Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Firing shrinkage is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina-based ceramic core for directional solidification and preparation method thereof

The invention relates to an alumina-based ceramic core for directional solidification and a preparation method thereof. The refractory materials used in the alumina-based ceramic core include 65-95% of EC95 fused mullite, 5-30% of zirconium silicate, 2-8% of silica powder, 1-5% of titania powder and 1-10% of aluminium powder by weight percent, wherein EC95 fused mullite, F200 powder accounts for 10-30%, F320 powder accounts for 40-70% and F600 powder accounts for 10-30%. The preparation method is characterized by comprising the following steps: ball-milling the above powders and mixing the powder uniformly, putting the mixture into a molten plasticizer to be mixed, forming on a ceramic core forming machine through hot pressing, finishing a ceramic core formed through hot pressing and correcting the shape of the ceramic core, roasting in a box-type resistance furnace, and adopting a high-temperature reinforcer and a room-temperature reinforcer to respectively carry out high-temperature reinforcement and room-temperature reinforcement on the ceramic core discharged from the furnace. The alumina-based ceramic core prepared by the preparation method has the characteristics of high high-temperature strength, good creep resistance, small firing shrinkage, low firing temperature and good metallurgical and chemical properties.

Owner:SHENYANG RES INST OF FOUNDRY

Blank body of fine porcelain ceramic, preparation method and application thereof

The invention relates to a blank body of fine porcelain ceramic, a preparation method and an application thereof. The raw materials of the blank body comprise the following components in the percentage by weight: 30-50% of calcined kaolin with high aluminum, low contraction and low thermal expansion, 10-20% of porcelain waste powder, 10-20% of quartz sand and 20-40% of ball clay. The invention also further discloses fine porcelain ceramic and a preparation method thereof. The fine porcelain ceramic can be used for casting a product with the size greater than 1,000 mm, and the product is flat, straight and regular and is not easy to deform.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Gradient porous material and preparation method thereof, atomizer and electronic atomization device

PendingCN111728273AExtended service lifeConnect with natureTransportation and packagingMetal-working apparatusCompression moldingSpray dried

The invention relates to a gradient porous material and a preparation method thereof, an atomizer and an electronic atomization device. The preparation method of the gradient porous material comprisesthe following steps of: preparing raw materials of all functional layers into corresponding slurry, wherein the slurry of at least two functional layers is prepared from different raw materials; respectively spray-drying the slurry of each functional layer to prepare dry granulation powder of each functional layer; and distributing the dry granulation powder of each functional layer according toa preset gradient structure, carrying out compression molding, and sintering to prepare the gradient porous material with a plurality of functional layers. According to the preparation method of the gradient porous material, the interface bonding force between functional layers is improved.

