Fixture and method for measuring maximum tensile and shearing force of lap joint of friction stir welding

A technology of friction stir welding and lap joints, which is applied to measuring devices, using stable shear force to test material strength, and using stable tension/pressure to test material strength, etc., can solve the influence of measurement results and the inability to load On the same straight line, etc., to achieve the effect of eliminating the additional bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

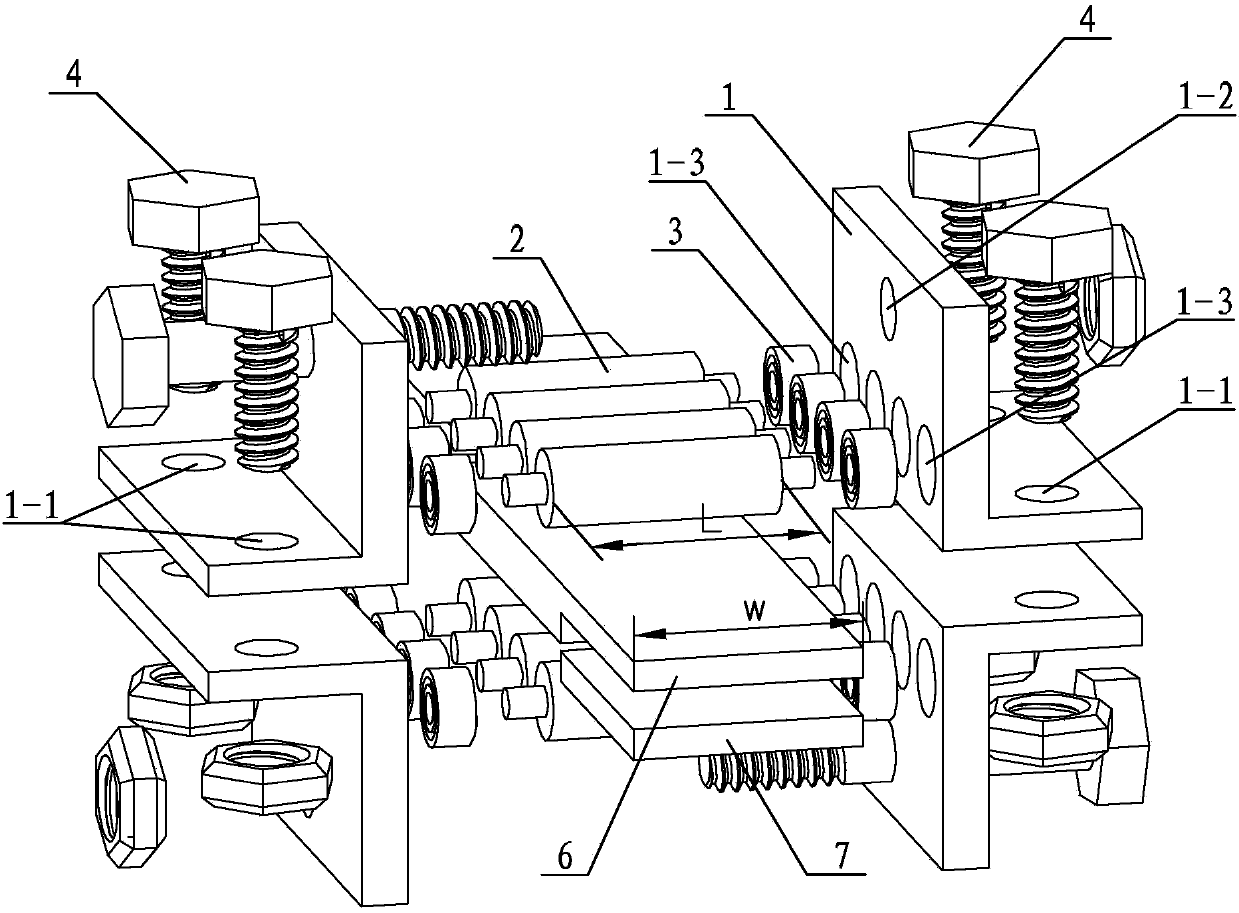

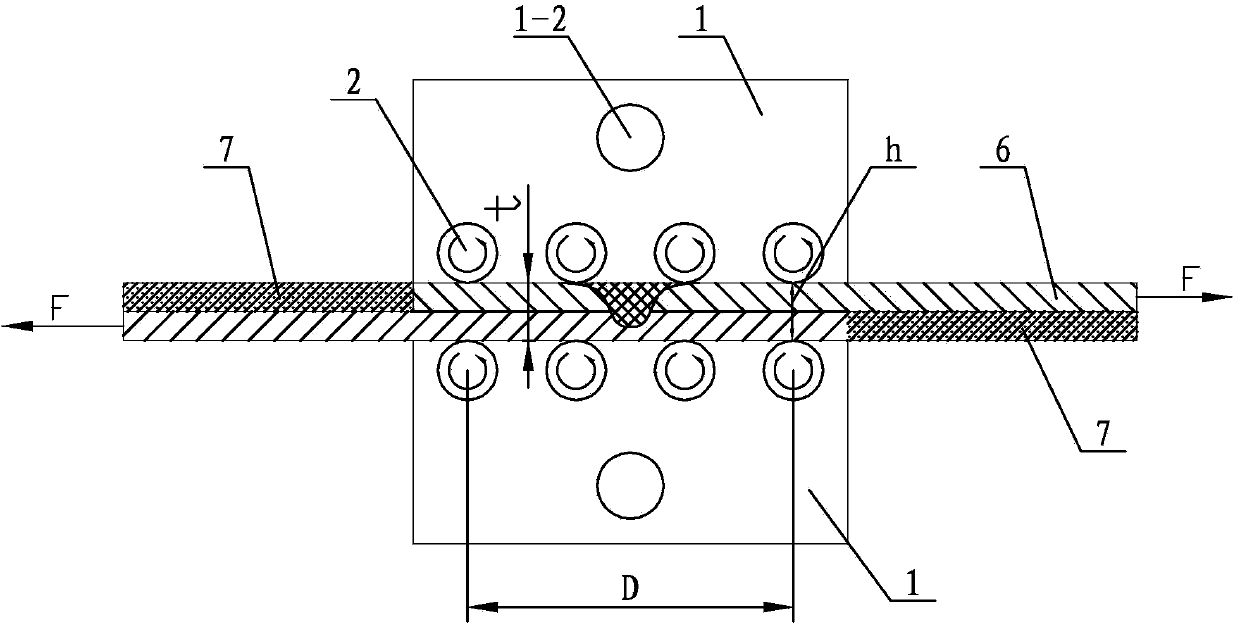

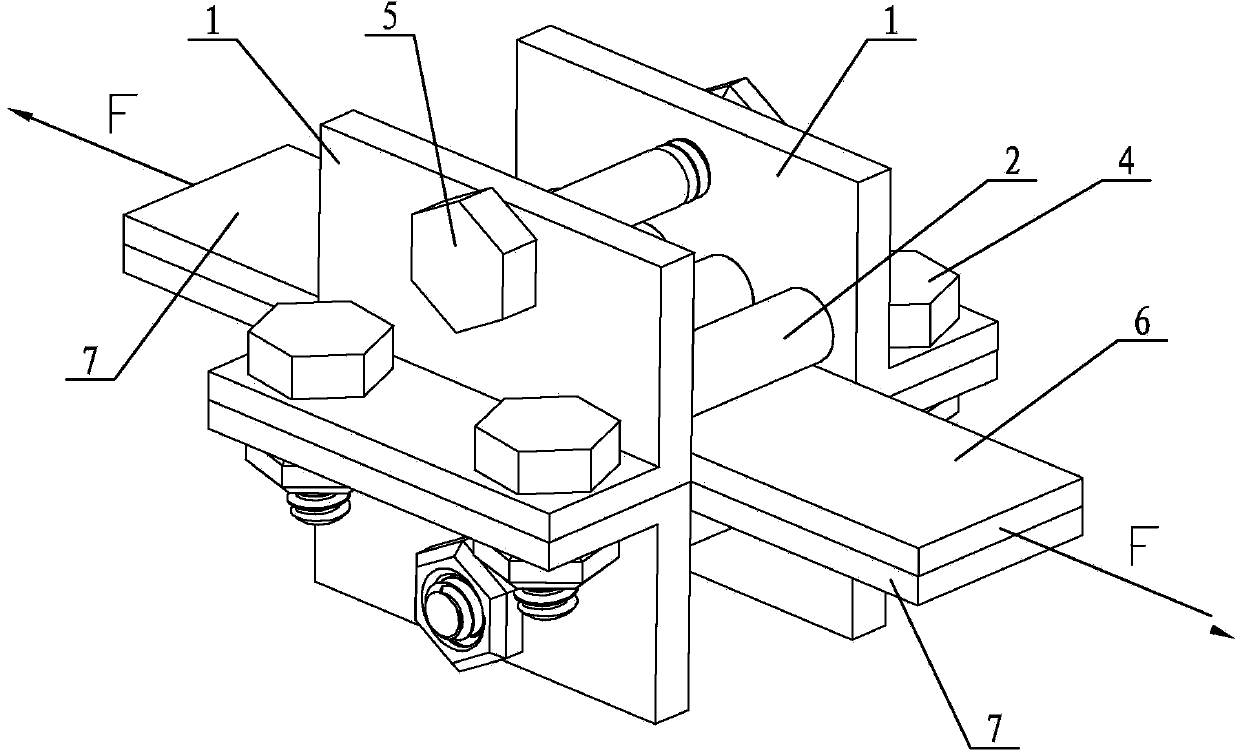

[0015] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes two second connecting elements 5, four L-shaped support plates 1, four first connecting elements 4, eight rollers 2 and sixteen positioning bearings 3, each L Two first connection holes 1-1 are provided on the short plate of the L-shaped support plate 1, and a second connection hole 1-2 and four bearing mounting holes 1-3 are provided on the long plate of each L-shaped support plate 1 , the four bearing mounting holes 1-3 are arranged along the same horizontal line, and the long plate of each L-shaped support plate 1 is provided with four bearing mounting holes 1-3 at the bottom, and the eight rollers 2 are arranged in two layers, each layer Four rollers 2 are arranged in parallel, the four rollers 2 on the upper layer are arranged opposite to the four rollers 2 on the lower layer one by one, two L-shaped support plates 1 are symmetrically arranged at both e...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the roller shaft 2 of this embodiment is a stepped shaft, the diameter of both ends is smaller than the diameter of the middle working part. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 This embodiment will be described. In this embodiment, the roller 2 and the positioning bearing 3 are interference fit. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com