Corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and preparation method thereof

A technology of polyvinyl chloride and sheathing material, which is applied to cables, insulated cables, conductors and other directions, can solve problems such as the reduction of physical properties, and achieve the effects of simple preparation method, good physical properties and use performance, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare CMP-grade flame-retardant and smoke-suppressing PVC cable sheath material A1 as follows:

[0049] The toughening modifier was weighed according to the parts by weight in Example 1 in Table 1, and heated to 160° C. while stirring to make it in a molten state.

[0050] Then take polyvinyl chloride, common plasticizer, flame retardant plasticizer, flame retardant, smoke suppressant, stabilizer and auxiliary agent according to the weight part in embodiment 1 in table 1, pour the raw material that weighs into Put it into the high mixer for mixing, mix evenly and then add it to the internal mixer for banburying. After the material is plasticized into a ball, pour it into the feeder while it is hot, and then evenly add it into the single-screw extruder from the feeder.

[0051] An injection device is added above the metering section of the single-screw extruder, and the toughening modifier in the molten state is injected into the single-screw extruder quantitatively by...

Embodiment 2-4

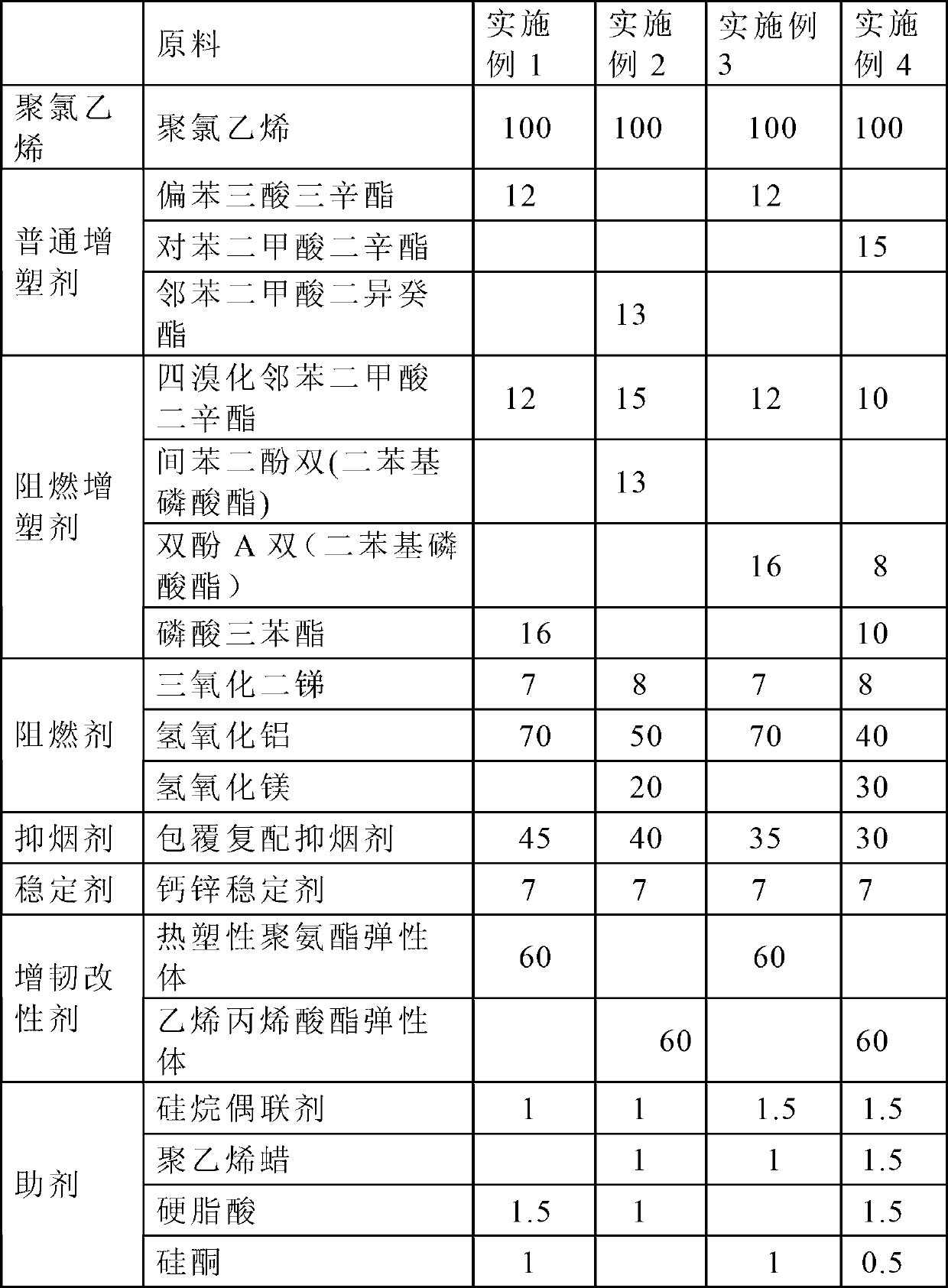

[0055] According to the method of Example 1 and the raw material components and parts by weight of Examples 2-4 in Table 1, CMP grade flame-retardant and smoke-suppressing PVC cable sheathing materials A2-A4 were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com