Method for preparing zinc molybdate by using cationic membrane electrolysis method

A cationic membrane, zinc molybdate technology, applied in the electrolysis process, electrolysis components, organic diaphragms, etc., can solve the problems of long reaction time with additives, difficulty in large-scale production, complicated preparation process, etc., and achieves reduced preparation cost and easy operation. , The effect of the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

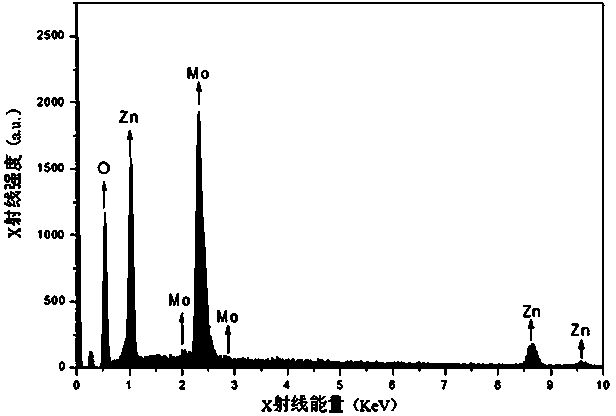

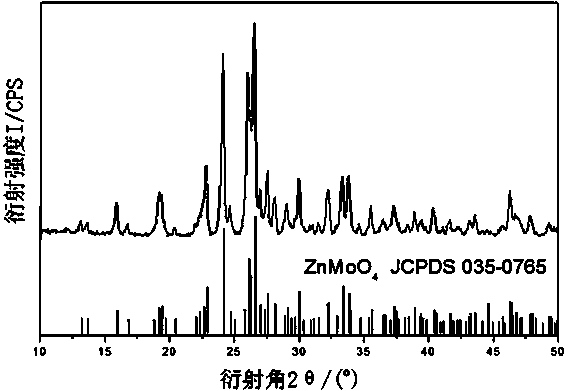

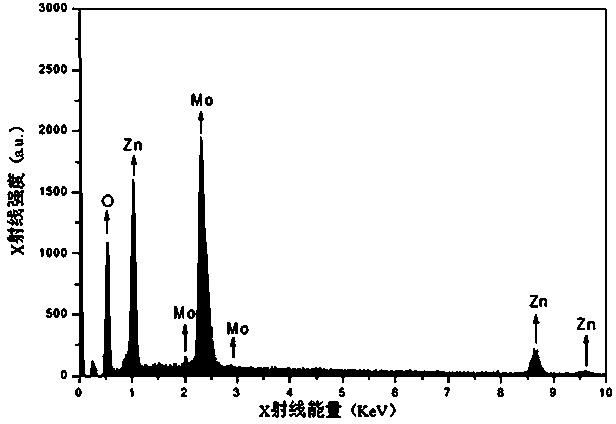

Image

Examples

Embodiment 1

[0035] A kind of method utilizing cationic membrane electrolysis to prepare zinc molybdate, concrete steps are as follows:

[0036] (1) Use zinc sheet as anode, inert electrode as cathode, 95ml of sodium molybdate aqueous solution with a concentration of 0.01mol / L as anolyte, 90ml of alkali solution as catholyte, and double-chamber electrolysis with cationic membrane as diaphragm In the tank, the method of constant voltage electrolysis is adopted, and the temperature range is controlled from room temperature to 50°C. Constant voltage electrolysis of sodium molybdate aqueous solution for 10 minutes, namely Na + The ions are all transferred to the cathode chamber;

[0037] The inert electrode is a titanium mesh;

[0038] Described alkali solution is the sodium hydroxide aqueous solution that concentration is 0.01mol / L;

[0039] The cationic membrane is Nafion perfluorosulfonic acid 212 type cationic exchange membrane;

[0040] The voltage of the constant voltage electrolysis ...

Embodiment 2

[0045] A kind of method utilizing cationic membrane electrolysis to prepare zinc molybdate, concrete steps are as follows:

[0046] (1) Use zinc sheet as anode, inert electrode as cathode, 95ml of sodium molybdate aqueous solution with a concentration of 0.01mol / L as anolyte, 90ml of alkali solution as catholyte, and double-chamber electrolysis with cationic membrane as diaphragm In the tank, the method of constant current electrolysis is adopted, and the temperature range is controlled from room temperature to 50°C to electrolyze the sodium molybdate aqueous solution for 5.1min, that is, Na + The ions are all transferred to the cathode chamber;

[0047] The inert electrode is a titanium mesh;

[0048] Described alkali solution is the sodium hydroxide aqueous solution that concentration is 0.01mol / L;

[0049] The cationic membrane is Nafion perfluorosulfonic acid 212 type cationic exchange membrane;

[0050] The current density of the constant current electrolysis is 75mA / c...

Embodiment 3

[0055] A kind of method utilizing cationic membrane electrolysis to prepare zinc molybdate, concrete steps are as follows:

[0056] (1) Use zinc sheet as anode, inert electrode as cathode, 95ml of sodium molybdate aqueous solution with a concentration of 0.01mol / L as anolyte, 90ml of salt solution as catholyte, and double-chamber electrolysis with cationic membrane as diaphragm In the tank, the method of constant current electrolysis is adopted, and the temperature range is controlled from room temperature to 50°C to electrolyze the sodium molybdate aqueous solution for 5.1min, that is, Na + The ions are all transferred to the cathode chamber;

[0057] The inert electrode is a titanium mesh;

[0058] Described salt solution is the sodium chloride aqueous solution that concentration is 0.01mol / L;

[0059] The cationic membrane is Nafion perfluorosulfonic acid 212 type cationic exchange membrane;

[0060] The current density of the constant current electrolysis is 75mA / cm 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com