High toughness and high tensile strength thick steel plate with excellent material homogeneity and production method for same

A manufacturing method and technology of uniformity, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of small reduction, long construction period, increased manufacturing cost, etc., and achieve excellent elongation and toughness. The effect of shortening and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

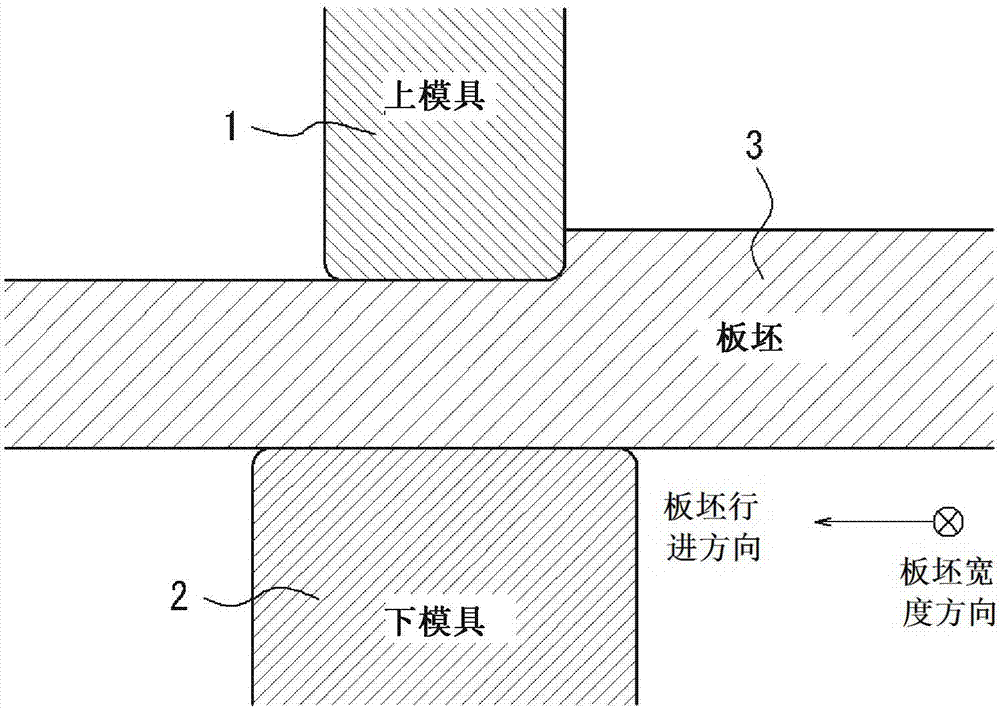

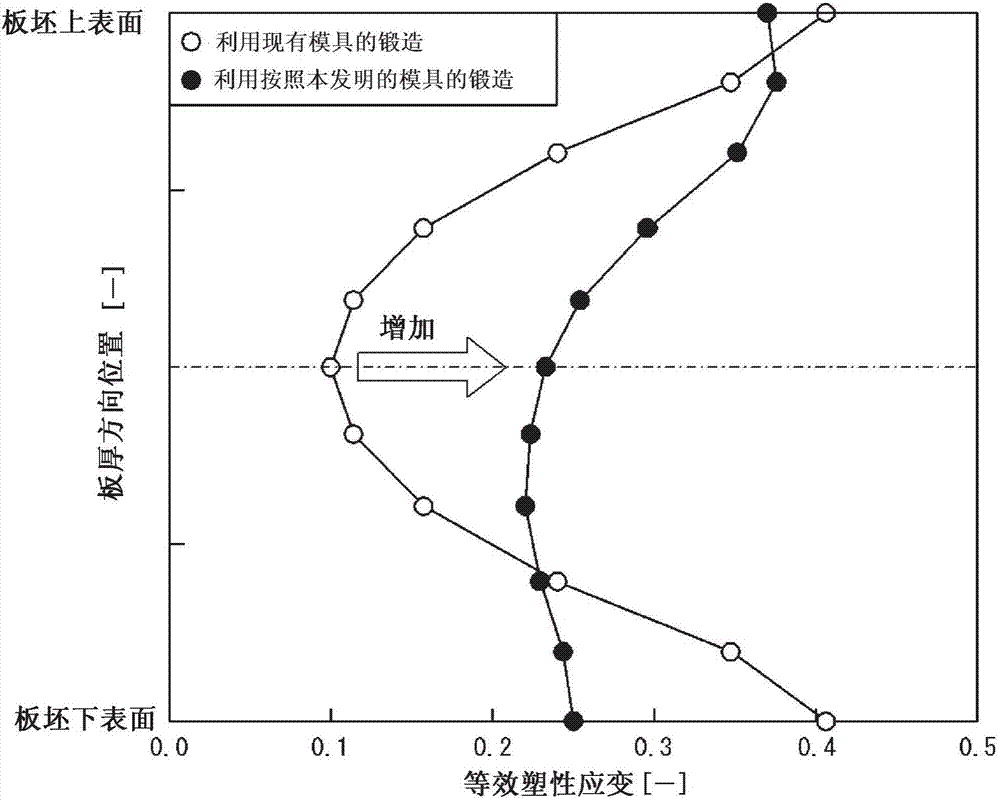

Method used

Image

Examples

Embodiment

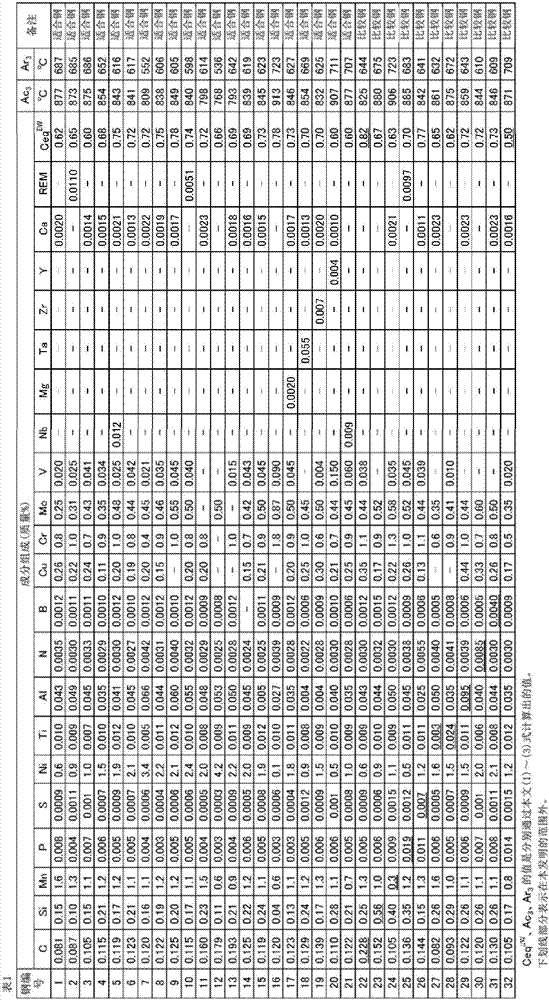

[0146] Steels of steel numbers 1 to 32 shown in Table 1 were melted to form continuous cast slabs, and then hot forged and hot rolled under the conditions shown in Table 2. The number of passes of hot rolling is set to 10 or less. At this time, the plate thickness is set within a range of 100 to 240 mm. Then, quenching and tempering were performed under the conditions shown in Table 3, and steel sheets shown as Sample Nos. 1 to 44 in Tables 2 and 3 were produced. Next, these steel sheets were subjected to the following tests.

[0147] (1) Tensile test

[0148] Cut out a round bar tensile test piece (Φ: 12.5mm, GL: 50mm) from the thickness center of each steel plate in a direction perpendicular to the rolling direction, and measure the yield strength (YS) and tensile strength (TS) .

[0149] (2) Tensile test in plate thickness direction

[0150] For each steel plate, three round bar tensile test pieces (φ10 mm) were cut out in the thickness direction, and the reduction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com