Cone-disc Continuously Variable Transmission and Its Speed-regulating Mechanism

A continuously variable transmission, speed regulating mechanism technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc. It can achieve the effect of simple structure, eliminating additional bending moment and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and given embodiment, the present invention will be further described:

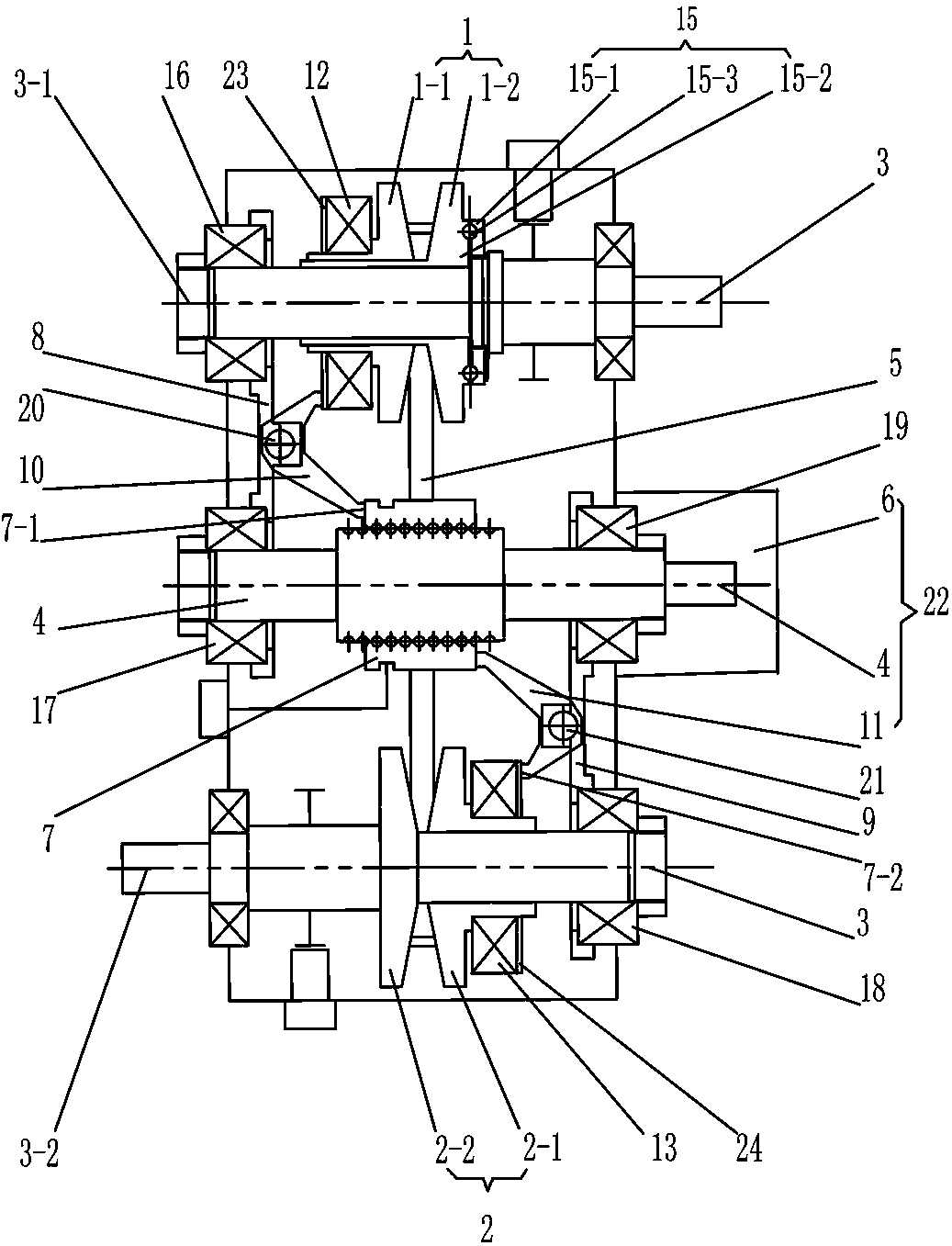

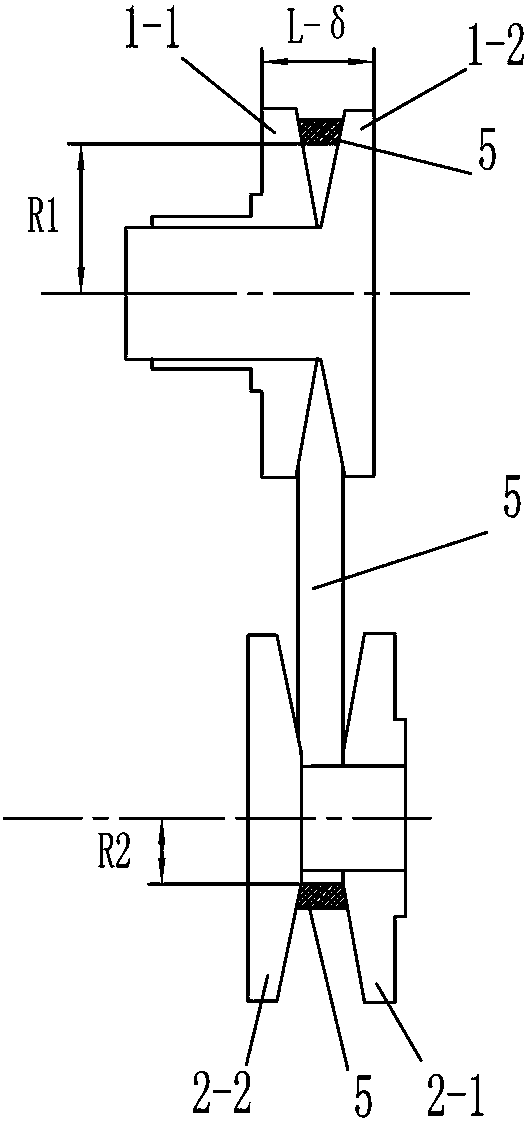

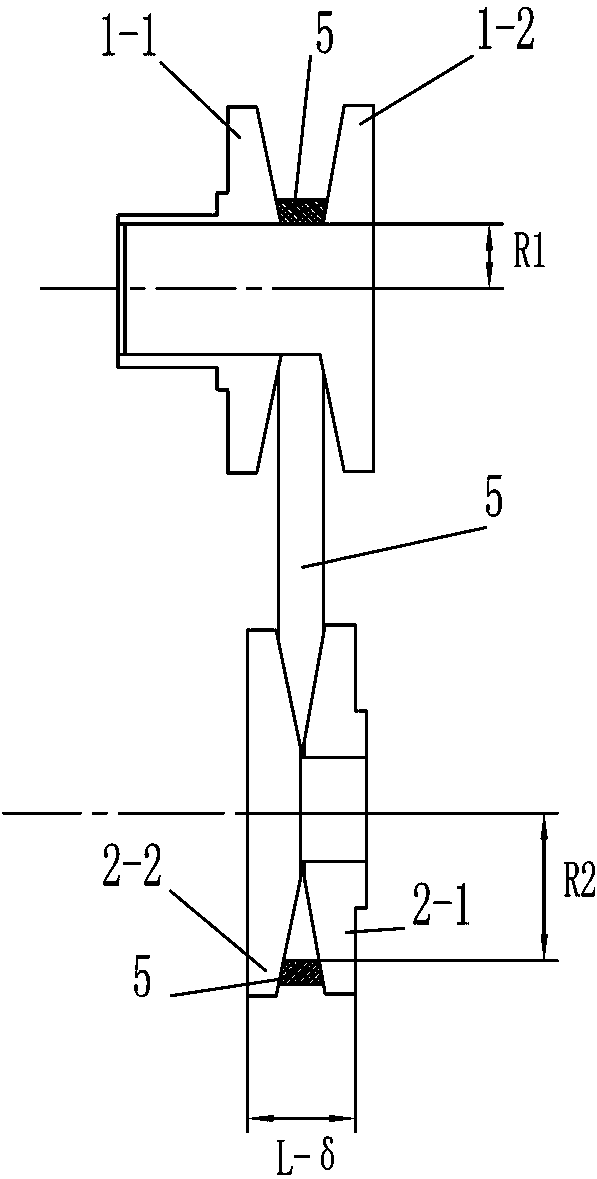

[0035] Such as Figure 1-8 As shown, a speed regulating mechanism includes a speed regulating shaft 4 and a speed regulating motor 6, and the speed regulating shaft 4 is connected with the speed regulating motor 6, and is characterized in that it also includes a speed regulating nut 7, a driving shaft lever bracket 8, and a Moving shaft lever bracket 9, driving shaft speed regulating lever 10 and moving shaft speed regulating lever 11, said speed regulating shaft 4 is provided with threads, said speed regulating nut 7 is connected on the thread of speed regulating shaft 4, said driving shaft The shaft speed regulating lever 10 is hinged on the driving shaft lever bracket 8 and one end is offset against the speed regulating nut 7, and the driven shaft speed regulating lever 11 is hinged on the driven shaft lever bracket 9 and one end is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com