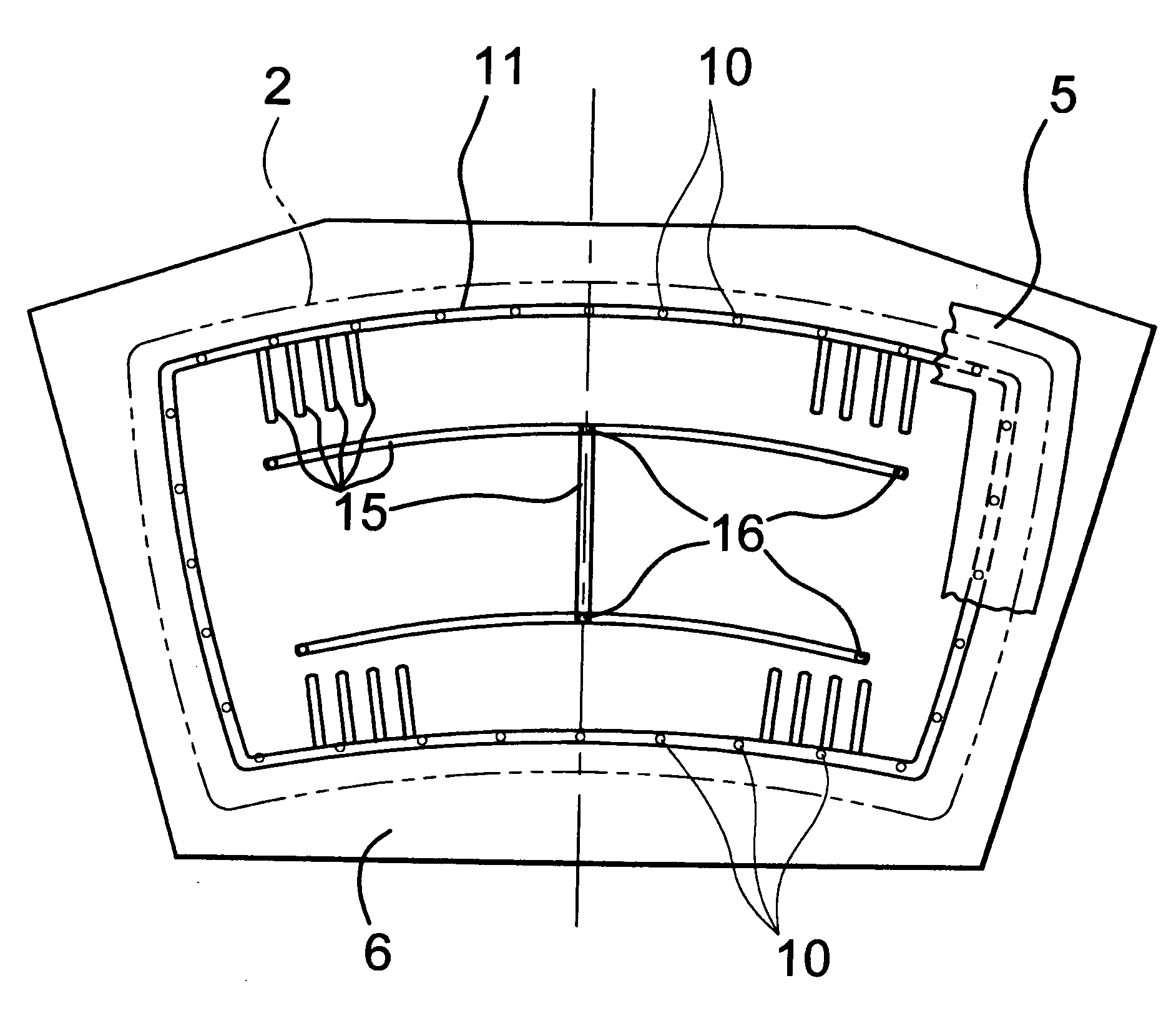

Press bending station for the bending of glass sheets

ActiveUS20050061034A1Glass drawing apparatusGlass transportation apparatusPositive pressureEngineering

A press bending station includes an annular mold (5) and a full-face mold (6). Holes (10), selectively connected to a negative pressure source, are placed in portions of the full-face mold (6) that are determined by the configuration of the annular mold when the annular mold comes into contact with a heated glass sheet (2) during the press bending process. The sheet (2) is drawn by negative pressure through the holes (10) towards the full-face mold (6) and thus acquires its shape. Positive pressure may be selectively applied to the holes (10) to release the sheet (2). According to the invention, at least some of the holes (10) are arranged in at least one groove (11) formed in the mold face of the full-face mold. The grooves (11) according to the invention accelerate considerably the removal by negative pressure of the air between the molding face of the full-face mold (6) and the glass sheet (2) to be bent and thus improve the press bending process.

