Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Good material uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel aerogel multifunctional material and preparation method thereof

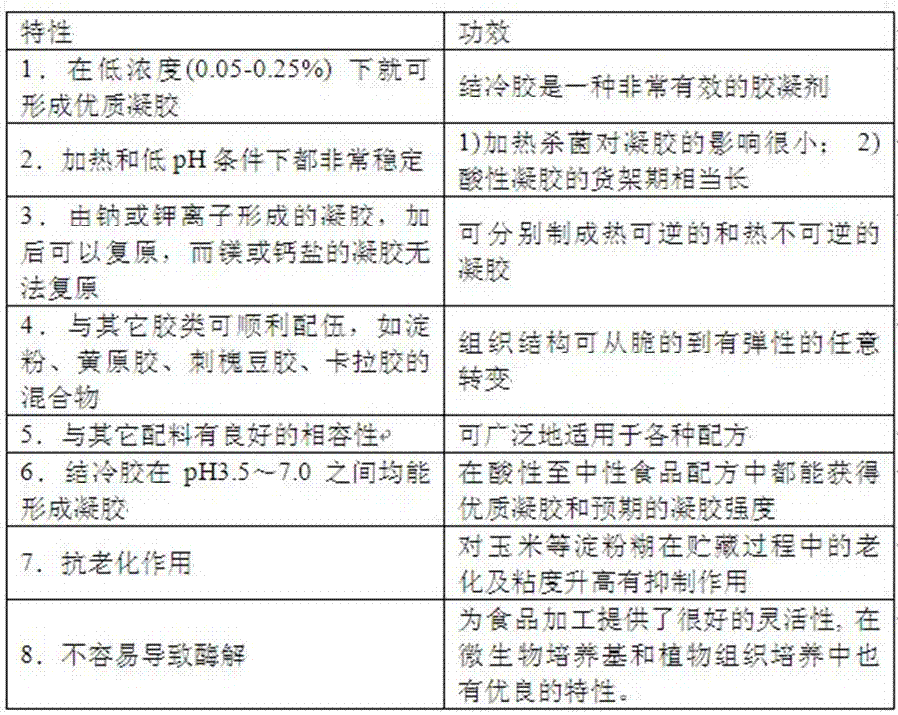

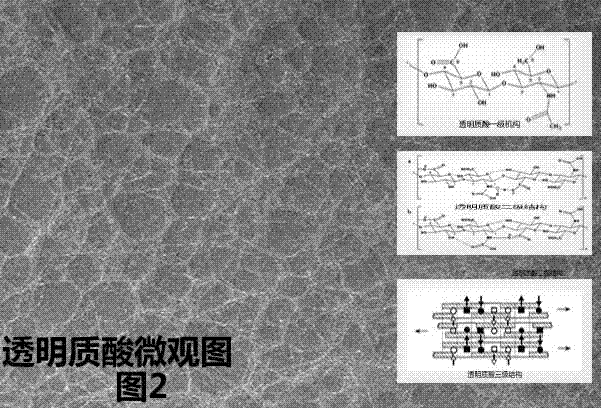

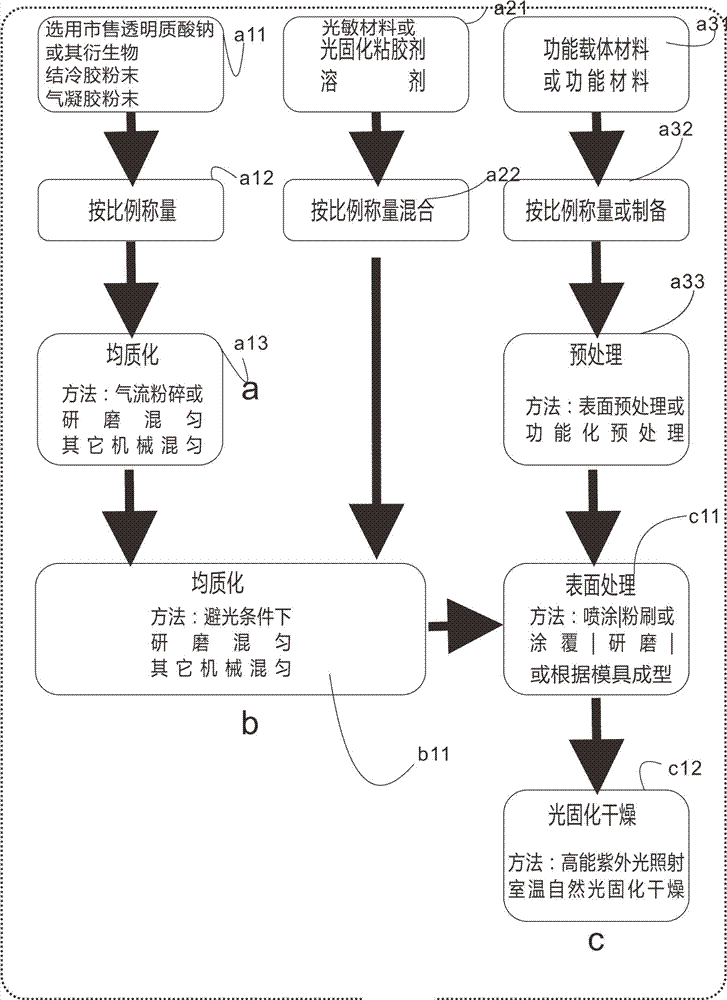

InactiveCN106928908AGood material uniformityGood formabilityHeat-exchange elementsAerogel preparationWeather resistanceChemistry

The invention provides a novel aerogel multifunctional material and a preparation method thereof. The multifunctional aerogel composite is prepared from gellan gum, hyaluronic acid as well as derivatives or mixture of the gellan gum and the hyaluronic acid, aerogel, a novel light-sensitive material, a novel solvent or novel ionic liquid or a novel mixed solvent formred by the above solvents or essential oil and the like by a high-energy photocuring method. The composite material has the characteristics of low density, low heat-conducting coefficient, high weather resistance, environmental friendliness and the like. A functional carrier or a functional material coated with the composite material has high heat-isolating, heat-insulating, cold-accumulating, moisturizing, moisture-proof, moisture-retaining and anti-haze characteristics, and the characteristics and the use range of the materials can be improved. The multifunctional material is extremely widely applied, and can be widely applied in the fields of haze prevention and control, disease diagnosis and treatment, medicine, military industry, chemical industry, spaceflight, navigation, aviation, high-speed train, paper making, printing, water treatment, agriculture and animal husbandry, a cold chain system, food and cosmetic safety.

Owner:广州市芯检康生物科技有限公司

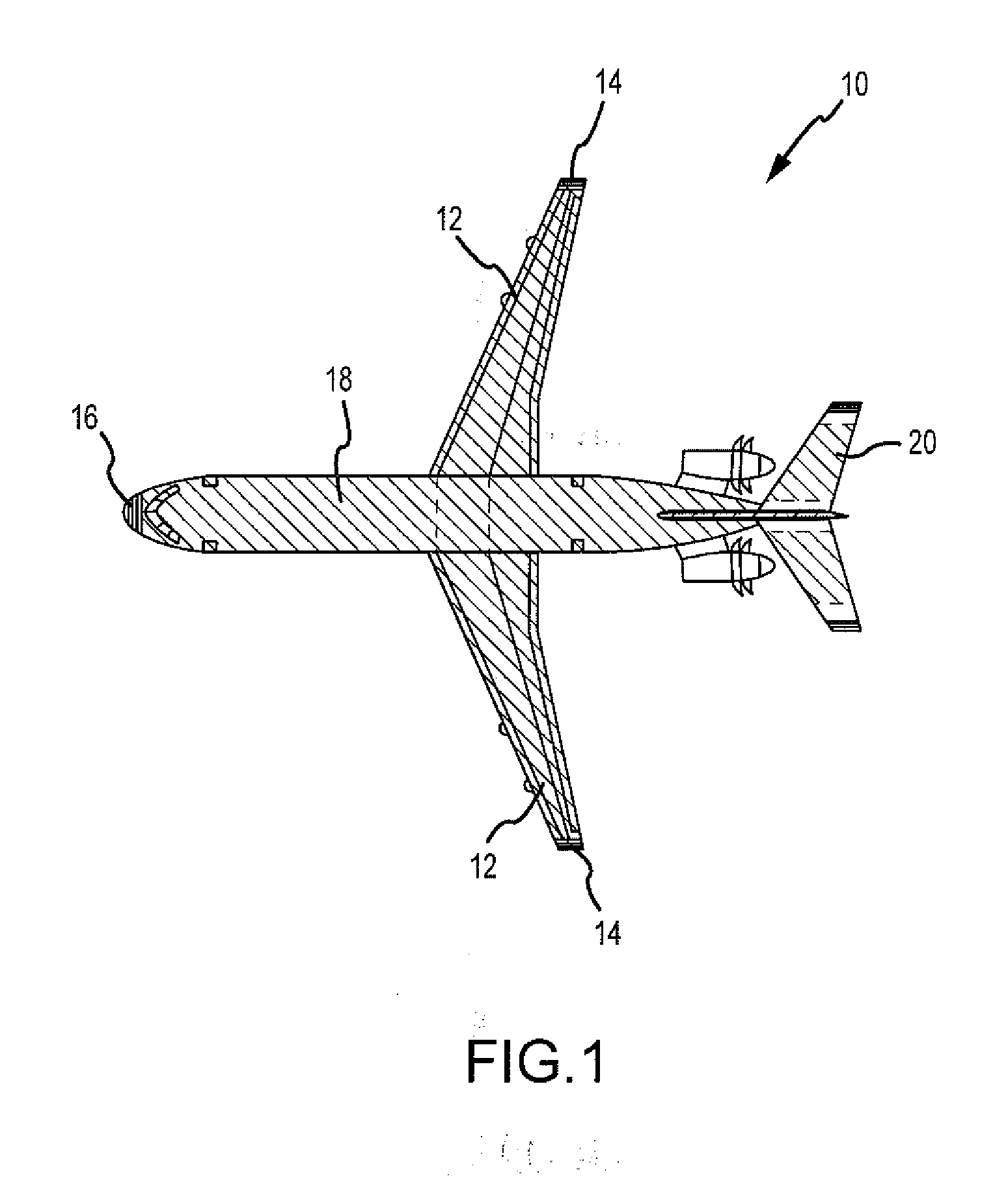

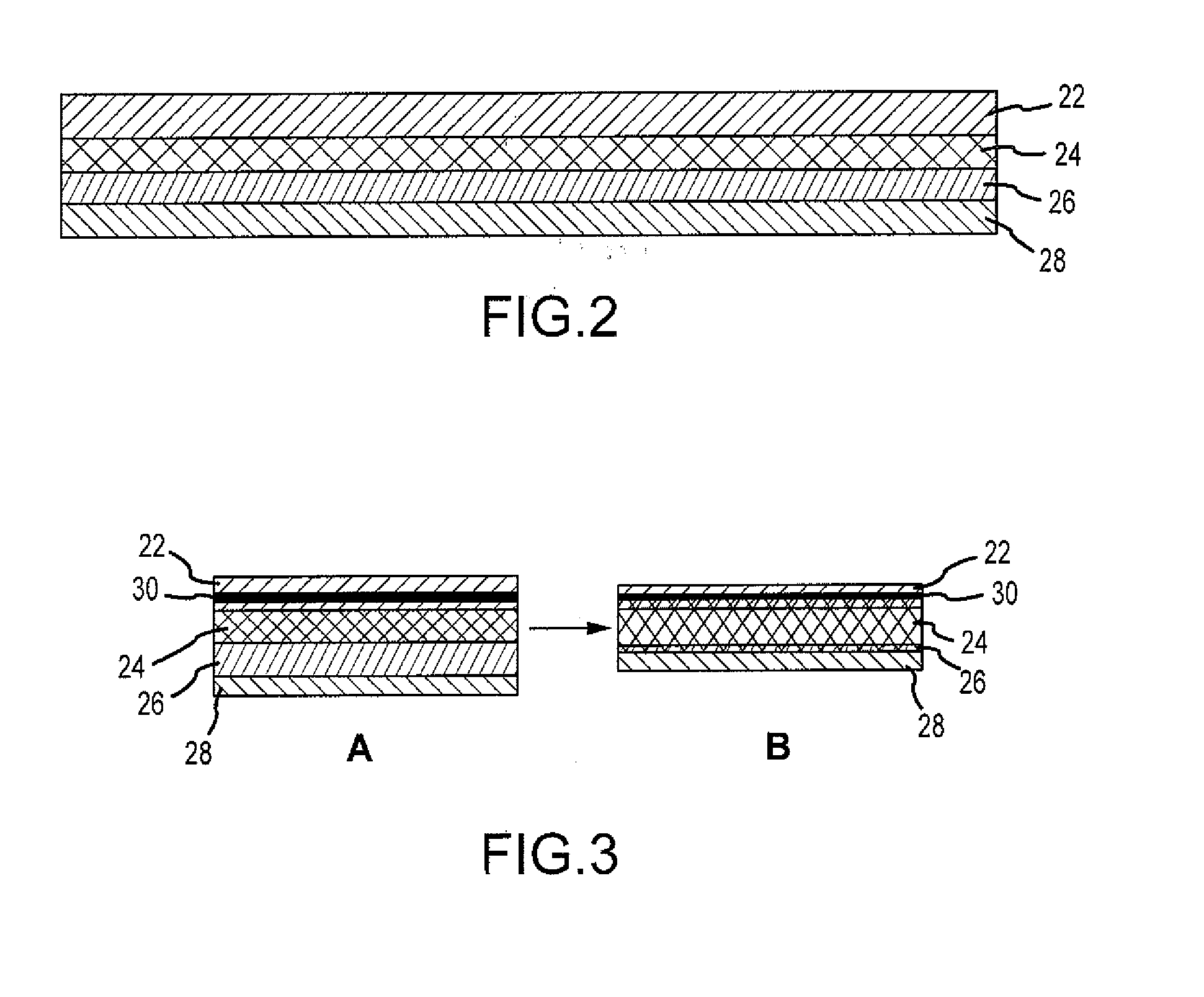

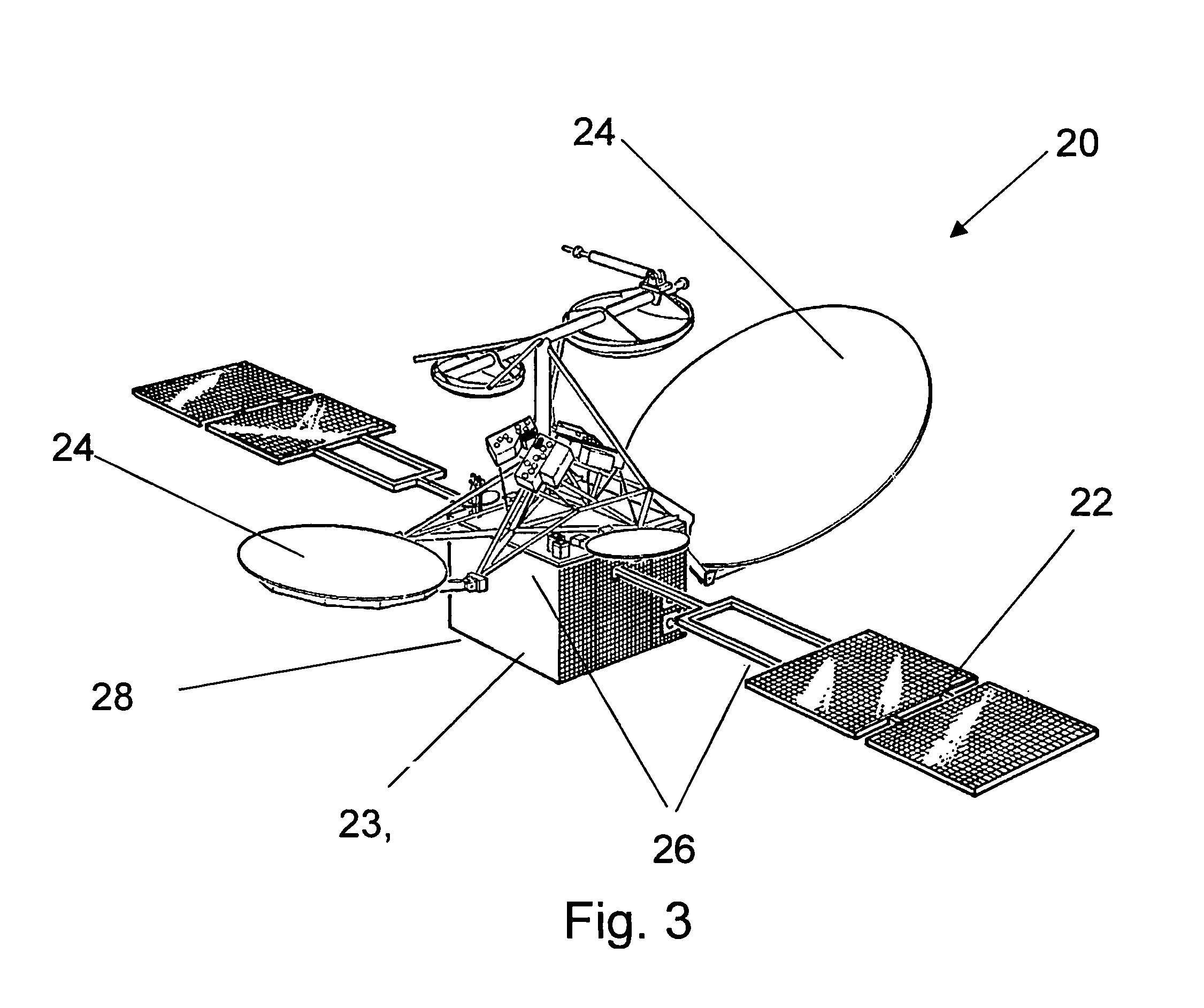

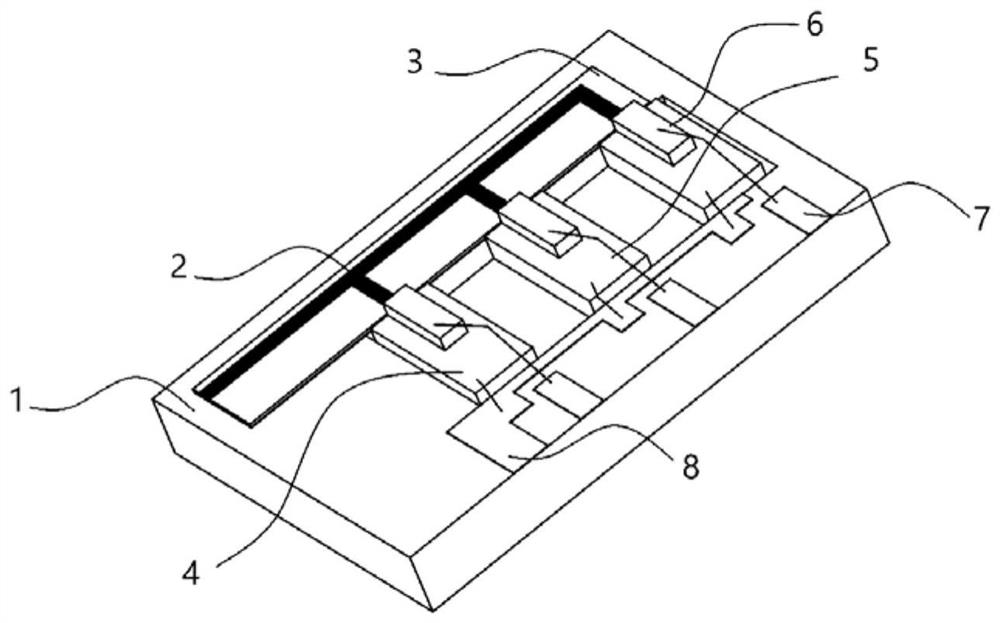

System and method for fabrication of integrated lightning strike protection material

ActiveUS20090258220A1Extended flow timeReduce laborAdhesive processesRecord information storageLightning strikeEngineering

