Organosilicon coating and preparation method thereof

An elastic coating and silicone technology, applied in the coating and other directions, can solve the problems of poor substrate adhesion, long surface drying time, easy peeling, etc., and achieve excellent electrical insulation, fast curing speed, and low overall cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

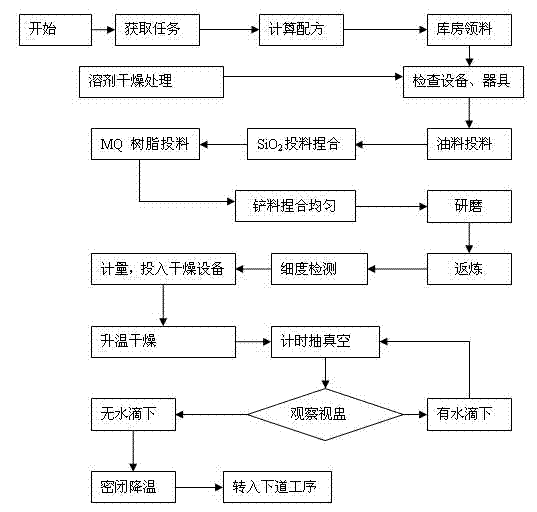

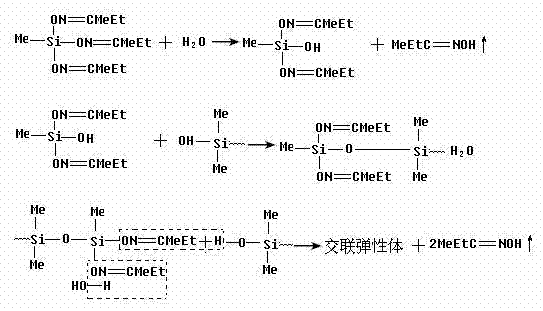

Method used

Image

Examples

Embodiment 1

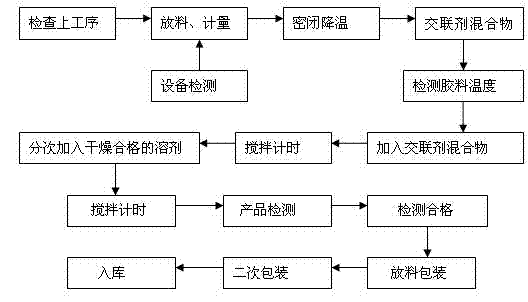

[0037] Select 90 parts of high-viscosity α, ω-dihydroxy polydimethylsiloxane, viscosity at 500mPa.s / 25°C, 10 parts of MQ resin, 10 parts of fumed silica, and knead them evenly in a kneader. The rubber material is transferred to a three-roll machine for grinding, and then transferred to a drying kettle to heat up and stir after being uniform. Keep the temperature of the rubber material at 100 ℃ and vacuum degree = 0.085 Mpa, stir and vacuum dry for 2 hours, and seal it for use.

[0038] Put the dried rubber into a planetary stirring tank, and when the rubber is sealed and cooled within 30°C, add 0.3 parts of a vulcanization accelerator formulated with organotin, 2 parts of methyl tributylketoximosilane and vinyl tributyl ketone silane 2 parts of butanone oximinosilane, 1 part of propylaminotriethoxysilane and 1 part of 3-glycidyloxypropyltrimethoxysilane, stirred at high speed for 20 minutes, added 70 parts of dry-treated 120# solvent oil, Stir for 20 minutes to obtain a silico...

Embodiment 2

[0040] Select 110 parts of high-viscosity α, ω-dihydroxy polydimethylsiloxane, viscosity 60000mPa.s / 25℃, 20 parts of MQ resin, 15 parts of fumed silica, knead evenly in the kneader, and glue Transfer the material to a three-roll machine for grinding, and then transfer it to a drying kettle for heating and stirring. Keep the temperature of the rubber material at 130 ℃ and vacuum degree = 0.090 Mpa. Stir and vacuum dry for 3 hours, and then seal it for use.

[0041] Put the dried rubber into a planetary stirring tank, and when the rubber is sealed and cooled within the range of 40 °C, add 0.6 parts of a vulcanization accelerator formulated with organotin, 2.3 parts of methyl tributylketoximosilane and vinyl tributyl ketone silane 2.3 parts of methyl ethyl ketoxime silane, 2 parts of propylaminotriethoxysilane and 1.5 parts of 3-glycidyl etheroxypropyl trimethoxysilane, stir at high speed for 25 minutes, add 80 parts of dry-treated 200# solvent gasoline, stir After 25 minutes, th...

Embodiment 3

[0043] Select 120 parts of high-viscosity α, ω-dihydroxy polydimethylsiloxane, viscosity at 100000 mPa.s / 25°C, 30 parts of MQ resin, 30 parts of precipitated white carbon black, knead evenly in the kneader, Transfer the rubber material to a three-roll machine for grinding, and then transfer it to a drying kettle for heating and stirring. Keep the temperature of the rubber material at 150 ℃ and vacuum degree = 0.095 Mpa. Stir and vacuum dry for 4 hours, and seal it for use.

[0044] Put the dried rubber material into the planetary stirring tank, and when the rubber material is sealed and cooled within the range of 50 ℃, add 1 part of vulcanization accelerator prepared by organotin, 3 parts of methyl tributylketoxime silane and vinyl tributyl ketone silane 3 parts of methyl ethyl ketoxime silane, 3 parts of propylaminotriethoxysilane and 1 part of 3-glycidyloxypropyltrimethoxysilane, stirred at high speed for 30 minutes, added 90 parts of dry-treated 200# solvent gasoline, Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com