Owner:PILKINGTON AUTOMOTIVE DEUT GMBH +1

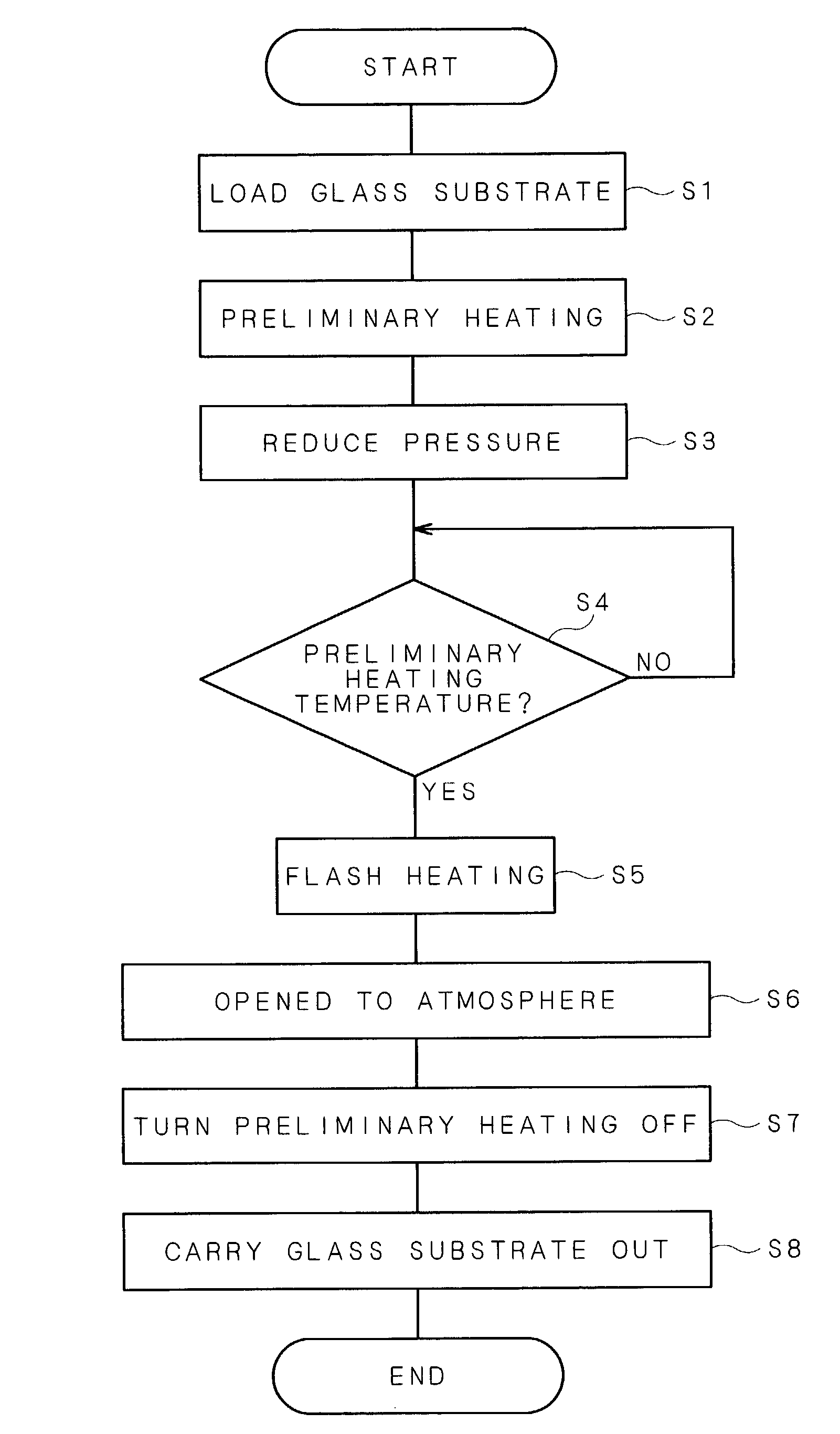

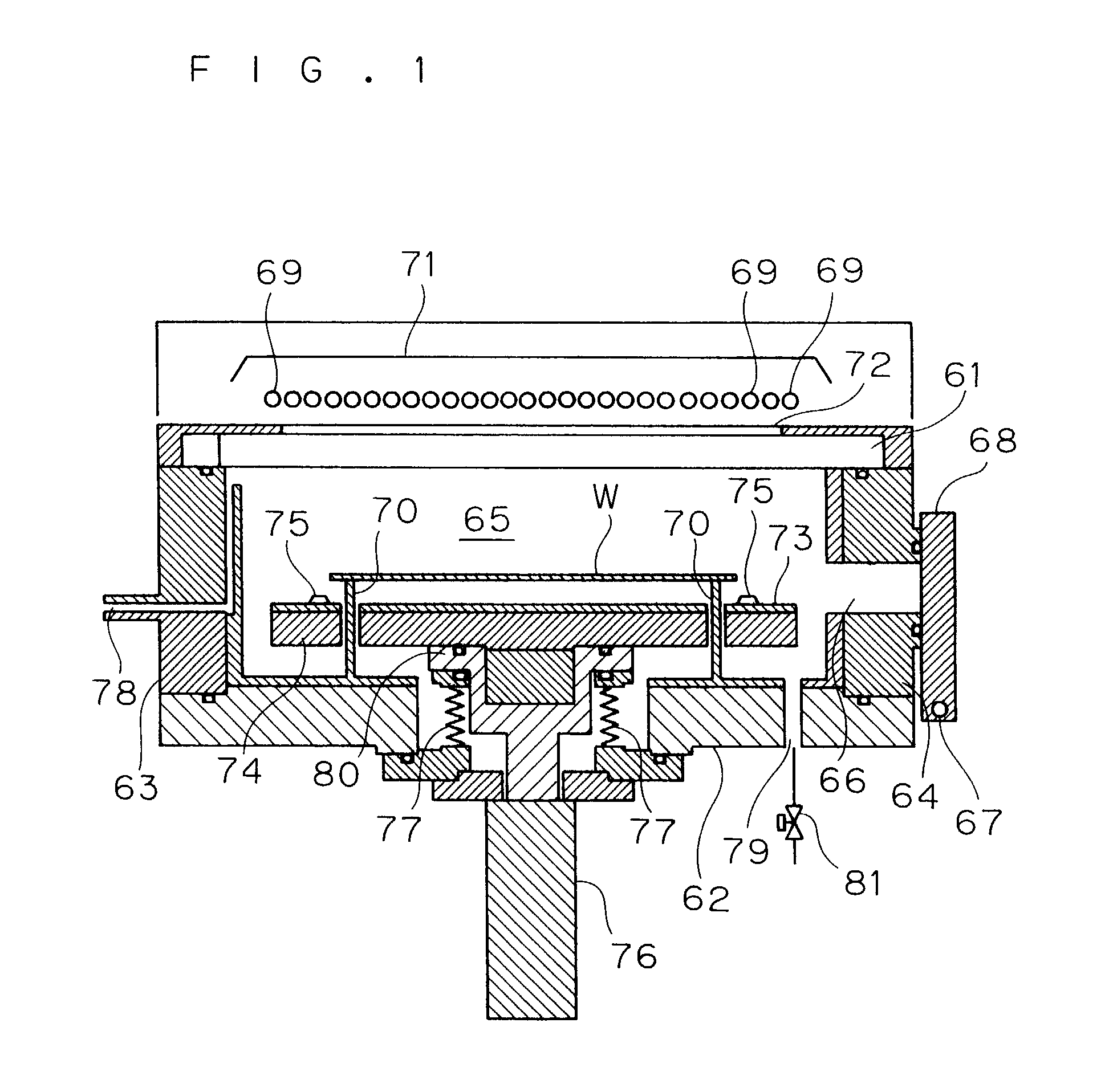

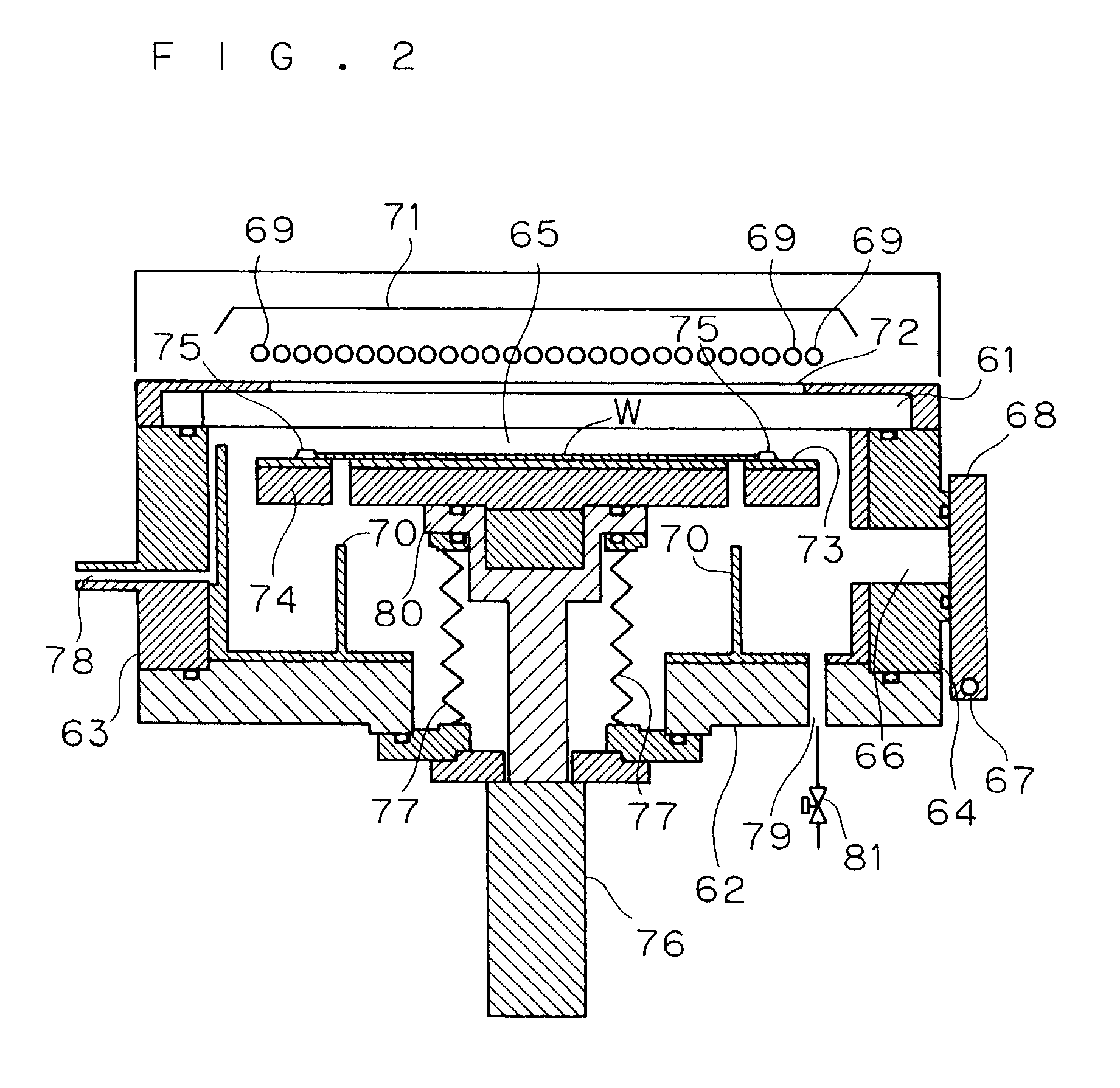

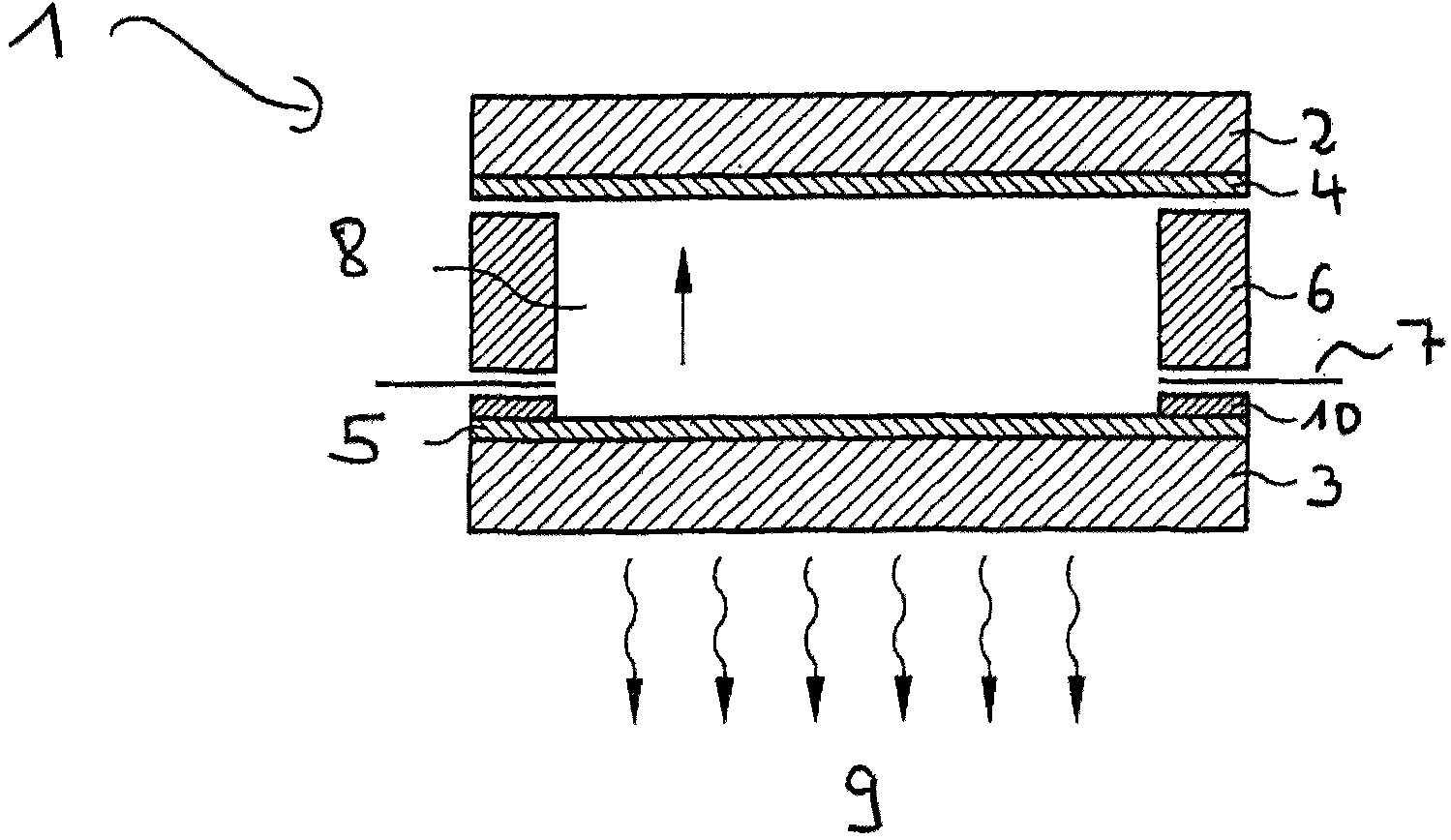

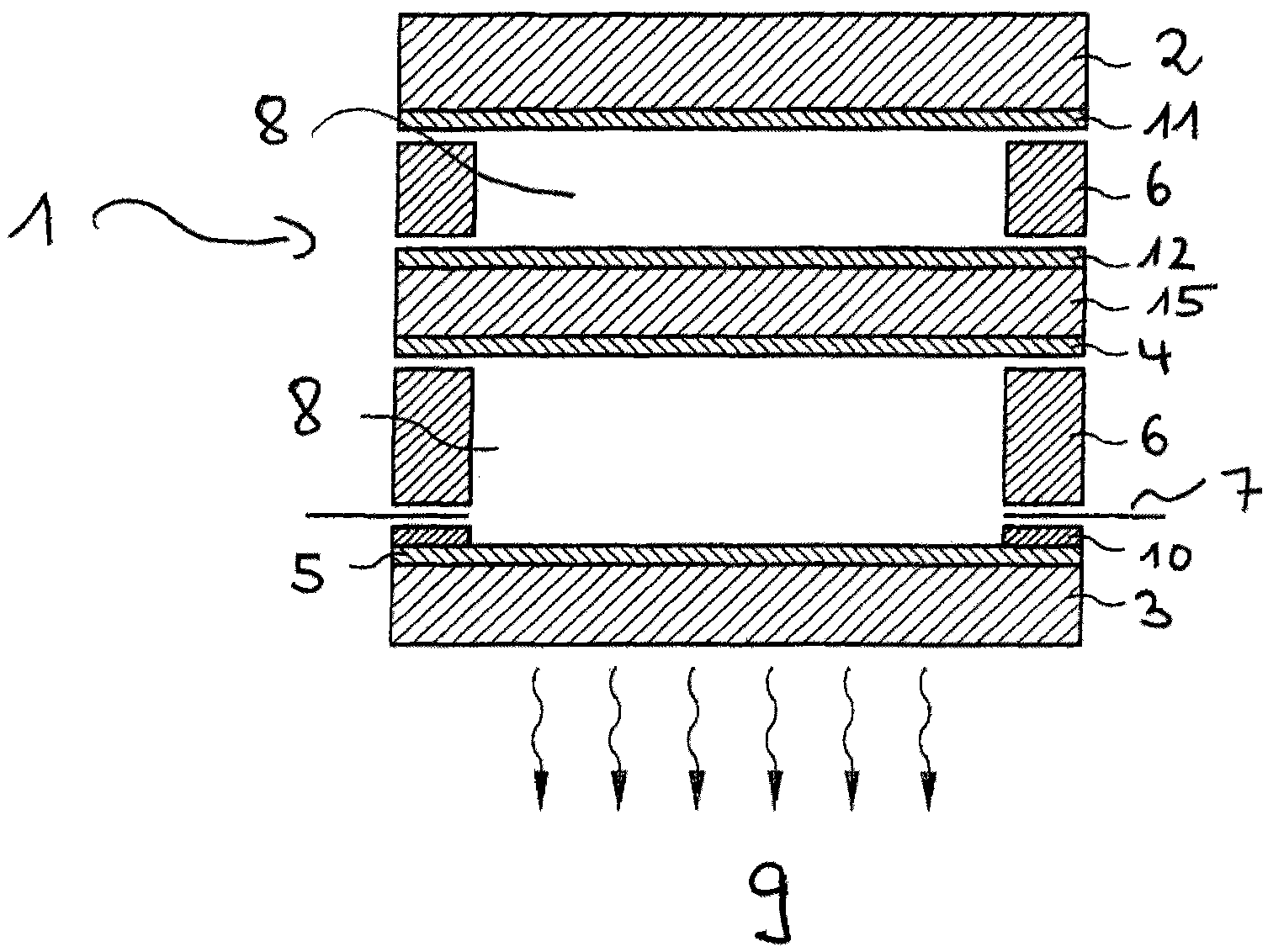

Heat treatment apparatus and heat treatment method of substrate

ActiveUS7255899B2Well formedExcellent characteristicsBlowing machine gearingsGlass furnace apparatusAmorphous siliconIrradiation

A heat diffusion plate and a heating plate are placed in a heat treatment chamber in this order. The heating plate is used for preliminarily heating a glass substrate to a temperature in a range from 200° C. to 400° C. The glass substrate thus preliminarily heated is subjected to a heat treatment by flash light irradiation by a xenon flash lamp. The flash light irradiation makes it possible to uniformly heat an amorphous silicon film on the glass substrate, and consequently to be poly-crystallized. Thus, it becomes possible to provide a heat treatment technique capable of carrying out a uniform heat treatment on the silicon film on the glass substrate sufficiently.