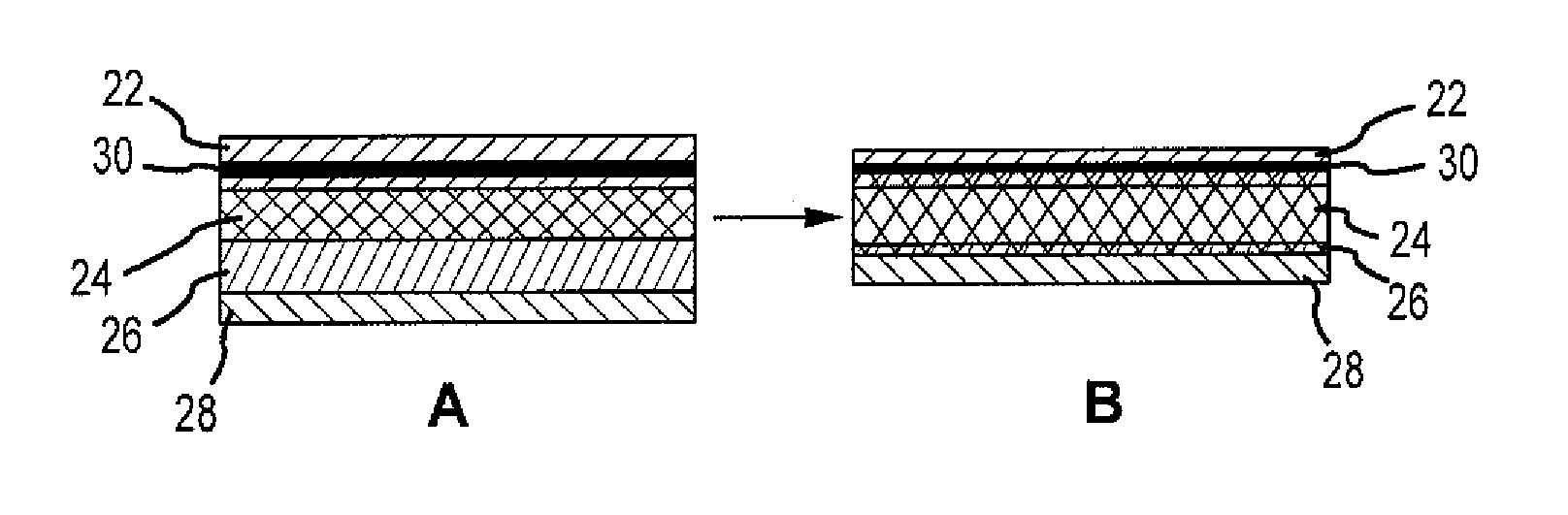

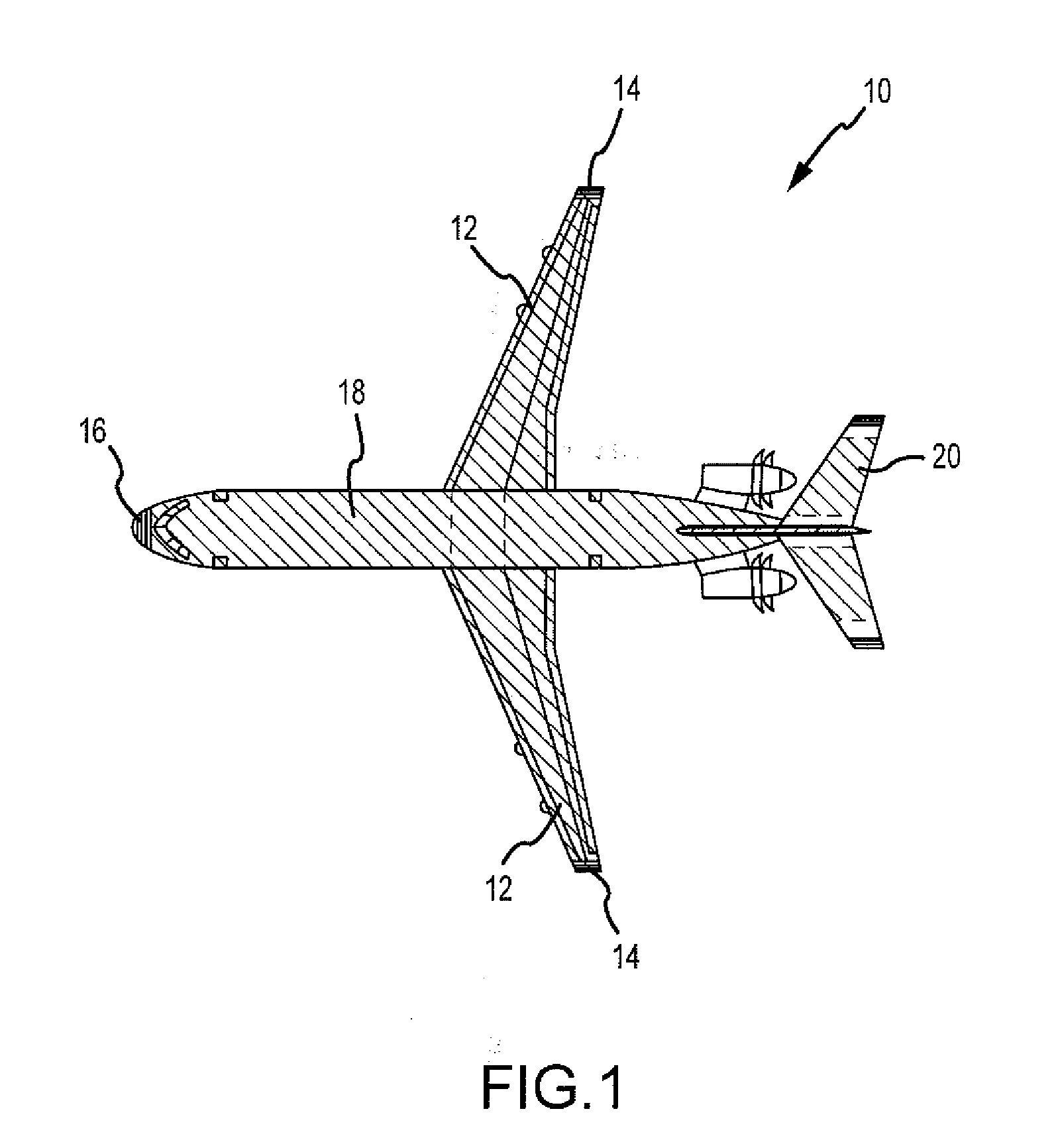

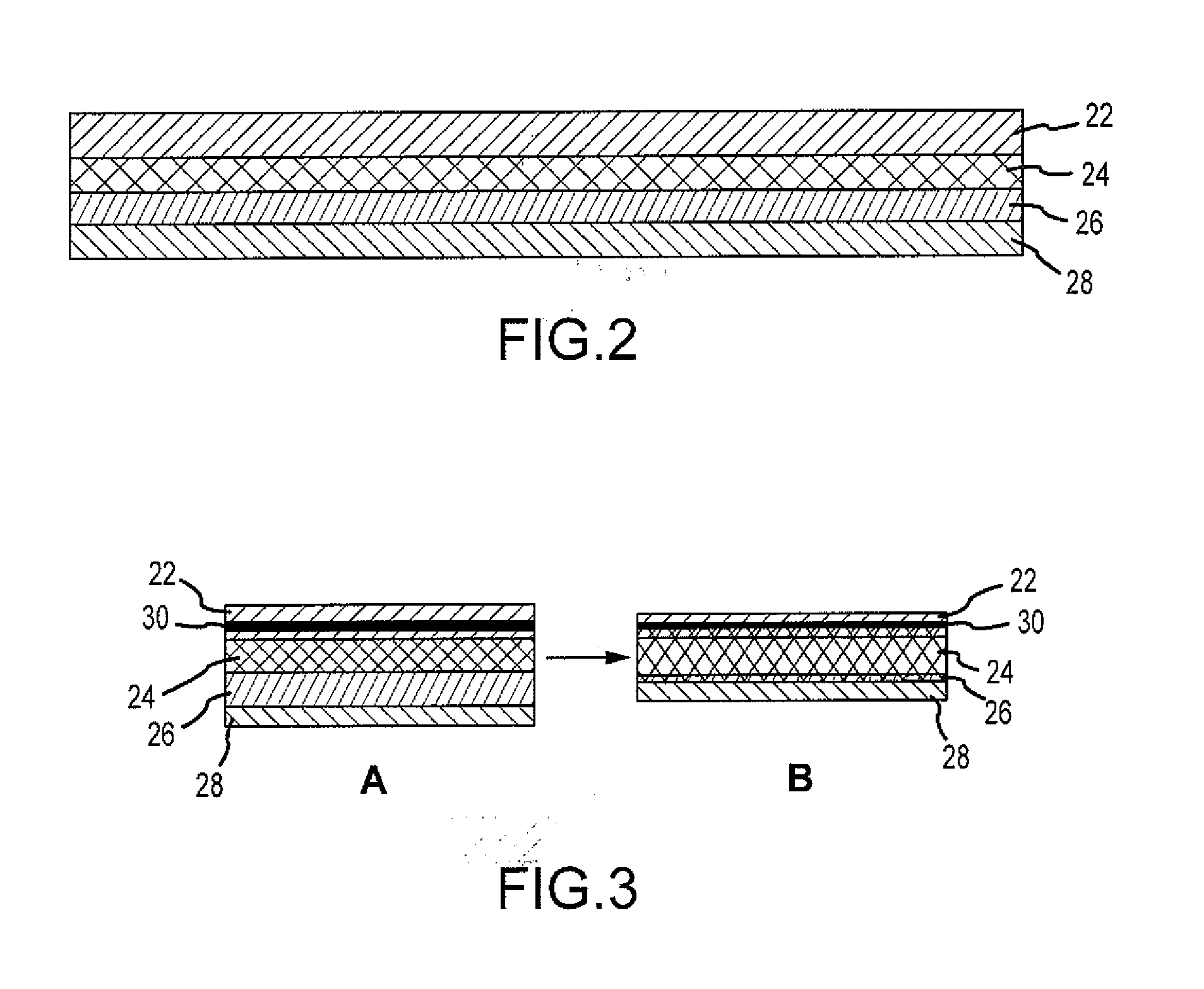

The invention is directed to an integrated lightning strike protection system adapted for automated placement on a composite structure comprising a surfacing layer consisting of an organic polymer resin, a conductive layer of an expanded metal foil, an isolation / tack layer, and a carrier paper layer. In another embodiment of the invention, there is provided an integrated lightning strike protection system comprising an integrated lightning strike protection material consisting of an expanded metal foil encapsulated in organic polymer resin mounted on a carrier paper, and an automated placement machine suitable for placing the material on an aircraft composite part for protection of the composite part from lightning strikes. In another embodiment of the invention, there is provided a method for fabricating a composite structure with lightning strike protection.

Owner:THE BOEING CO

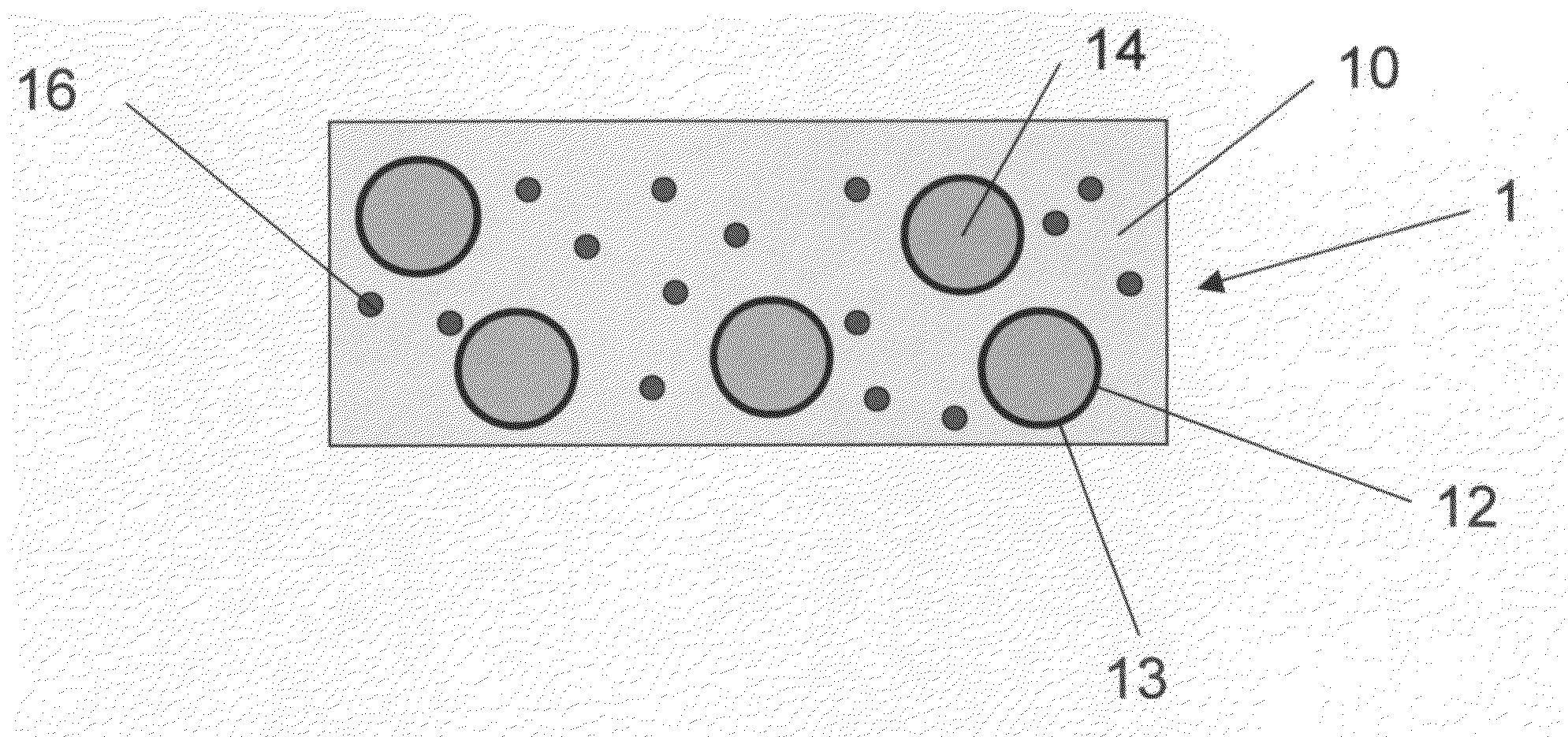

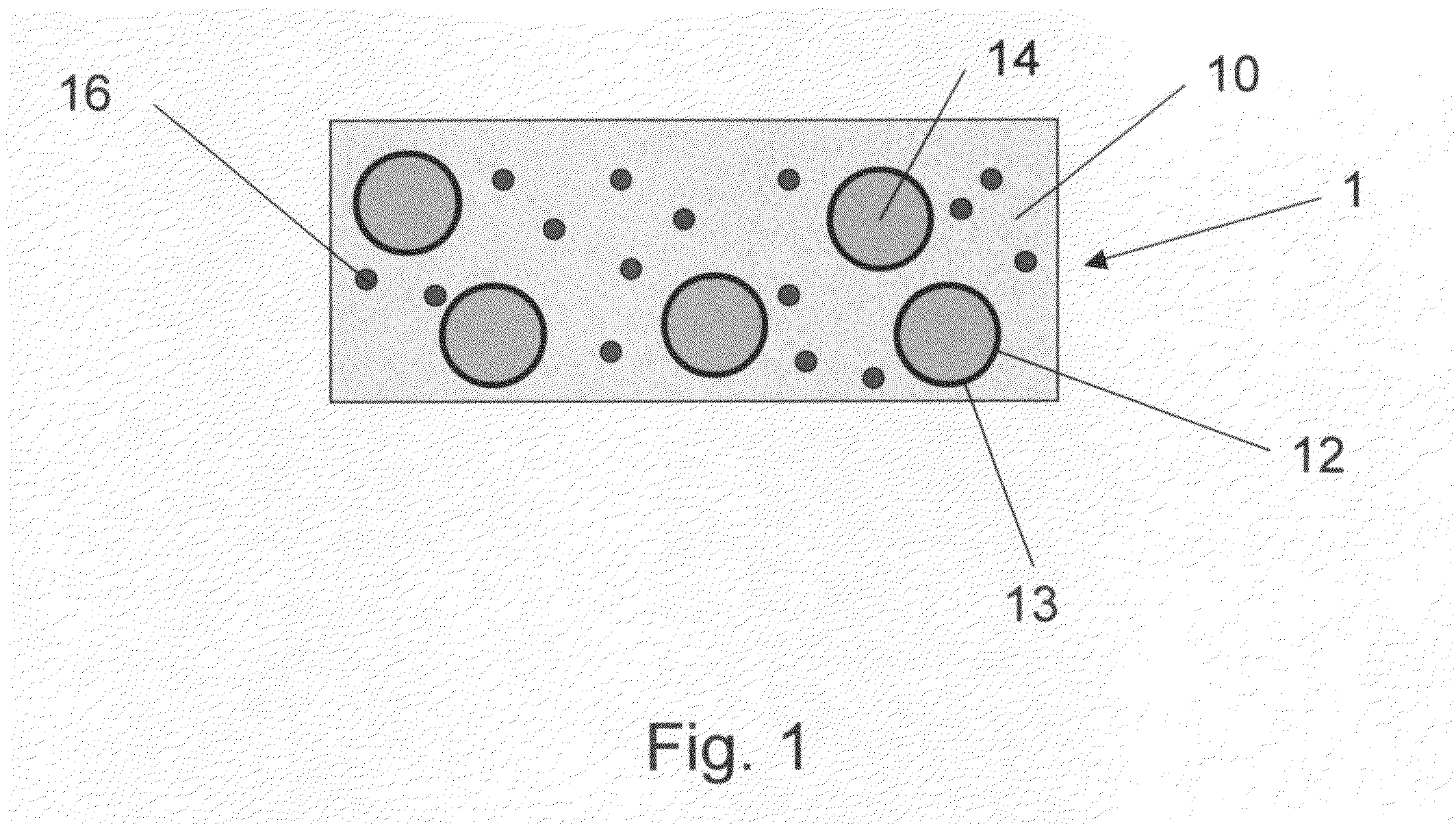

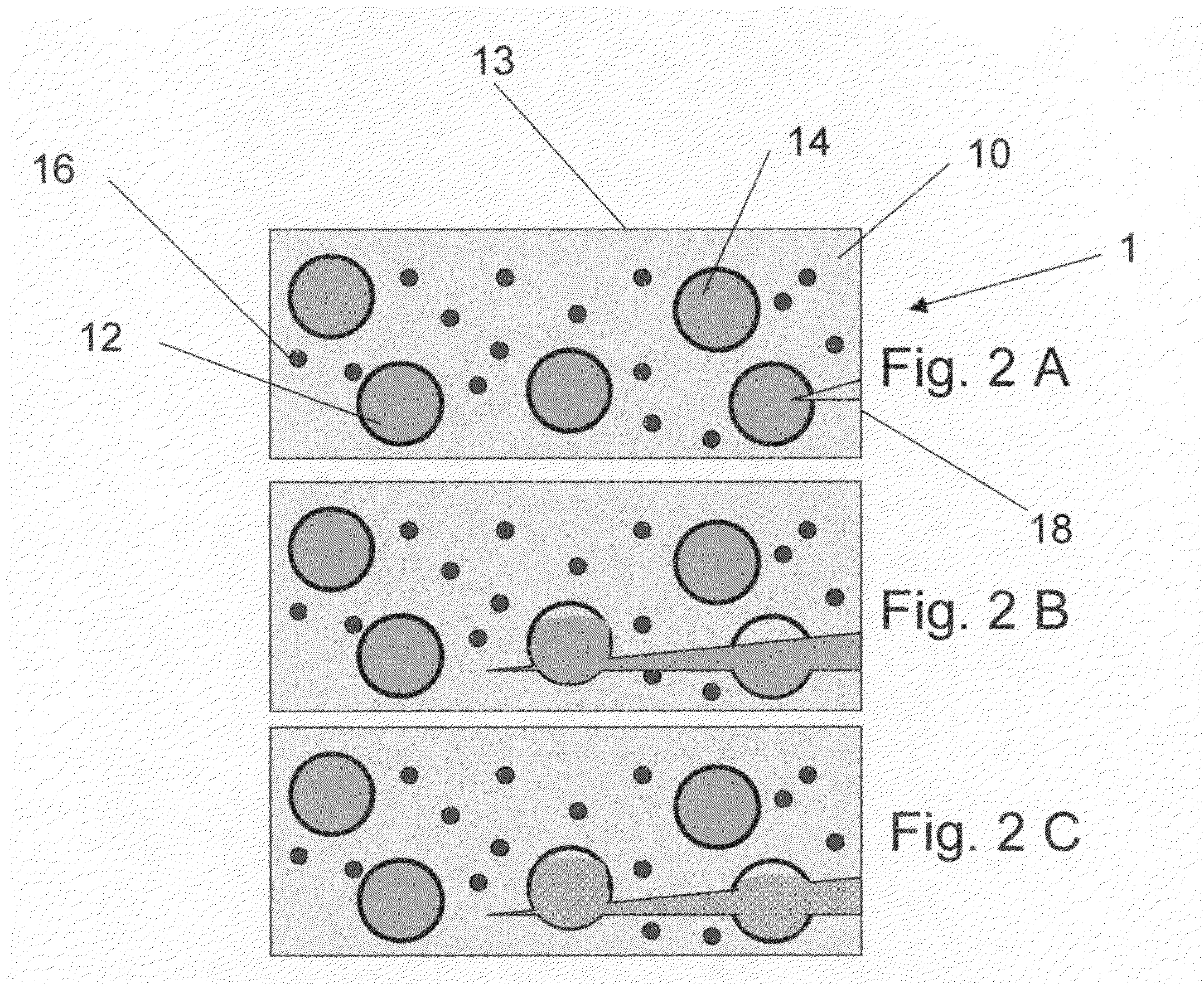

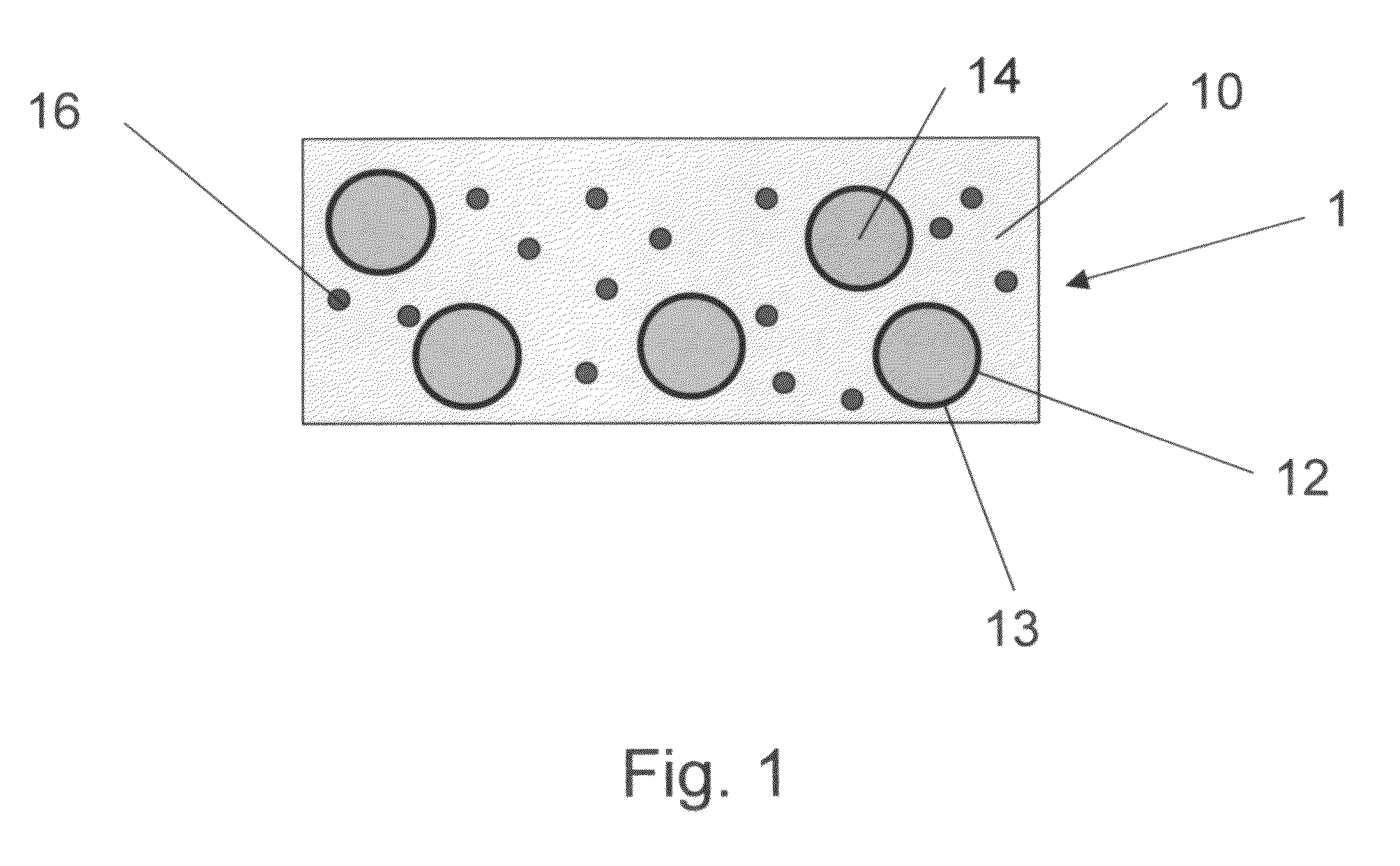

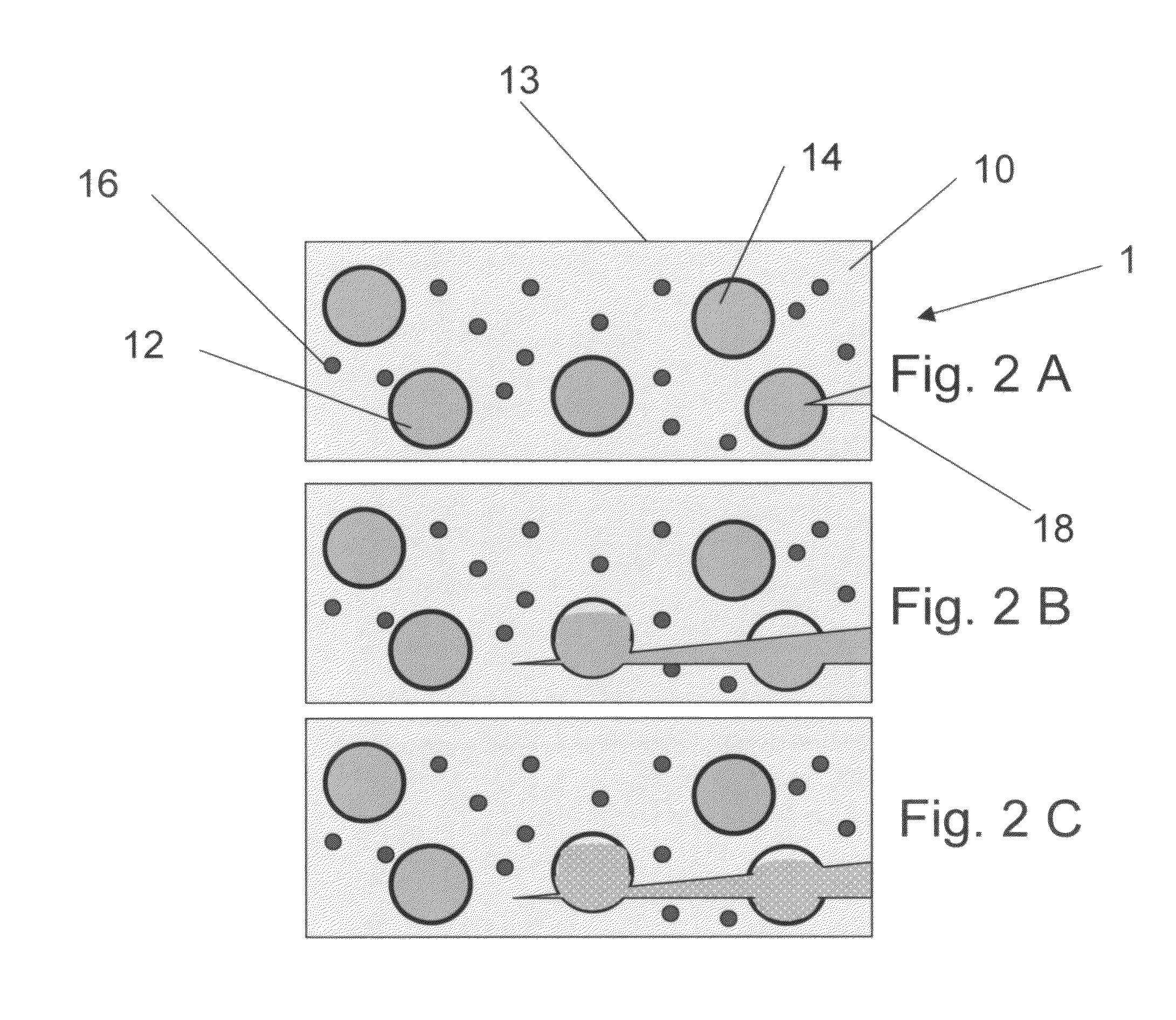

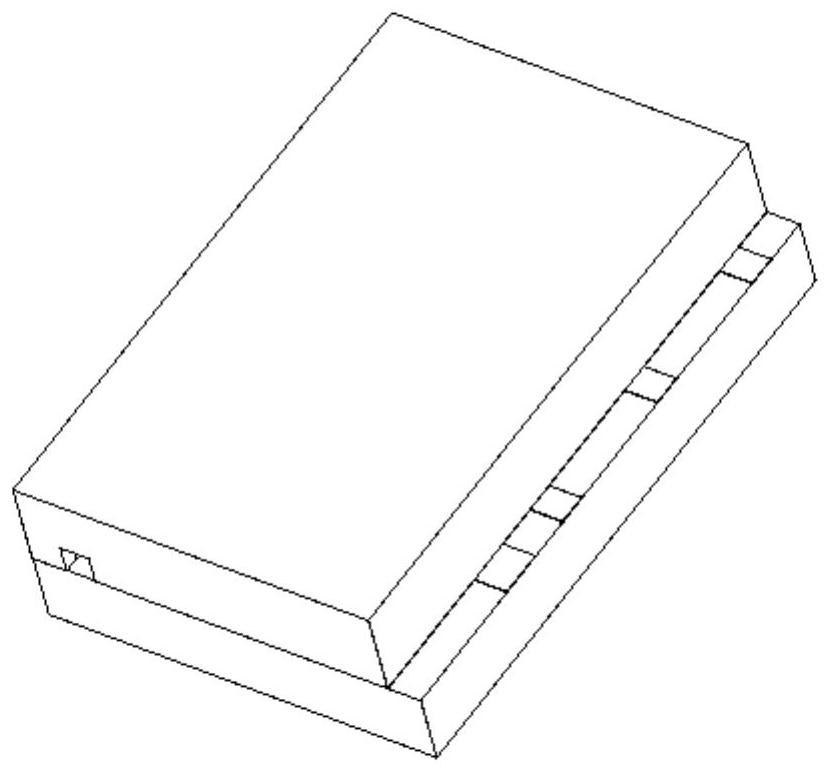

Self healing composite material and method of manufacturing same

InactiveUS20090036568A1Large operating rangeFaster rate of healingRadio transmissionThin material handlingEmulsionRestorative material

A self-healing material comprises a matrix embedded with micro-pockets of a healing-agent releasable by a crack in the matrix. The healing-agent is able to bond to the matrix to repair the crack. The healing-agent is contained in microcapsules. A corresponding catalyst for the healing-agent is embedded in the matrix and contained in a plurality of microcapsules as an emulsion. The emulsion comprises an oil, a perfluorated solvent, a hydrophobic ionic liquid, or mixtures thereof. A method of manufacturing the self-healing material comprises the steps of identifying an operational temperature range of the material, providing at least one substance as the healing-agent, which substance remaining substantially in a liquid state within the operational temperature range, identifying an operational evaporation rate of the healing-agent and providing the substance with a curing time according to the evaporation rate.

