Glass bending process

A process and bending technology, applied in the field of pressing and bending of heated glass plates, can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the drawings of the patent application are not intended to limit the exact scale of the elements of the invention, but that the drawings of the patent application are intended to be used in conjunction with the remainder of the specification. Unless expressly stated to the contrary, it should also be understood that the illustrated differences (which may be fractions of a unit of measure) between the various elements of the invention are not intended to be exact measurements of those between the various elements difference.

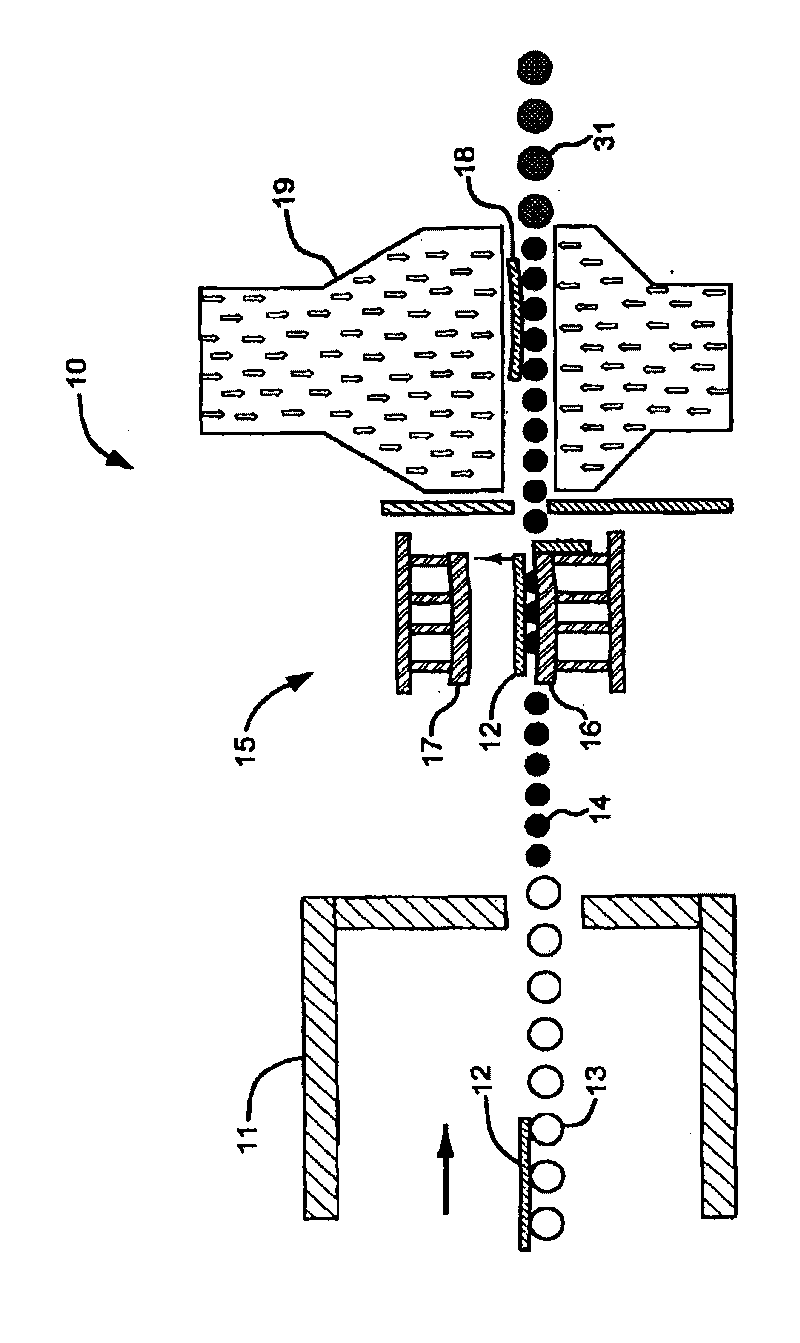

[0020] Figure 1 is an illustration of a prior art glass bending line 10 similar to the Bamford patent in which a preheating furnace 11 heats a glass sheet 12 on furnace rollers 13 along the direction indicated by the arrow in the furnace 11. sent in the direction. As the hot glass sheet 12 exits the preheating furnace 11, the hot glass sheet 12 is conveyed to a continuous conveyor 14 (e.g., a conveyor belt, flat roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com