Electrically heatable glass pane, method for production of same and window

A glass plate and electric heating technology, which is applied in the manufacture of the glass plate and the special contact field of the conductive coating, can solve the problems that did not mention the arc spraying process of the manufacturing connection strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

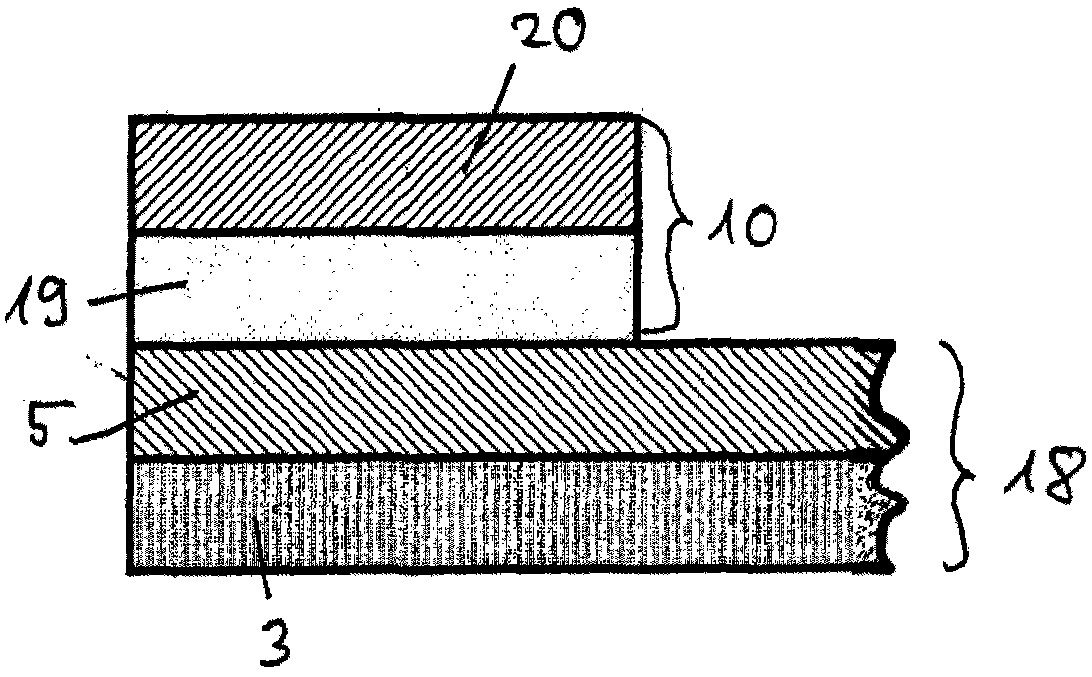

[0084] exist figure 1 , a cross-sectional view of a glass sheet 18 according to the invention is shown. The support structure and the bottom are formed from float glass 3 on which a conductive coating 5 (for example made of ITO) is applied. The coating 5 can be applied by methods known from the prior art, for example by sputtering. At the edge of this coated glass pane 18 , the contact piece 10 is applied, in this case in the form of 2 separate layers made of aluminum 19 and zinc 20 . Both the aluminum coating 19 and the zinc coating 20 are applied by galvanoplastic methods (for example using plasma or arc spraying).