Owner:MPB COMM +1

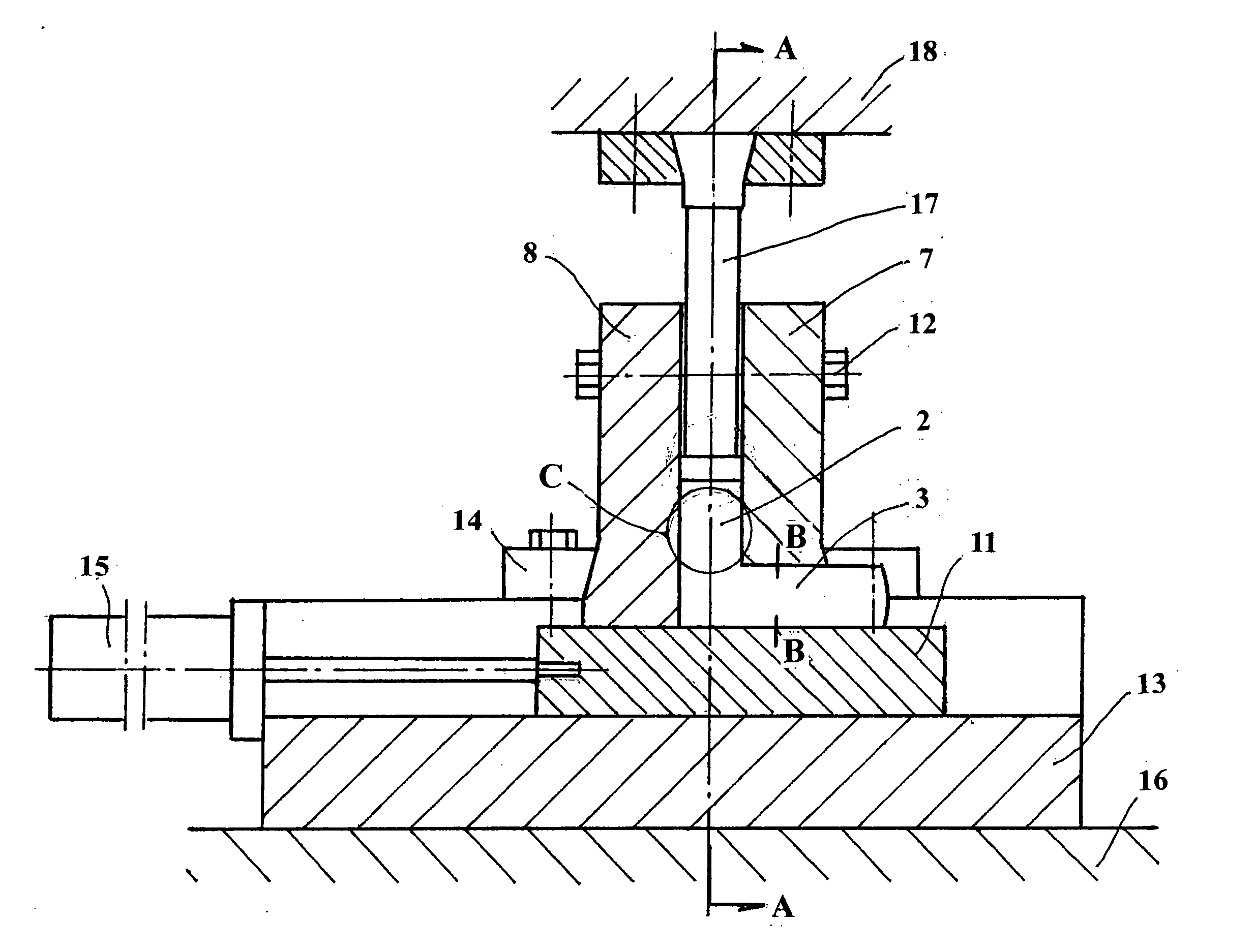

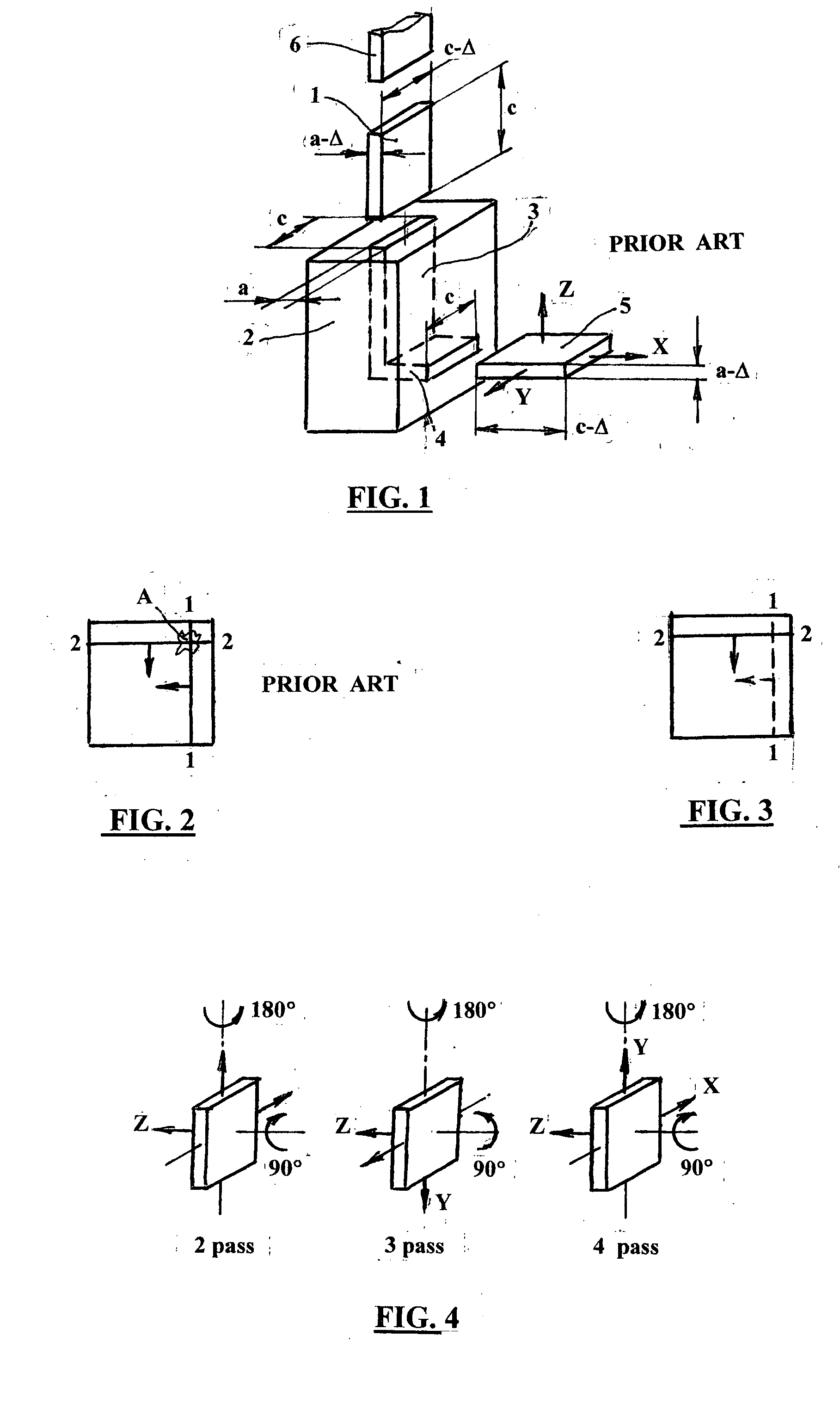

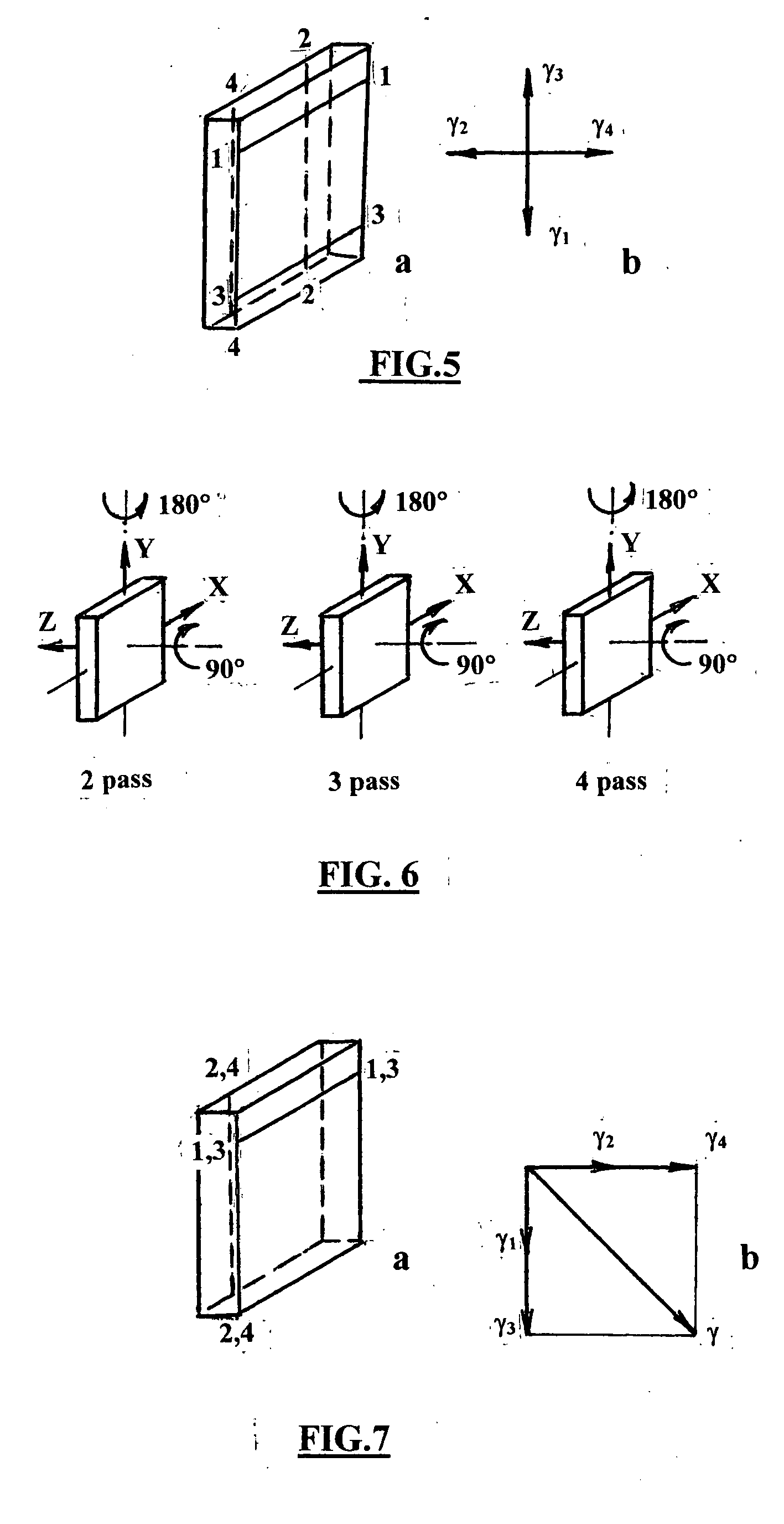

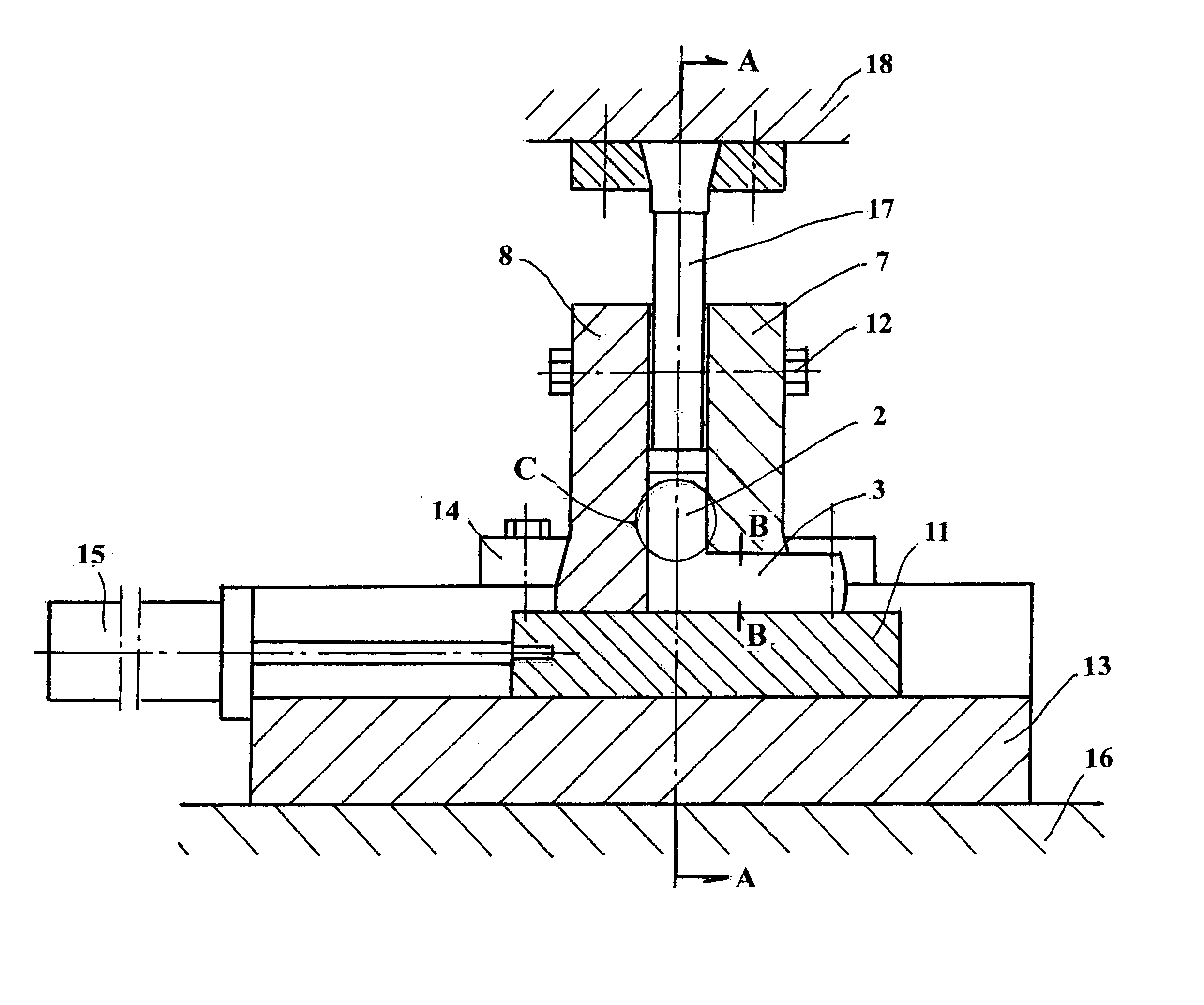

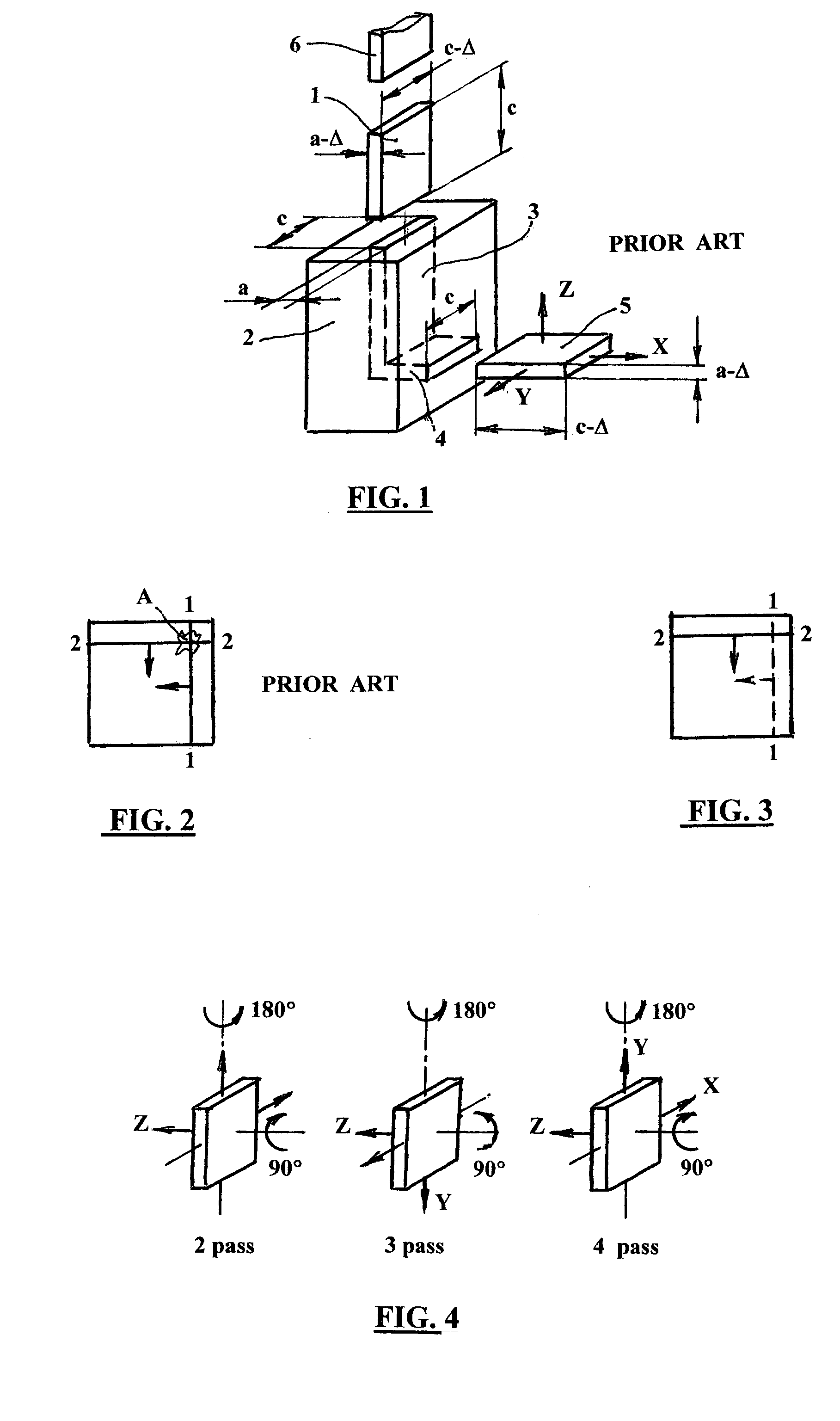

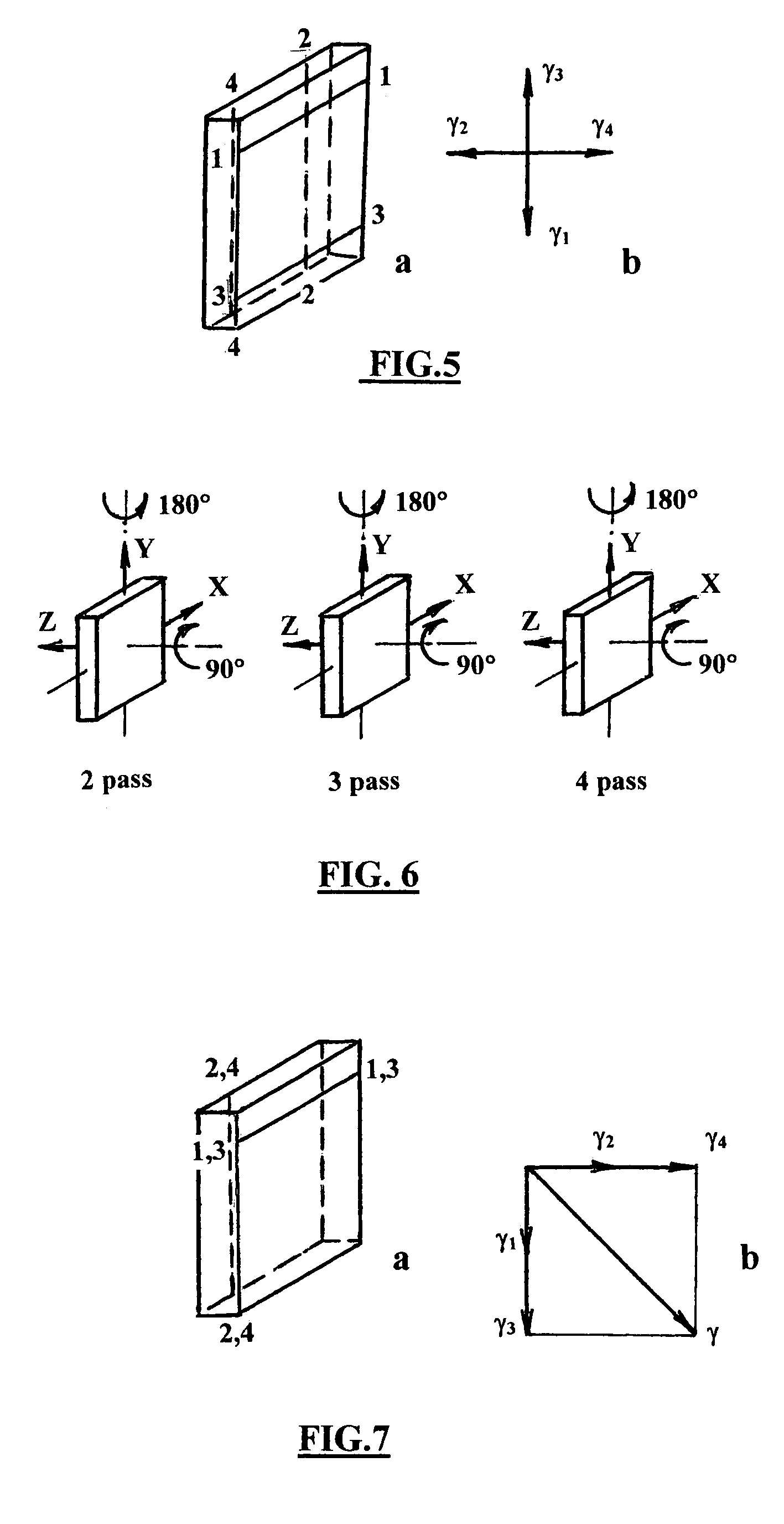

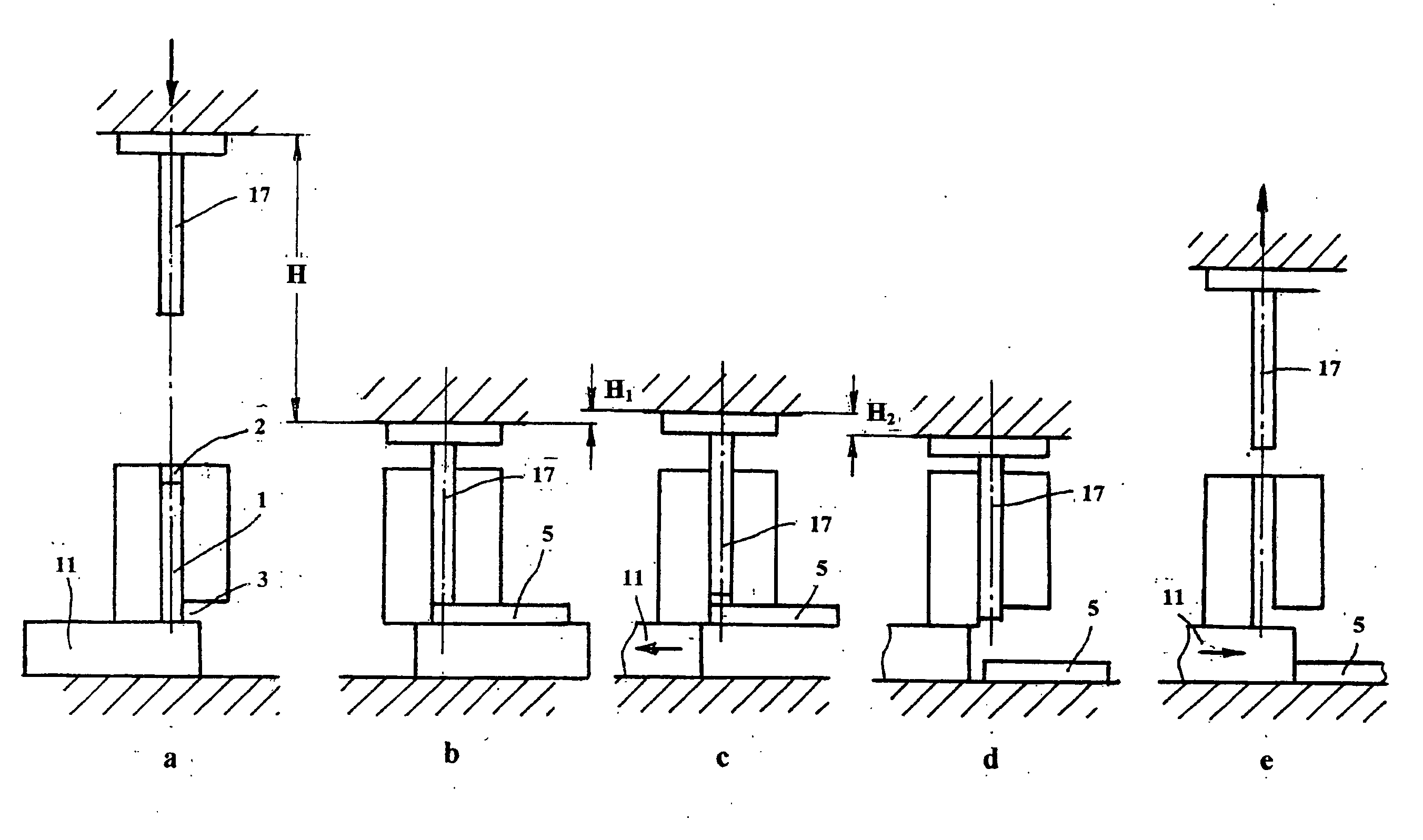

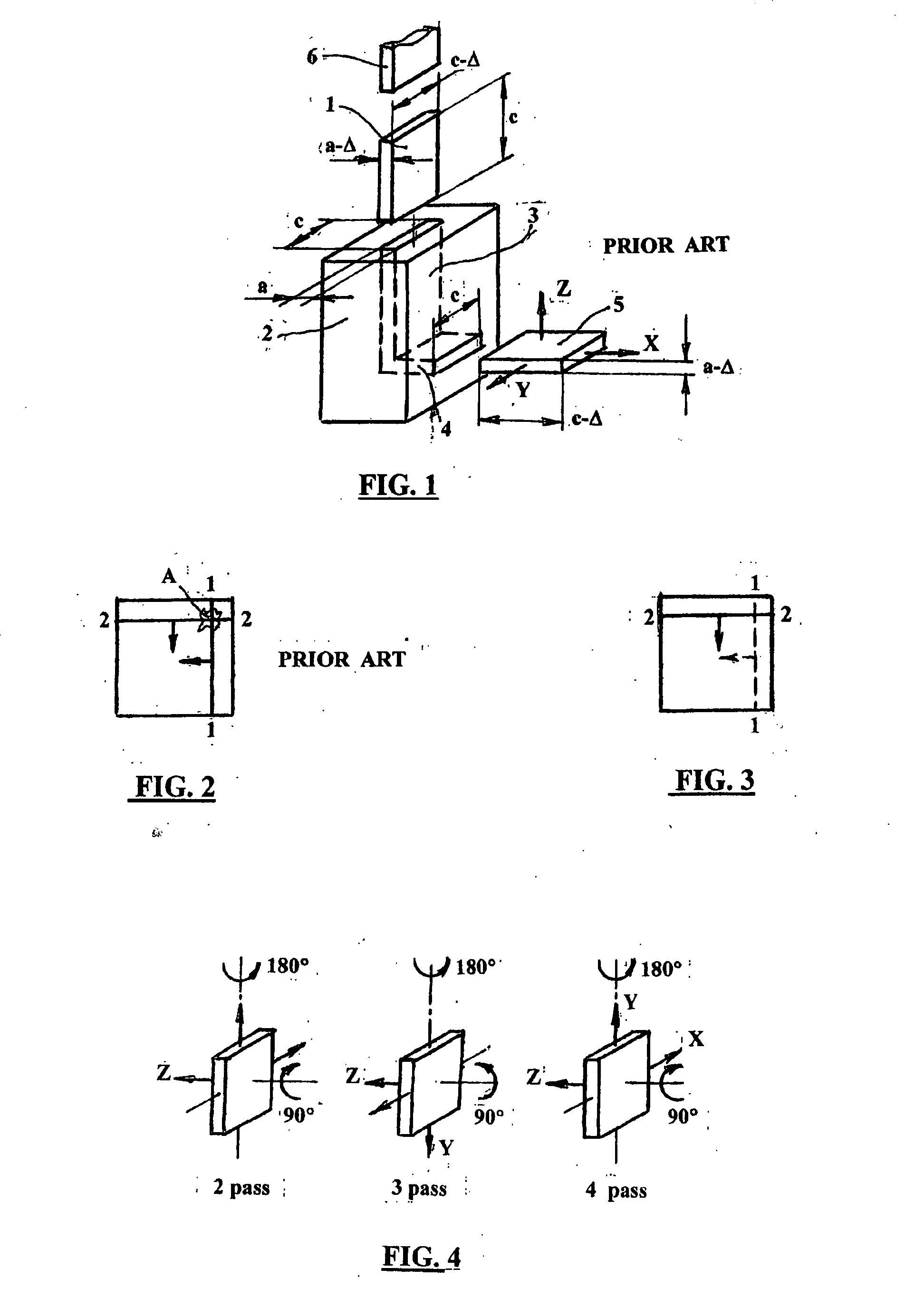

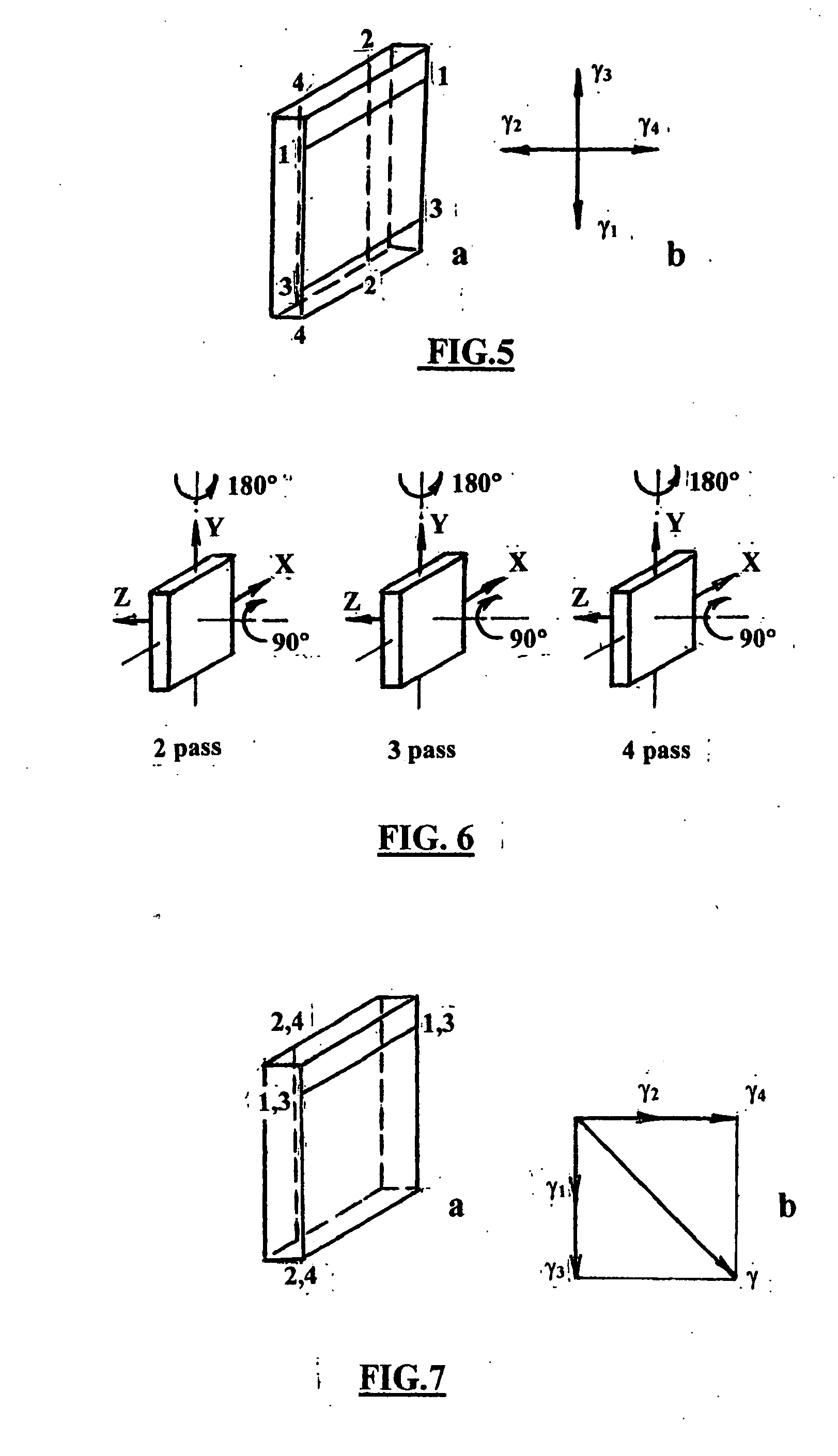

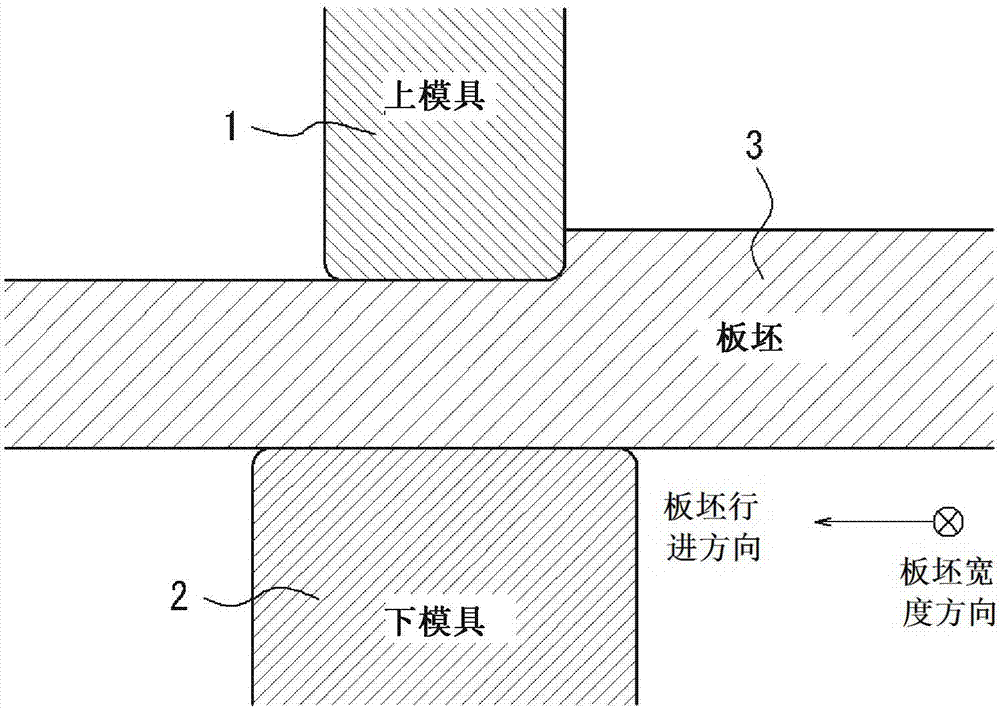

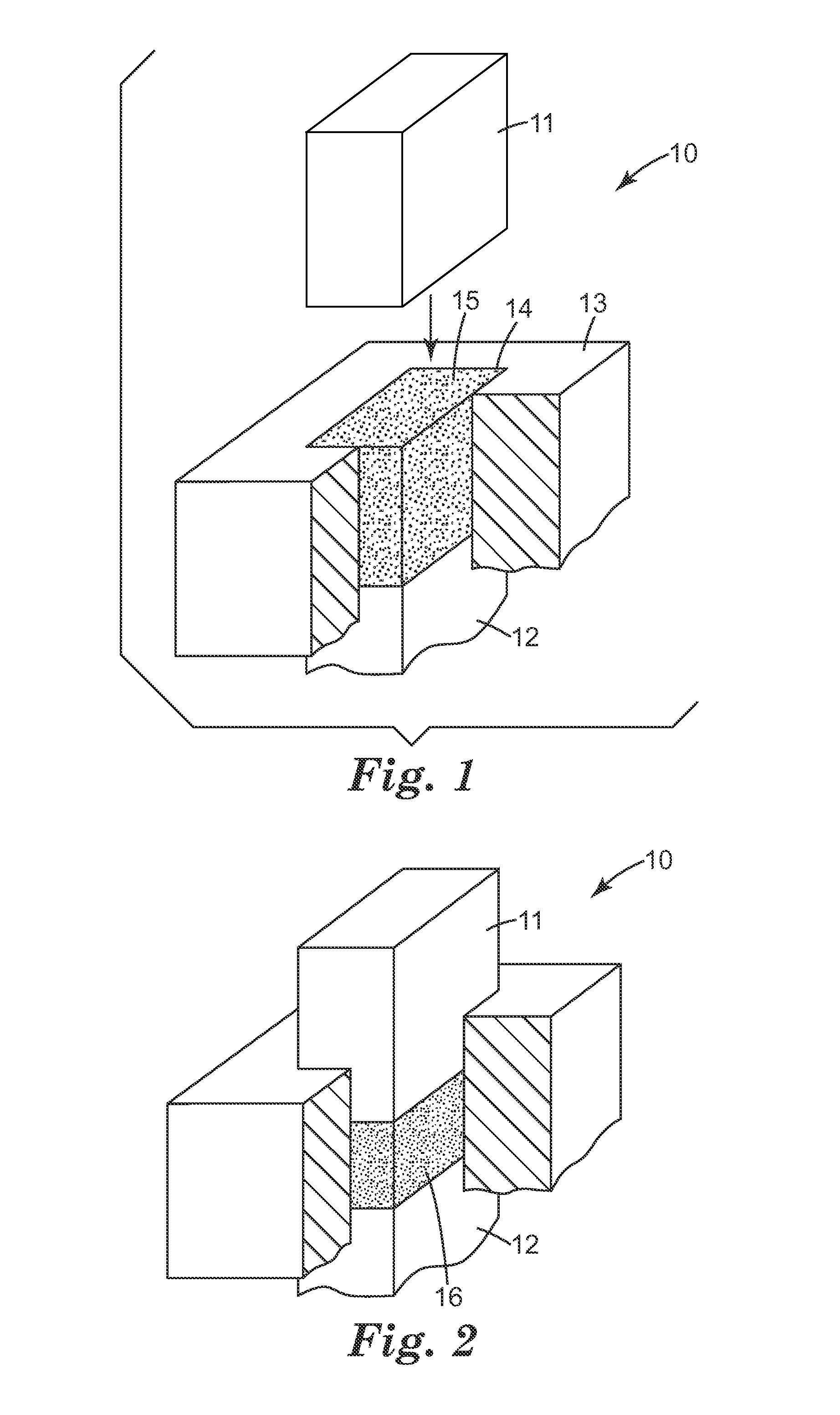

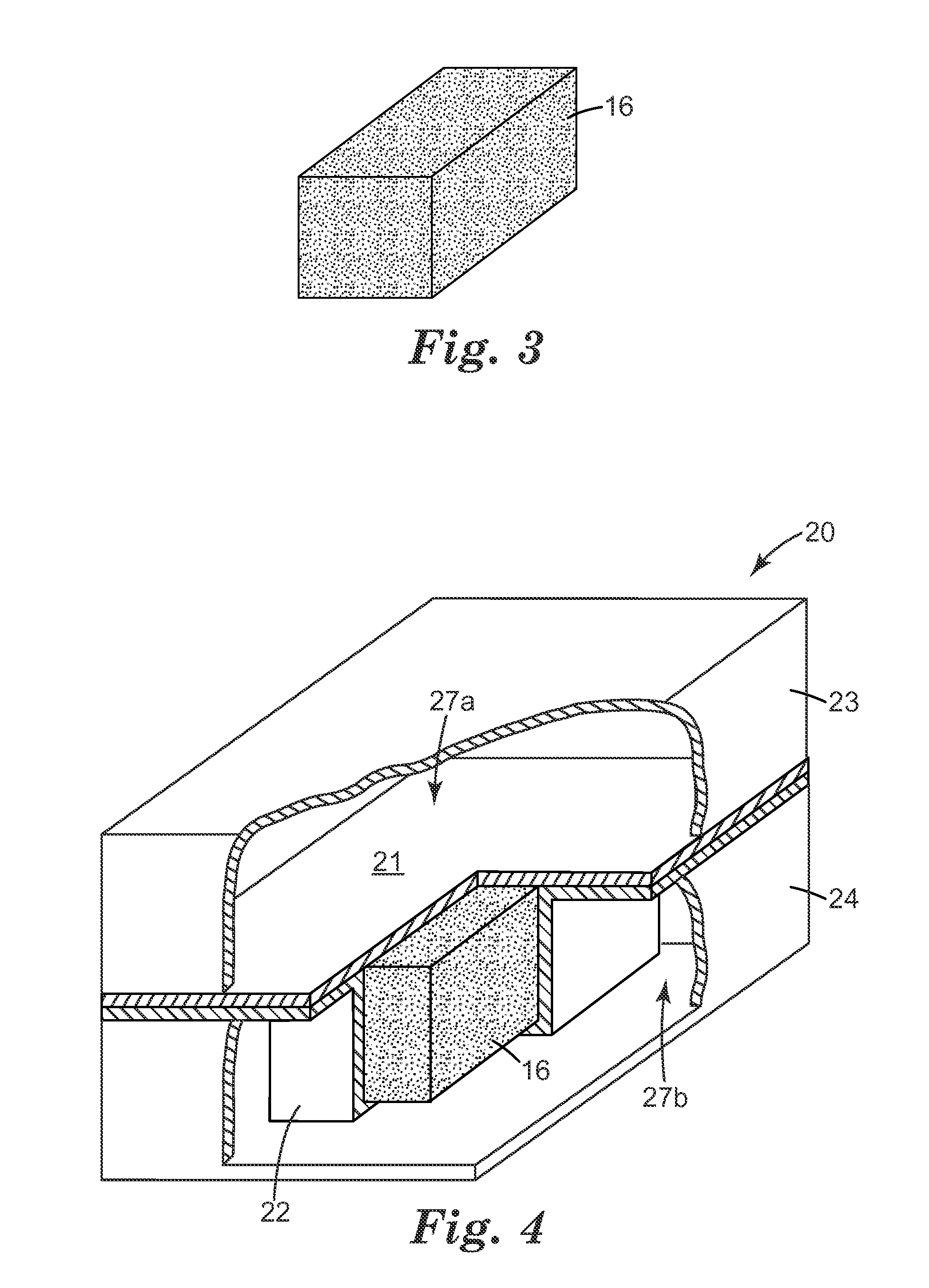

Method and apparatus for equal channel angular extrusion of flat billets

InactiveUS20050016243A1Reliable billet ejectionReduce pressureWork treatment devicesMetal rolling arrangementsCost effectivenessControl system

The invention comprises a method and apparatus for equal channel angular extrusion (ECAE) of flat billets to control material structure and properties. The improvements of the method include the special systems of billet orientations, billet lubrication, billet ejection from dies, and a press / die control system those eliminate surface cracks, flashes and billet reshaping or deburring between passes. Therefore, multi-pass ECAE becomes a cost-effective industrial operation and may be applied to large billets.