Owner:DAINIPPON SCREEN MTG CO LTD

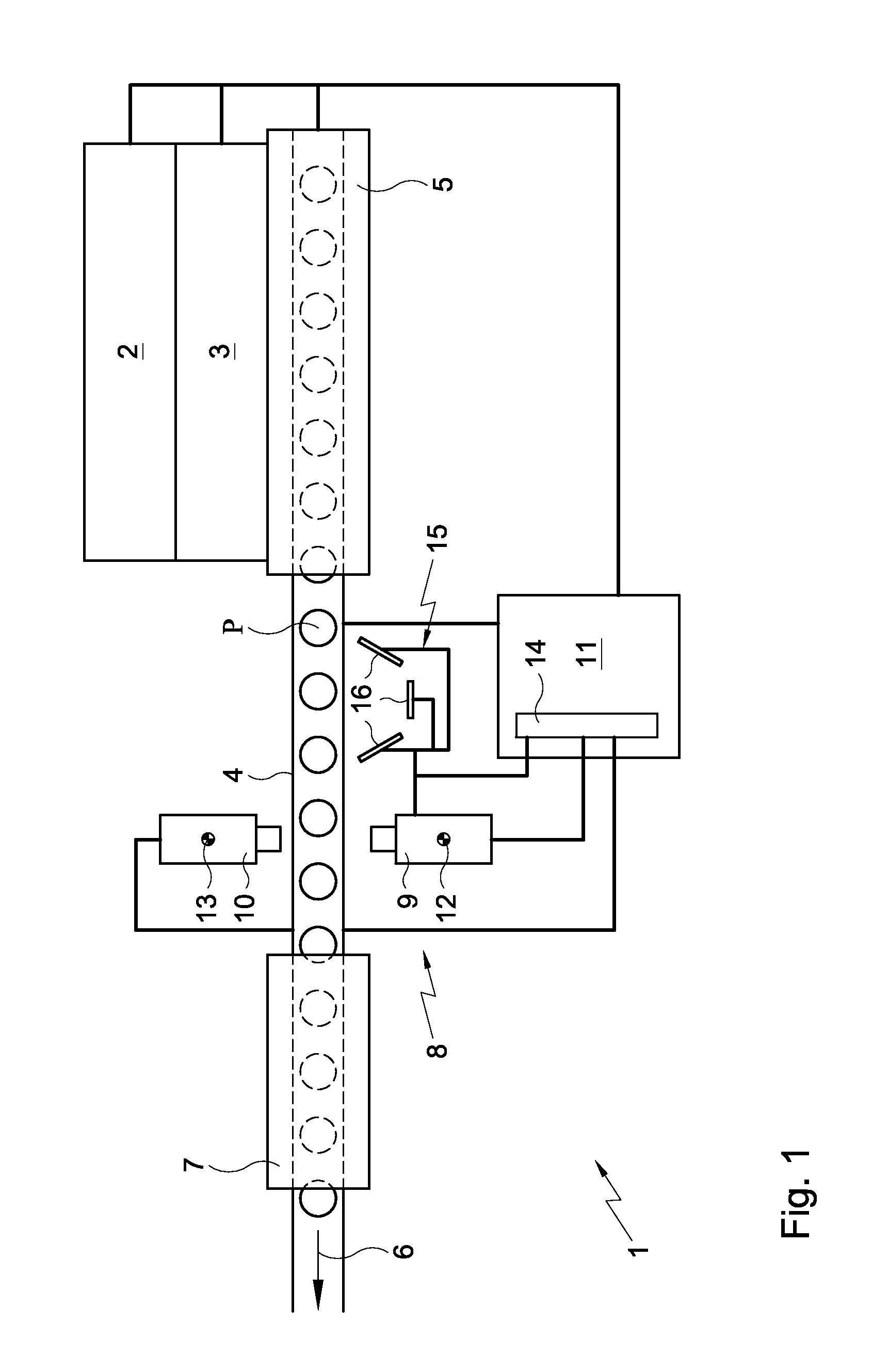

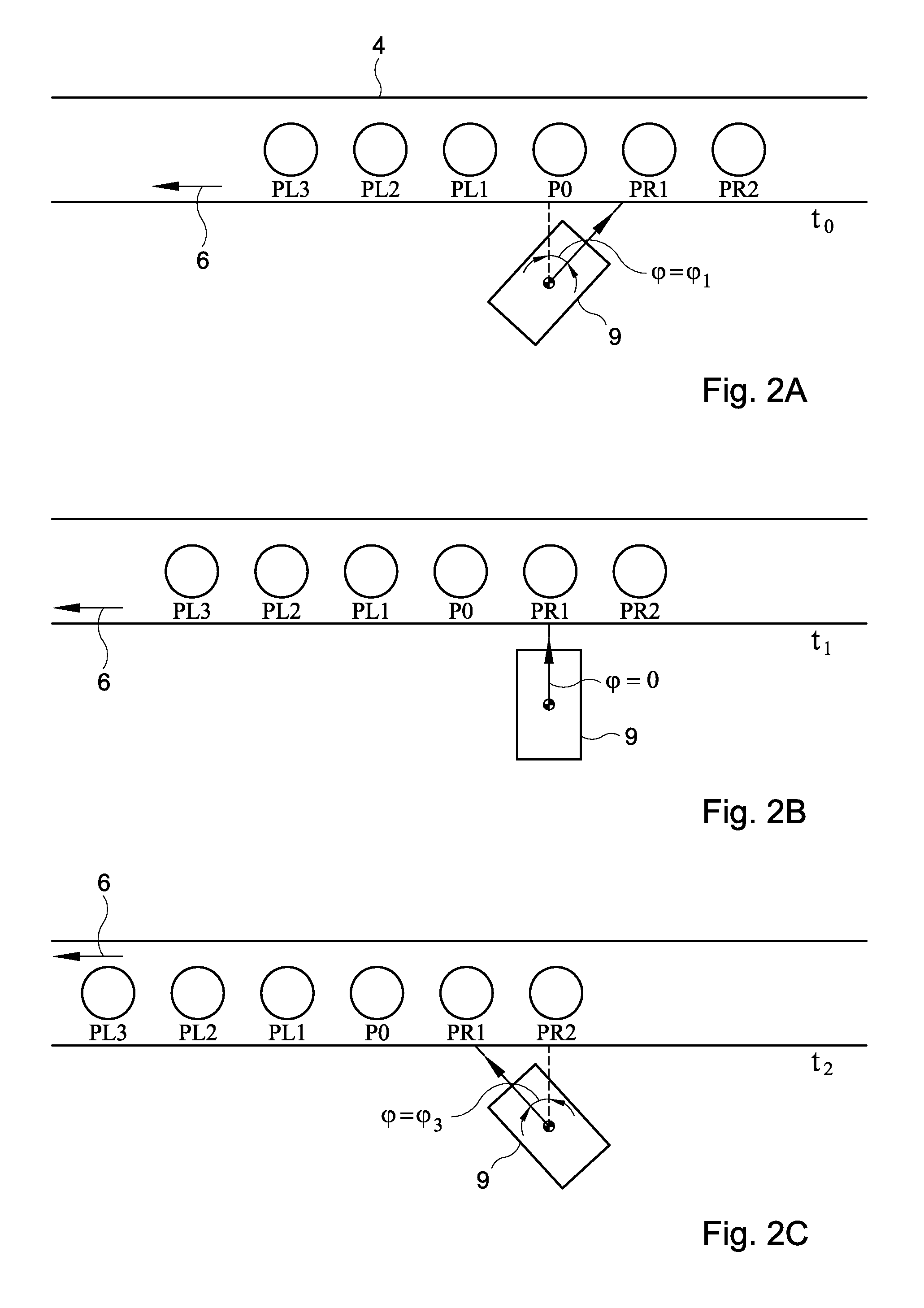

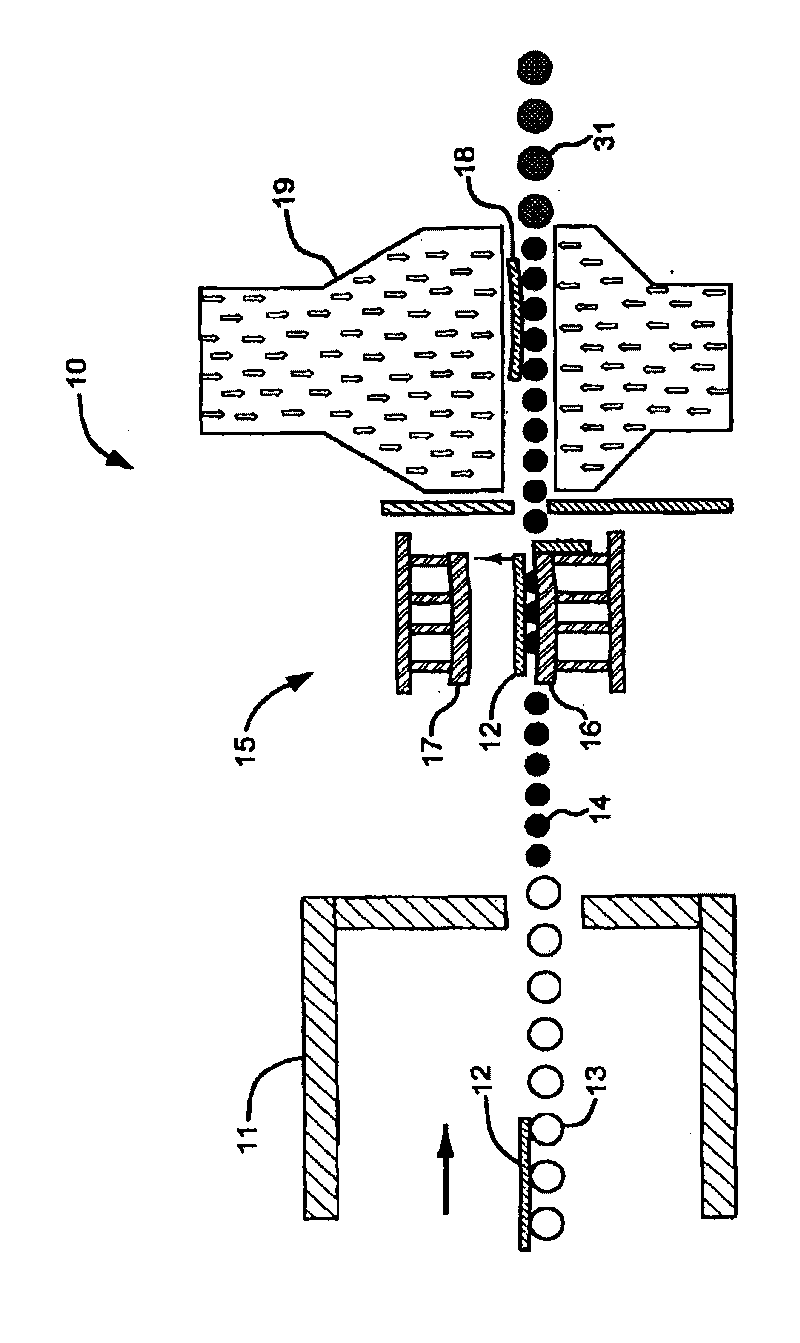

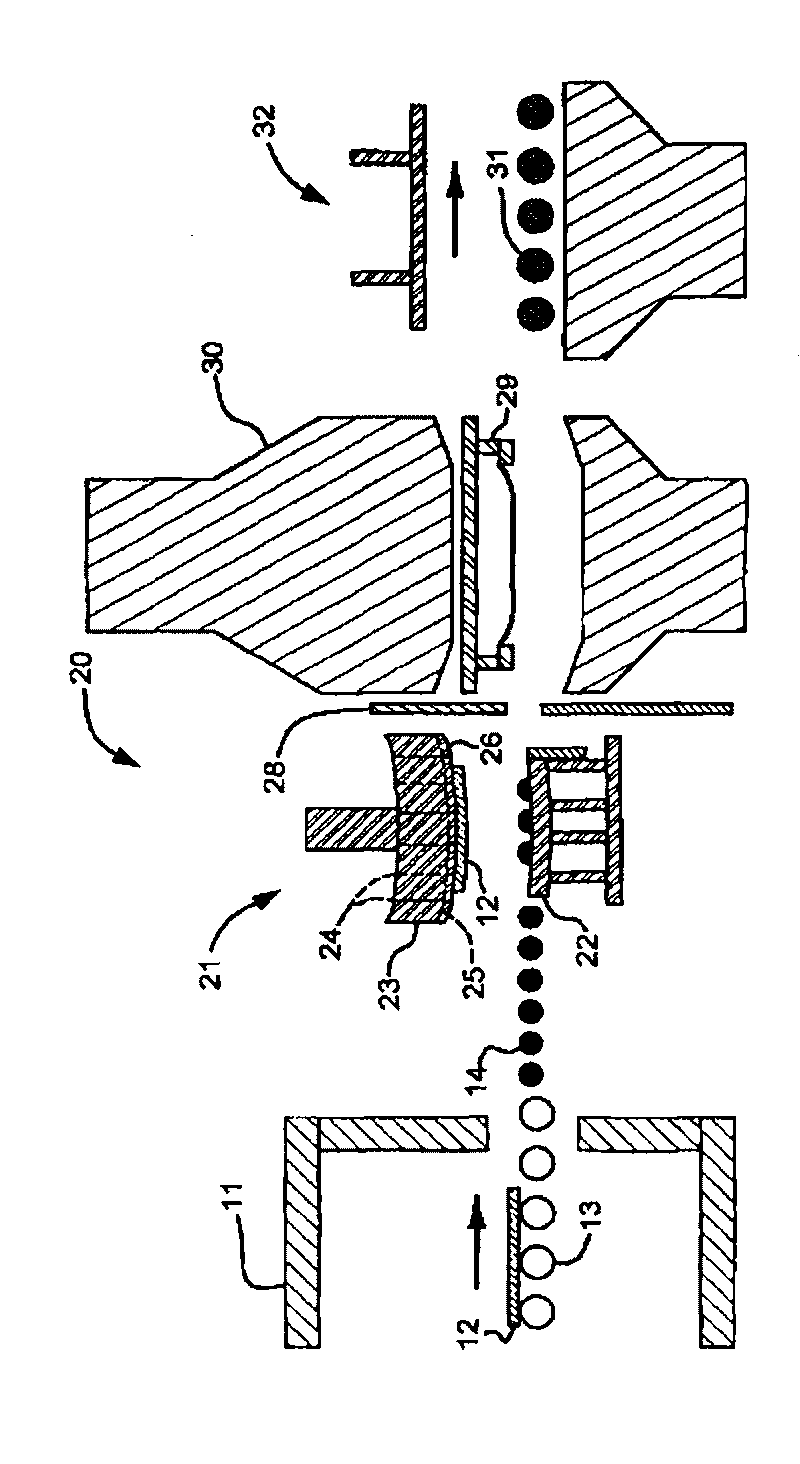

Method of producing glass products from glass product material and an assembly for performing said method

ActiveUS20140174127A1Eliminate the effects ofBlowing machine gearingsGlass furnace apparatusMaterials scienceRadiation

The invention is related to a method of producing glass products from glass product material. Said method comprises the steps of heating the glass product material, shaping the heated glass product material into a glass product, cooling the shaped glass product, and inspecting the shaped glass products by means of at least one sensor sensitive to infrared radiation In said inspecting step a first image of the glass product is taken under a first viewing angle. In addition a second image of said glass product is taken under a second viewing angle which is different from the first viewing angle. The first image is compared with the second image for eliminating parasite reflections. The first and second images are analyzed for detecting whether said glass product is defective or not. An assembly is described for performing said method of producing glass products from glass product material.

Owner:CENT VOOR TECHN INFORMATICA

Glass bending process

ActiveCN101720308AImproved forming cycle timeImprove shape repeatabilityGlass transportation apparatusGlass reforming apparatusMechanical engineeringGlass sheet

A glass bending line for quickly shaping a complex bent glass sheet is provided that includes moving a ring-type female mold, which has a heated glass sheet placed on it, and a full face heated male mold, toward one another. Upon making shaping contact between the glass sheet and the male mold, a vacuum is applied through holes extending through the male mold, for a time sufficient to form the glass sheet to a desired shape. When the glass sheet has been shaped, the vacuum is terminated and pressurized air is connected to the holes to release the bent glass sheet from the male mold. The bent glass sheet is then quickly transported to a quenching station or an annealing station on a continuous conveying device. Hence, the complex bent glass sheet is achieved without the use of a shuttle ring.