Owner:SHENZHEN SMOORE TECH LTD

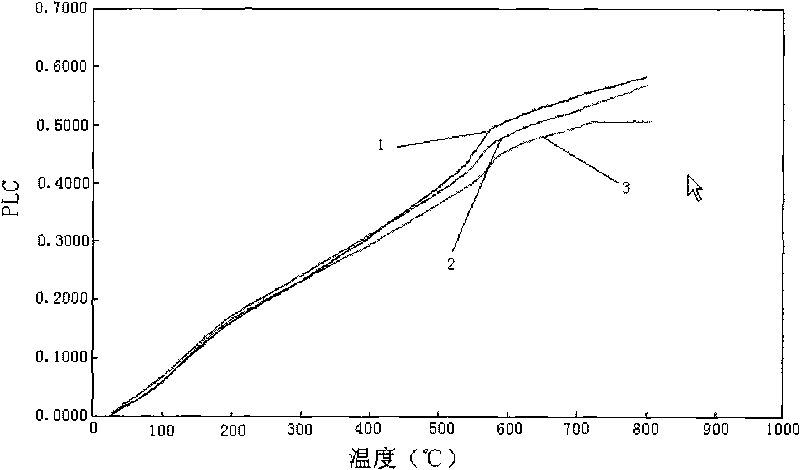

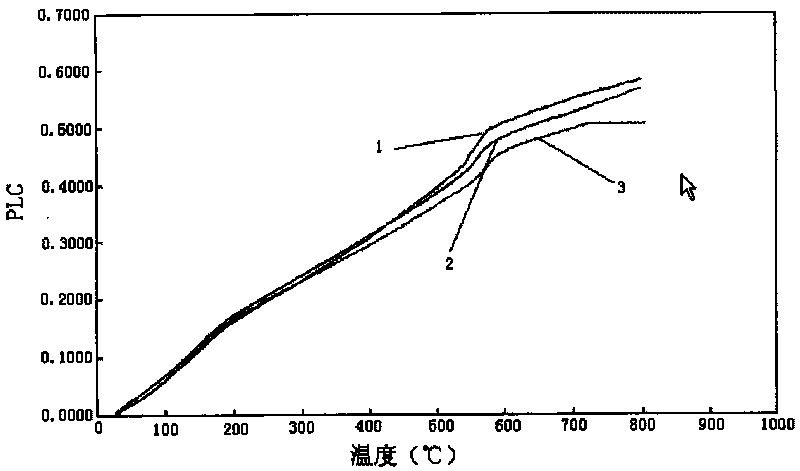

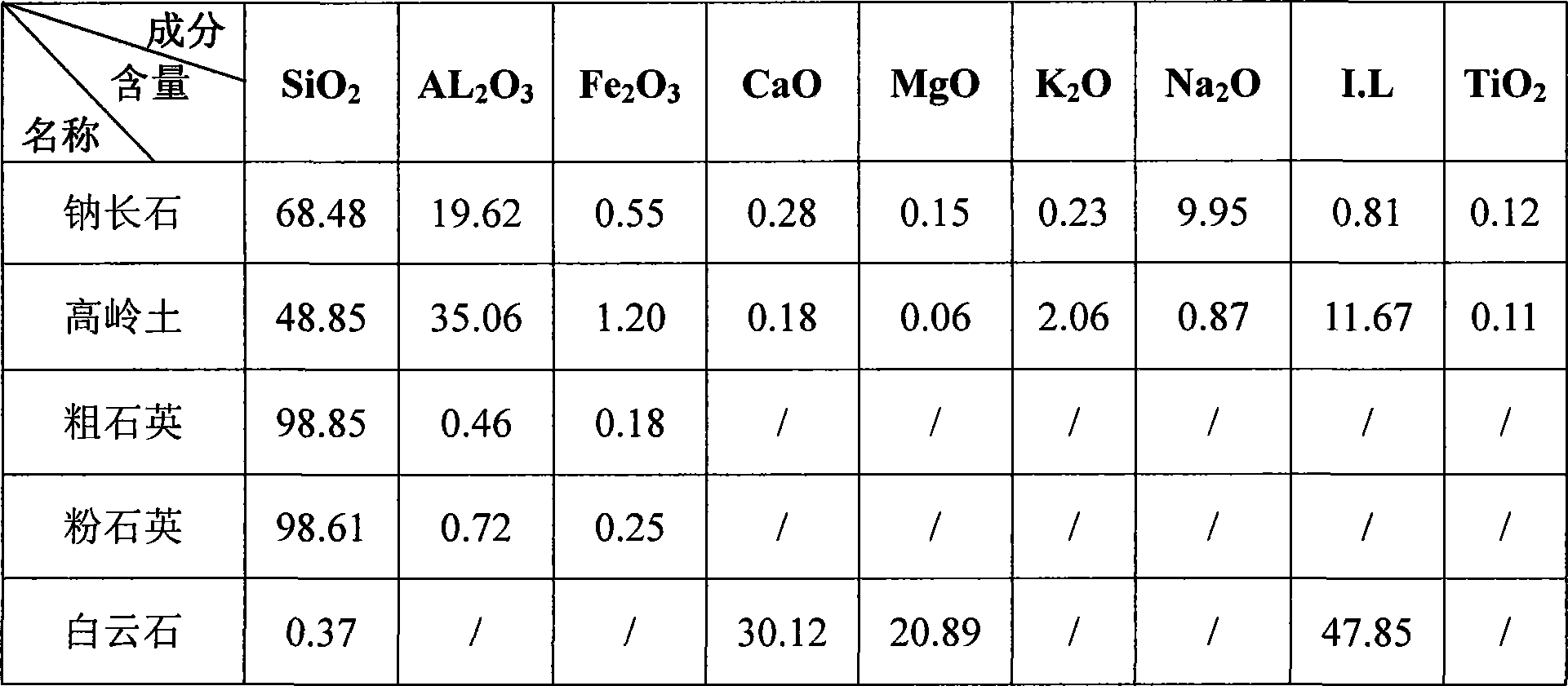

Low temperature high silicon stoneware and its making process

The present invention is low temperature high silicon stone ware and its making process. The low temperature high silicon stone ware has great amount of quartz in different granularities introduced to increase the expansion coefficient of the biscuit. It is prepared with the materials including albite 15-35 wt%, kaolin 25-40 wt%, quartz 35-50 wt% and dolomite 1-5 wt%, and through a common stone ware baking process. The low temperature high silicon stone ware features the firing range of 1,175-1,225 deg.c and water absorption of 1-4 %.

Owner:HUNAN HUALIAN YIBAILI CERAMIC IND

Preparation method of honeycomb-shaped Mn-based low-temperature denitration catalyst

ActiveCN108067296AFiring shrinkage is smallThe shape is not easy to deformGas treatmentMolecular sieve catalystsManganese oxideLarge pore

The invention discloses a preparation method of a honeycomb-shaped Mn-based low-temperature denitration catalyst. The preparation method comprises steps as follows: (1), titanium dioxide, a molecularsieve and a solution containing manganese nitrate, cerium nitrate and iron nitrate are mixed uniformly, a mixture is dried, roasted at low temperature and smashed, and a powdery material is obtained;(2), the powdery material obtained in the step (1) is subjected to a forming process of the denitration catalyst, and the honeycomb-shaped Mn-based low-temperature denitration catalyst is obtained. The catalyst prepared with the method has larger pore volume and higher strength and is good in forming performance and not prone to cracking, the active components are manganese oxides in different valence states, and the catalyst is excellent in denitration performance and has good capability of resisting water vapor and SO2 poisoning.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-creep zircon overflowing brick and preparation method thereof

ActiveCN103524139AHigh temperature low flexural strengthImproved high temperature flexural strengthFiberPolymer science