Owner:ENGINEERED PERFORMANCE MATERIALS

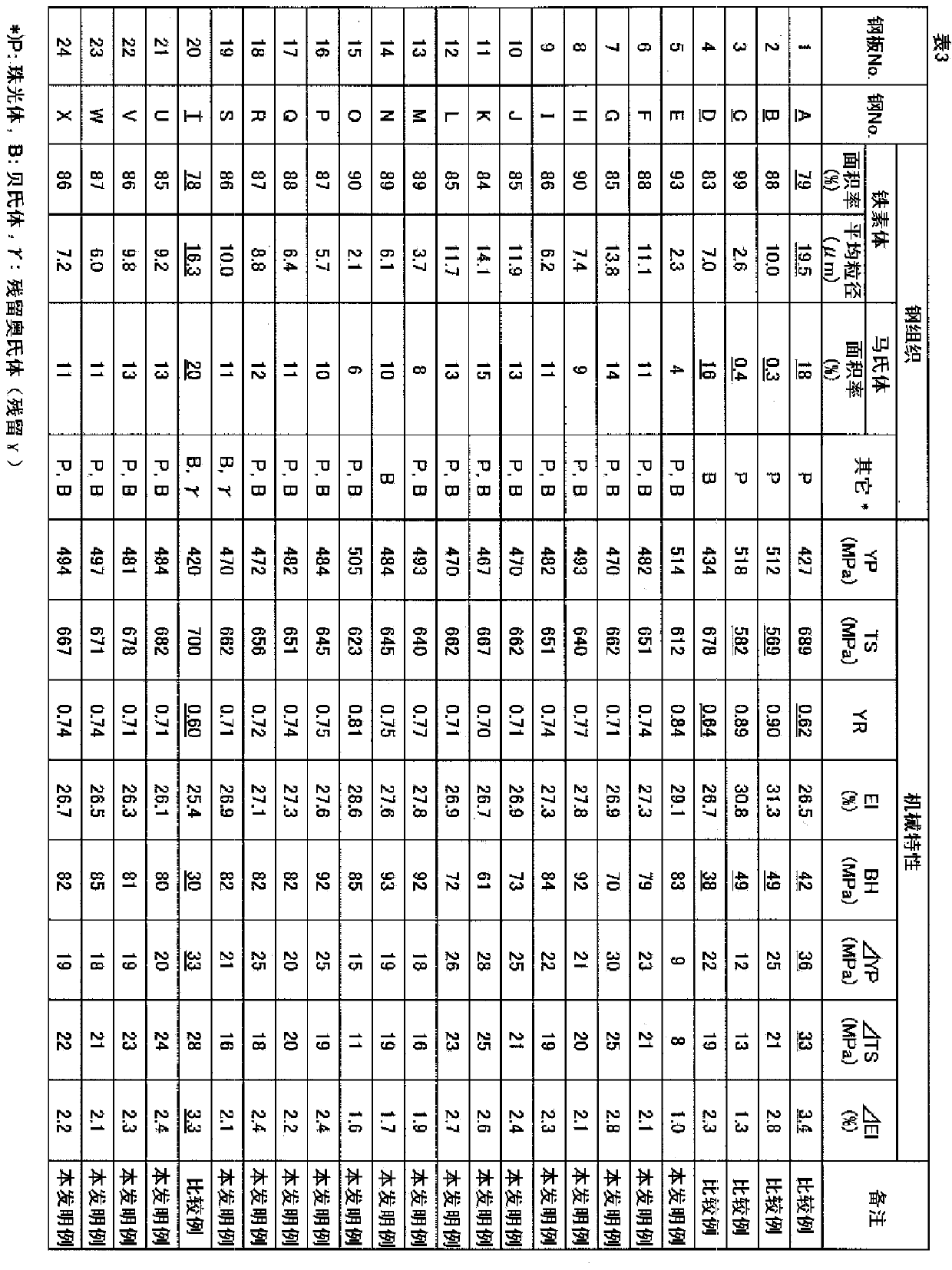

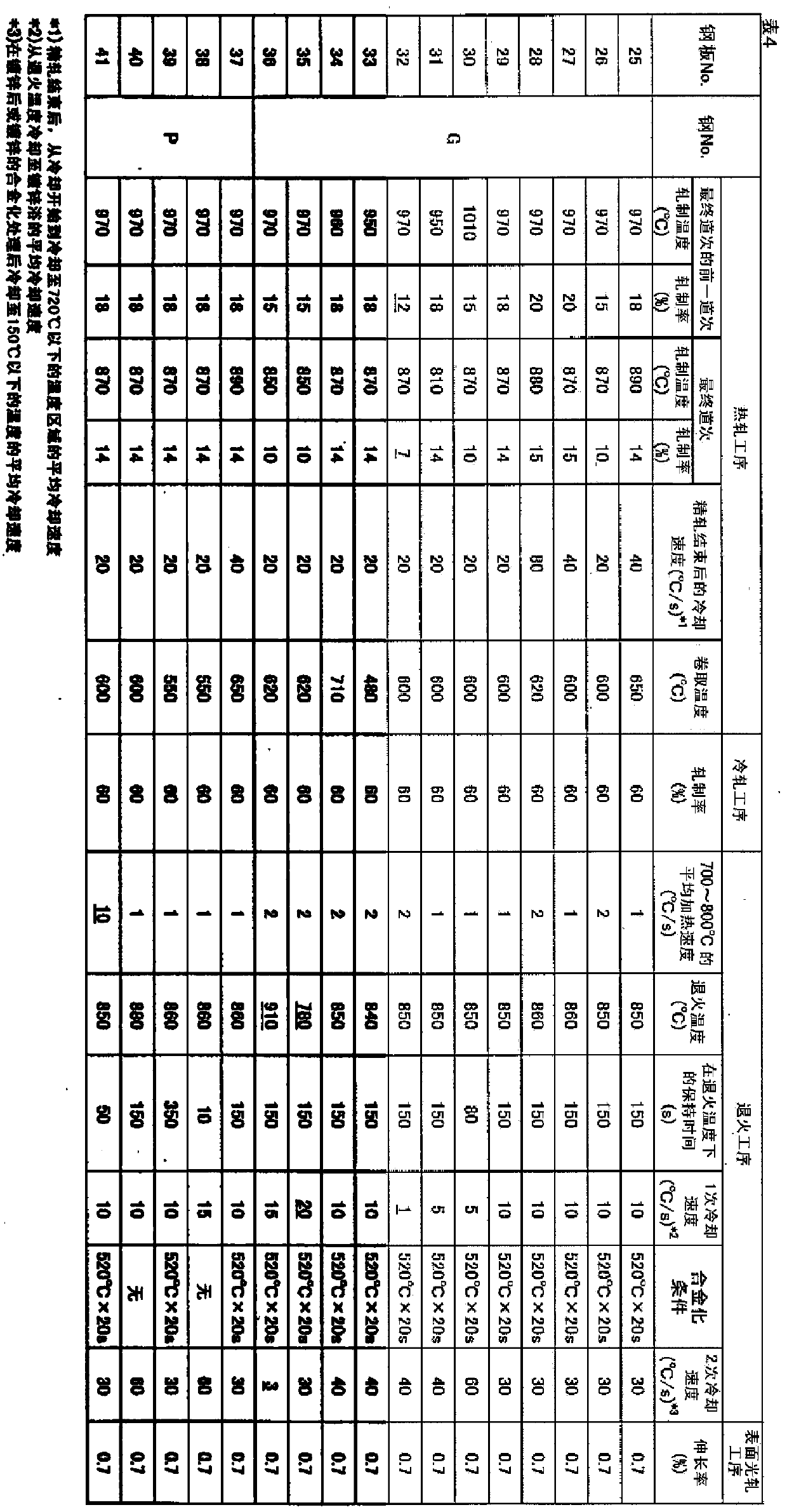

Hot-dip galvanized steel sheet and production method therefor

ActiveCN104093873AHigh strengthExcellent material uniformity with little variationHot-dipping/immersion processesFurnace typesMetallurgyYield ratio

Owner:JFE STEEL CORP

Method and apparatus for equal channel angular extrusion of flat billets

InactiveUS7191630B2Eliminate surface cracksGood material uniformityWork treatment devicesMetal rolling arrangementsCost effectivenessControl system

The invention comprises a method and apparatus for equal channel angular extrusion (ECAE) of flat billets to control material structure and properties. The improvements of the method include the special systems of billet orientations, billet lubrication, billet ejection from dies, and a press / die control system those eliminate surface cracks, flashes and billet reshaping or deburring between passes. Therefore, multi-pass ECAE becomes a cost-effective industrial operation and may be applied to large billets.