Owner:PILKINGTON NORTH AMERICA INC

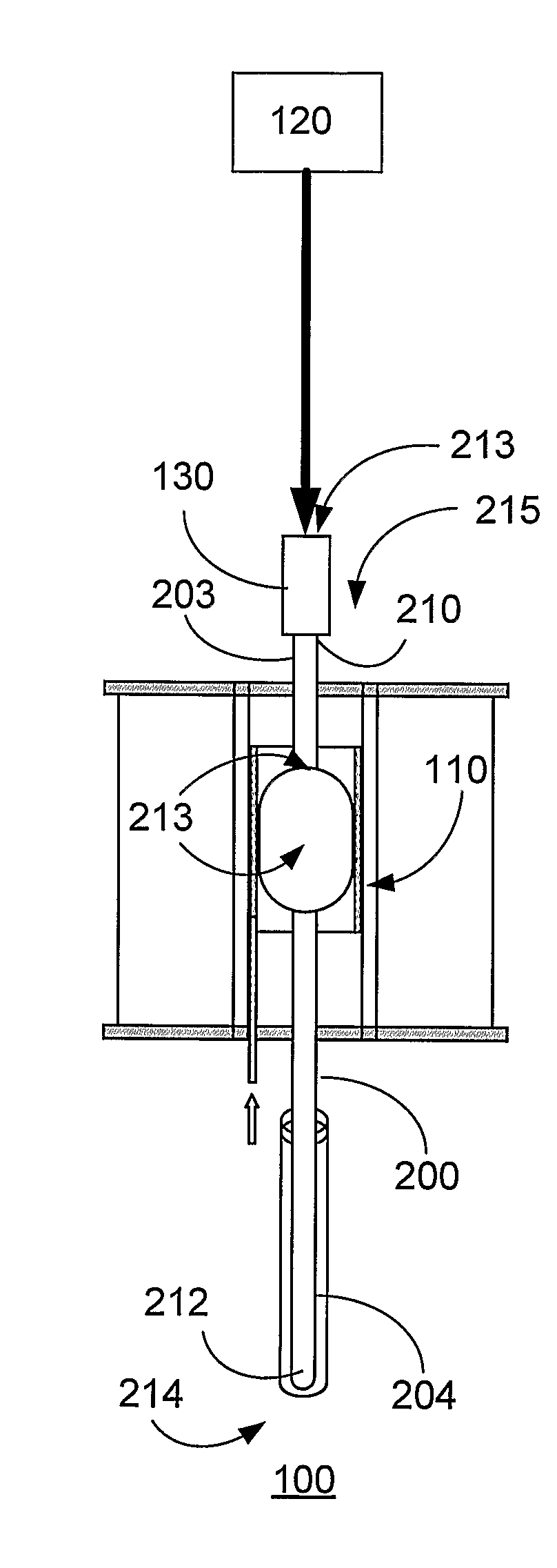

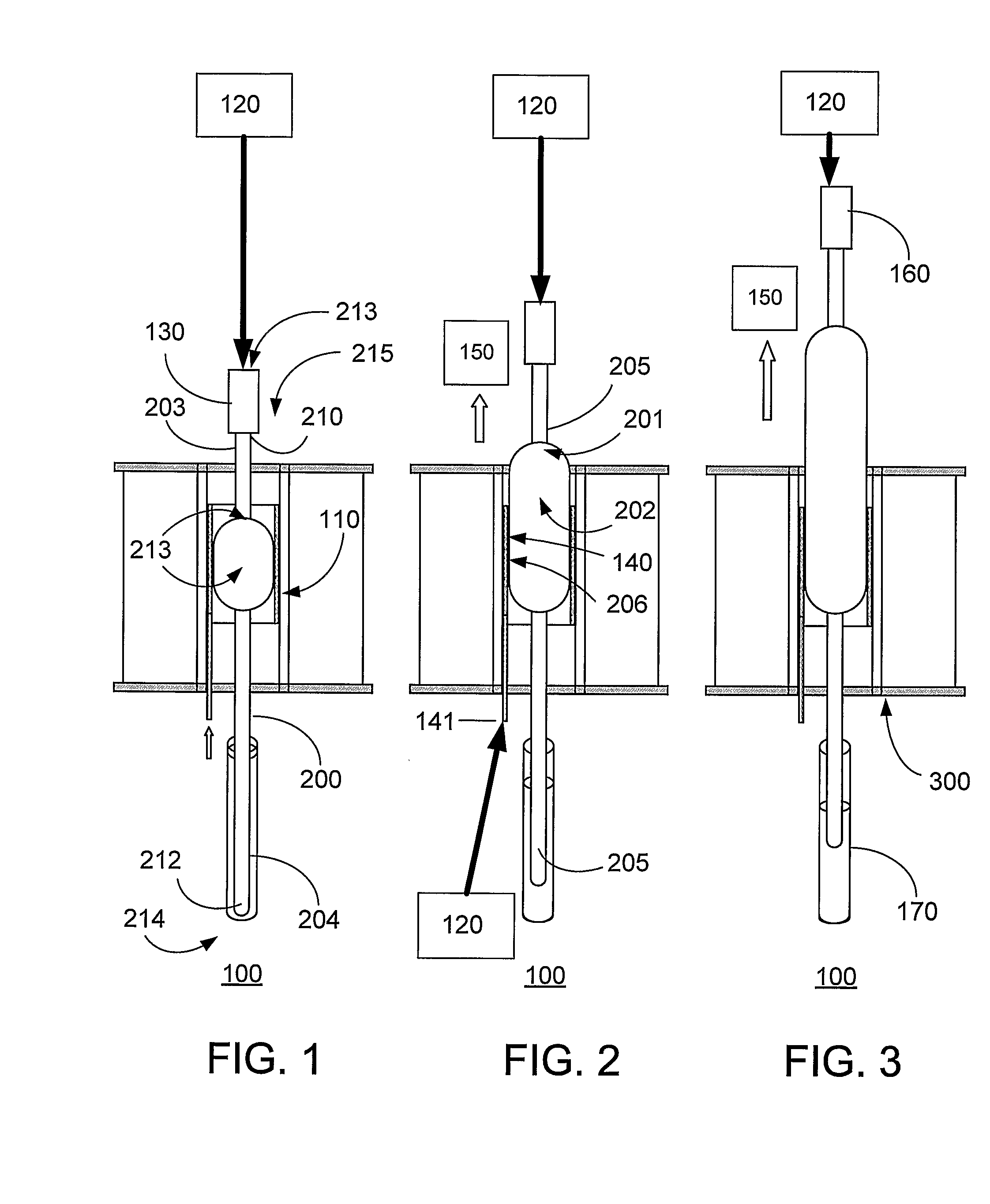

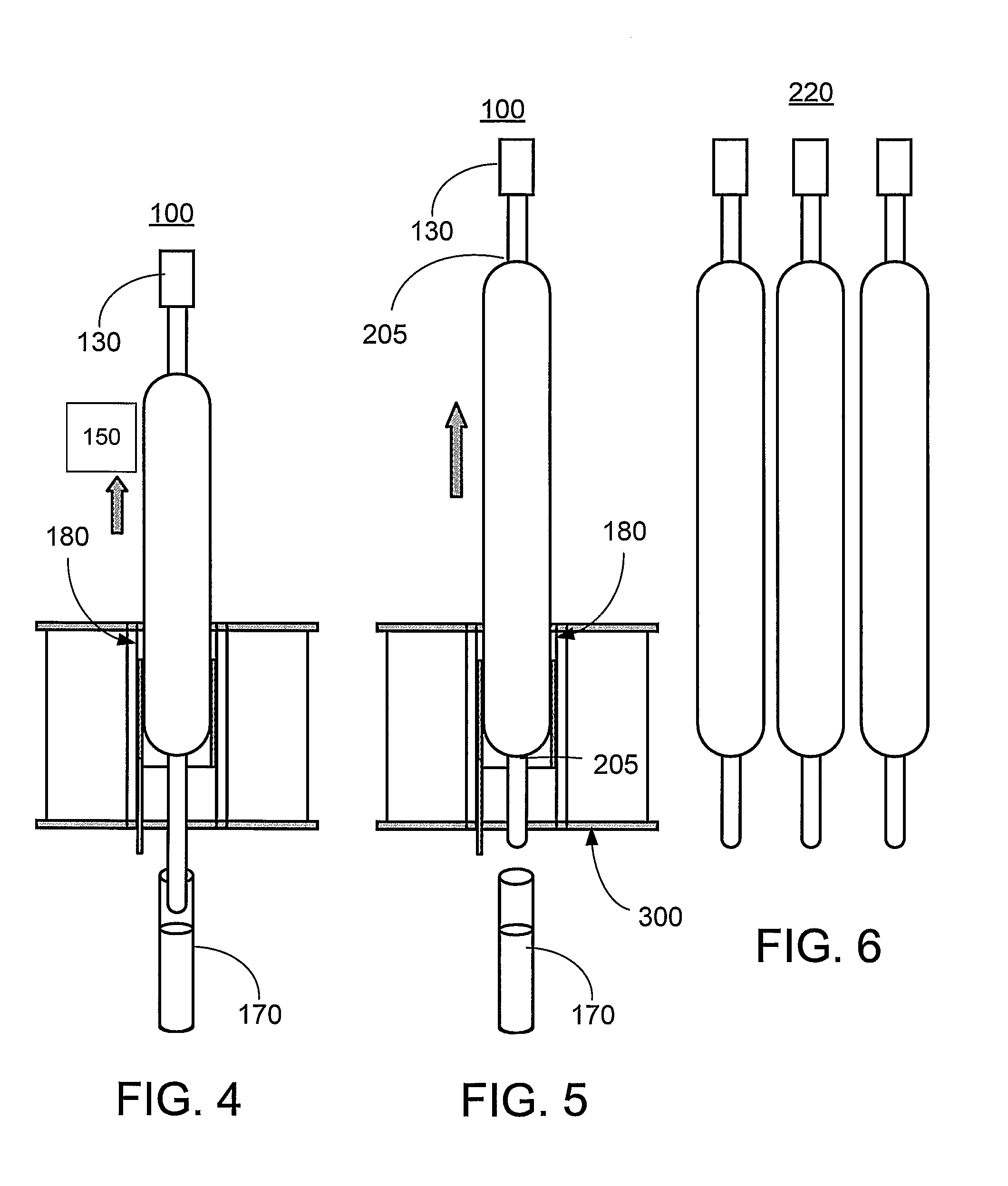

Ultra Thin Glass Drawing and Blowing

InactiveUS20100107694A1Large thin sheet widthReduce widthRibbon machinesGlass drawing apparatusAir bearingDisplay device

Systems, methods, apparatus and products relate to drawing and blowing of ultra thin glass substrates, such as flexible display glass sheets, for example, organic light emitting diode (OLED) displays, liquid crystal displays (LCDs), and / or other flexible substrate applications, such as lighting, and / or other technologies, such as electro-wetting (EW), electro-phoretic display applications, etc. A localized heat source centripetally heats a vertical glass pre-form, while a pressurized air source blows the heated glass to expansion. An air bearing may centripetally blow air against the expanding pre-form to limit expansion and prevent contact of the pre-form with the localized heat source. Meanwhile, the pre-form is pulled vertically to draw the heated glass. The pre-form may float in a floatation mechanism to compensate for gravity when the pre-form is pulled upward. The blown and drawn pre-form may be cooled, coated with a polymer layer, and cut into a ribbon by in-line devices as it exits the air bearing. For example, a laser may helicoidally cut a polymer-coated blown and drawn pre-form into a ribbon, which may be rolled for collection.