The invention relates to a low-creep zircon overflowing brick and a preparation method thereof. The low-creep zircon overflowing brick comprises, by mass, 100% of zircon powder, wherein zircon oxide short fibers account for, by mass, 0.0-4.0% of the zircon powder, silicon oxide powder accounts for, by mass, 0.1-2.0% of the zircon powder, and composite additives account for, by mass, 0.1-0.8% of the zircon powder. The composite additives can be La2O3, or CeO2, or combination of La2O3 and Y2O3, or combination of CeO2 and Y2O3, or combination of La2O3, CeO2 and Y2O3. According to the low-creep zircon overflowing brick and the preparation method thereof, strength of green bodies is improved, firing shrinkage of the green bodies is reduced, manufacturing yield of products is improved, bonding strength of crystal boundaries of zircon is enhanced, the high-temperature bend-creep rate of products is effectively lowered, and the service life of super-large-size overflowing bricks is prolonged.

Owner:ZIBO GT INDAL CERAMICS

Photosensitive conductive paste, method for producing multilayer electronic component using same, and multilayer electronic component

ActiveCN107003605ASuppress disconnectionImprove reliabilityPhotodevelopable thick filmNon-conductive material with dispersed conductive materialConductive pasteFrit

Provided is a photosensitive conductive paste which is capable of suppressing / preventing the occurrence of delamination between a conductor layer and an insulating layer even in cases where this photosensitive conductive paste is used for the formation of the conductor layer if a multilayer electronic component having a conductor layer and an internal conductor layer is produced by an integral firing process, and which enables fine patterning. This photosensitive conductive paste contains (a) a conductive powder in an amount of from 70.3% by mass to 85.6% by mass (inclusive) of the total mass of the paste, (b) a photosensitive resin composition containing an alkali-soluble polymer, a photosensitive monomer, a photopolymerization initiator and a solvent, and (c) a glass frit, and this photosensitive conductive paste is configured so as to satisfy such requirements that the mass ratio of the glass frit to the conductive paste, namely (glass frit / conductive paste) is from 0.020 to 0.054 (inclusive) and the softening point of the glass frit is not lower than the sintering initiation temperature of the conductive powder. As the glass frit, one having a softening point of 560 DEG C or more is used.