Owner:ENGINEERED PERFORMANCE MATERIALS

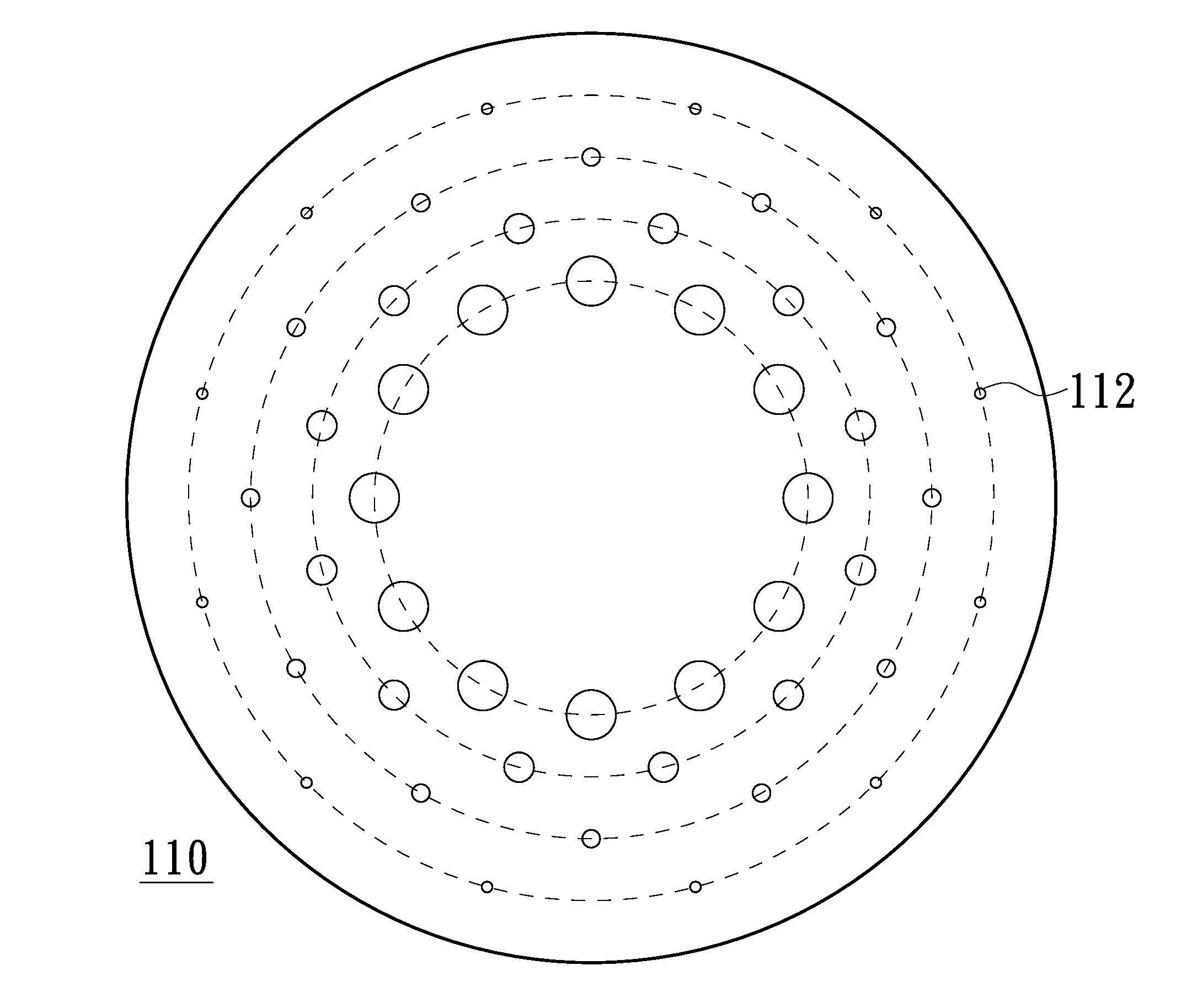

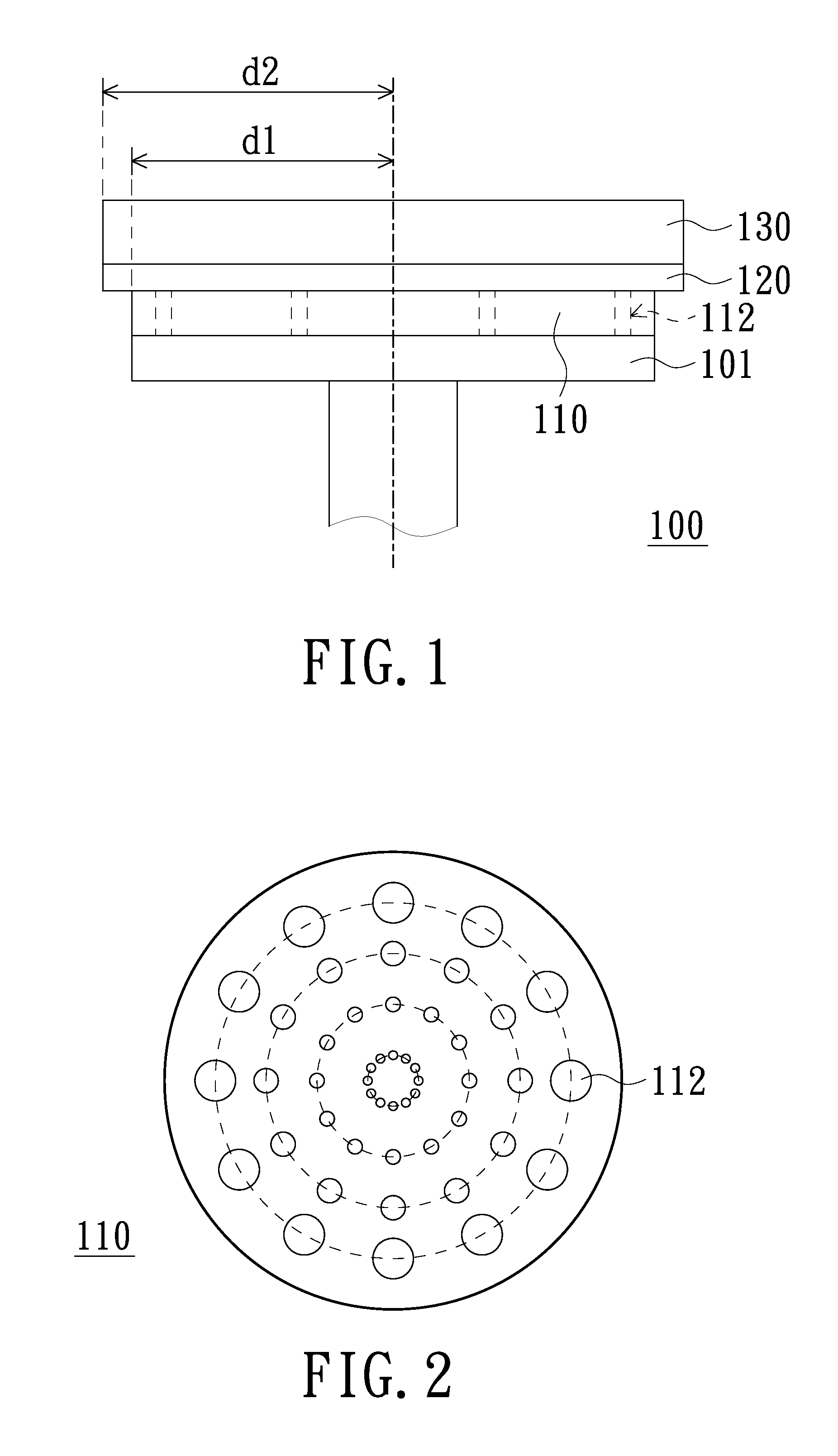

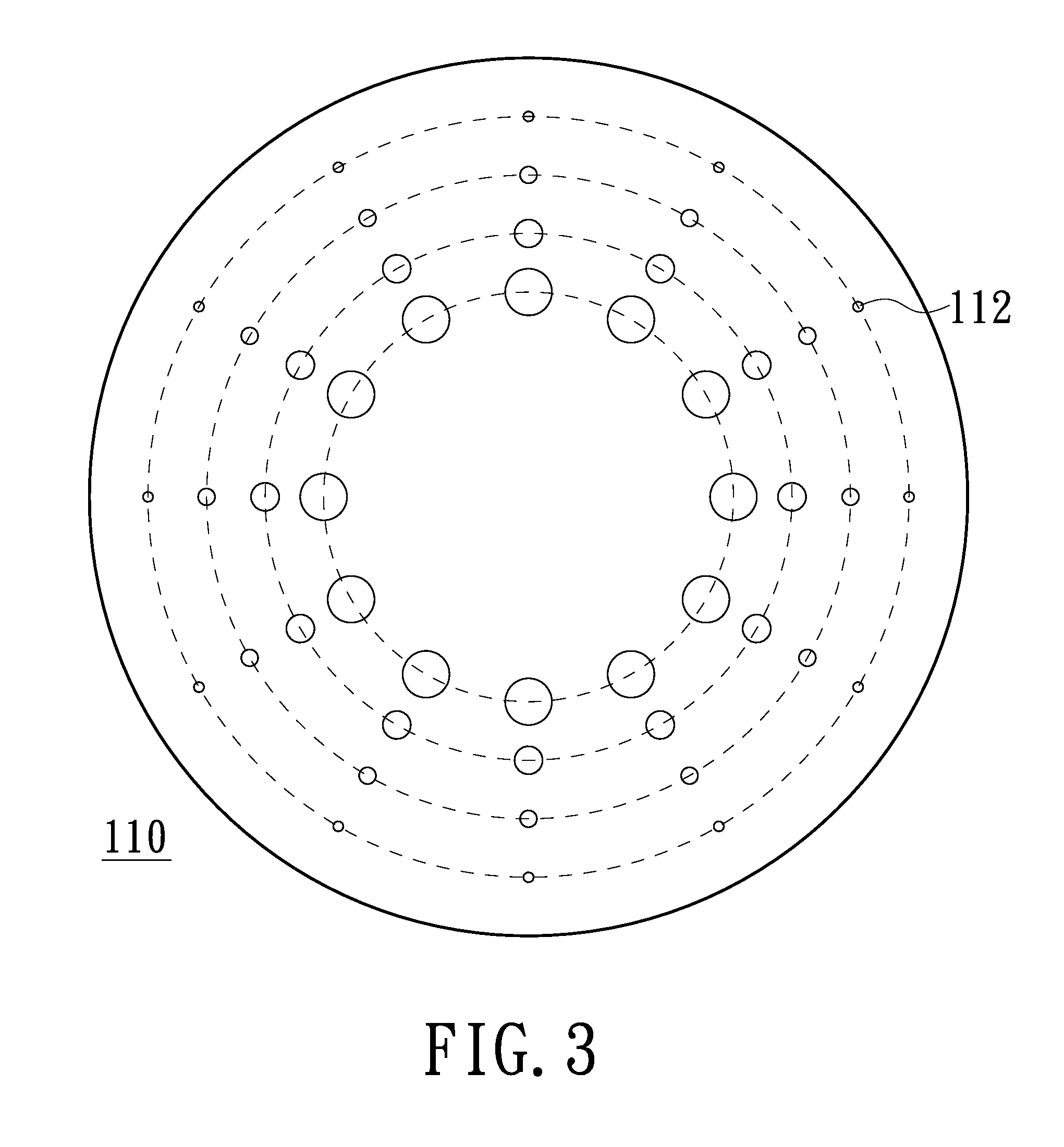

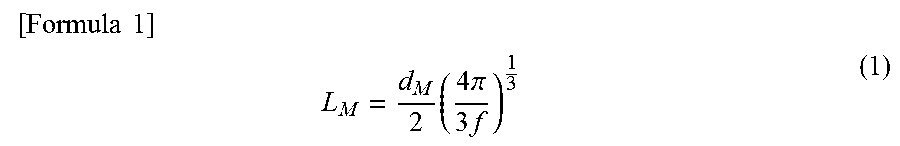

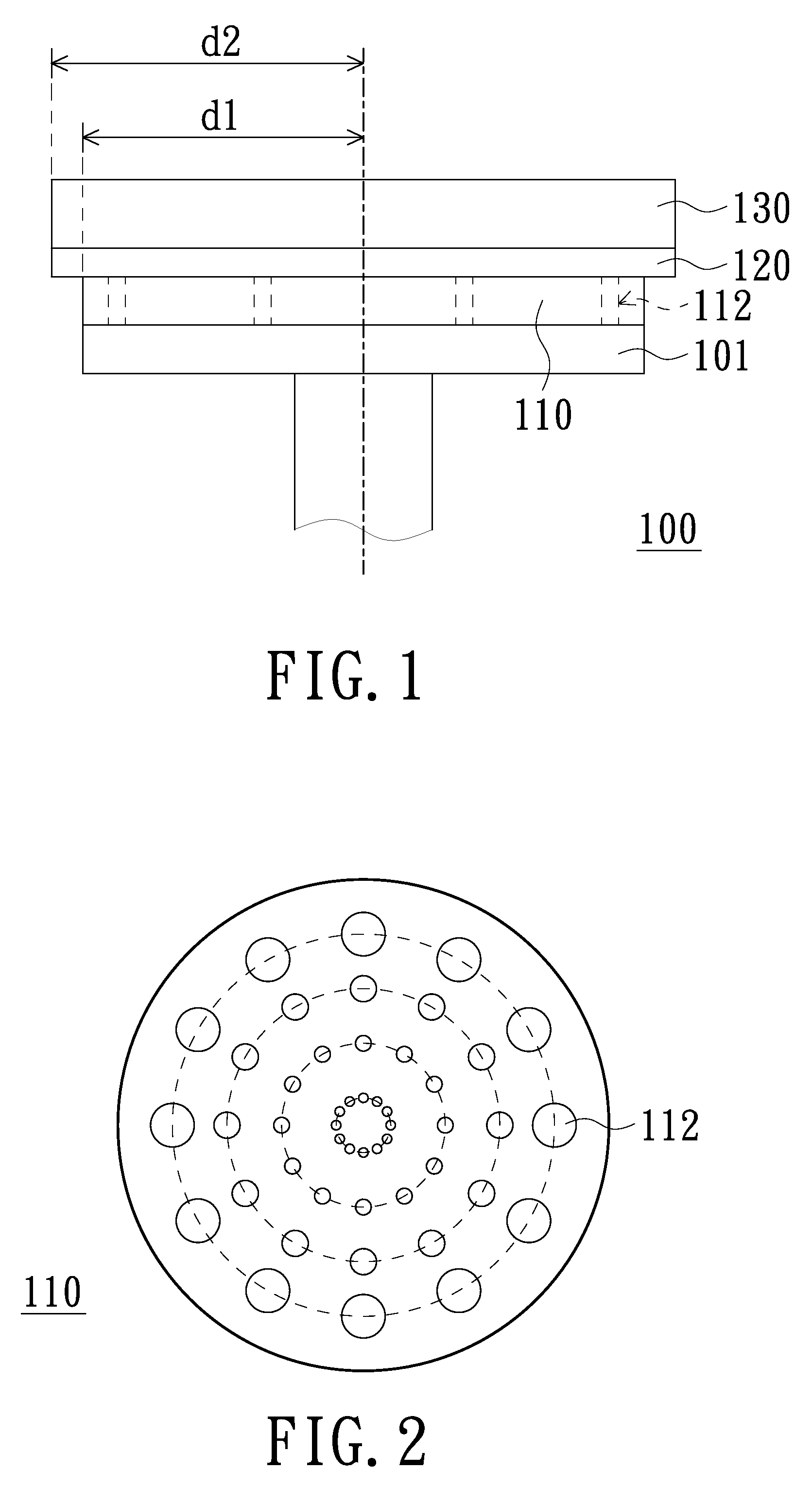

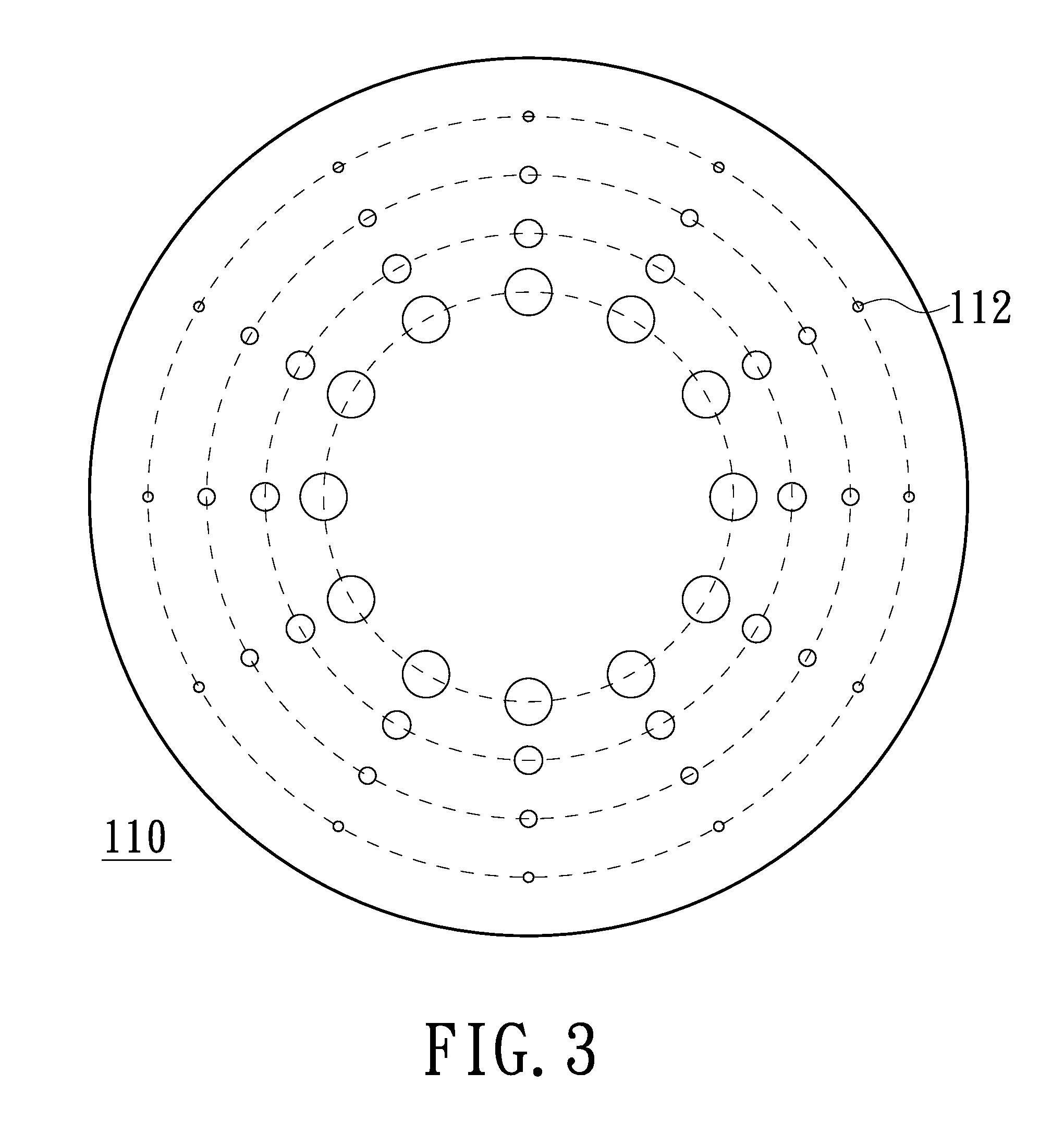

Chuck and semiconductor process using the same

ActiveUS20140065553A1Improve processing yieldGood material uniformitySleeve/socket jointsSemiconductor/solid-state device testing/measurementSemiconductor packageUltimate tensile strength

An apparatus of semiconductor process including a chuck and a vacuum source is provided. The chuck has a plurality of holes for holding a semiconductor substrate, and the vacuum source is used for providing vacuum suction through the holes to make the semiconductor substrate be subjected to varied suction intensities according to a warpage level thereof.

Owner:UNITED MICROELECTRONICS CORP

Self healing composite material and method of manufacturing same

InactiveUS8865798B2Large operating rangeFaster rate of healingSynthetic resin layered productsCellulosic plastic layered productsEmulsionLiquid state

A self-healing material comprises a matrix embedded with micro-pockets of a healing-agent releasable by a crack in the matrix. The healing-agent is able to bond to the matrix to repair the crack. The healing-agent is contained in microcapsules. A corresponding catalyst for the healing-agent is embedded in the matrix and contained in a plurality of microcapsules as an emulsion. The emulsion comprises an oil, a perfluorated solvent, a hydrophobic ionic liquid, or mixtures thereof. A method of manufacturing the self-healing material comprises the steps of identifying an operational temperature range of the material, providing at least one substance as the healing-agent, which substance remaining substantially in a liquid state within the operational temperature range, identifying an operational evaporation rate of the healing-agent and providing the substance with a curing time according to the evaporation rate.

Owner:MPB COMM +1

Method and apparatus for equal channel angular extrusion of flat billets

InactiveUS20070131013A1Eliminate surface cracksGood material uniformityCost effectivenessControl system

Owner:ENGINEERED PERFORMANCE MATERIALS

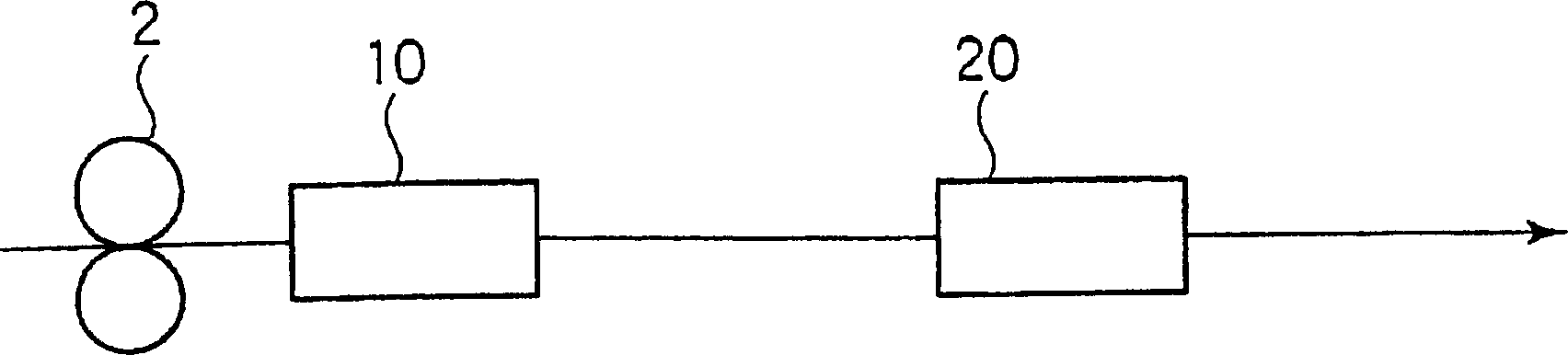

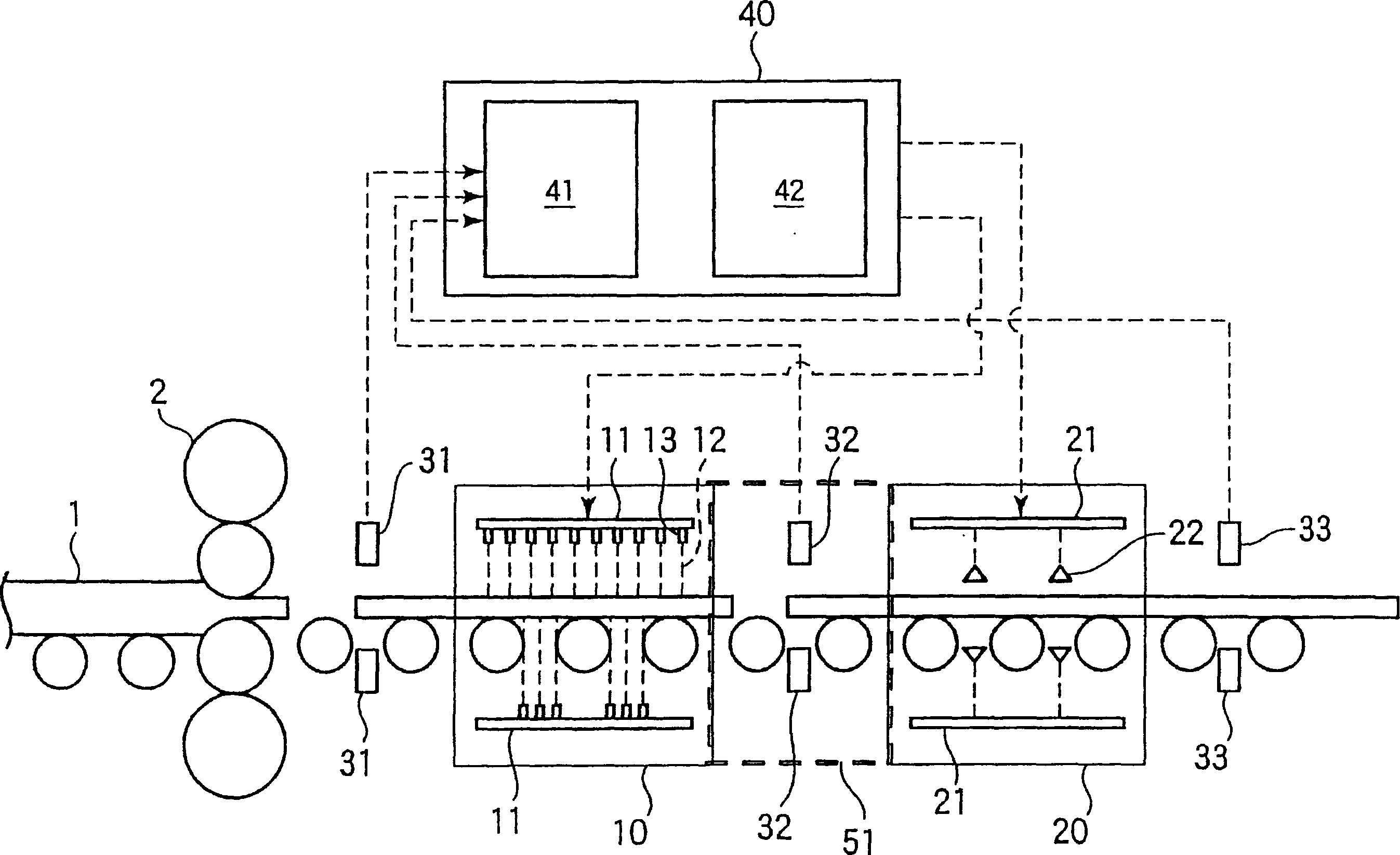

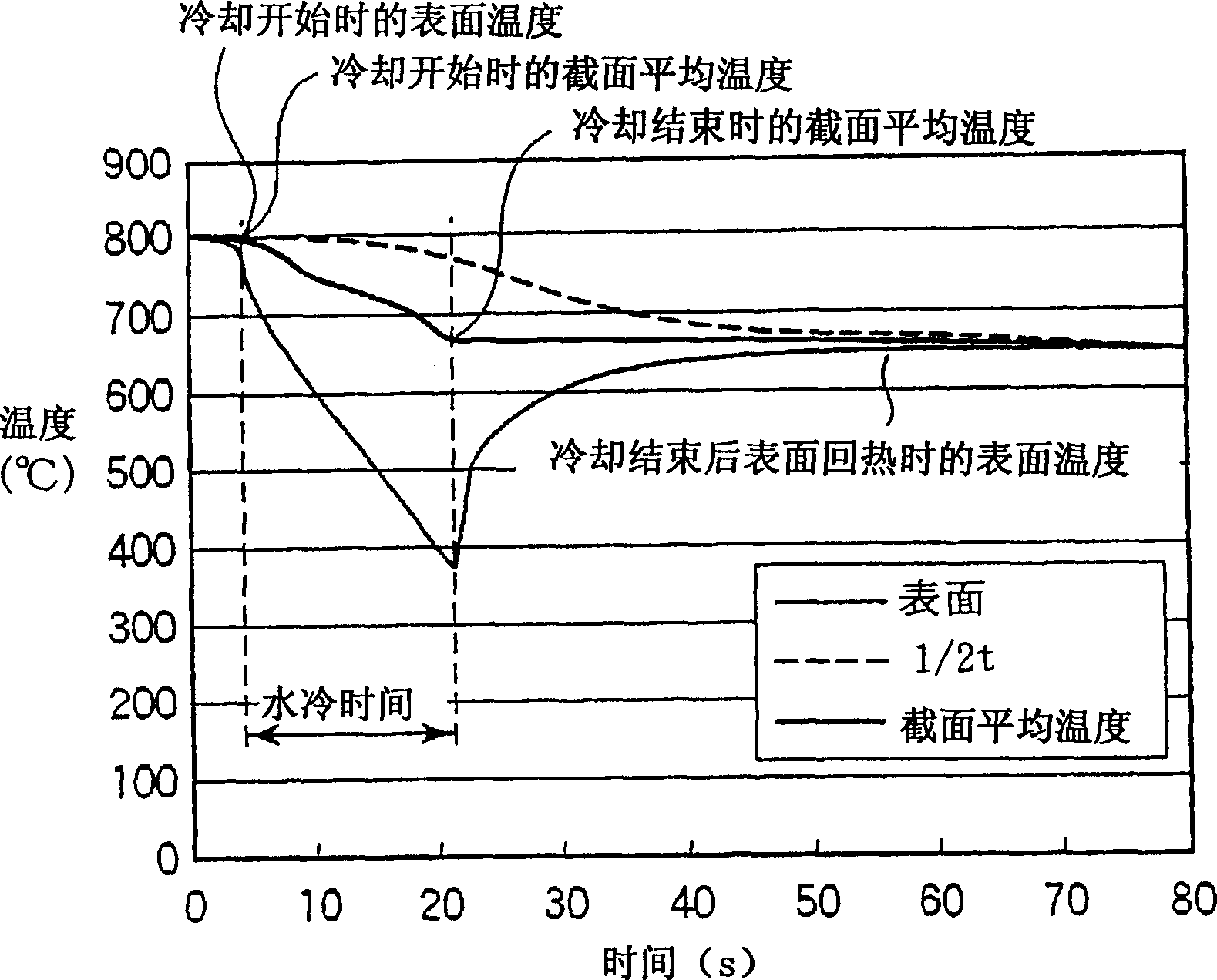

Device and method for controllably cooling thick steel plate

InactiveCN1802225AGood material uniformityWork treatment devicesMetal rolling arrangementsSheet steelHardness

