Non-ionic aqueous epoxy resin emulsion and its preparation method

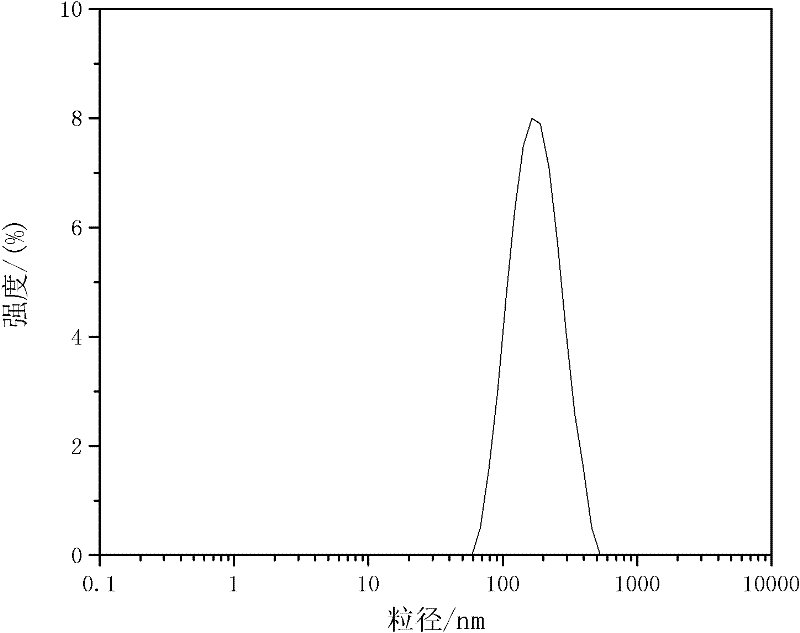

A technology of water-based epoxy resin and epoxy resin, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of cumbersome preparation methods and unfavorable large-scale production, and achieve simple preparation process, good storage stability, particle size small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

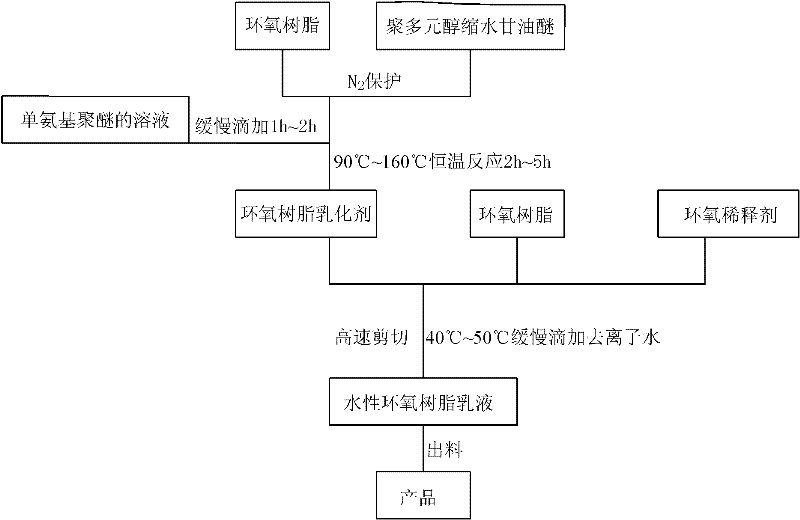

Method used

Image

Examples

Embodiment 1

[0040] Prepare raw materials according to the following components and their mass percentages in the total materials:

[0041] Component Mass percent (wt.%)

[0042] E-51 40%,

[0043] Epoxy Emulsifier 13%,

[0044] Deionized water 37%,

[0045] Trimethylolpropane Triglycidyl Ether 10%,

[0046] Wherein said epoxy resin emulsifier component and component mass percent content are as follows:

[0047] E-51 18%,

[0048] M-2070 57%,

[0049] Polyethylene Glycol Diglycidyl Ether 15%,

[0050] Propylene Glycol Methyl Ether 10%,

[0051] In a reactor equipped with reflux, heating and stirring devices, add epoxy resin E-51 and polyethylene glycol diglycidyl ether, mix well, raise the temperature to 120 ° C, and then slowly drop M- 2070 solution (about 1h after dripping), continue to react at constant temperature for 2h, and obtain a slightly yellow epoxy resin emulsifier.

[0052] Mix the above-prepared epoxy resin emulsifier, epoxy resin E-51, and trimethylolpropane triglyc...

Embodiment 2

[0061] Prepare raw materials according to the following components and their mass percentages in the total materials:

[0062] Component mass percentage (wt.%)

[0063] E-44 34%,

[0064] Epoxy Emulsifier 16%,

[0065] Deionized water 45%,

[0066] Octyl Glycidyl Ether 5%,

[0067] Wherein said epoxy resin emulsifier component and component mass percent content are as follows:

[0068] E-44 23%,

[0069] M-600 25%,

[0070] M-2070 20%,

[0071] Polypropylene Glycol Diglycidyl Ether 20%,

[0072] Propylene Glycol Butyl Ether 12%,

[0073] In the reactor equipped with reflux, heating and stirring devices, add epoxy resin E-44 and polypropylene glycol diglycidyl ether, mix well, raise the temperature to 125°C, and then slowly add M-600 dissolved in propylene glycol butyl ether dropwise, M-2070 solution (about 1.5h after dripping), continue to react at constant temperature for 3h, and obtain a slightly yellow epoxy resin emulsifier.

[0074] Mix the epoxy resin emulsifie...

Embodiment 3

[0081] Prepare raw materials according to the following components and their mass percentages in the total materials:

[0082] Component Mass percent (wt.%)

[0083] E-51 25%,

[0084] Epoxy resin emulsifier 20%,

[0085] Deionized water 50%,

[0086] Phenyl Glycidyl Ether 5%,

[0087] Wherein said epoxy resin emulsifier component and component mass percent content are as follows:

[0088] E-51 30%,

[0089] M-1000 12%,

[0090] M-2070 15%,

[0091] Polypropylene Glycol Triglycidyl Ether 30%,

[0092] Propylene Glycol Methyl Ether 13%,

[0093] In the reaction device equipped with reflux, heating and stirring devices, add epoxy resin E-51 and polypropylene glycol triglycidyl ether, mix well, raise the temperature to 130°C, and then slowly add M-1000 dissolved in propylene glycol methyl ether dropwise, M-2070 solution (after about 1 hour of dripping), continue to react at constant temperature for 2.5 hours to obtain a slightly yellow epoxy resin emulsifier.

[0094] M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com