Composition for high-strength and high-toughness rock plate blank and application of composition

A high-toughness, high-strength technology, applied in the field of rock slabs, can solve the problems of low-cost rock slab body composition, and it is not easy to increase the strength of rock slabs, so as to increase toughness, reduce the situation of cutting cracks, The effect of improving tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

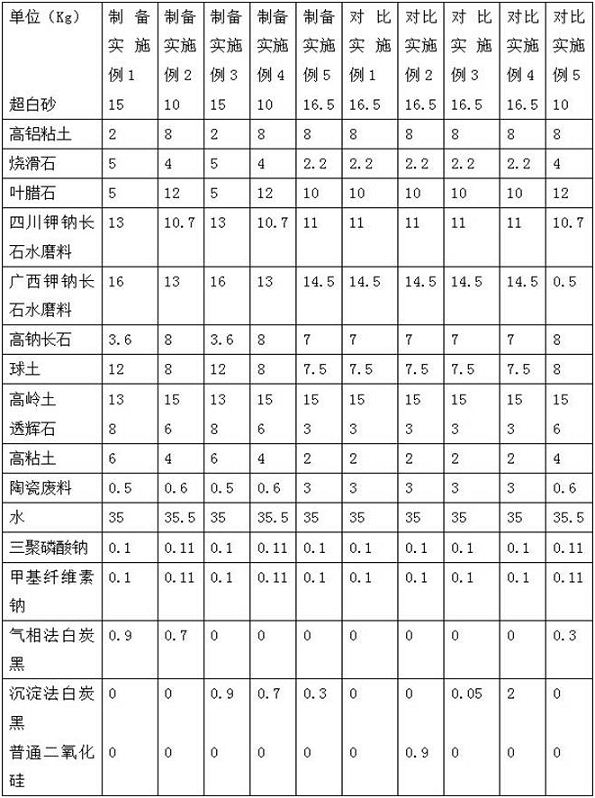

[0130] (1) Green body ingredients: Weigh each raw material of the composition for the high-strength and high-toughness rock slab green body of the present invention as shown in Table 1 below:

[0131] (2) Billet processing: Mix the raw materials weighed in step (1) to make them evenly mixed, then add water, sodium tripolyphosphate and sodium methyl cellulose in the amounts shown in Table 1 and place them in a ball mill Ball milling is carried out until the processing fineness of the slurry is 250 mesh and more than 0.8%, and the specific gravity is 1.67g / ml;

[0132] (3) Slurry screening and iron removal: Pass the slurry obtained in step (2) through a 100-mesh vibrating screen twice to remove coarse particles, and then put the slurry into a high-frequency Gauss automatic magnetic separator for iron removal. , to obtain a slurry with coarse particles and iron-containing fine impurities removed;

[0133] (4) Spray pulverization: the slurry obtained in step (3) is atomized by a ...

preparation Embodiment 2

[0137] (1) Green body ingredients: Weigh each raw material of the composition for the high-strength and high-toughness rock slab green body of the present invention as shown in Table 1 below:

[0138] (2) Billet processing: Mix the raw materials weighed in step (1) to make them evenly mixed, then add water, sodium tripolyphosphate and sodium methyl cellulose in the amounts shown in Table 1, and then place them in the Carry out ball milling in a ball mill until the processing fineness of the slurry is 250 mesh and more than 0.9%, and the specific gravity is 1.68g / ml;

[0139] (3) Slurry screening and iron removal: Pass the slurry obtained in step (2) through a 90-mesh vibrating screen twice to remove coarse particles, and then put the slurry into a high-frequency Gauss automatic magnetic separator for iron removal. , to obtain a slurry with coarse particles and iron-containing fine impurities removed;

[0140] (4) Spray pulverization: the slurry obtained in step (3) is atomize...

preparation Embodiment 3

[0144] (1) Green body ingredients: Weigh each raw material of the composition for the high-strength and high-toughness rock slab green body of the present invention as shown in Table 1 below:

[0145] (2) Billet processing: Mix the raw materials weighed in step (1) to make them evenly mixed, then add water, sodium tripolyphosphate and sodium methyl cellulose in the amounts shown in Table 1, and then place them in the Carry out ball milling in a ball mill until the processing fineness of the slurry is 1.0% of the 250-mesh sieve, and the specific gravity is 1.69 g / ml;

[0146] (3) Slurry screening and iron removal: Pass the slurry obtained in step (2) through an 80-mesh vibrating screen twice to remove coarse particles, and then put the slurry into a high-frequency Gauss automatic magnetic separator for iron removal. , to obtain a slurry with coarse particles and iron-containing fine impurities removed;

[0147] (4) Spray pulverization: the slurry obtained in step (3) is atomiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com