A device for controllably cooling a thick steel plate capable of suppressing the occurrence of a difference in the hardness of the thick steel plate between the surface and the center thereof without lowering rolling efficiency and efficiently mass-producing the thick steel plate with low yield ratio, wherein a gentle cooling zone in which steel structure is partially transformed into ferrite is disposed on the outlet side of a rolling machine and a rapid cooling zone in which the remaining austenite is transformed into perlite, bainite, and martensite is disposed on the rear side of the gentle cooling zone. Namely, the gentle cooling zone and the rapid cooling zone controllable independently of each other are disposed in that order.

Owner:JFE STEEL CORP

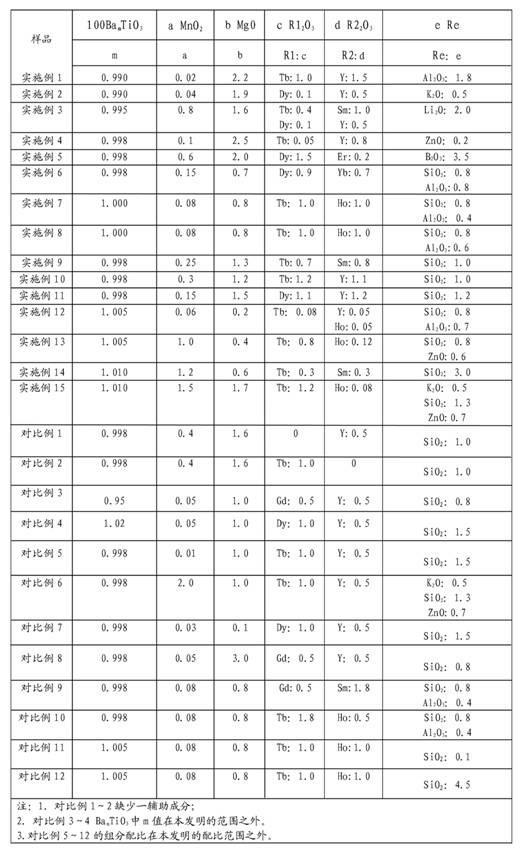

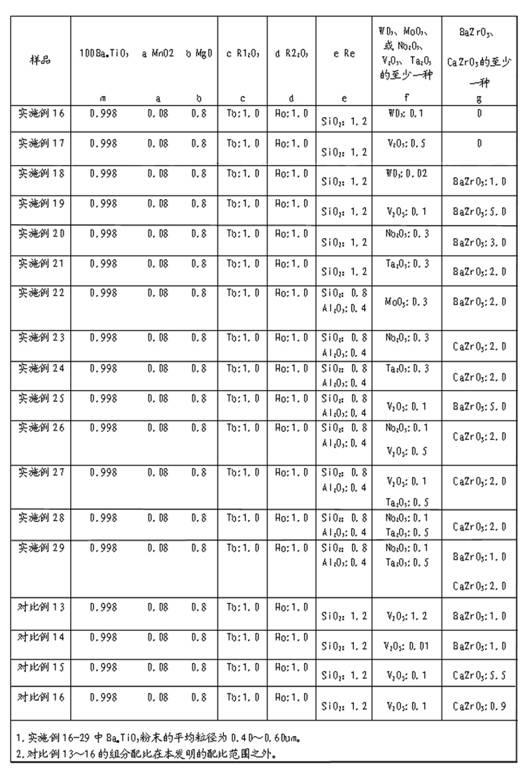

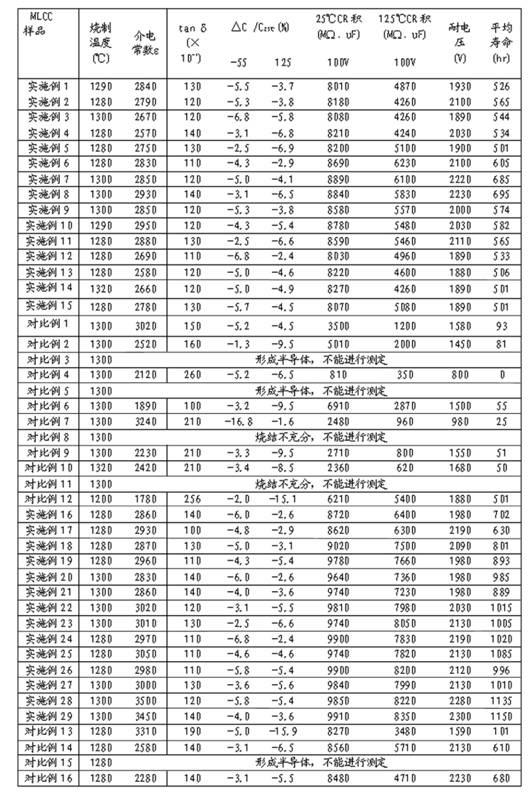

Multilayered ceramic capacitor medium ceramic material with reducing resistance

InactiveCN102020465AGood temperature characteristicsGood material uniformityFixed capacitor dielectricStacked capacitorsInsulation resistanceCapacitance

A multilayered ceramic capacitor medium ceramic material with reducing resistance comprises BamTiO3 which is a primary constituent, MnO2, MgO, CaO, R12O3, R22O3 and Re agglutinant which are auxiliary constituents, wherein R1 is elected from at least one of Gd, Tb and Dy; R2 is selected from at least one of Y, Sm, Ho, Er and Yb; the Re agglutinant is selected from at least one of B2O3, ZnO, SiO2, Al2O3, K2O and Li2O; the ceramic material is suitable for producing a middle and high voltage multilayered ceramic capacitor with a rated voltage greater than 100V; the room-temperature dielectric constant thereof can be controlled between 2500 and 3500; the temperature characteristic of electrostatic capacity and the material uniformity are good; the cost of products is low; the insulation resistivity, the acceleration life of insulation resistor and voltage resistance are high; and the reliability performance is good. The performance requirement of EIA standard X7R is satisfied completely.

Owner:仙桃市中星电子材料有限公司 +1

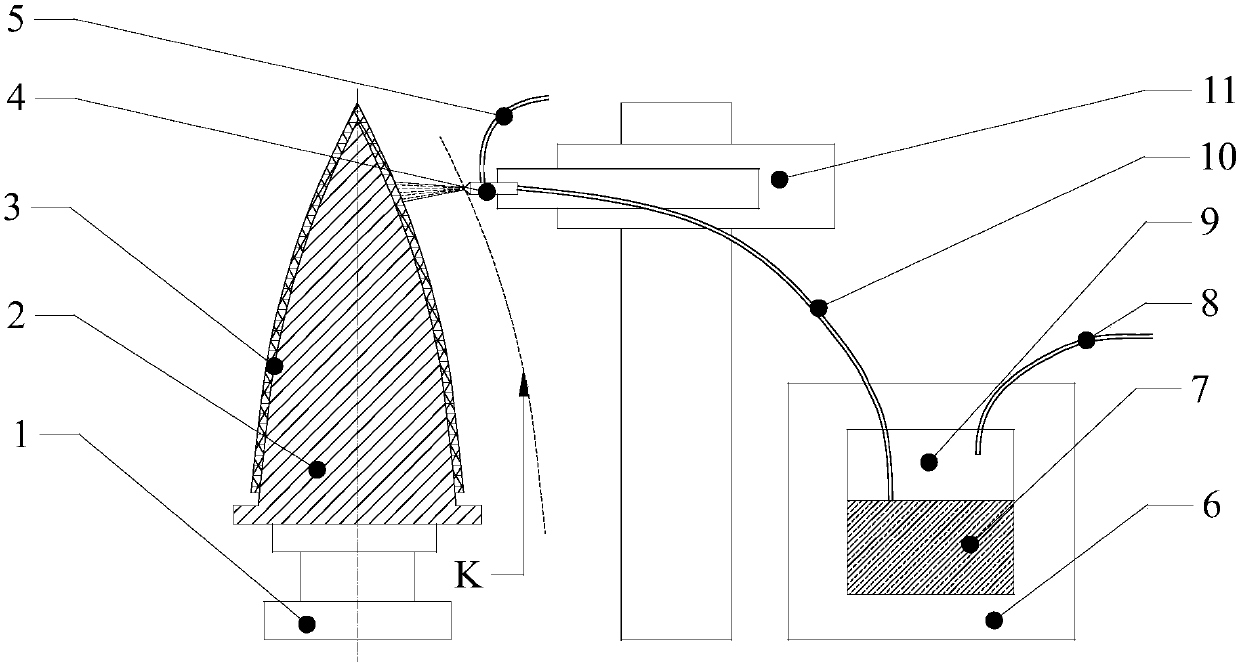

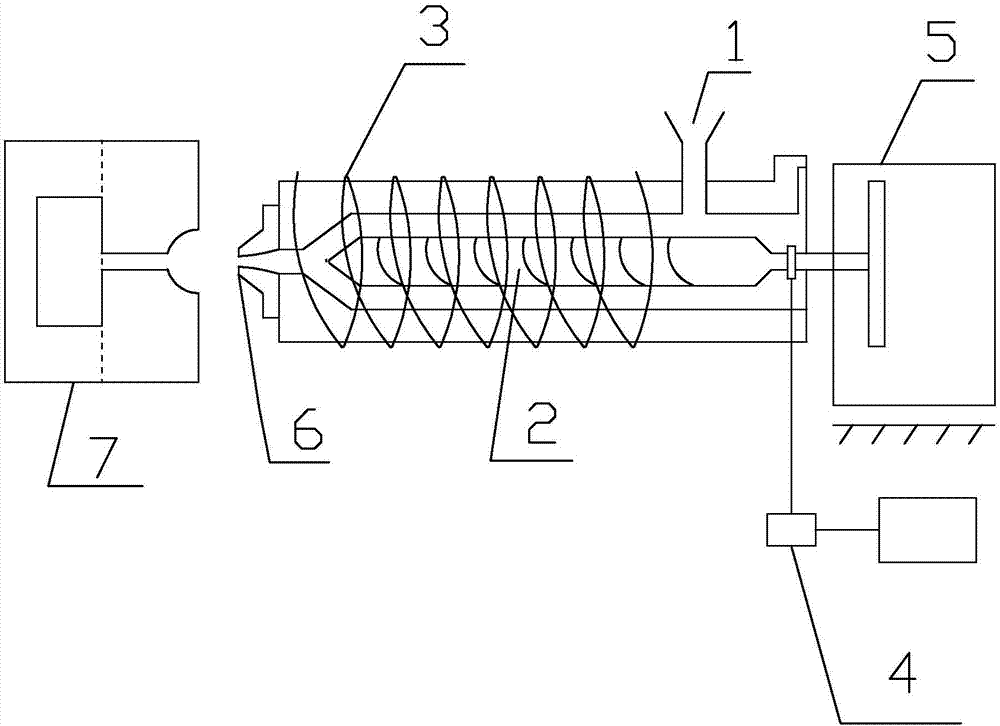

Jet molding device and method for resin based composite antenna housing

InactiveCN107891616AGood material uniformityImprove molding quality and pass rateDomestic articlesAirflowEngineering

The invention discloses a jet molding device for a resin based composite antenna housing. The jet molding device comprises a male mold, a reinforced fiber fabric, a rotating turntable, a jet device, atwo-dimensional moving device and a resin generation device, wherein the male mold is sleeved with the reinforced fiber fabric; the rotating turntable is arranged below the male mold and used for driving the male mold and the reinforced fiber fabric to rotate around respective vertical axes; the jet device is used for atomizing resin and jetting the resin into the reinforced fiber fabric; the two-dimensional moving device is connected with the jet device and used for driving the jet device to conduct two-dimensional movement along the offset curve of the outline of the male mold; and the resin generation device is connected with the jet device and used for heating the resin and conveying the resin to the jet device. The resin is jet to the reinforced fiber fabric through high-pressure airflow, the resin more easily permeates into the fabric, and the material uniformity is better. The jet molding process can be directly monitored through naked eyes and other means, defects existing inthe molding process can be treated in real time, and thus the molding quality and the percent of pass are improved.

Owner:SHANGHAI RADIO EQUIP RES INST

Steel sheet and plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing heat-treated sheet, method for producing steel sheet, and method for producing plated steel sheet

ActiveUS20190085421A1High strengthHigh elongationHot-dipping/immersion processesFurnace typesMean free pathSheet steel

Provided herein is a plated steel having high strength with excellent elongation, excellent hole expansibility, and excellent material uniformity, and a method for producing such a plated steel. The steel sheet provided herein has a specific composition, and a steel structure that contains ferrite as a primary phase, and 2 to 12% of perlite, and 3% or less of martensite by volume, and in which the remainder is a low-temperature occurring phase. The ferrite has an average crystal grain diameter of 25 μm or less. The perlite has an average crystal grain diameter of 5 μm or less. The martensite has an average crystal grain diameter of 1.5 μm or less. The perlite has a mean free path of 5.5 μm or more. The steel sheet has a tensile strength of 440 MPa or more.

Owner:JFE STEEL CORP

Cushion for polishing pad and polishing pad using the cushion

ActiveUS8211543B2Good surface smoothnessIncrease ratingsRevolution surface grinding machinesSynthetic resin layered productsPhase differenceEngineering

Owner:KURARAY CO LTD

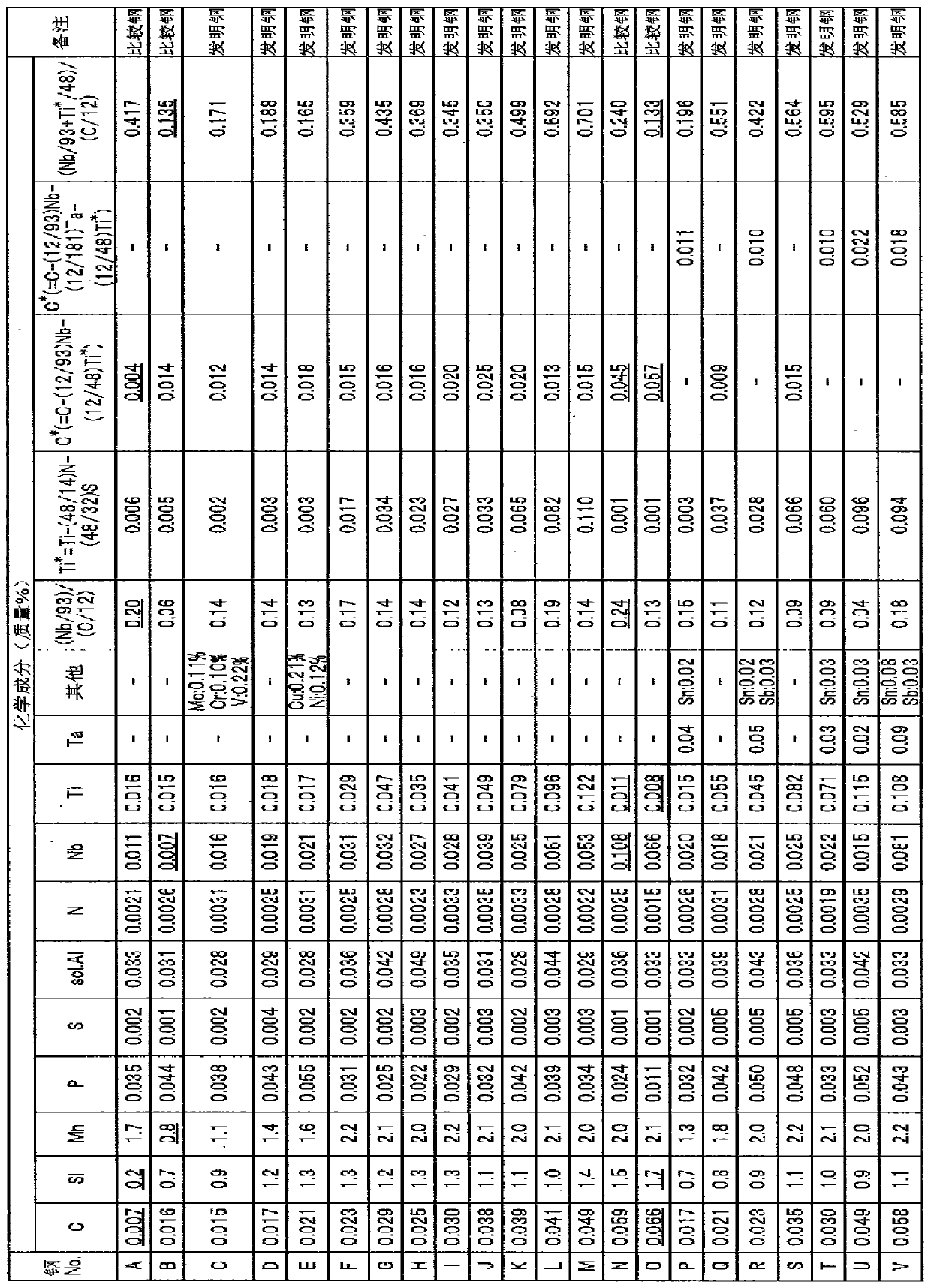

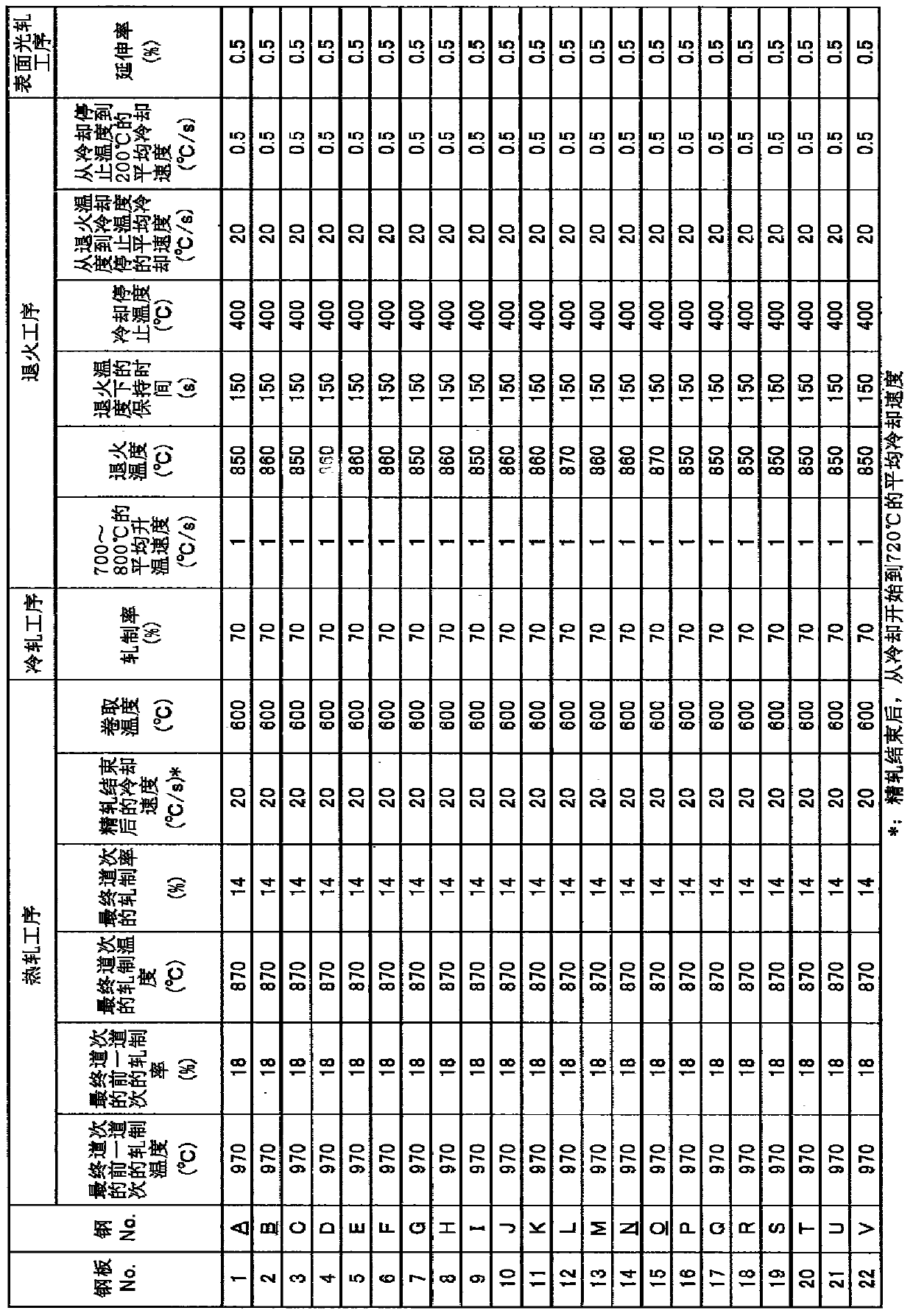

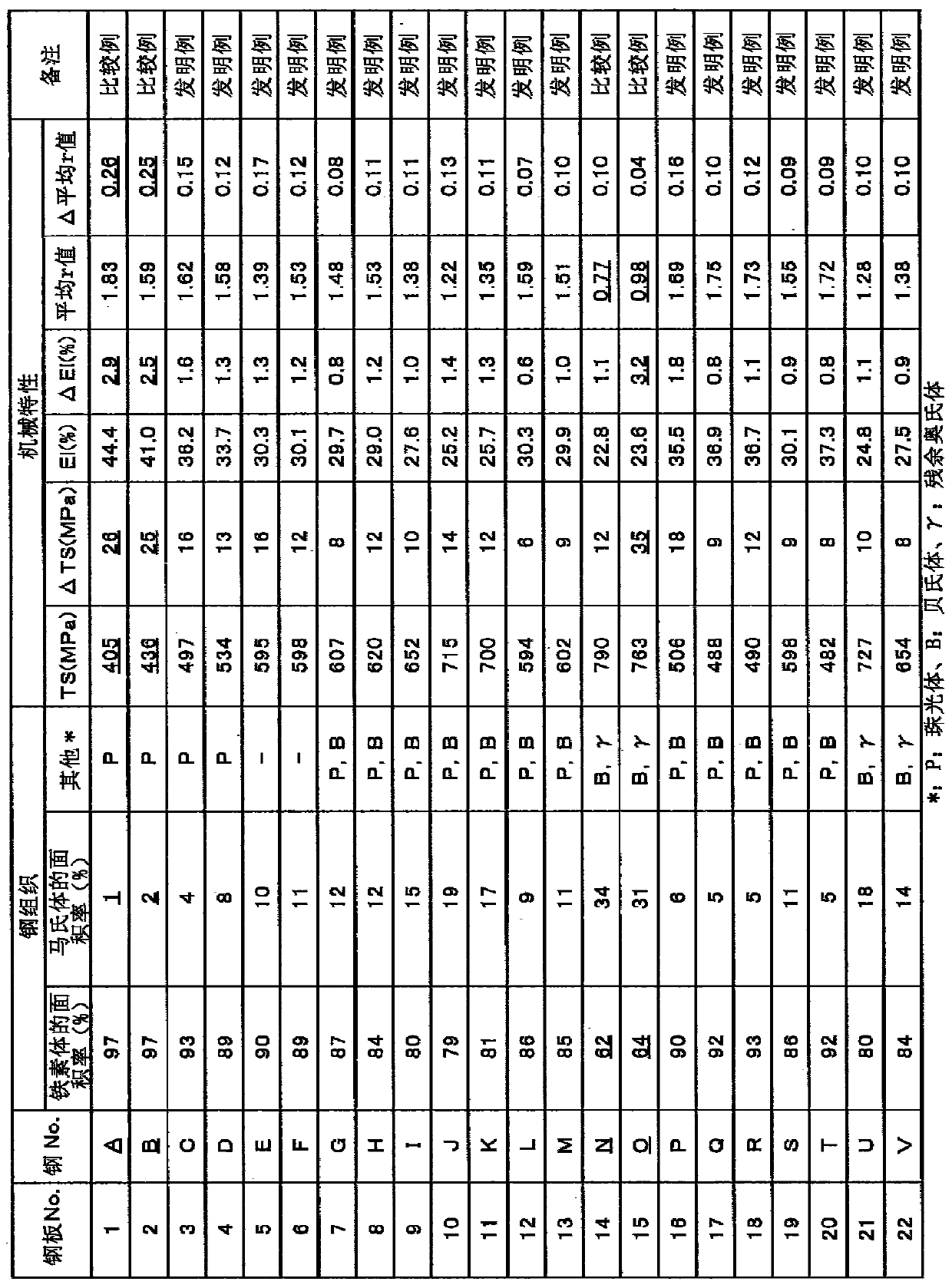

High-strength cold-rolled steel plate having excellent deep drawability and in-coil material uniformity, and method for manufacturing same

ActiveCN103857817AExcellent deep drawabilityGood material uniformityFurnace typesMetal rolling arrangementsSheet steelHigh intensity

Proposed are a high-strength cold-rolled steel plate having an excellent deep drawability and in-coil material uniformity, and a method for manufacturing same. The component composition is as follows, in weight%: C: 0.010 to 0.060%, Si: more than 0.5 to 1.5%, Mn: 1.0 to 3.0%, P: 0.005 to 0.100%, S: 0.010% or less, sol.Al: 0.005 to 0.500%, N: 0.0100% or less, Nb: 0.010 to 0.100%, and Ti: 0.015 to 0.150%, wherein (Nb / 93) / (C / 12) < 0.20, 0.005 <= C* <= 0.025, and (Nb / 93 + Ti* / 48) / (C / 12) >= 0.150 (where C* = C - (12 / 93)Nb - (12 / 48)Ti*, Ti* = Ti - (48 / 14)N - (48 / 32)S) are satisfied; and the remainder is iron and unavoidable impurities. The structure has a ferrite phase representing no less than 70% in area ratio, and a martensite phase representing no less than 3% in area ratio. The tensile strength is no less than 440 MPa and the average r value is no less than 1.20.