Owner:CORNING INC

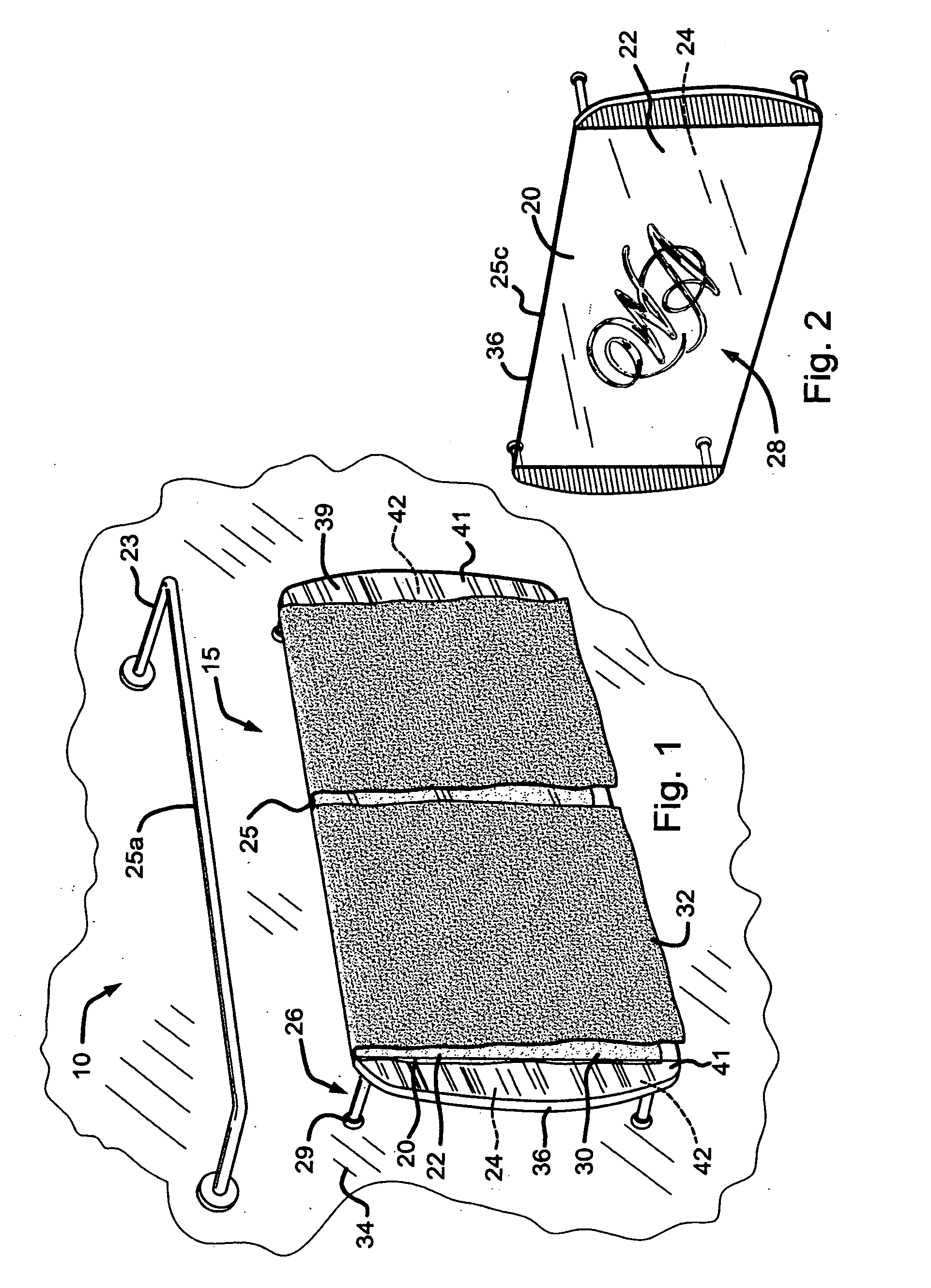

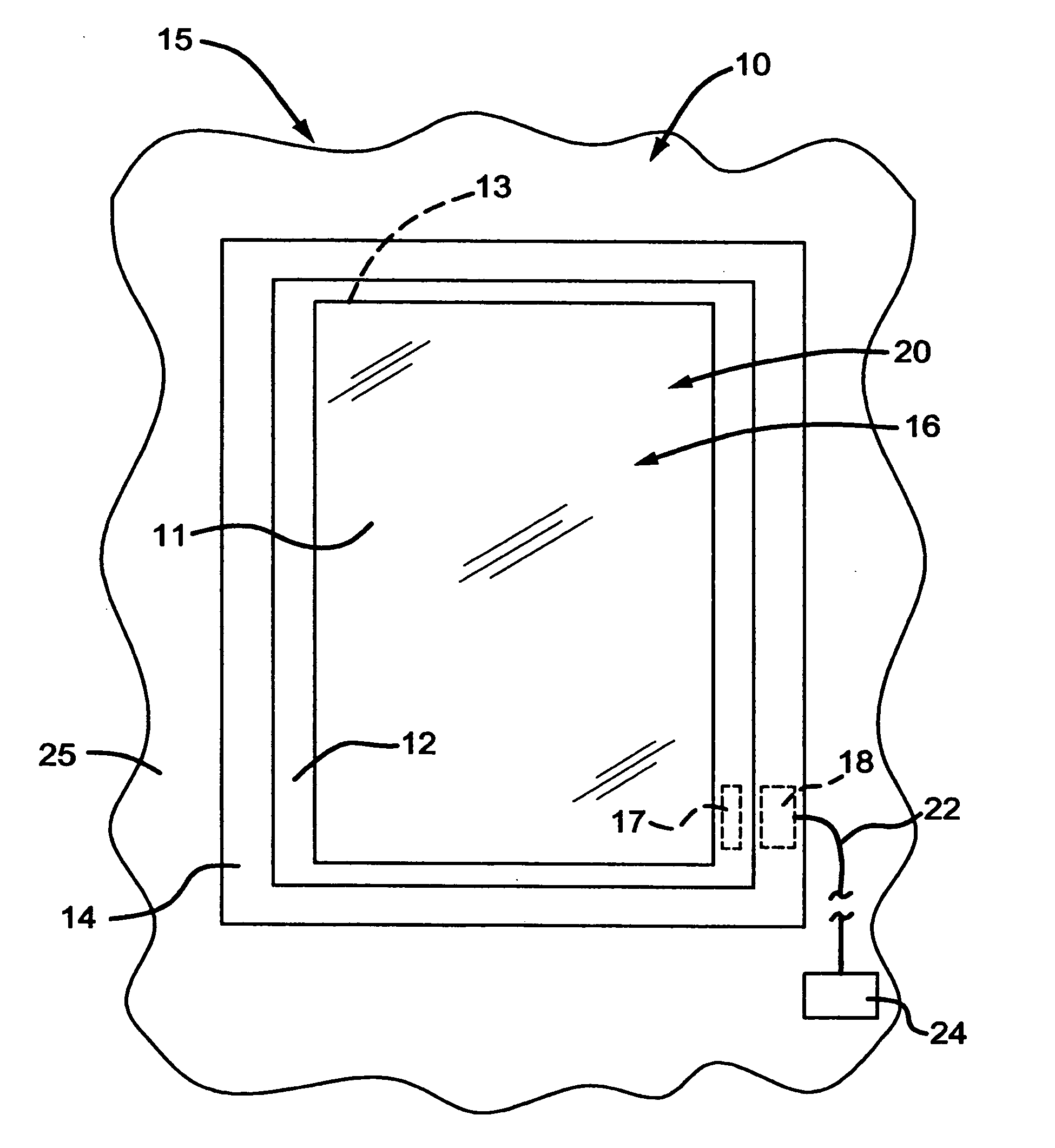

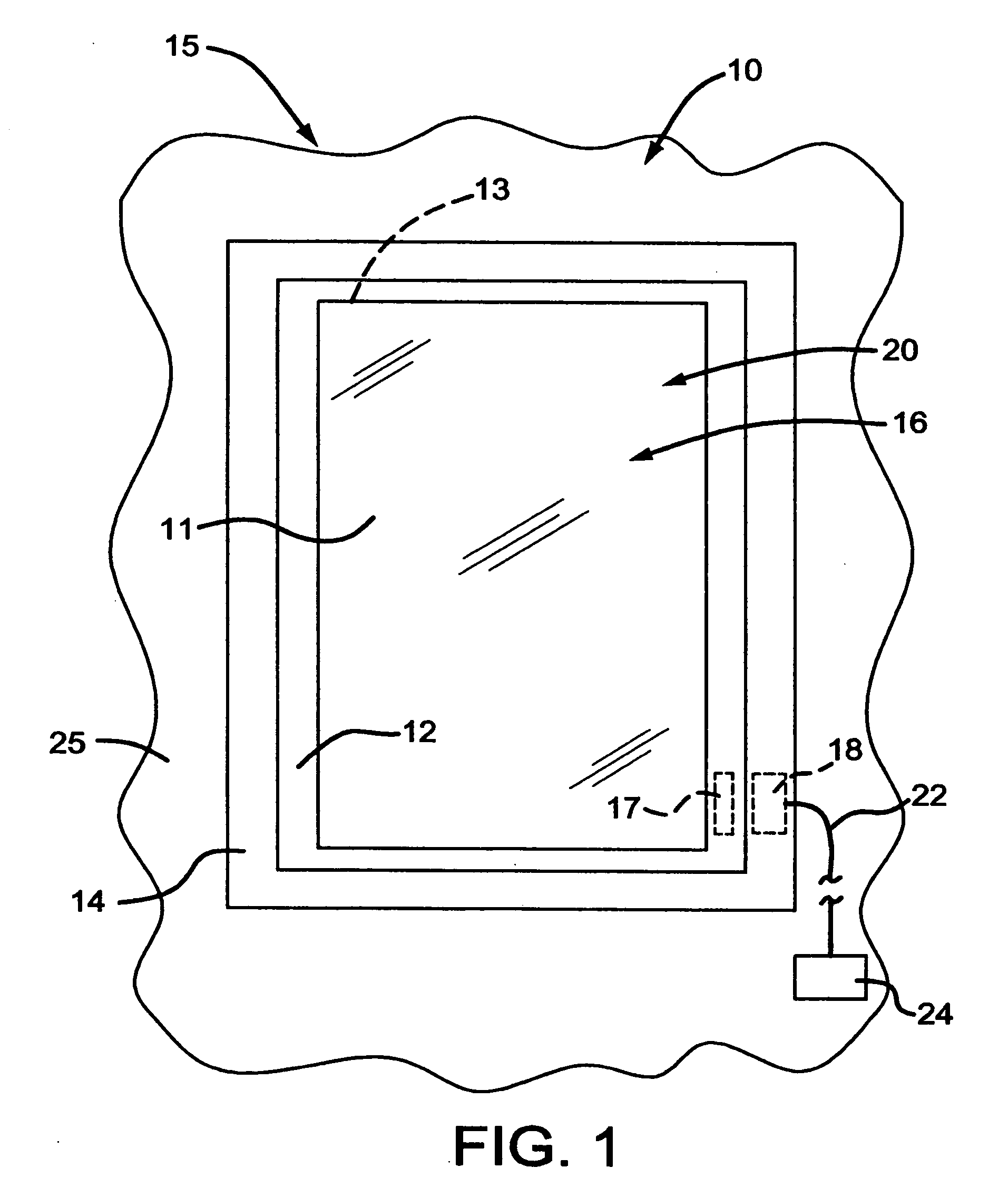

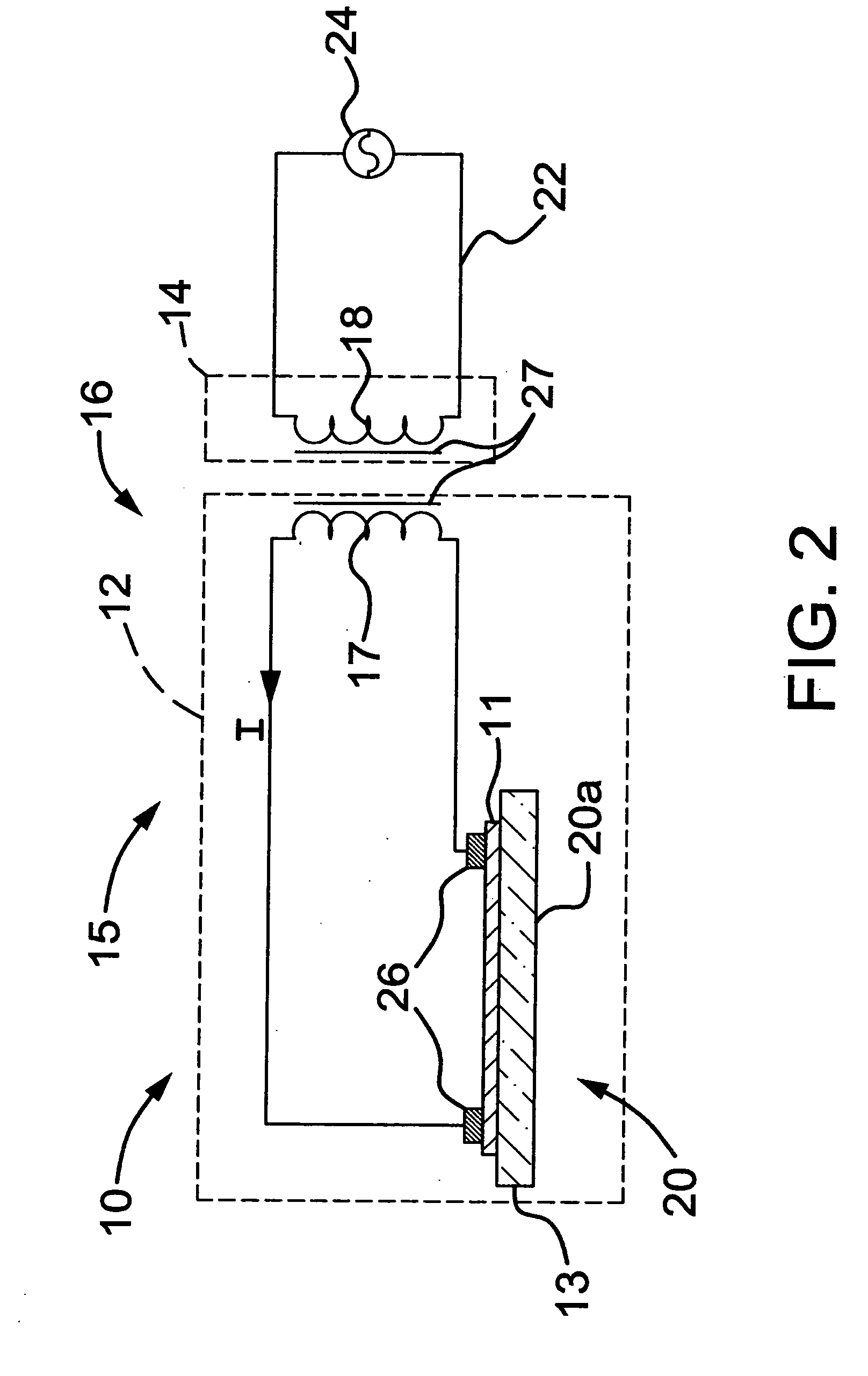

Wireless inductive coupling assembly for a heated glass panel

A wireless inductive coupling assembly for a heated glass panel assembly is provided that includes a metal oxide coated glass panel with a panel frame, an opening frame that cooperates with the coated glass panel frame to allow the panel to cover a panel opening, a receiving coil that is positioned in the panel frame and that is wired to the panel, and a sending coil that is positioned in the opening frame and that is wired to an electrical power source. When the electrical power source supplies electrical power to the sending coil, the sending coil wirelessly induces an electrical current in the receiving coil, which causes the dielectric panel to provide heat.

Owner:ENGINEERED GLASS PRODS

Electrically heatable glass pane, method for production of same and window

The invention relates to an electrically heatable sheet of glass (10), including at least one electrically conductive coating applied on at least one side of the sheet of glass and also to at least one contacting applied at least in regions on the coating, the contacting being configured as a spray coating.

Owner:THERM IC PRODS NFG

Lenticular fireplace

InactiveUS20050155262A1Domestic stoves or rangesLighting and heating apparatusLenticular lensComputer science

A lenticular fireplace and methods for simulating a fire within a fireplace. In one respect, a fire is simulated with a lenticular screen. The lenticular screen includes a lenticular lens layer and an image layer, wherein the image layer comprises one or more images of a fire. A device is coupled to the lenticular screen that moves the lenticular screen to alter a viewed image of the fire. In another respect, the lenticular screen is disposed within a fireplace enclosure. In another respect, a fireplace includes a convertible heated glass apparatus. The apparatus is used in a front wall of an enclosure.