Owner:MURATA MFG CO LTD

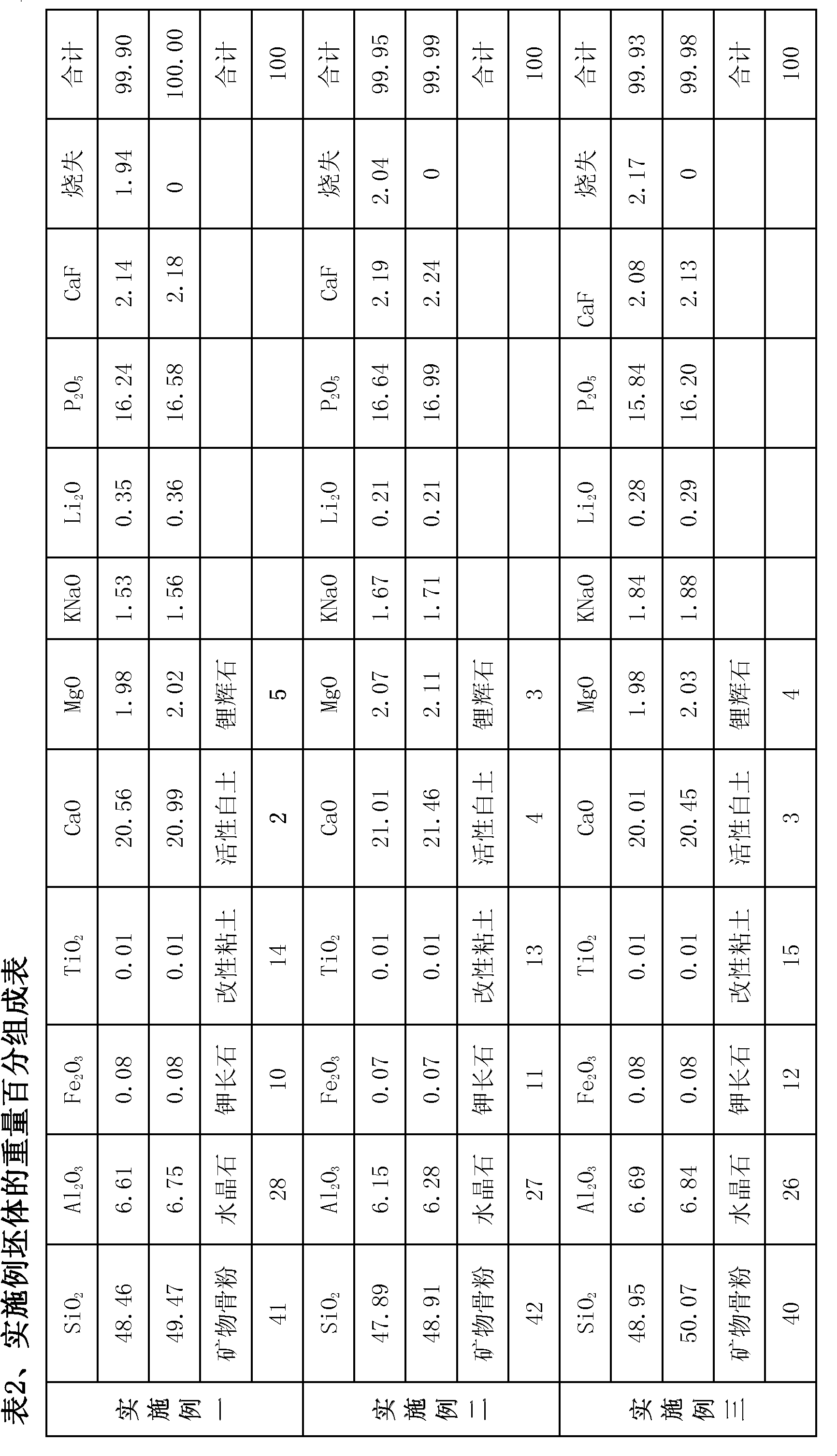

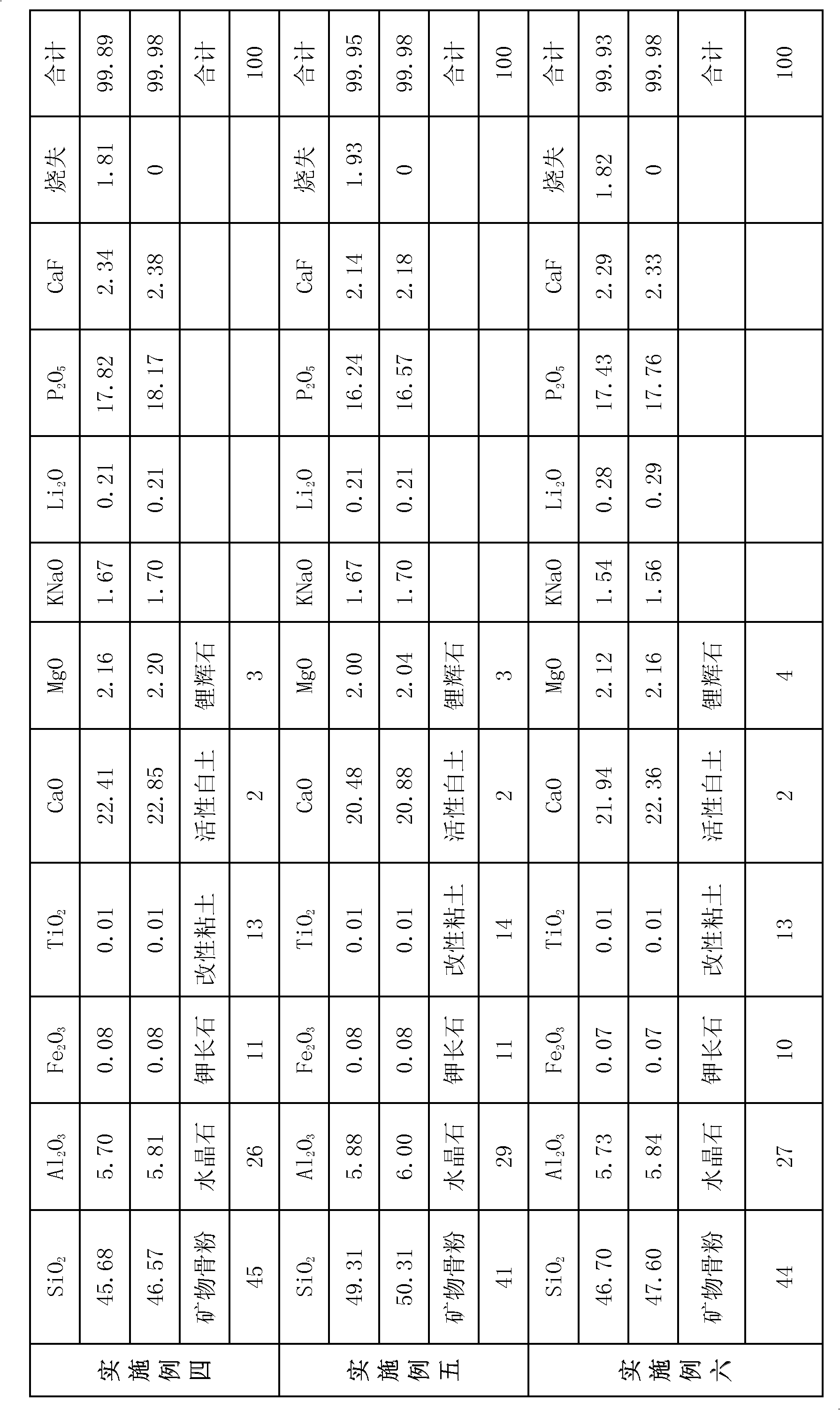

Mineral bone powder, crystal bone china and production method of the crystal bone china

ActiveCN102153340AThe chemical composition of the green body is stableGood formabilityApatitePotassium

The present invention relates to a mineral bone powder, crystal bone china and a production method of the crystal bone china. The mineral bone powder is synthesized by mineral apatite and dolomite. A crystal bone china green body consists of ingredients in weight percent as follows: 39-46% of mineral bone powder, 25-32% of crystal, 9-15% of potassium feldspar, 12-18% of synthetic clay, 1-5% of nano-activated clay, and 2-6% of spodumene. The production method of the crystal bone china includes the steps of ingredient mixing, molding, biscuiting, glazing and glaze firing; the crystal needs calcination acid treatment; and the product is formed by biscuiting and glaze firing. For the crystal bone china, by reasonable ingredient mixing, mineral bone powder and crystal are adopted as main materials for producing high-grade china, the firing temperature range is wide, the firing control is easy, and the crystal bone china integrates the characteristics of high white degree, good semi-transparency, high mechanical strength and good thermal stability; and the scientific and rational production method which is easy to implement effectively ensures the quality and the qualified rate of the product and is conducive to industrial production.