Owner:JFE STEEL CORP

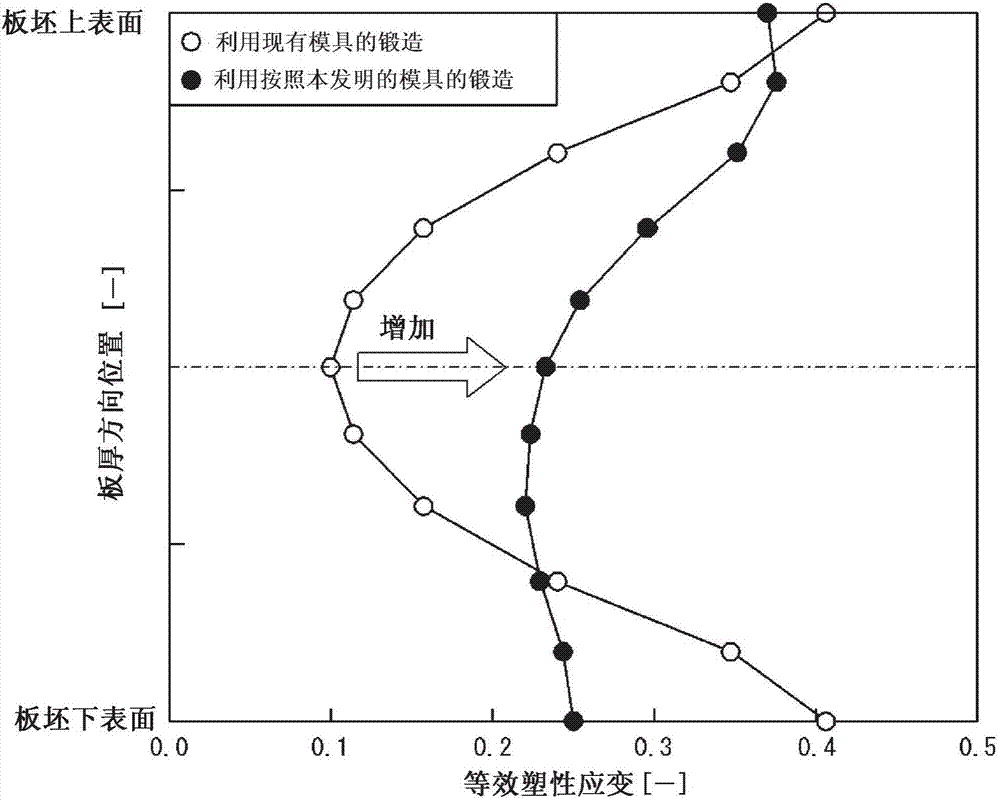

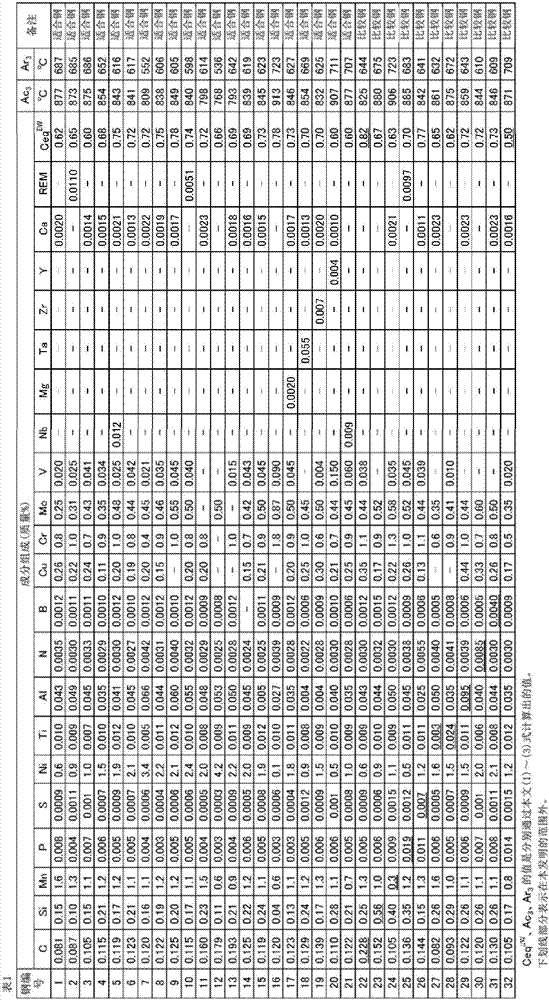

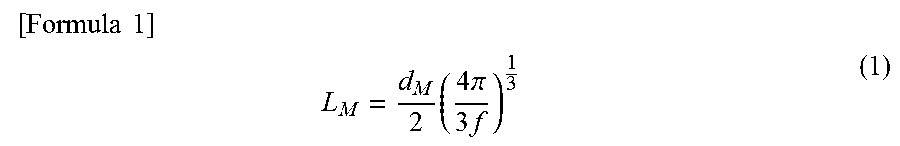

High toughness and high tensile strength thick steel plate with excellent material homogeneity and production method for same

ActiveCN107109561AHigh elongationImprove toughnessFurnace typesThin material handlingSheet steelToughness

A high tensile strength thick steel plate of excellent strength, elongation and toughness of the mid-thickness part and excellent material homogeneity is provided by: heating a continuously cast slab, the components of which have been adjusted to a prescribed composition, to 1200-1350 DEG C and then hot casting under conditions of temperature: at least 1000 DEG C, strain rate: not more than 3 / s, and cumulative rolling reduction: at least 15% using a mold in which the opposing short sides of the mold differ and, when the length of the shorter short side is 1, the length of the longer short side is 1.1-3.0; then allowing the slab to cool to obtain a steel raw material; after heating said steel raw material again to the Ac3 point-1250 DEG C and then performing at least two passes of hot-rolling in which rolling reduction per single pass is at least 4%, allowing the steel to cool to obtain a thick steel plate; and after heating again to the Ac3 point-1050 DEG C and then cooling rapidly to 350 DEG C or less, tempering said thick steel plate at 550-700 DEG C.

Owner:JFE STEEL CORP

High-strength cold-rolled steel sheet with excellent material homogeneity and production method therefor

ActiveUS20170022582A1Improve ductilityStrong expandabilityFurnace typesHeat treatment furnacesMean free pathChemical composition

A high-strength cold-rolled steel sheet having good ductility, hole expandability, and delayed fracture resistance and being excellent in material homogeneity. The steel sheet has a chemical composition containing, in mass %, C: 0.15 to 0.25%, Si: 1.2 to 2.2%, Mn: 1.7 to 2.5%, P: 0.05% or less, S: 0.005% or less, Al: 0.01 to 0.10%, N: 0.006% or less, Ti: 0.003 to 0.030%, B: 0.0002 to 0.0050%, and Fe and inevitable impurities. The steel sheet has a microstructure that includes ferrite having an average crystal grain diameter of 4 μm or less at a volume fraction of 5 to 20%, retained austenite at a volume fraction of 5% or less, including 0%, and tempered martensite at a volume fraction of 80 to 95%. Additionally, the mean free path of the ferrite is 3.0 to 7.5 μm.

Owner:JFE STEEL CORP

Chuck and semiconductor process using the same

ActiveUS9022392B2Warpage of the semiconductor substrate can be eliminatedImprove processing yieldSleeve/socket jointsSemiconductor/solid-state device testing/measurementEngineeringUltimate tensile strength

Owner:UNITED MICROELECTRONICS CORP

Nano magnesium-aluminum anti-corrosion coating and preparation method thereof

ActiveCN104673054ALow dielectric lossGood material uniformityAntifouling/underwater paintsPaints with biocidesDiethylenetriamineDipropylene glycol

The invention discloses a nano magnesium-aluminum anti-corrosion coating. The coating comprises a first component and a second component, wherein the second component is formed by mixing a component A with a component B; the first component comprises components as follows: epoxy resin, hydroxyl acrylic resin and ammonium dihydrogen phosphate; the component A comprises components as follows: nano magnesium oxide, nano aluminum oxide, nano titanium dioxide, nano zirconium dioxide, nano rare earth oxide and deionized water; the component B comprises components as follows: butanol, filler, barium sulfate, diethylenetriamine and dipropylene glycol butyl ether. The invention further discloses a preparation method of the nano magnesium-aluminum anti-corrosion coating. The coating is high in mechanical strength and excellent in wear resistance, hardness, compressive strength and impact resistance, meanwhile, the preparation technology is simple and easy to operate, the cost is lower, the production process is safe and environment-friendly, and no pollutant is produced.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

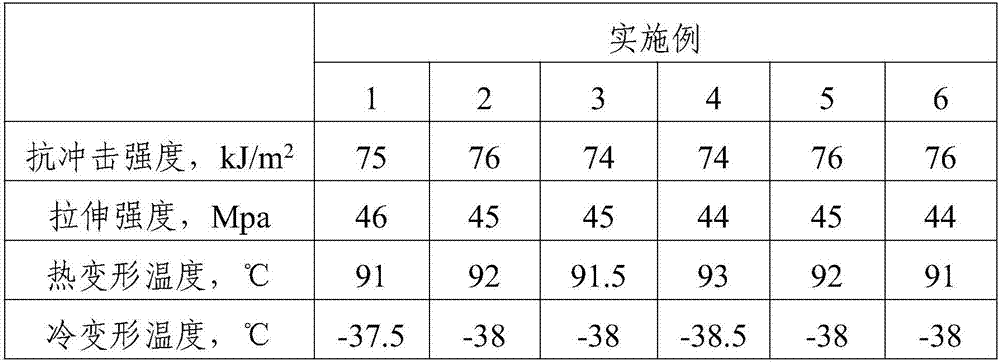

High-strength corrosion-resistant plastic for septic tank

InactiveCN106867097AReduce the difference in expansion coefficientIncrease viscosityLinear low-density polyethyleneAntioxidant

The invention provides high-strength corrosion-resistant plastic for a septic tank. The high-strength corrosion-resistant plastic is prepared from 50 to 70 parts by mass of linear low-density polyethylene, 40 to 60 parts by mass of polypropylene, 8 to 12 parts by mass of attapulgite, 4 to 9 parts by mass of phytic acid, 10 to 16 parts by mass of mica flake, 3 to 10 parts by mass of silicon carbonate whiskers, 15 to 22 parts by mass of nanometer calcium carbonate, 5 to 10 parts by mass of polyurea, 2 to 5 parts by mass of an antioxidant, 2 to 4 parts by mass of an antistatic agent, 3 to 5 parts by mass of methacryloxypropyltrimethoxysilane and 0 to 2 parts by mass of vinyl acetate. The high-strength corrosion-resistant plastic has excellent resistance to penetration, acid and base corrosion resistance, high and low temperature resistance, mechanical strength, impact strength greater than or equal to 74 kJ / m<2>, tensile strength greater than or equal to 44 Mpa, a heat distortion temperature greater than 90 DEG C and a cold deformation temperature less than -37 DEG C.

Owner:四会市恒星智能科技有限公司

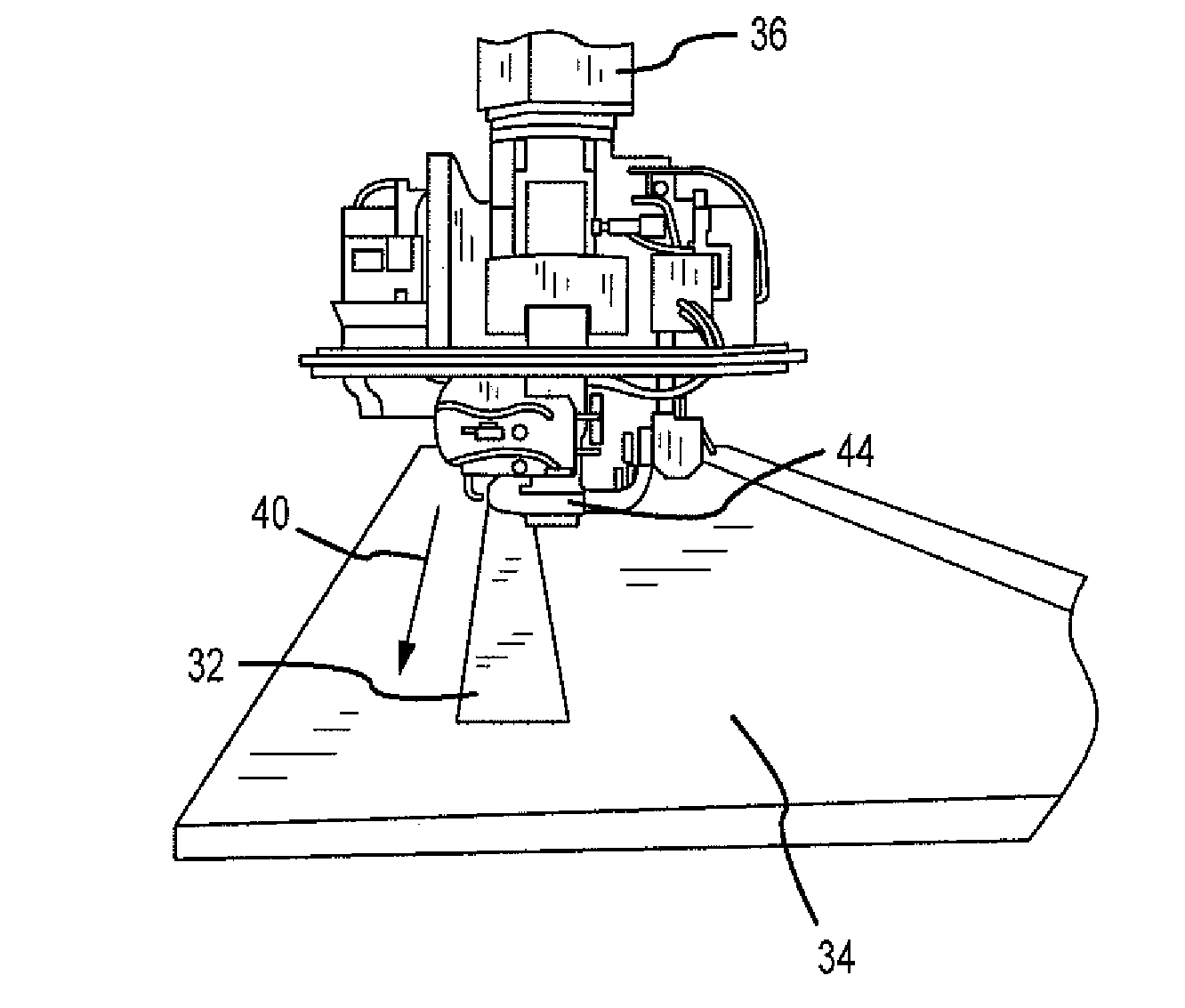

Method for Fabrication of Integrated Lightning Strike Protection Material

ActiveUS20120145319A1Reduce laborReduces resourceVehicle componentsAircraft static dischargersLightning strikeEngineering

The invention is directed to an integrated lightning strike protection system adapted for automated placement on a composite structure having a surfacing layer consisting of an organic polymer resin, a conductive layer of an expanded metal foil, an isolation / tack layer, and a carrier paper layer. In another embodiment of the invention, there is provided an integrated lightning strike protection system having an integrated lightning strike protection material consisting of an expanded metal foil encapsulated in organic polymer resin mounted on a carrier paper, and an automated placement machine suitable for placing the material on an aircraft composite part for protection of the composite part from lightning strikes. In another embodiment of the invention, there is provided a method for fabricating a composite structure with lightning strike protection.

Owner:THE BOEING CO

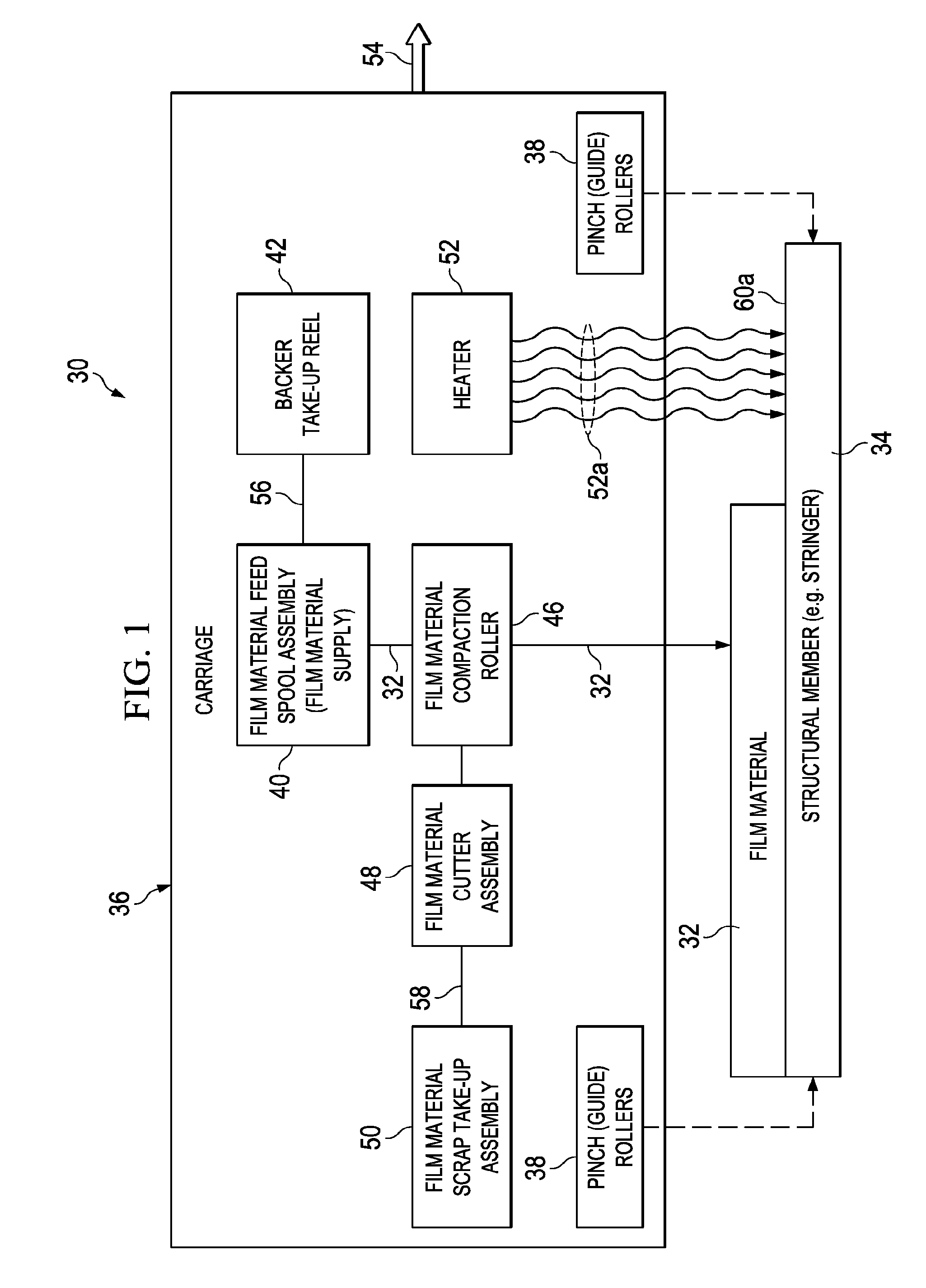

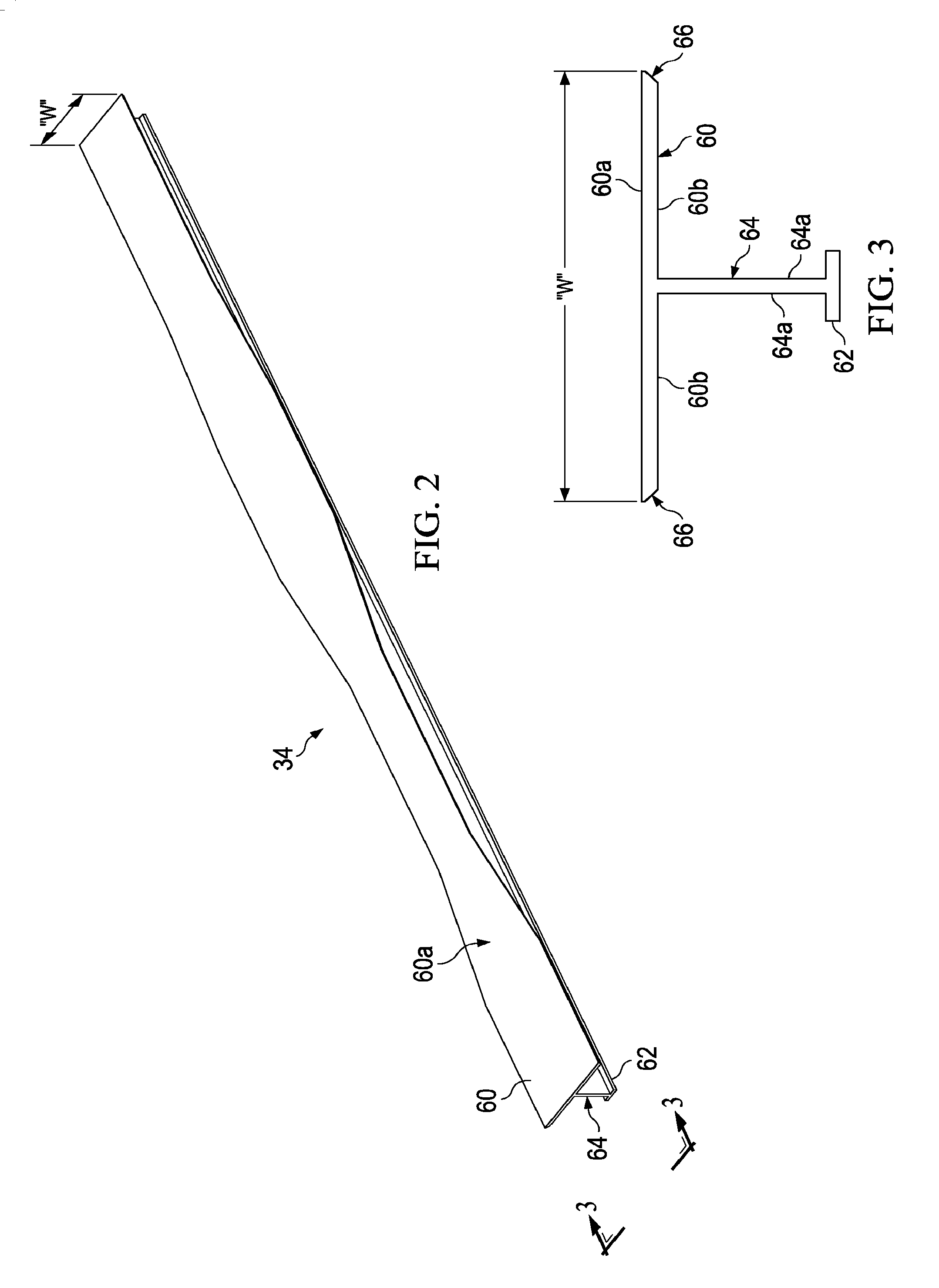

Apparatus for applying film material to elongate members

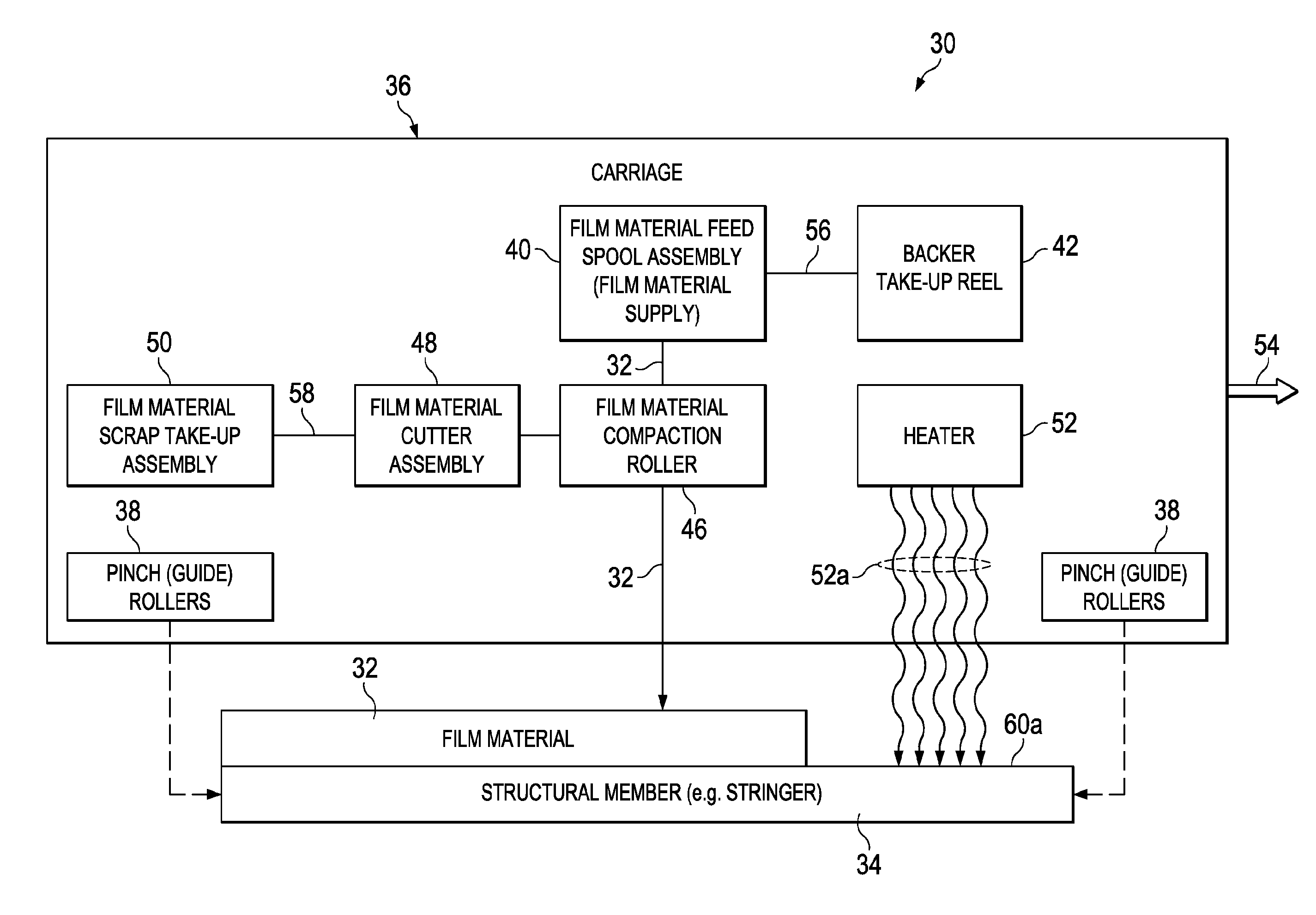

ActiveUS20150136328A1Easy to set upLow costLamination ancillary operationsLaminationEngineeringFilm material

