Production process for flat tempered glass

A production process and glass technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of not improving glass thermal stability, appearance quality, power consumption, and ineffective control of wave curvature, etc., to achieve Reduced probability, good safety, low bow curvature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

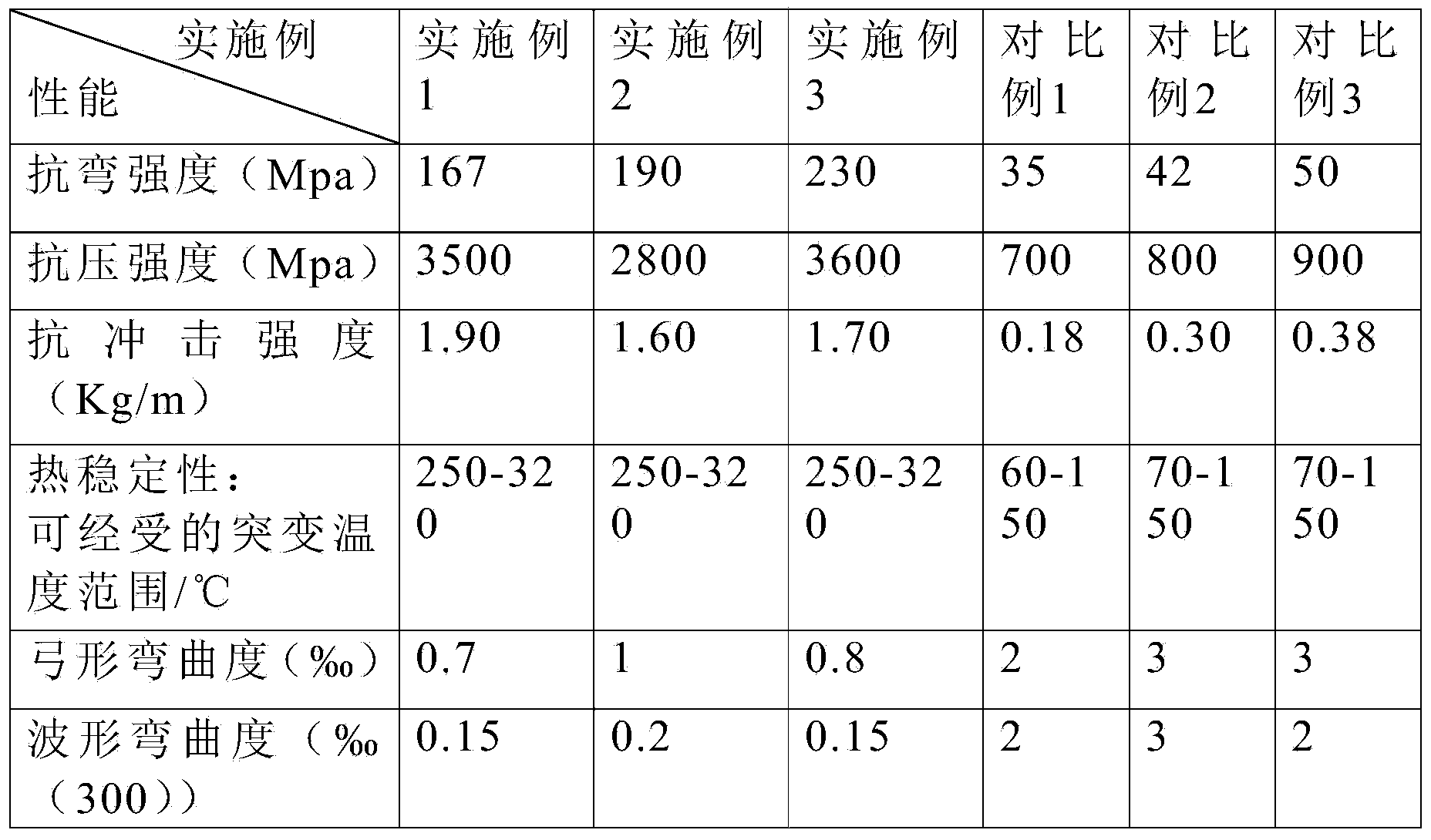

Examples

Embodiment 1

[0020] Cut the float glass with a thickness of 12mm, smooth the edge of the cut glass, clean it, and clean the dust, oil, impurities, etc. on the glass surface, so as to prevent these impurities from being brought into the convection tempering furnace, causing Pockets are formed on the surface of the final tempered glass product;

[0021] Put the above-mentioned cleaned glass horizontally on the roller table, and send it into the convection tempering furnace through the ceramic roller table for heating treatment. The heating treatment is simultaneous heating of the upper and lower surfaces of the glass: the first section: the heating temperature of the upper surface of the glass : 470°C, lower surface heating temperature: 460°C, heating time 180s; second zone: glass upper surface heating temperature: 695°C, lower surface heating temperature: 690°C, heating time 250s;

[0022] The above-mentioned heated glass is taken out of the furnace and sent to the flat air grid, firstly th...

Embodiment 2

[0024] Cut the float glass with a thickness of 5mm, smooth the edge of the cut glass, clean it, and clean the dust, oil, impurities, etc. on the glass surface, so as to prevent these impurities from being brought into the convection tempering furnace, causing Pockets are formed on the surface of the final tempered glass product;

[0025]Put the above-mentioned cleaned glass horizontally on the roller table, and send it into the convection tempering furnace through the ceramic roller table for heating treatment. The heating treatment is simultaneous heating of the upper and lower surfaces of the glass: the first section: the heating temperature of the upper surface of the glass : 480°C, lower surface heating temperature: 470°C, heating time 150s; second zone: glass upper surface heating temperature: 700°C, lower surface heating temperature: 695°C, heating time 220s;

[0026] The above-mentioned heated glass is taken out of the furnace and sent to the flat air grid, firstly thro...

Embodiment 3

[0028] Cut the float glass with a thickness of 19mm, smooth the edge of the cut glass, clean it, clean the dust, oil, impurities, etc. on the glass surface, so as to avoid these impurities being brought into the convection tempering furnace, causing Pockets are formed on the surface of the final tempered glass product;

[0029] Put the above-mentioned cleaned glass horizontally on the roller table, and send it into the convection tempering furnace through the ceramic roller table for heating treatment. The heating treatment is simultaneous heating of the upper and lower surfaces of the glass: the first section: the heating temperature of the upper surface of the glass : 460°C, lower surface heating temperature: 450°C, heating time: 200s; second interval: glass upper surface heating temperature: 690°C, lower surface heating temperature: 685°C, heating time: 280s;

[0030] The above-mentioned heated glass is taken out of the furnace and sent to the flat air grid, firstly through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com