Water -borne anticorrosion paint and method for preparing same

A technology of anti-corrosion coatings and anti-corrosion pigments, which is applied in the field of coatings to achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

[0014] Prepare the following raw materials:

[0015] Waterborne epoxy resin (OudraSperse WB 6001, Dow Chemical)

[0016] Silica sol (PA30, Shandong Baite New Material Co., Ltd.)

[0017] Anti-corrosion pigments: zinc phosphate (Taicang Chengxin Chemical Co., Ltd.), modified zinc phosphate (MZP 409, Changsha Ruishi Environmental Protection New Material Co., Ltd.), zinc molybdate (Taizhou Xinyuan Chemical Co., Ltd.), aluminum tripolyphosphate (Weihai Tianchuang Fine Chemical Co., Ltd.), calcium ion exchange pigment (SHIELDEXAC5 ion exchange antirust pigment, Grace China Co., Ltd.).

[0018] Pigments and fillers: iron oxide red (Zibo Yanyong iron oxide red factory), titanium dioxide (R737, Shanghai Xujiang Industrial Co., Ltd.), barium sulfate (Shanghai Jianghu Titanium White Chemical Products Co., Ltd.), talcum powder (Jiangxi Shanggao County Xuefeng Powder Co., Ltd.), mica powder (Dongguan Ruiqi Chemical Co., Ltd.).

[0019] Auxiliaries: wetting agent (FLASH-X 330, Halox Com...

Embodiment 6~ Embodiment 10

[0035] As an improved scheme of the water-based anticorrosion paint provided by the present invention, the anticorrosion pigment also contains aluminum tripolyphosphate and / or calcium ion exchange pigment. The weight of the water-based epoxy resin is 1 to 9 times the weight of the silica sol, more preferably, the weight of the water-based epoxy resin is 3 to 5 times the weight of the silica sol.

[0036] Prepare each raw material, source of raw material is the same as embodiment 1~embodiment 5, the weight ratio of each raw material is shown in table 3. Among them, the weight ratios of water-based epoxy resin and silica sol are 1:1, 3:1, 4:1, 5:1, and 9:1, respectively.

[0037] The weight proportion of each component of the water-based anticorrosion coating in the embodiment 6~the embodiment 10 of table 5

[0038]

[0039]

[0040] The preparation method is the same as in Example 1 to Example 5.

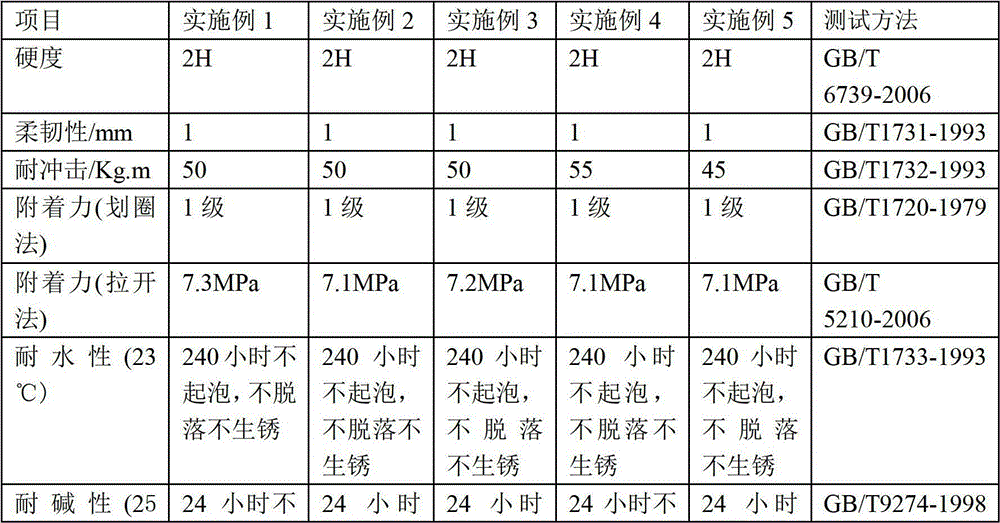

[0041] Performance Testing

[0042] The performance test data of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com