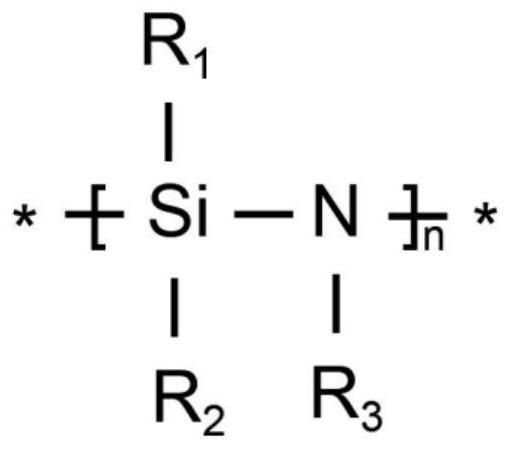

Methyl polysilazane resin and preparation method thereof

A technology of methylpolysilazane and methyldichlorosilane, which is applied in the field of methylpolysilazane resin and its preparation, can solve the problems of environmental pollution, cumbersome operation process and high cost, and achieve simple and convenient operation, strong Adhesion, little pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

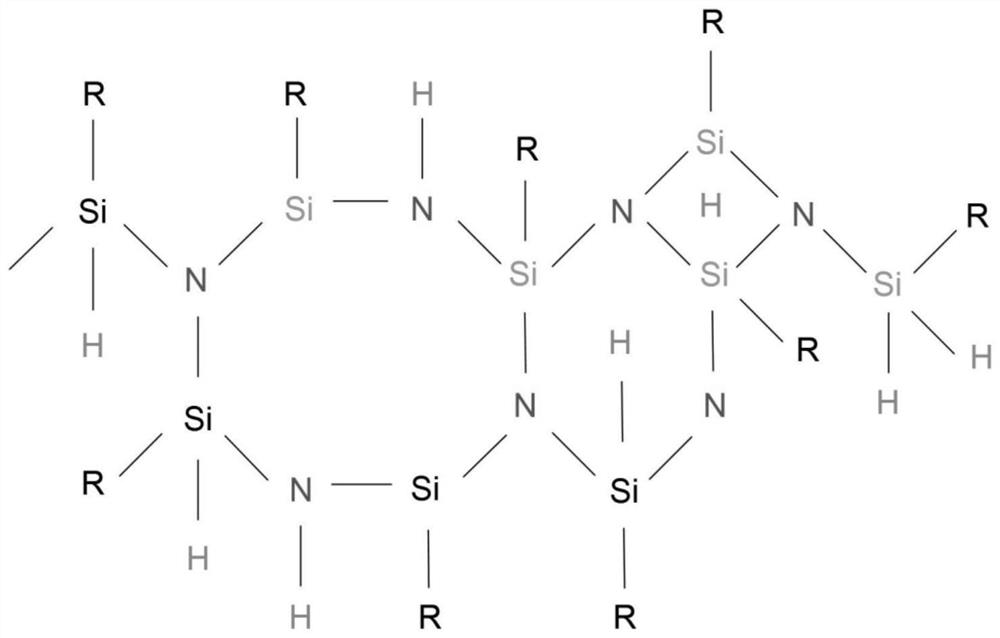

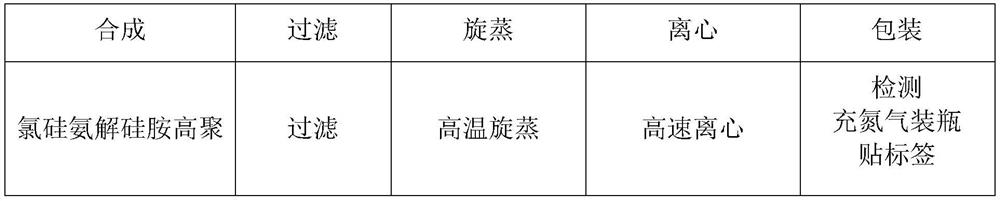

Method used

Image

Examples

Embodiment 1

[0018] ①Add 45g methyldichlorosilane, 45g trichlorosilane and 500g solvent together into a refrigerable tubular reactor or a stirrable reactor, mix the raw materials evenly and refrigerate, and control the polymerization temperature at -30℃~40℃ It is advisable; ②Slowly feed 0.3L / h*4h of ammonia gas into the reactor; ③Stop feeding ammonia gas; ④Filter impurities NH 4 Cl; ⑤ rotary steaming; ⑥ centrifugation.

Embodiment 2

[0020] ①Put 50g of methyldichlorosilane, 50g of trichlorosilane and 500g of solvent together into a refrigerable tubular reactor or a stirrable reactor, mix the raw materials evenly and refrigerate, and control the polymerization temperature at -30℃~40℃ It is advisable; ②Slowly feed 0.3L / h*4h of ammonia gas into the reactor; ③Stop feeding ammonia gas; ④Filter impurities NH 4 Cl; ⑤ rotary steaming; ⑥ centrifugation.

Embodiment 3

[0022] ①Put 50g of methyldichlorosilane, 45g of trichlorosilane and 500g of solvent together into a refrigerable tubular reactor or a stirrable reactor, mix the raw materials evenly and refrigerate, and control the polymerization temperature at -30°C to 40°C It is advisable; ②Slowly feed 0.3L / h*4h of ammonia gas into the reactor; ③Stop feeding ammonia gas; ④Filter impurities NH 4 Cl; ⑤ rotary steaming; ⑥ centrifugation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com