Owner:淄博泰山瓷业有限公司

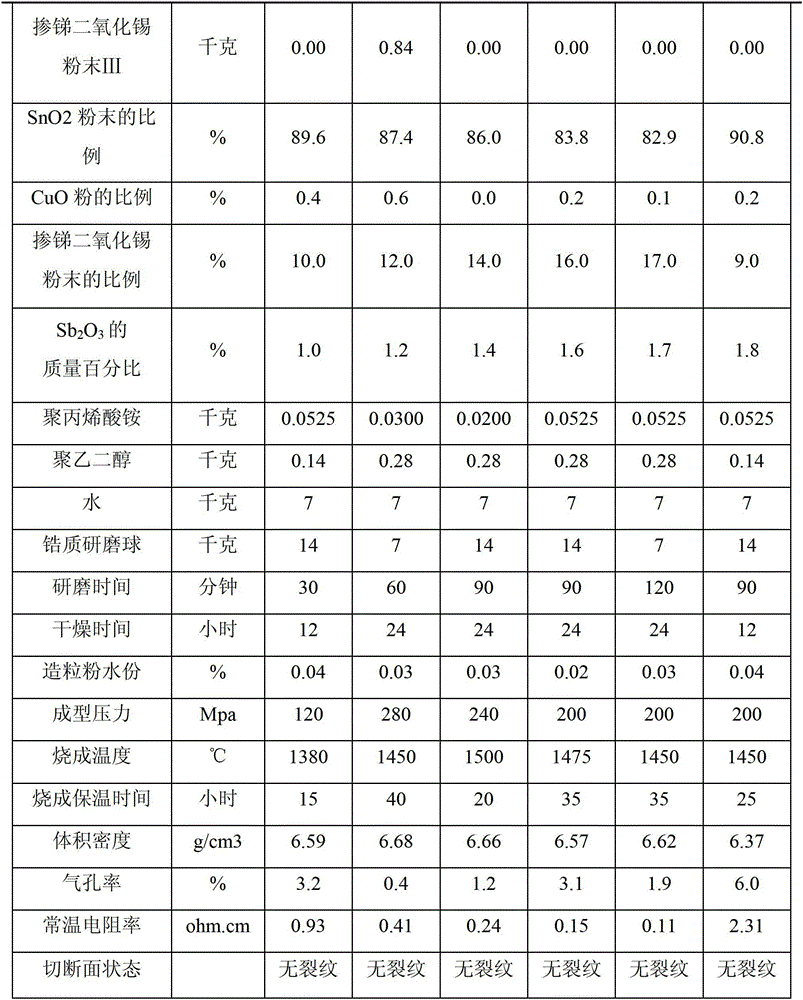

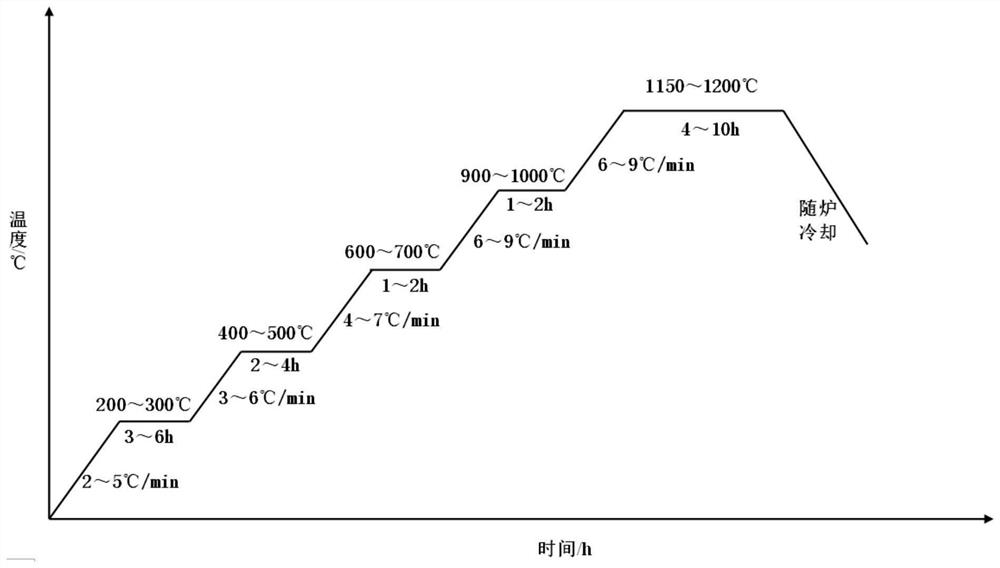

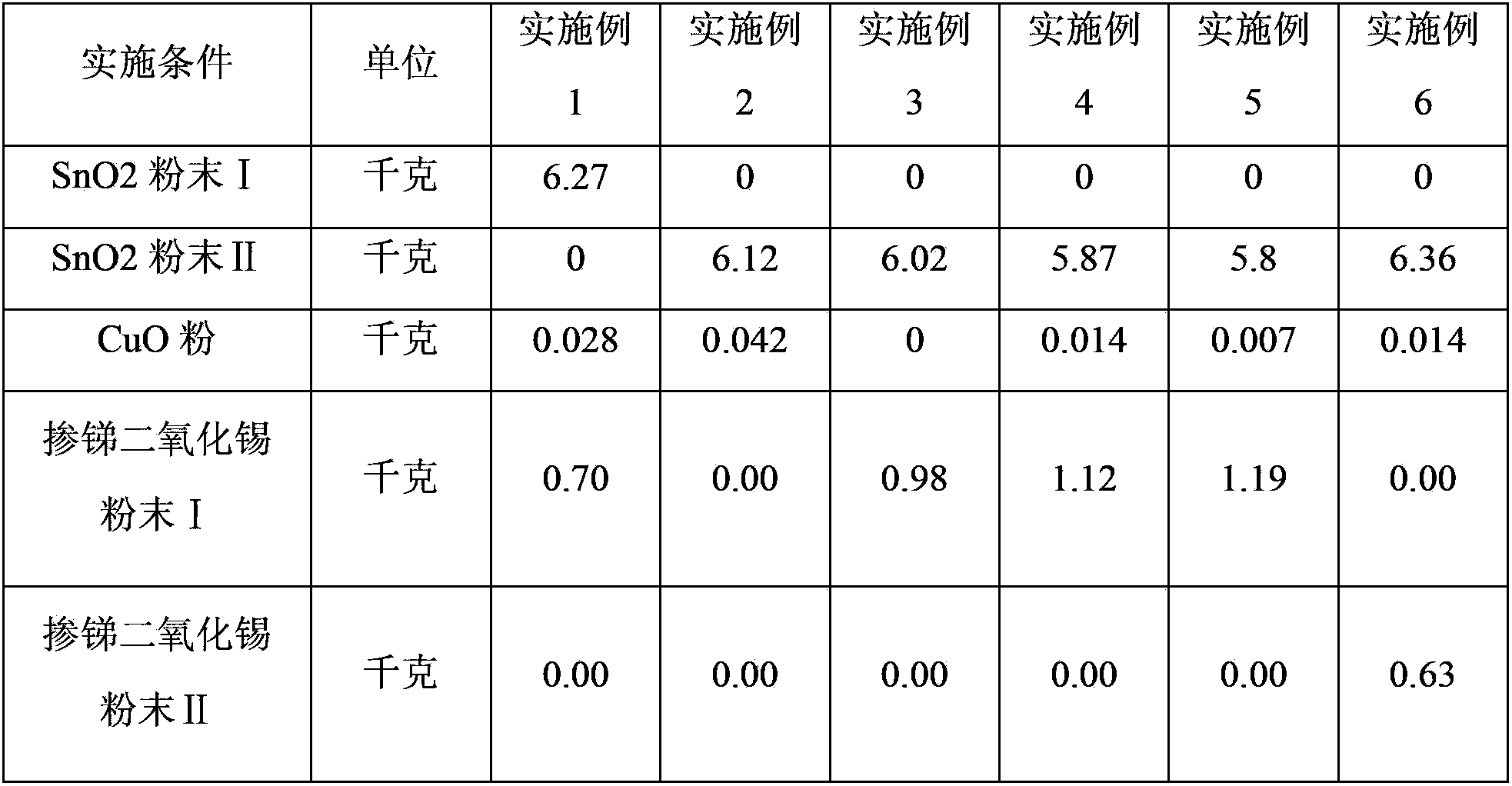

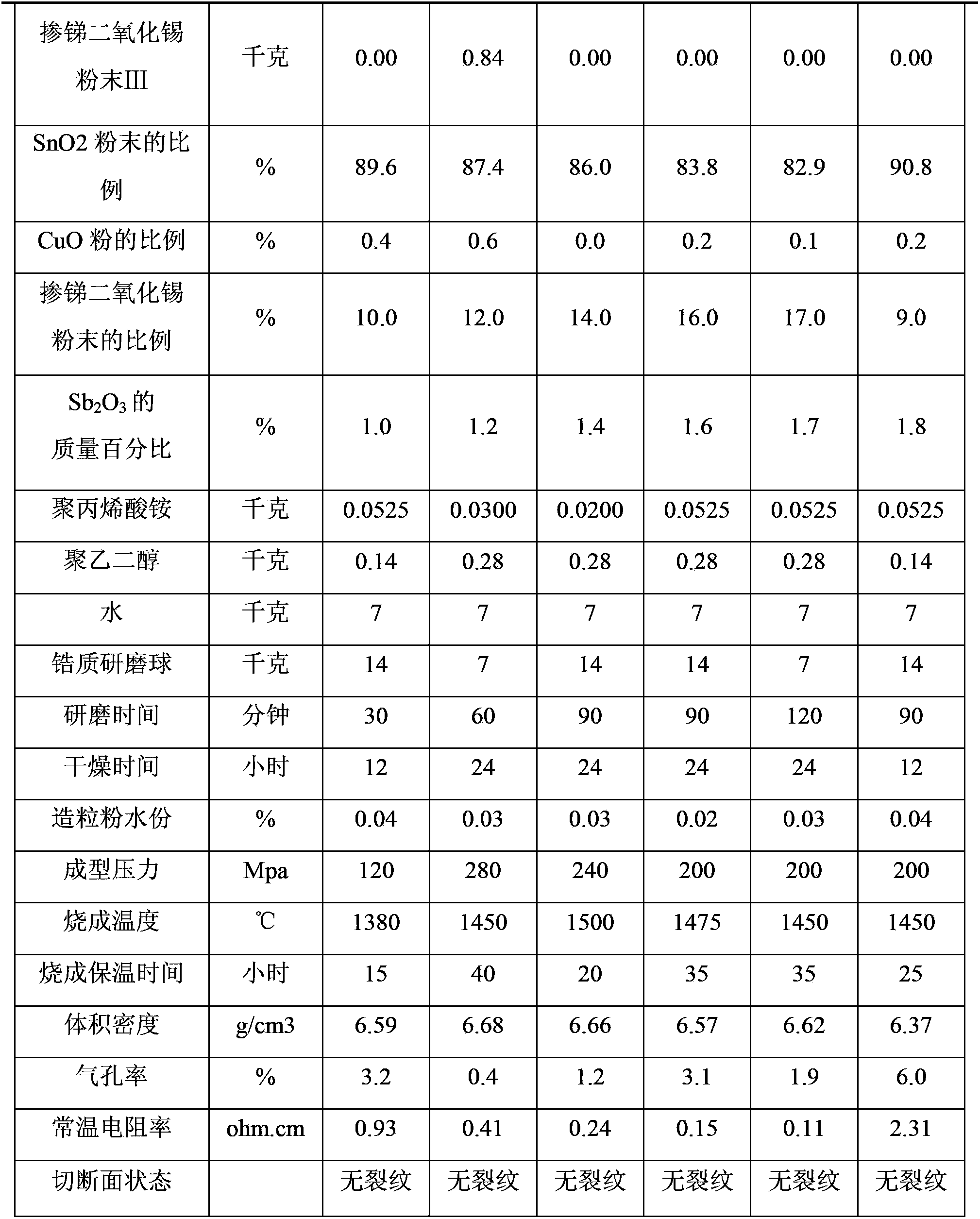

Preparation method of stannic oxide ceramic electrode

The invention discloses a preparation method of a stannic oxide ceramic electrode, belonging to the field of a ceramic technology. The method comprises the steps of: by taking nano antimony-doped stannic oxide powder and CuO powder as sintering aids, blending SnO2 powder with the sintering aids; then, adding a dispersing agent and a bonding agent into the mixture obtained from the former step; and carrying out wet grinding, drying, crushing granulation and isostatic compaction and then firing to prepare the stannic oxide ceramic electrode, wherein the mass percent of the SnO2 powder is 83-91% of the ingredients, the mass percent of the nano antimony-doped stannic oxide powder in the sintering aids is 9-17% of the ingredients, and the mass percent of the CuO powder is 0-0.6% of the ingredients. The preparation method is simple in technology and high in product pass rate, and the obtained stannic oxide ceramic electrode is high in density and low in resistivity at the room temperature and the high temperature.

Owner:ZIBO GT INDAL CERAMICS

Method for reducing firing shrinkage coefficient of alumina ceramic material and product made by the same

The invention discloses a method for reducing the firing shrinkage coefficient of an alumina ceramic material and product made by the same. The firing shrinkage coefficient of the alumina ceramic material can be reduced by adopting metal aluminum powder instead of aluminum oxide powder so as to reduce the firing deformation rate of the product; the accurate control on size of alumina ceramic product can be implemented, and the post-processing cost of the product can be reduced by controlling the firing shrinkage coefficient to be tiny; the method for reducing the firing shrinkage coefficient of the alumina ceramic material is suitable for industrialized production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Corundum-silicon carbide crystal whisker composite ceramic material taking natural minerals as raw materials and preparation method thereof

