Graphene modified aqueous epoxy heavy anti-corrosion coating and detection method thereof

A technology for graphene modification and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex graphene addition steps, environmental pollution, etc., and achieve easy industrial batch production, stable chemical properties, grainy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with embodiment.

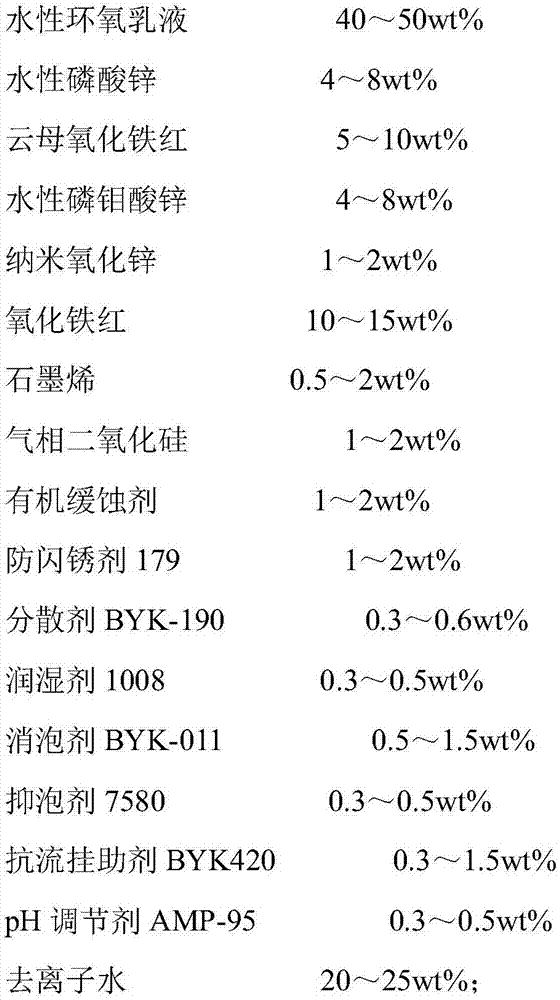

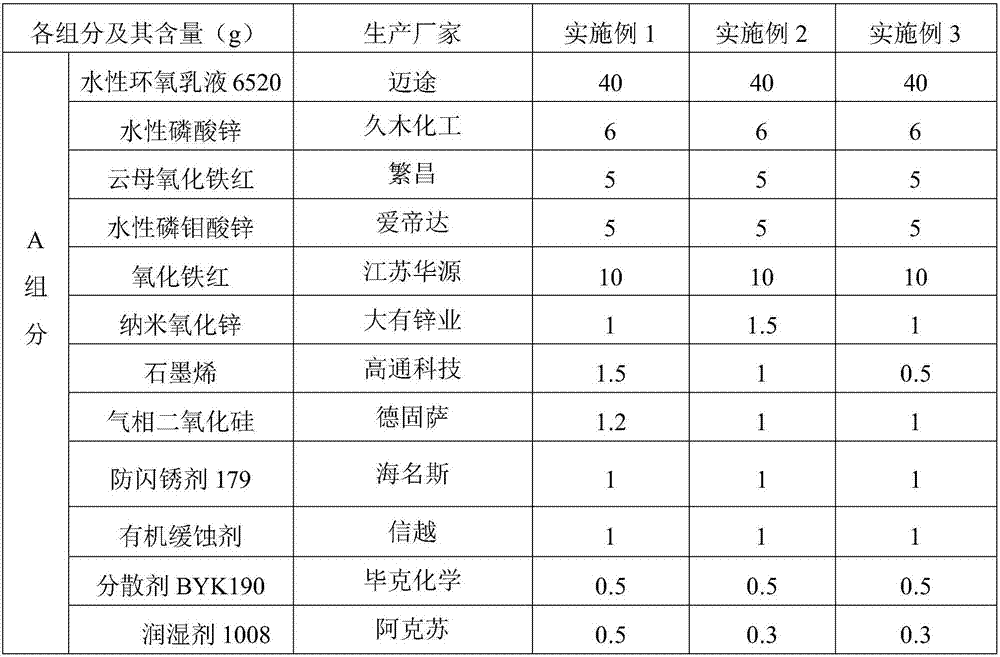

[0028] See Table 1 for the components and contents of graphene-modified water-based epoxy heavy-duty anticorrosion coatings in Examples 1 to 3.

[0029] Table 1:

[0030]

[0031]

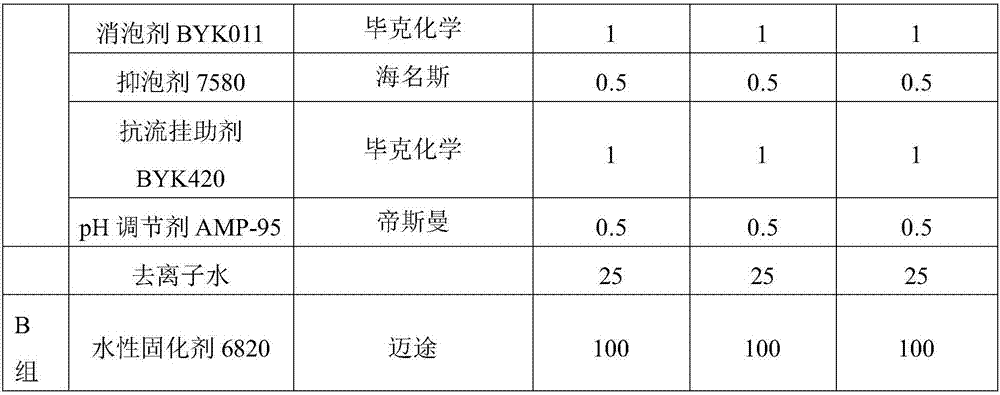

[0032] According to the general testing standards and conventional testing methods in this industry, the main performance indicators of the finished graphene-modified water-based epoxy heavy-duty coatings made in Example 1 and the commercially available similar epoxy coatings are detected and compared. The test results are shown in Table 2 .

[0033] Table 2:

[0034] The test data in table 2 shows that compared with similar products, the graphene modified water-based epoxy heavy-duty anti-corrosion coating of the present invention is environmentally friendly, has excellent anti-corrosion performance, strong substrate adhesion, good flexibility and impact resistance, and has extremely strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com