An apparatus including a carriage adapted to be mounted on and movable along the elongate composite stringer, and a compaction roller mounted on the carriage for compacting film material against the flange surface as the carriage moves along the stringer. The apparatus also includes a film feed roll assembly on the carriage adapted to hold a quantity of film material and to dispense the film material to the compaction roller. The apparatus also includes a take-up reel on the carriage adapted for taking up a backing on the film material as the film material is being dispensed to the compaction roller, a heater on the carriage for heating the flange surface as the carriage moves along the composite stringer, and a film trimmer for trimming edges of the film material to match a contour of the composite stringer after the film material has been compacted against the flange surface.

Owner:THE BOEING CO

Carbon based friction plates of powder metallurgy, and manufacturing technique

This invention discloses a carbon-based friction disk for producing brake by powder metallurgy. The carbon-based friction disk is composed of: specifically treated carbon powder 20-40 wt.%, copper 15-30 wt.%, iron 5-15 wt.%, tin 2-5 wt.%, silicon dioxide 3-10 wt.%, manganese 0.5-2 wt.%, and phenolic resin 2-5 wt.%. The carbon-based friction disk has such advantages as high friction strength, uniform properties, simple process and low energy consumption.

Owner:张雯

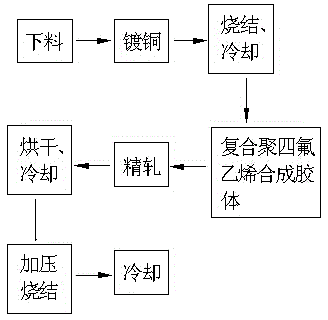

Production technique for steel-base copper-plastic compound material

InactiveCN104943275ASimple structureHigh composite strengthSynthetic resin layered productsMetal layered productsCopper platingHydrogen

The invention discloses a production technique for steel-base copper-plastic compound material. The production technique comprises the following steps of 1 blanking, 2 copper plating, 3 sintering and cooling, 4 colloid synthesis with compound teflon, 5 finish rolling, 6 stoving and cooling, 7 pressure sintering and 8 cooling. The protective gas is nitrogen-hydrogen mixed gas. When pressure sintering is conducted, the heating temperature ranges from 370 to 380 DEG C, and the pressure ranges from 40.0 to 50.0 MPa. The production technique for the steel-base copper-plastic compound material has the advantages that the quality and the stability of product are improved, and the combined strength is high.

Owner:CHUZHOU DASHI AUTO PARTS

Manufacturing method of zirconium oxide porcelain piece used for all-ceramic false tooth

InactiveCN107162588AGood material uniformityHigh densityArtificial teethClinical therapyMaterials science

The invention discloses a manufacturing method of a zirconium oxide porcelain piece used for an all-ceramic false tooth and belongs to the field of all-ceramic false tooth materials used for lost teeth repair. The manufacturing method includes the following steps: 1) with a zirconium porcelain mixture material as a raw material, performing injection molding to obtain a green body of the zirconium oxide porcelain piece for all-ceramic false teeth; 2) performing dewaxing treatment, low-temperature pre-sintering, mechanical processing and silk-screen printing to the green body; and 3) inspecting and packaging the final product. The zirconium oxide porcelain piece used for all-ceramic false teeth has high internal homogeneity, high density and high breaking strength. An all-ceramic false tooth inner crown produced from the zirconium oxide porcelain piece has high mechanical strength and high density. The zirconium oxide porcelain piece used for the all-ceramic false teeth is designed through CAD / CAM and is processed to manufacture an all-ceramic false tooth inner crown green body which is then sintered, so as to reach strength and appearance effects required in clinical therapy.

Owner:SHAOXING HUAJING SCI TECH

Hot-rolled steel sheet and method for producing same

ActiveUS20140299238A1Good material uniformityMaintain good propertiesHot-dipping/immersion processesFurnace typesChemical compositionImpurity

A hot rolled steel sheet has a chemical composition including, by mass %, C: 0.060% to 0.120%; Si: 0.10% to 0.70%; Mn: 1.00% to 1.80%; P: 0.10% or less; S: 0.010% or less; Al: 0.01% to 0.10%; N: 0.010% or less; Nb: 0.010% to 0.100%, wherein Nb is contained so that content of solute Nb is 5% or more relative to the total Nb content; the balance being Fe and incidental impurities. The hot rolled steel sheet has a microstructure containing ferrite of not more than 15 μm in average crystal grain diameter by a volume fraction of not less than 75%, the balance being low-temperature-induced phases. The hot rolled steel sheet can be suitably utilized for manufacturing a cold rolled steel sheet or hot-dip galvanized steel sheet having a tensile strength of 590 MPa or more, excellent in material homogeneity and capable of giving excellent cold rolling property.

Owner:JFE STEEL CORP

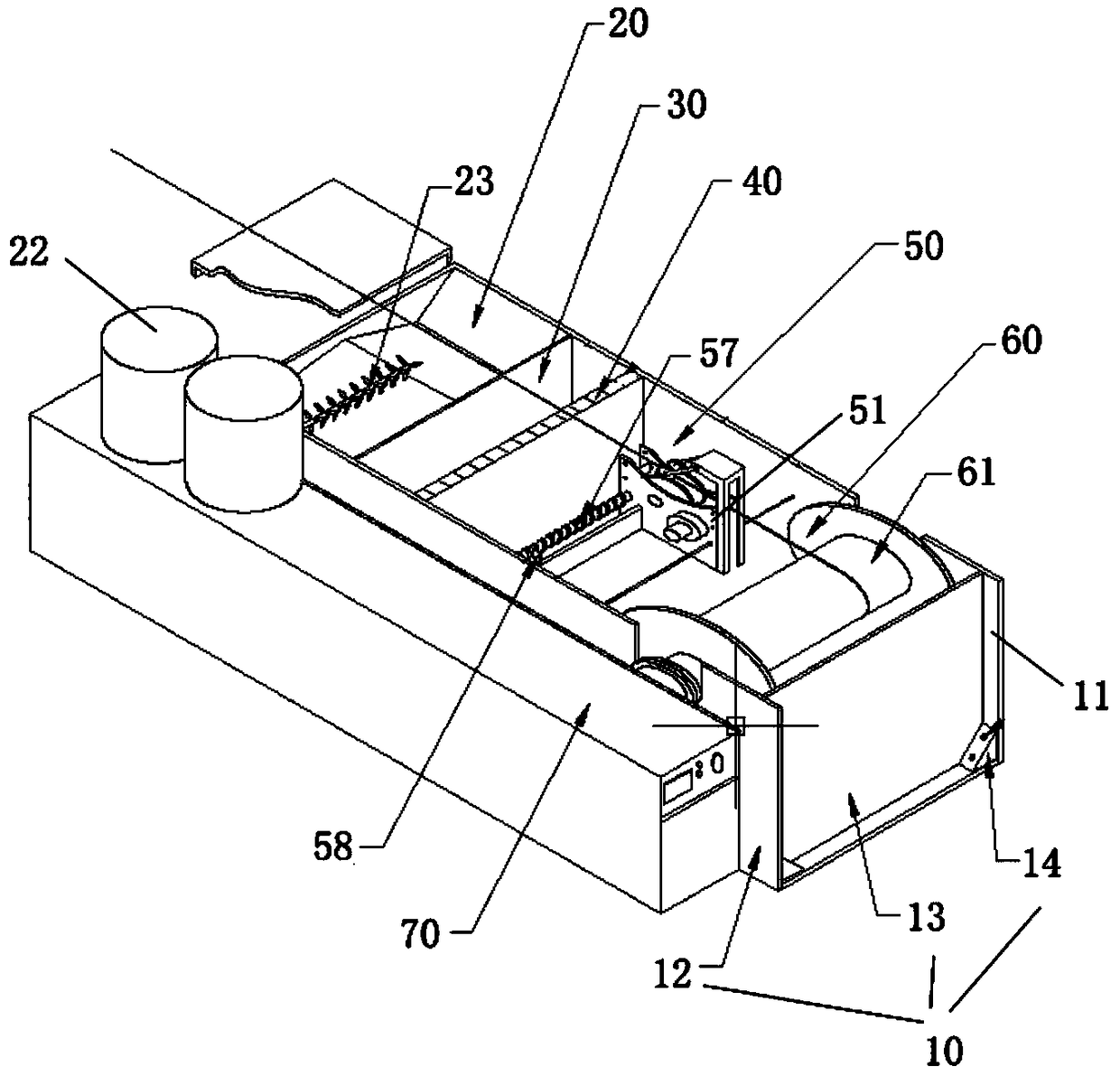

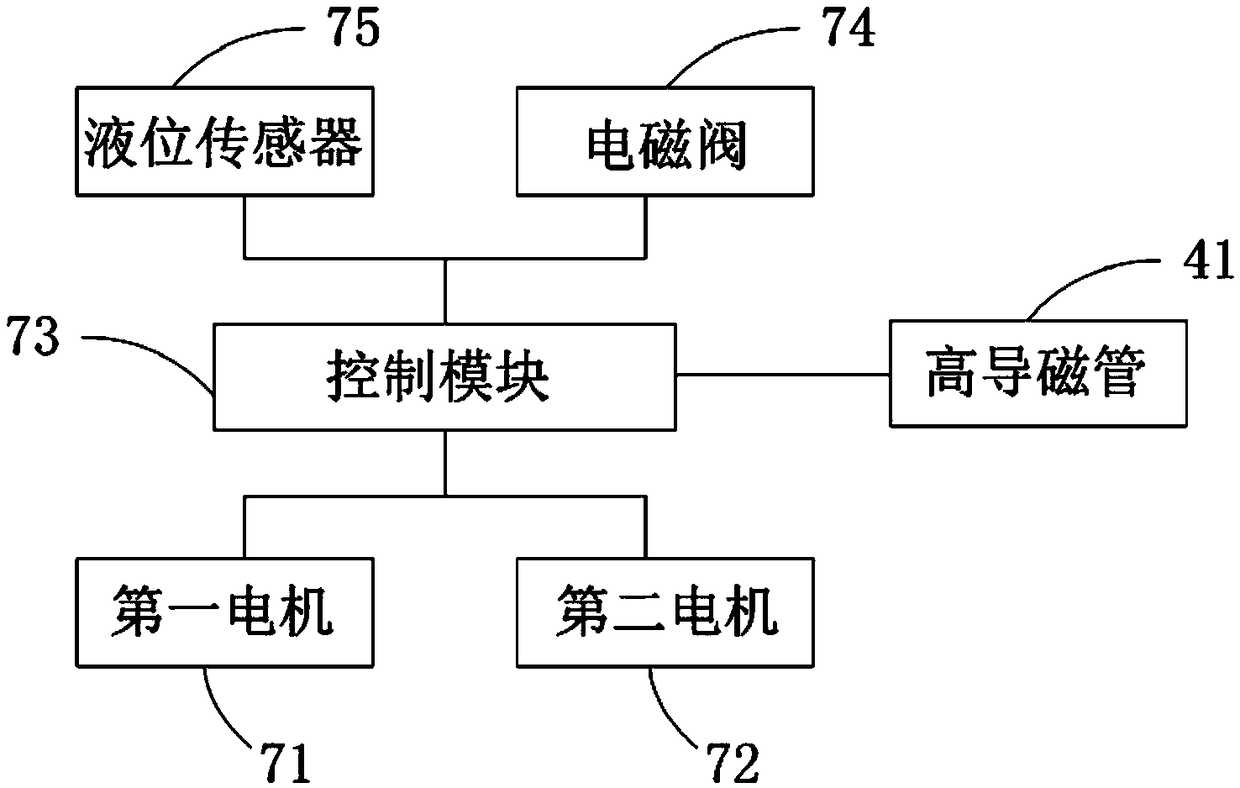

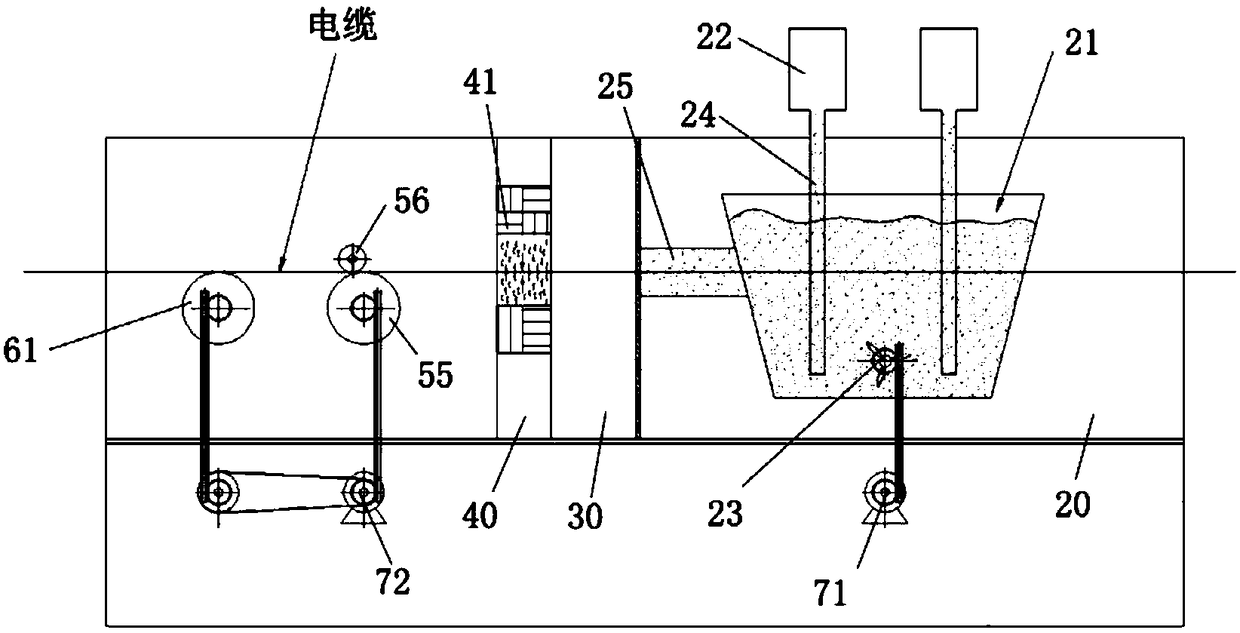

Cable outer coating molding device and molding method

PendingCN109509589AQuality improvementImprove flexibilityInsulating conductors/cablesEngineeringElectric cables

The invention provides a cable outer coating molding device and molding method. The cable outer coating molding device comprises a host machine frame; the cable outer coating molding device further comprises a dipping bin, a natural curing bin, a heating bin and a guide wheel shaping bin which are sequentially disposed in the host machine frame along a cable conveying direction; the dipping bin isused for stirring and mixing raw materials, and coating the mixed raw materials on the outside of a cable, so that a cable outer coating can be obtained; the natural curing bin is used for performingnatural curing on the cable outer coating in the natural curing bin; the heating bin is used for performing heating semi-qualitative curing on the cable outer coating inside the heating bin; and theguide wheel shaping bin is used for shaping the cable outer coating in the guide wheel shaping bin according to a calibrated outer diameter size. With the cable outer coating molding device and molding method provided by the invention adopted, the integrated automatic molding of the cable outer coating is realized, a material utilization rate is improved, production costs are reduced, and the molding quality of cable products is improved.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

Hot-rolled steel sheet and method for producing same

ActiveUS9574254B2Good material uniformityMaintain good propertiesHot-dipping/immersion processesFurnace typesChemical compositionImpurity

A hot rolled steel sheet has a chemical composition including, by mass %, C: 0.060% to 0.120%; Si: 0.10% to 0.70%; Mn: 1.00% to 1.80%; P: 0.10% or less; S: 0.010% or less; Al: 0.01% to 0.10%; N: 0.010% or less; Nb: 0.010% to 0.100%, wherein Nb is contained so that content of solute Nb is 5% or more relative to the total Nb content; the balance being Fe and incidental impurities. The hot rolled steel sheet has a microstructure containing ferrite of not more than 15 μm in average crystal grain diameter by a volume fraction of not less than 75%, the balance being low-temperature-induced phases. The hot rolled steel sheet can be suitably utilized for manufacturing a cold rolled steel sheet or hot-dip galvanized steel sheet having a tensile strength of 590 MPa or more, excellent in material homogeneity and capable of giving excellent cold rolling property.

Owner:JFE STEEL CORP

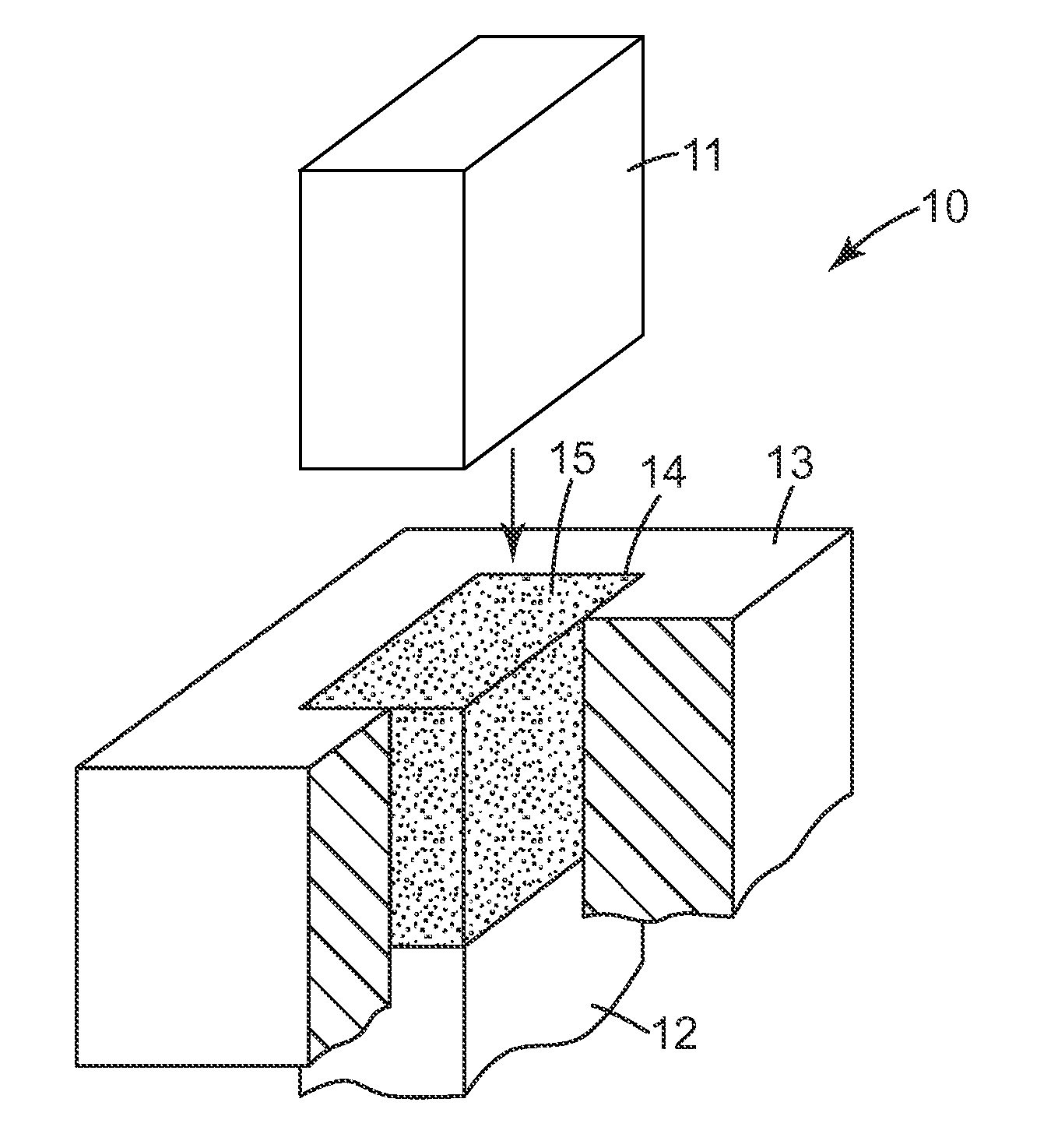

Method for making a dental blank, a press and a system for making dental blanks

InactiveUS20110014589A1Accurate shapeGood material uniformityDental implantsTeeth fillingEngineeringMachine press

The invention relates to a method of making a dental blank which combines uniaxial pressing isostatic pressing techniques. The invention also includes a press for performing the method and a system comprising a uniaxial and a isostatic press. The invention may help in efficient manufacturing of dental blanks at minimized costs and maximized quality.

Owner:3M INNOVATIVE PROPERTIES CO

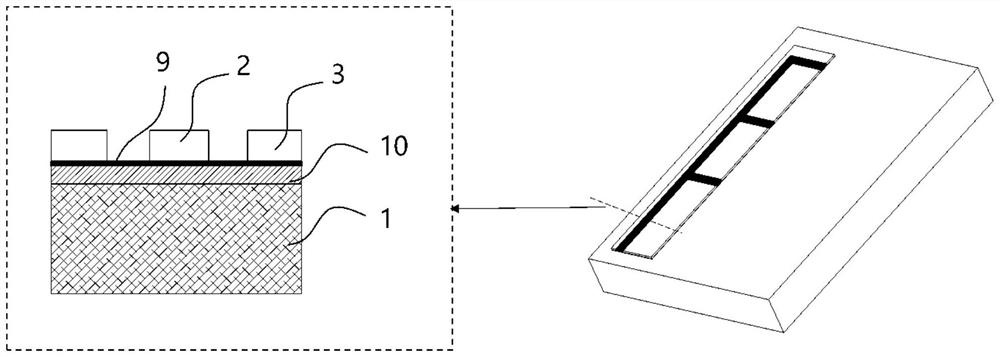

Semiconductor laser light source module based on planar waveguide combiner and manufacturing method

PendingCN113193468AGood material uniformityLight transmission loss is smallLaser detailsOptical light guidesLaser lightErbium lasers

The invention relates to a semiconductor laser light source module based on a planar waveguide combiner, and the module comprises a bearing substrate which is provided with N electrodes; N semiconductor lasers, wherein bare chips on the semiconductor lasers are respectively bonded with the corresponding electrodes through leads; an optical waveguide combining structure sequentially comprising a waveguide layer, a reflection dielectric layer and a bonding layer from top to bottom; the waveguide layer being provided with a waveguide circuit pattern, the waveguide circuit pattern comprising N light inlets and one light outlet, and the N light inlets being in one-to-one correspondence with light outlet points of bare chips on the N semiconductor lasers; and a covering box. The invention further provides two manufacturing methods of the semiconductor laser light source module based on the planar waveguide combiner. According to the semiconductor laser light source module based on the planar waveguide type combiner provided by the invention, the large-aperture waveguide is prepared by a method of directly etching on the wafer, so that the laser coupling difficulty is greatly reduced, and the size of a device is greatly reduced.

Owner:三序光学科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com