ActiveCN108276017ASolve the problem of not easy to mixImprove performanceComposite ceramicAluminum silicate

The invention discloses a corundum-silicon carbide crystal whisker composite ceramic material taking natural minerals as raw materials. The corundum-silicon carbide crystal whisker composite ceramic material is prepared from a basic material and a binding agent, wherein the basic material is prepared from the following components: 65 to 90 weight percent of aluminum silicate minerals and 10 to 35weight percent of metal aluminum powder and the dosage of the binding agent is 6 to 12 weight percent of the basic material. Furthermore, the invention discloses a preparation method of the corundum-silicon carbide crystal whisker composite ceramic material taking the natural minerals as the raw materials. A mixture of the natural minerals and the metal aluminum powder is used as a raw material system and corundum and silicon carbide crystal whiskers are introduced through an in-situ synthesis manner, so that the problem in the prior art that industrial powder and aggregate are not easy to mixuniformly is effectively solved and the performance of the corundum-silicon carbide composite ceramic material is improved to the greatest extent. The corundum-silicon carbide crystal whisker composite ceramic material disclosed by the invention has the advantages of easiness for obtaining the raw materials, simple technology, low firing temprature and high rate of finished products; the corundum-silicon carbide crystal whisker composite ceramic material has important meanings of improving the quality of the corundum-silicon carbide composite ceramic material and saving the product cost, andis good for progression and development of popularization and application and an industry technology.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for manufacturing large-size refractory bricks

InactiveCN105777153AFiring shrinkage is smallGuaranteed firing rateCeramicwareWater contentPelletizing

