Electro-hydraulic brake system

A hydraulic braking and electronic technology, applied in braking control systems, brakes, brake components, etc., can solve problems such as hidden dangers in reliability and safety, leakage of nitrogen gas from high-pressure accumulators, etc., to achieve good braking feeling, The effect of fast response and reduced axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

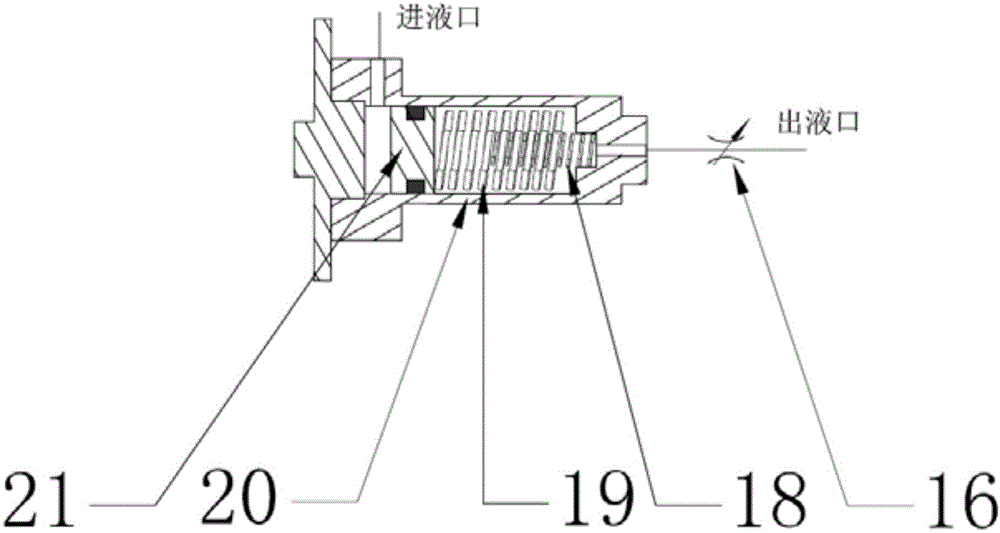

[0049] like figure 1 As shown, a motor-driven electro-hydraulic braking system includes:

[0050] Brake pedal 1, a pedal displacement sensor 25 for obtaining the displacement of the driver's depressing the brake pedal, a hydraulic pressure sensor 23 for judging the driver's braking intention, a liquid storage tank 13, and a sensor for simulating the pedal braking feedback force pedal simulator 20;

[0051]A brake pedal push rod 2 with two branches connected to the brake pedal 1, one of the branches of the brake pedal push rod 2 is set against the linear motion mechanism, a certain gap is reserved between the two, and it is connected with the brake master cylinder 14 The pistons are located on the same axis, so that when the motor fails, the driver’s pedal force can drive the rack or lead screw to move forward, pushing the master cylinder piston to generate braking force; the other branch of the brake pedal push rod 2 is connected to the secondary master cylinder 24 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com