Owner:HNI TECH INC

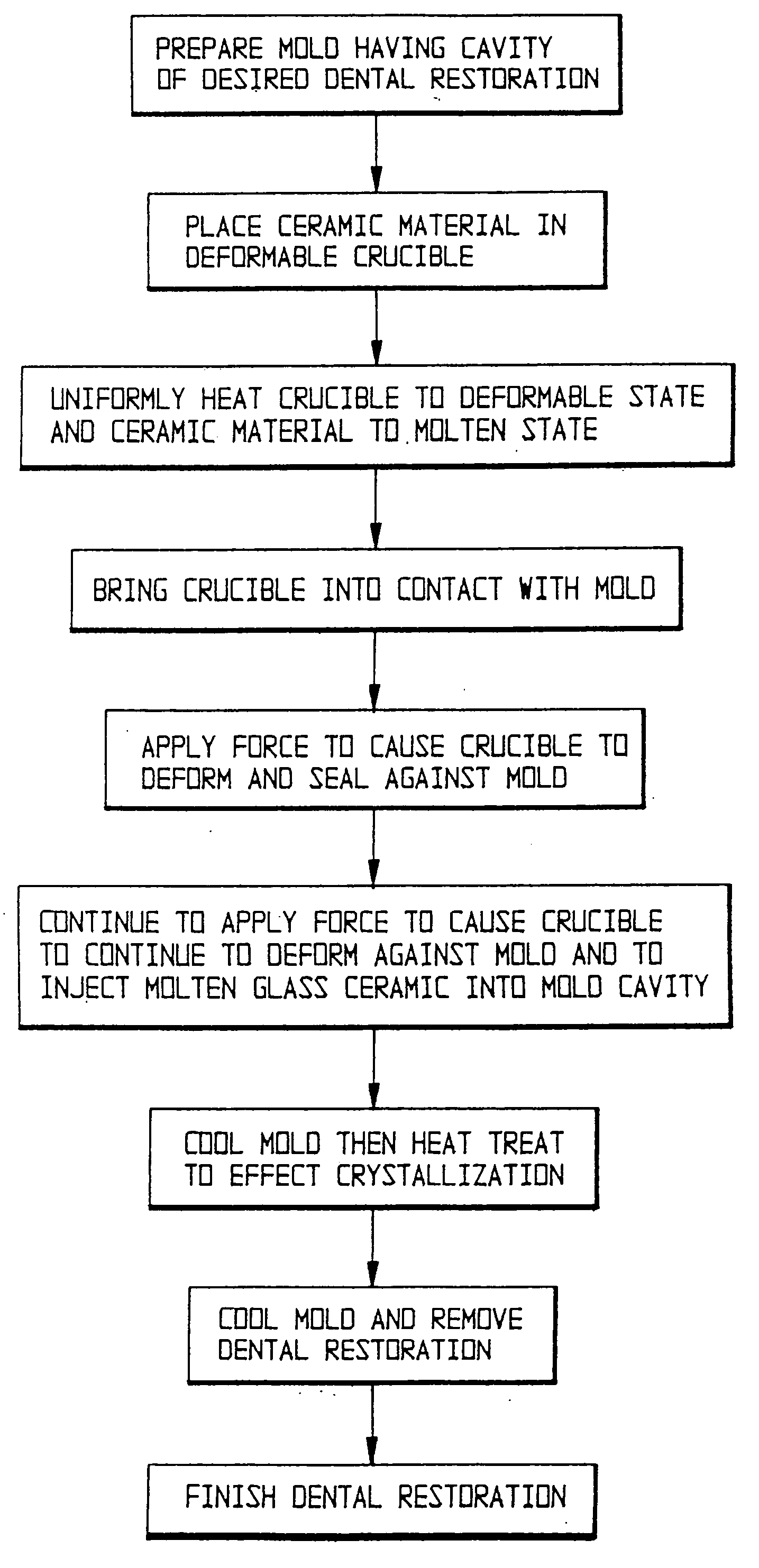

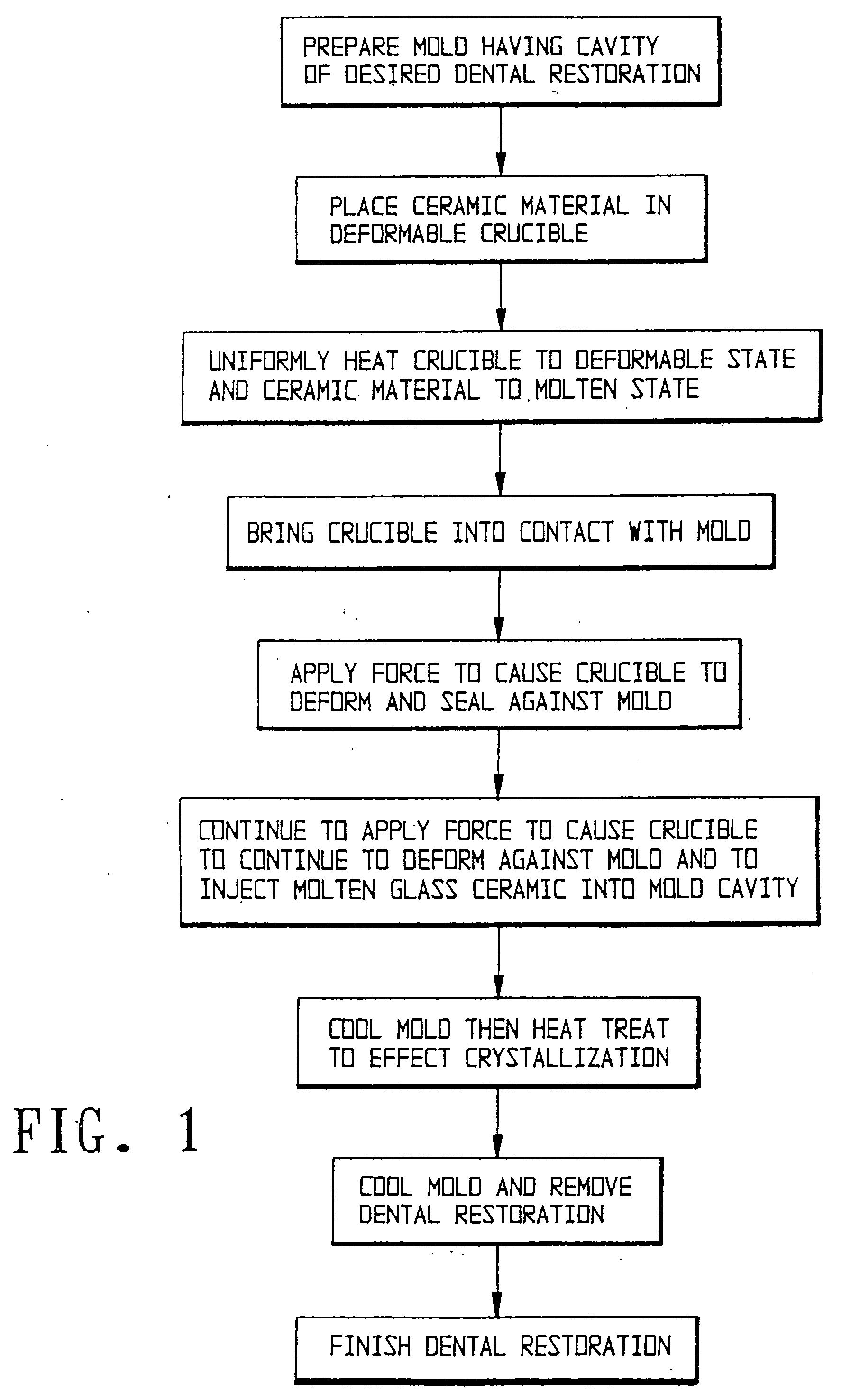

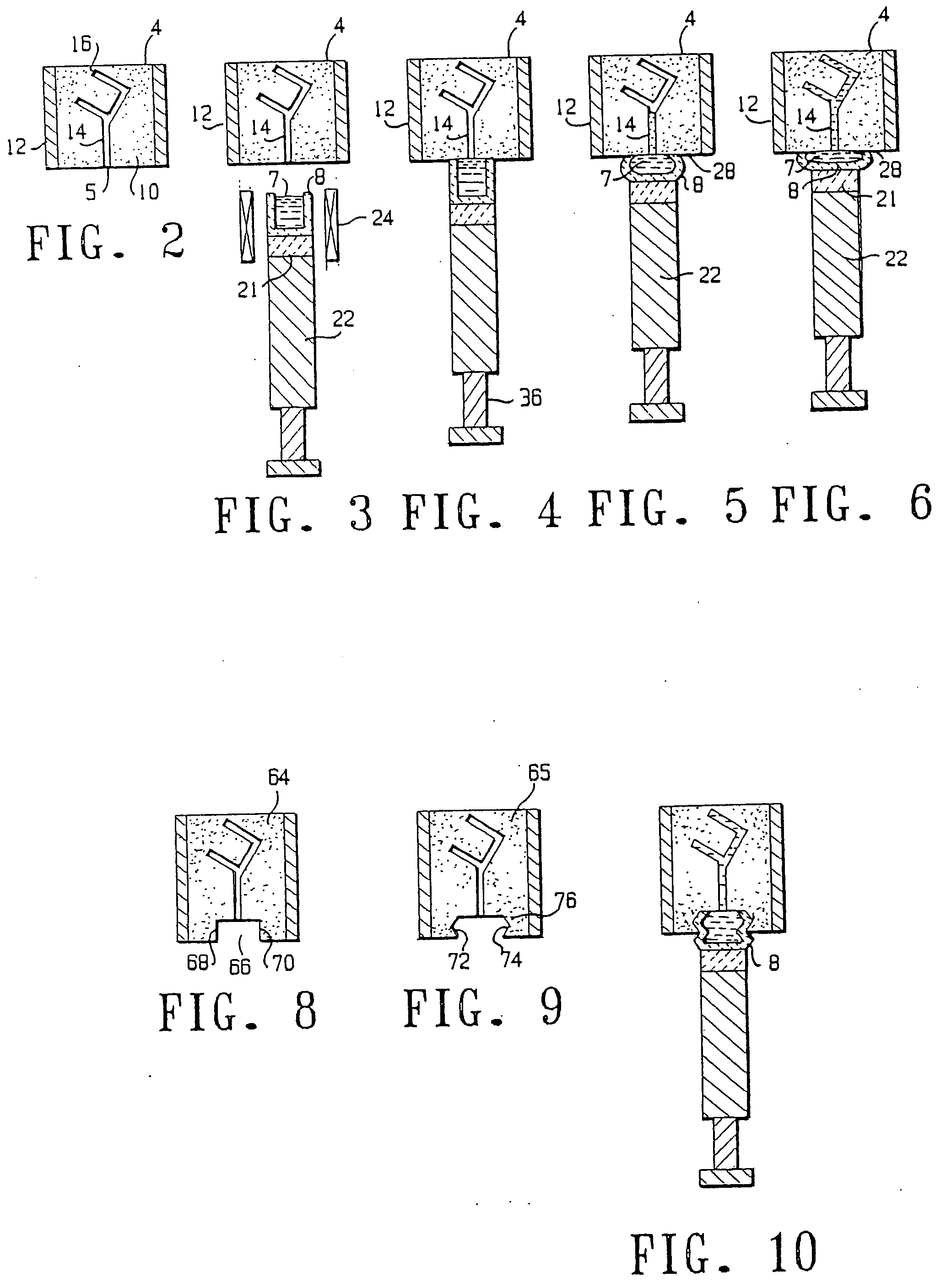

Method for molding dental restorations and related apparatus

InactiveUS20050115460A1Readily molded into dental restorationEasy to useImpression capsOther chemical processesWorking temperatureDental restoration

The present invention is concerned with a process for the formation of dental restorations from glass-ceramic materials, and the resulting dental restorations. In this invention, a dental restoration is prepared by placing a glass-ceramic material in a heat-pressure deformable crucible. Heat is then applied to the crucible in order to bring the glass-ceramic material to working range at temperatures above its liquidus temperature. The crucible in which the glass-ceramic material is placed has heat-pressure deformation properties which are matched to the working temperature of the glass-ceramic material being heated. The heat deformation properties of the crucible must be such that when the glass-ceramic material in the crucible is in the working range, the crucible is heat-pressure deformable without rupturing. Once the glass-ceramic material is heated to its working temperature, the crucible is brought into contact with a mold having a preformed cavity therein, the cavity being in the shape of the desired dental restoration. As the distance between the heated glass-ceramic material and the mold is decreased, the crucible is deformed to form a seal with the mold, thereby facilitating the injection of the molten glass-ceramic material into the mold cavity. An interactive seal between the crucible and the mold may be provided for. The composite process may be carried out in a vacuum. The resulting dental restoration has superior optical esthetic and strength properties. The invention further includes the heat-pressure deformable crucible. The invention includes dental restorations which are formed from particular lithium-disilicate glass-ceramics. In addition to forming dental restorations by the process of this invention, the dental restorations may be milled.

Owner:PETTICREW RICHARD W

Method for producing electrically conductive heated glass panels

InactiveUS7002115B2Robust external electrical connectionRailway vehiclesSemiconductor/solid-state device manufacturingControl signalLow emissivity

An electrically conductive heated glass panel assembly, control system, and method for producing panels are provided to warm objects and to insure unobstructed viewing through glass by removing moisture. An integrated connection circuit interconnects glass sheets, which have a low emissivity conductive coating deposited thereon. The circuit includes copper bus bars that are disposed onto the conductive coating through the use of a circularly rotating or an inline heating head and mask apparatus. A metallic tab, which extends from the glass sheet's peripheral edge, is disposed onto each conductive metal bus bar for external electrical connectivity. Two types of glazing channels are offered to interconnect multiple panels to external circuits and controls. A solid-state controller may be provided to obtain sensor control signals so as to drive a triac circuit that provides current flow through the panel for the desired heating.

Owner:ENGINEERED GLASS PRODS

Method and apparatus for a cloth heater

A cloth heater and method for using the heater are provided. The heater utilizes a horizontally disposed surface, a heated glass panel, and support members. The horizontally disposed surface may comprise the top edge or surface of the heated glass panel, or a surface on a separate rack that is above and vertically inline with the top edge of the heated glass panel. The heated glass panel also has two opposing major surfaces. The support members physically support the heated glass panel and have electrical leads that communicate electrical power to the heated glass panel, thus heating the heated glass panel. When a cloth is placed across the horizontally disposed surface, the horizontally disposed surface supports the cloth, and the cloth makes contact with the two opposing major surfaces of the heated glass panel, thus heating the cloth at both opposing major surfaces.