The invention belongs to the field of refractory materials, and provides a method for manufacturing large-size refractory bricks.The method for manufacturing the refractory bricks comprises the steps that spherical pelleting materials are adopted as a matrix, and fine particles with the grain size of 0.1 mm to 1 mm are adopted as aggregate; the spherical pelleting materials, water and a binding agent are manufactured into slurry in a stirrer, and the slurry is manufactured into spherical matrix pelleting materials with the water content of 0.2% to 0.5% through a centrifugal spraying pelletizer; the spherical matrix pelleting materials and the fine particles are subjected to dry blending in mixing equipment, and an even mixture is obtained; the mixture is directly contained in a mold and subjected to pressure forming in an isostatic pressing machine at the pressure of 90 MPa to 180 MPa, and blanks with enough strength are obtained; the formed blanks are dried for 24 h at the temperature of 120 DEG C, then heat preservation is carried out for 6 h to 10 h at the temperature of 1,500 DEG C to 1,650 DEG C, and the large-size refractory bricks can be obtained.The manufactured large-size refractory bricks have the advantages of being even in structure, high in density and strength and good in corrosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Environmentally-friendly and low-shrinkage ceramic and preparation method thereof

ActiveCN110698176AEfficient use ofFiring shrinkage is smallCeramic materials productionClaywaresCarbide siliconFoaming agent

The invention provides environmentally-friendly and low-shrinkage ceramic and a preparation method thereof. A ceramic green body comprises the following raw materials: a basic raw material and siliconcarbide, wherein the silicon carbide is 0.005 to 0.01 percent of the mass of the basic raw material. A small amount of silicon carbide foaming agent is added, so the firing shrinkage of the green body is reduced under the condition of not influencing the strength of the green body.

Owner:MONALISA GRP CO LTD

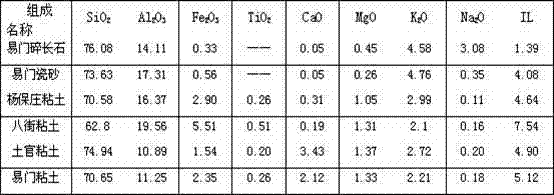

Ceramic railing with high weatherability, and preparation method thereof

ActiveCN102515701AReduce the maximum thermal expansion coefficientAvoid crackingFencingBridge structural detailsWeather resistanceGlaze

The invention provides a ceramic railing with high weatherability, and a preparation method thereof. Because of self-factors, when a ceramic railing is used, glaze-surface falling and cracks on parts of the structures can easily occur; under weather conditions with large temperature differences, glaze-surface bursting might occur, and normal application is severely influenced; during a firing procedures, because of uneven air flow, slow heat transfer and low heat exchange efficiency in a kiln, regular and controllable temperature gradient can hardly be formed longitudinally in a firing zone in the kiln, such that the firing period is prolonged. With the method provided by the invention, the technical problem is solved. According to the invention, a raw material formula is modified, and a local clay resource in Yunnan Province is adopted as a raw material. The formulas for a ceramic railing blank and a glaze are further optimized, and a firing process procedure is also modified, such that the weatherability of a finished product is improved. Indexes of performances such as water absorption rate, freezing resistance, quick-chilling resistance, quick-heating resistance and appearancequality of the ceramic railing product satisfy a construction colored glaze product standard JC / T765-2006.

Owner:YIMEN DIANYUAN CERAMIC

A kind of high porosity and high permeability nb2o5 ceramic membrane and preparation method thereof

InactiveCN104529448BHigh porosityImprove permeabilitySemi-permeable membranesPorositySeparation technology

The invention discloses a high-porosity high-permeability Nb2O5 ceramic membrane which is represented by the following general formula: Nb(2-2x-2y)Ta2xTiyO(5-delta), wherein x and y represents mole fractions, 0.1<=x<=0.3, and 0.02<=y<=0.07. Besides, the invention also discloses a preparation method of the high-porosity high-permeability Nb2O5 ceramic membrane. The Nb2O5 ceramic membrane disclosed by the invention simultaneously has high porosity, narrow pore size distribution range, high permeability, high mechanical strength and other performance, and effectively solves the problems that existing ceramic membranes made of aluminum oxide, cordierite, mullite and the like have performance defects, catalyst incompatibility and low catalytic conversion efficiency exist in waste water and waste gas purification treatment and so on, thus bringing major technical breakthrough to the ceramic membrane field, and being beneficial to promote application and development of fine filtration and separation technology in the fields of water treatment, food, medicine, chemical engineering and the like.

Owner:JINGDEZHEN CERAMIC UNIV

Fireproof inorganic quartz stone and preparation method thereof

The invention discloses fireproof inorganic quartz stone and a preparation method thereof. According to the preparation method, the raw materials are lightly sintered and sintered, so that a part of physical and chemical reactions of the raw materials can be completed, cremation of ore is realized, lattice defects are increased, sintering is promoted effectively, therefore, the preparation efficiency can be effectively improved; a double-sided hot-pressing mode is adopted for extrusion molding to obtain a green body, so that the green body is compact in structure, high in strength and small indrying and firing shrinkage, the size is easy to control, the layer density phenomenon of the green body can be effectively reduced, the total porosity of the green body is reduced, the fireproof performance can be effectively improved, and the using efficiency is increased; a plurality of times of extrusion is adopted, and extrusion time is prolonged, so that gas in the green body can be effectively and smoothly exhausted, the elasticity of the green body can be effectively improved, the strength of the green body can be effectively improved, the green body can be effectively prevented fromcracking, and the preparation efficiency of the green body can be effectively improved.

Owner:山东康洁利新材料有限公司

A micropore composite fired brick tackified and modified with acrylic acid

InactiveCN106242632AHarm reductionImprove plasticityCeramic materials productionCeramicwareThermal insulationSludge

A micropore composite fired brick tackified and modified with acrylic acid is disclosed. The micropore composite fired brick is prepared from, by weight, 40-43 parts of municipal sludge, 8-9 parts of mesoporous silica, 22-25 parts of shale, 38-40 parts of gangue, 14-15 parts of rice hull, a proper amount of water, 6-7 parts of nepheline tailings, 7-9 parts of bamboo charcoal, 3-4 parts of acrylic acid, 2-3 parts of borax and 5-6 parts of hilly loess. The nepheline tailings and the hilly loess are compounded with the acrylic acid through a series of processes, thus playing a role of a filling material and increasing viscosity of mixed mud materials. Through mixing with other raw materials, the water content of a brick blank is increased obviously and the ratio of briquetting of brick blanks is increased. The fired brick is compact in appearance, comprises micropores inside, and is good in thermal insulation effects, good in toughness, high in strength and not liable to break. The raw materials are simple and easily available. A process is convenient in industrial control and suitable for large-scale production.