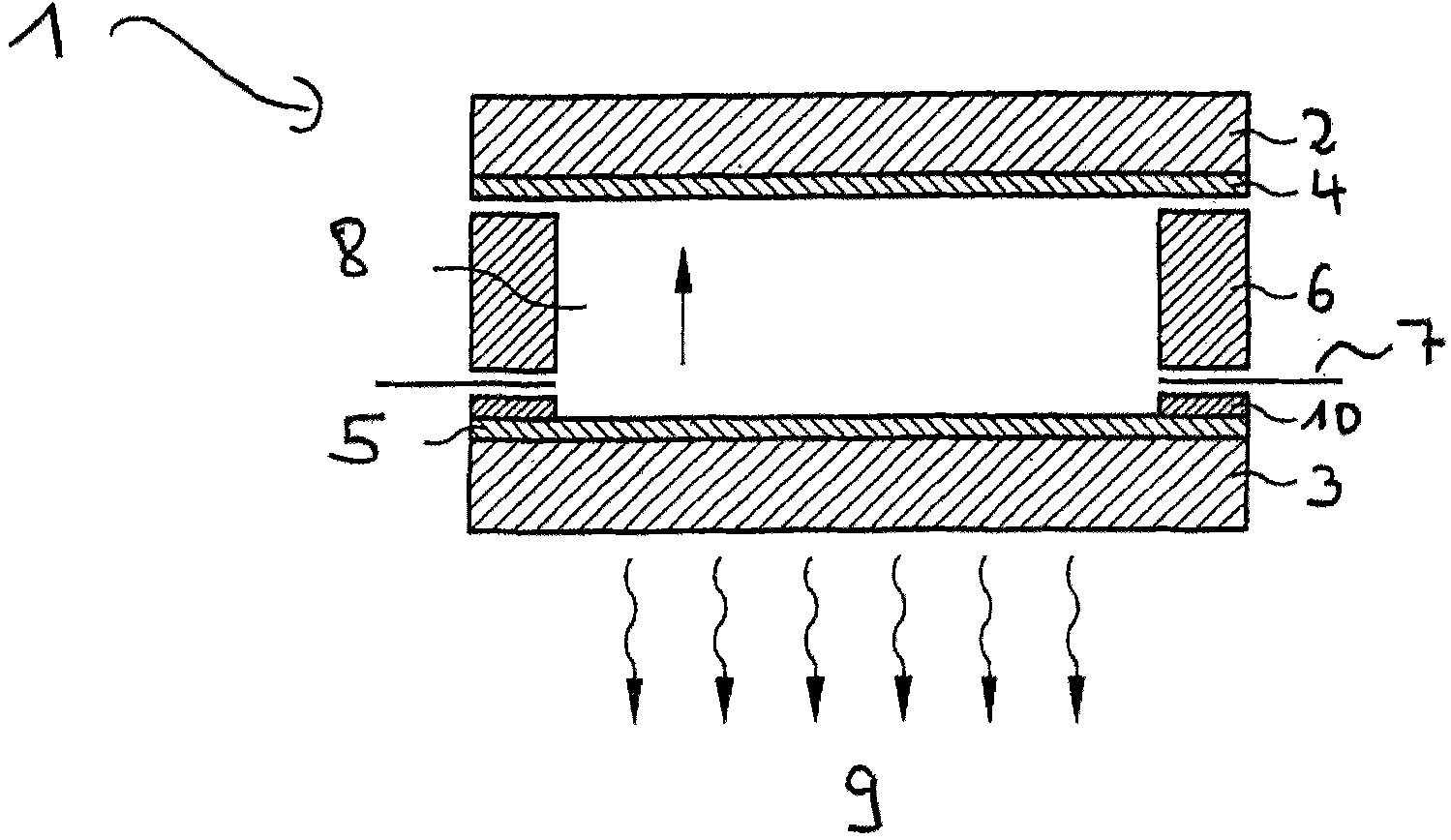

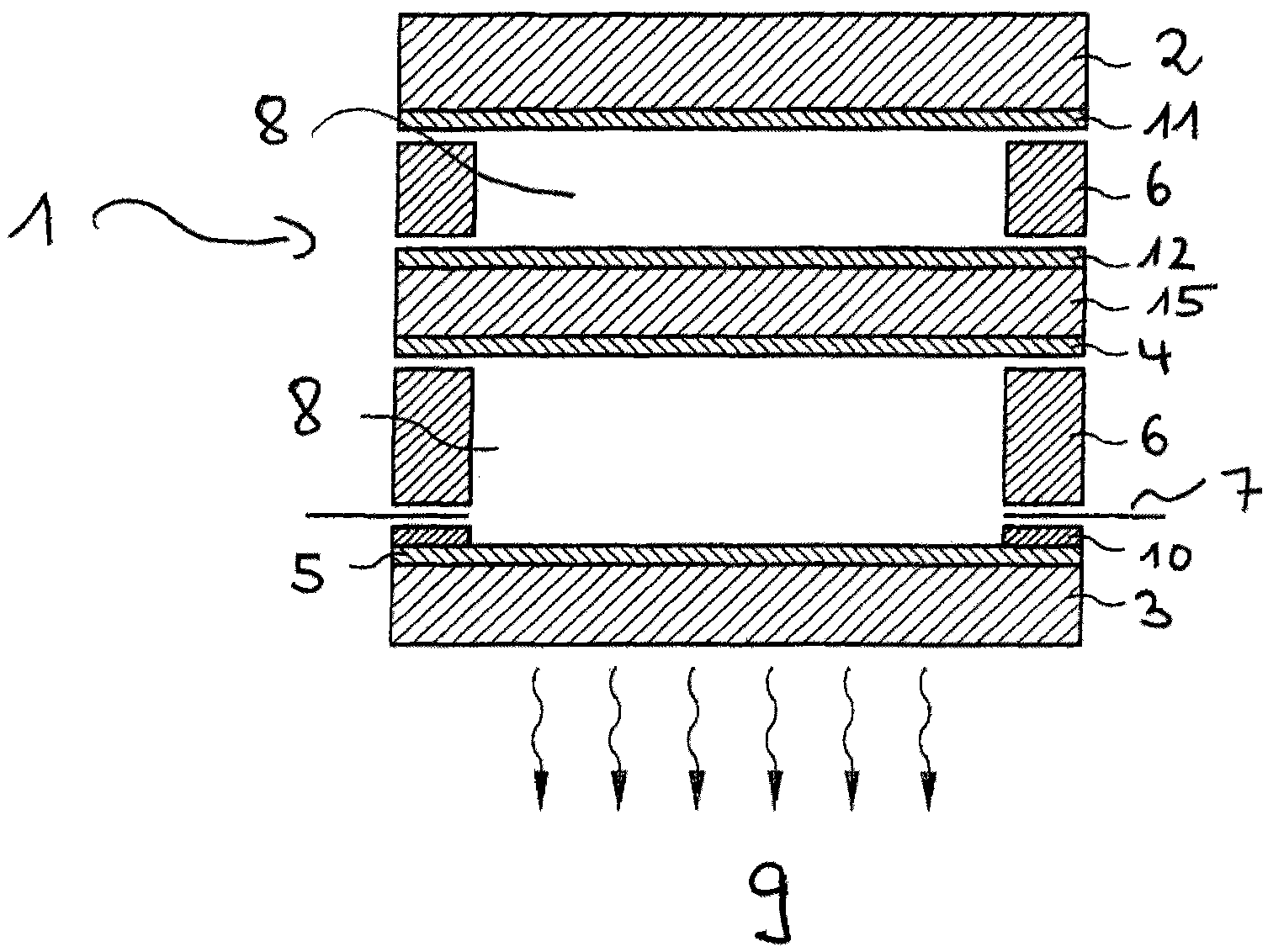

[0085] exist figure 2 In , a simple basic embodiment of a transparent heating element 1 based on float glass 2 on the outside and float glass 3 spaced apart at certain intervals is shown. The two float glasses are separated by a gasket 6 and sealed with an inert gas 8 at the same time. In a preferred embodiment, a high molecular weight inert gas such as k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com