Owner:ENGINEERED GLASS PRODS

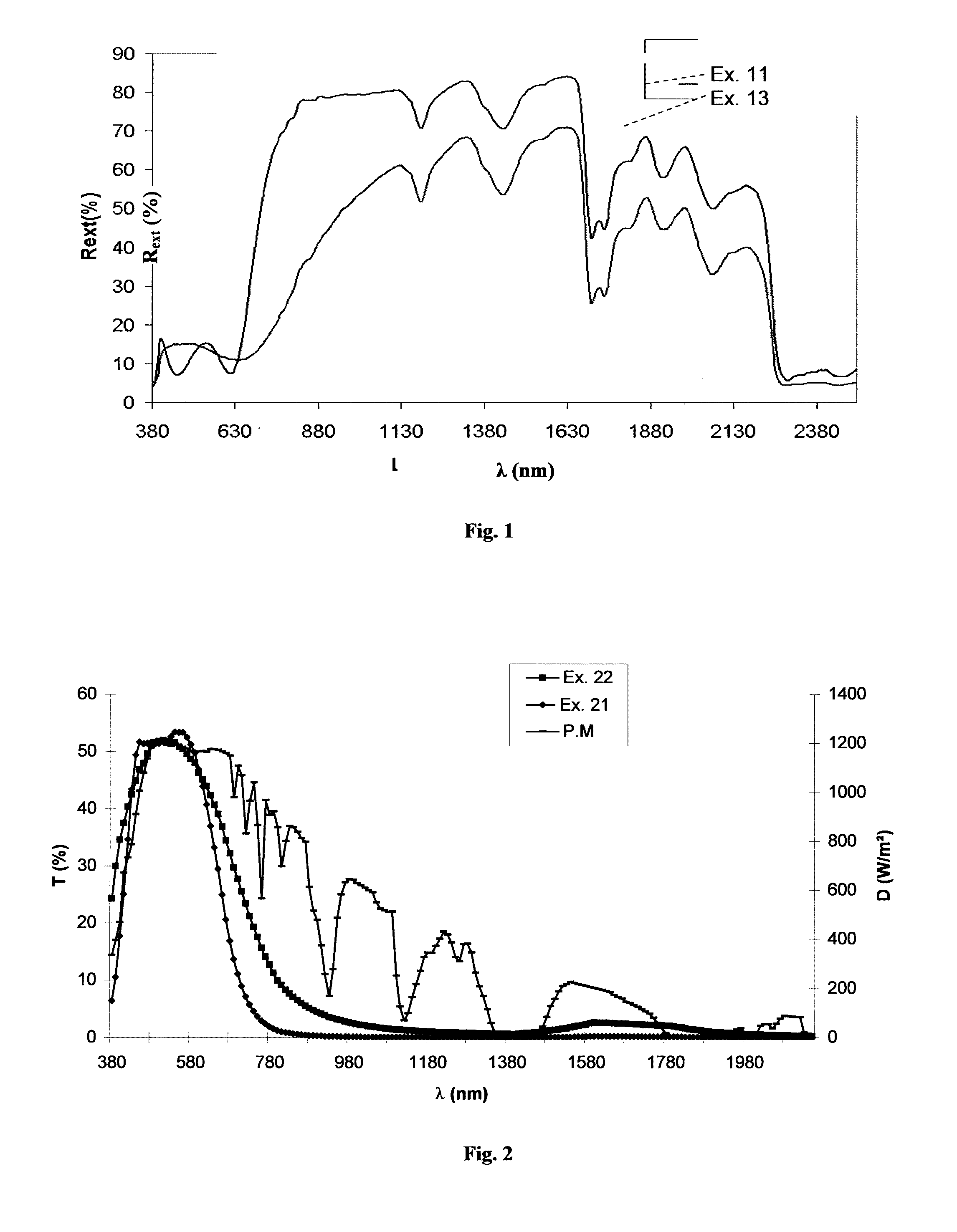

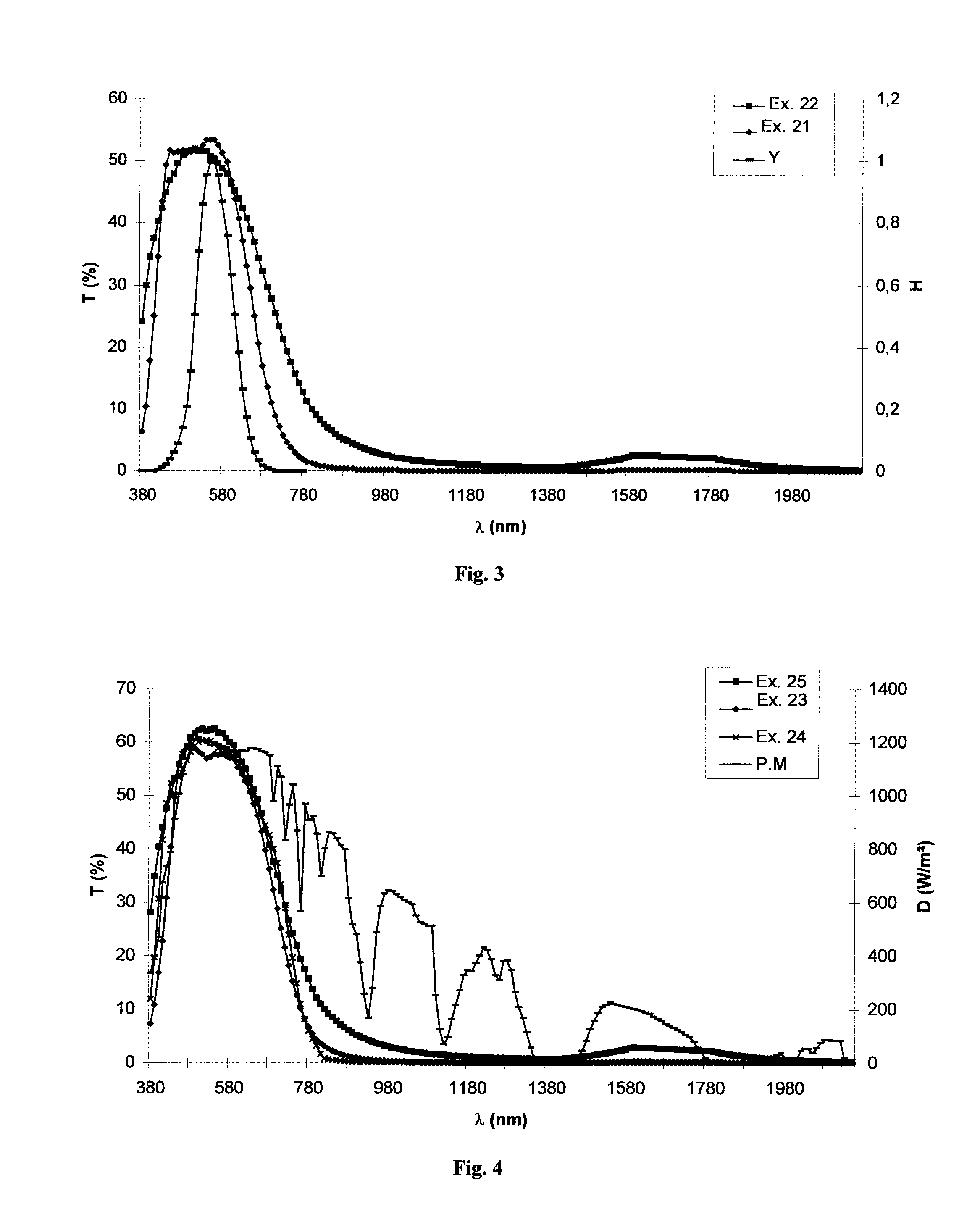

Transparent substrate which can be used alternatively or cumulatively, for thermal control, for electromagnetic armour and for heated glazing

ActiveUS20110236663A1Shorten the timePrevented being sensedElectric discharge tubesRecord information storageElectrical resistance and conductanceMaterials science

A glazing for thermal control and heating is provided. The glazing includes a transparent substrate including glass and provided with a thin-film stack including a plurality of functional layers. The thin-film stack includes at least three silver-based functional layers. The thin-film stack has a resistance R<1.5Ω per square.

Owner:SAINT-GOBAIN GLASS FRANCE

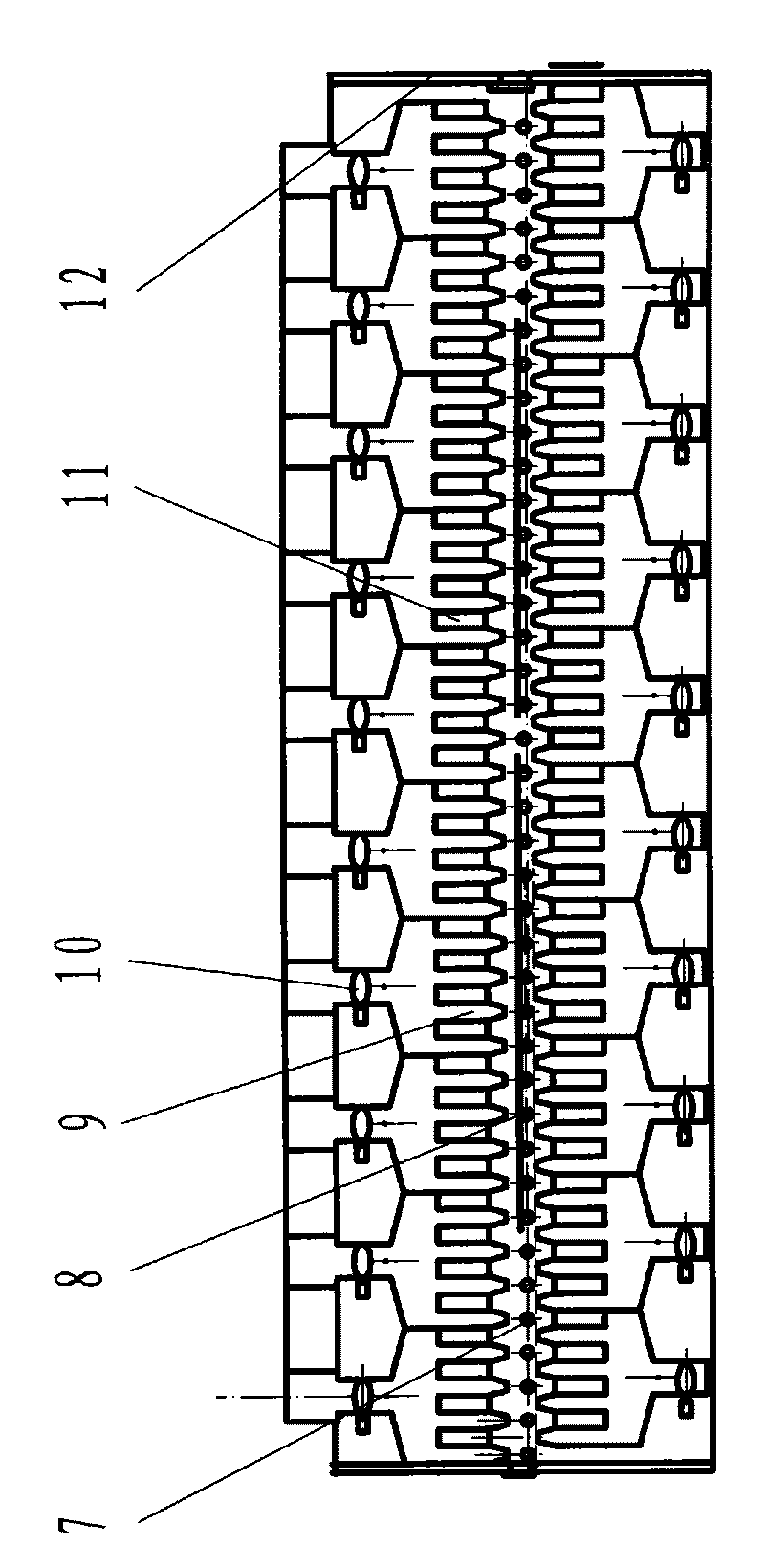

Energy-saving gas full-convection heating glass tempering furnace

InactiveCN101734844AImprove product qualityReduce manufacturing costGlass tempering apparatusGlass productionCombustion chamberMetallurgy

The invention relates to a novel energy-saving glass heat strengthening heating device, in particular to a glass tempering furnace adopting natural gas or industrial gas as energy and full-convection forced heating. The energy-saving gas full-convection heating glass tempering furnace mainly comprises a combustion chamber, a heat gas temperature pressure adjusting chamber, a high temperature forced convection heating chamber, a temperature and pressure measuring and process controlling system, a heat recycling system and the like. The energy-saving gas full-convection heating glass tempering furnace can improve the utilization efficiency of the energy maximally, saves the energy and reduces the production cost of tempered glass. The energy-saving gas full-convection heating glass tempering furnace is suitable for producing tempered glass for buildings or tempered glass for other purposes. The principle and structure of the energy-saving gas full-convection heating glass tempering furnace are suitable for glass tempering devices using liquid fuel such as diesel fuel as the energy.

Owner:王世忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com