Low-smoke-density PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) plastic for automobile interior and preparation method thereof

A technology for automobile interior parts and smoke density, which is applied in the field of low smoke density PC/ABS alloy for automobile interior parts and its preparation, and can solve the problems of poor flame retardant performance of the alloy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

[0030] According to the data corresponding to Example 1 in Table 1, four kinds of flame retardants such as decabromodiphenylethane, tris (2-chloropropyl) phosphate, melamine cyanurate and magnesium hydroxide are weighed, stirred and mixed evenly, and can be prepared Composite flame retardants.

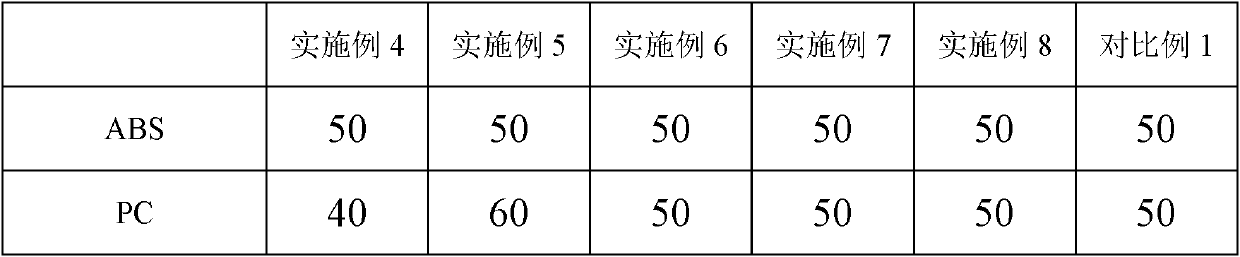

[0031] Table 1: Composite flame retardant formula table Unit: kg

[0032] Example 1

Embodiment 2

[0034] According to the data corresponding to Example 2 in Table 1, four kinds of flame retardants such as decabromodiphenylethane, tris (2-chloropropyl) phosphate, melamine cyanurate and magnesium hydroxide are weighed, stirred and mixed evenly, and can be prepared Composite flame retardants.

Embodiment 3

[0036] According to the data corresponding to Example 3 in Table 1, four kinds of flame retardants such as decabromodiphenylethane, tris (2-chloropropyl) phosphate, melamine cyanurate and magnesium hydroxide are weighed, stirred and mixed evenly, and can be prepared Composite flame retardants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com