Owner:安庆太极新型建材开发有限公司

Silicon oxide-based ceramic core for large-size directional hollow blade of heavy-duty gas turbine and preparation of silicon oxide-based ceramic core

PendingCN114249588APrevent viscous flowFiring shrinkage is smallFoundry mouldsFoundry coresMolding machinePlasticizer

The invention relates to a silicon oxide-based ceramic core for a large-size directional hollow blade of a heavy gas turbine and a preparation method of the silicon oxide-based ceramic core. The silicon oxide-based ceramic core adopts quartz glass powder as a base material, and adopts zircon powder, alumina powder and calcium oxide powder as mineralizing agents. The powder comprises the following components in percentage by weight: 60-95% of quartz glass powder, 1-30% of zircon powder, 0.5-5% of alumina powder and 0.1-5% of calcium carbonate powder. Paraffin, beeswax, polyethylene and polyethylene glycol are used as plasticizers for hot-press injection molding. The preparation method comprises the following steps: ball-milling and uniformly mixing the powder materials, putting the powder materials into a molten plasticizer for mixing, and carrying out hot-press injection molding on a ceramic core molding machine. A quartz glass rod / tube is pre-arranged in the position, corresponding to the thick and large section of the mold core, in the mold core mold before pressure injection, and the ceramic mold core formed through hot pressure injection molding is put into a box-type resistance furnace to be roasted after being trimmed and corrected. The silicon oxide-based ceramic core prepared by the invention has the characteristics of high high-temperature strength, good creep resistance, small firing shrinkage, stable size and high core removal efficiency.

Owner:SHENYANG RES INST OF FOUNDRY

Core making technology for investment casting

InactiveCN107127302AImprove deformation resistanceFiring shrinkage is smallFoundry mouldsFoundry coresWaxManufacturing technology

The invention discloses a core manufacturing process for investment casting, which includes the following steps: (1) Slurry preparation: put zircon powder and quartz glass in a ball mill for 2-4 hours, take them out and dry them, Make the moisture content lower than 0.2% by mass, and then add a stirrer to stir to obtain a slurry; (2) Forming: forming by hot pressing; (3) Bowl filling: bury the pressed ceramic core body in a container In the bowl of the filler, prevent the core from being deformed and damaged during the firing process; (4) filling filler: use industrial alumina baked at 1300°C for 4‑6h as filler; (5) shape: at an amplitude of 0.2‑0.5mm (6) Roasting: It is divided into two stages: wax removal and sintering. The core produced by this process can obviously improve the anti-deformation ability of the core, and reduce the shrinkage of the core during firing, and obtain High performance and high quality core.

Owner:东风精密铸造安徽有限公司

Inorganic fireproof building decoration material and process thereof

InactiveCN112647607AHigh strengthGood insulation performanceCovering/liningsClimate change adaptationBrickFoaming agent

The invention relates to the technical field of building decoration materials, and discloses an inorganic fireproof building decoration material which comprises a core layer, a filling layer and an inorganic fireproof layer. According to the inorganic fireproof building decoration material and the process thereof, the filling layer and the foamed concrete layer are formed by mixing the foaming agent, the cement, the fly ash, the stone powder and the water, so that the novel building energy-saving material which is light in weight, high in strength, non-absorbent and non-combustible is prepared by recycling waste. The building decoration material can be used for roof heat preservation and heat insulation, floor heating, ground cushion layer, inner partition wall and outer wall heat preservation and the like, so that the application range of the building decoration material is widened, finally, quartzite, waste silicon bricks, a mineralizing agent, a binding agent and an additive are mixed to form an inorganic fireproof layer, and waste recycling is adopted as well. The production cost of the building decoration material is further reduced, meanwhile, the blank firing shrinkage is reduced, the firing rejection rate of the building decoration material is reduced, and the effects of energy conservation, environmental protection and waste recycling are achieved.

Owner:陕西威斯特高新技术投资有限公司

Alumina-based ceramic core for directional solidification and preparation method thereof

The invention relates to an alumina-based ceramic core for directional solidification and a preparation method thereof. The refractory materials used in the alumina-based ceramic core include EC95 fused mullite, zirconium silicate, silica powder, titanium dioxide powder, aluminum pink. The powder contains 65-95% EC95 fused mullite, 5-30% zirconium silicate, 2-8% silicon dioxide powder, 1-5% titanium dioxide powder and 1-10% aluminum powder in percentage by weight. Among them, in EC95 fused mullite, F200 powder accounts for 10-30%, F320 powder accounts for 40-70%, and F600 powder accounts for 10-30%. The preparation method is as follows: ball milling and mixing the above-mentioned powder materials evenly, putting them into molten plasticizer for mixing, and hot-pressing injection molding on a ceramic core molding machine. The hot-press injection molded ceramic core is put into a box-type resistance furnace for firing after trimming and calibration. After being released from the furnace, the ceramic core is strengthened at high temperature and at room temperature with high temperature strengthening agent and room temperature strengthening agent. The alumina-based ceramic core prepared by the invention has the characteristics of high high-temperature strength, good creep resistance, small firing shrinkage, low firing temperature and good metallurgical and chemical properties.

Owner:SHENYANG RES INST OF FOUNDRY

A kind of rare earth garnet scintillation crystal and its production method

ActiveCN111704154BEasy to achieve dopingImprove high temperature creep resistancePolycrystalline material growthRare earth metal compounds preparation/treatmentRare-earth elementThermal dilatation

The invention provides a rare earth garnet scintillation crystal and a production method thereof. The rare earth garnet scintillation crystal has the following chemical formula: A 3 sc 2 B 3 o 12 ; Wherein, A is a kind of in rare earth elements such as Y, Cd, Lu, and B is a kind of in Al, Ga or In, and the effective segregation coefficient of A in this rare earth garnet scintillation crystal is 0.3-0.32, and Sc The effective segregation coefficient is 0.33, and the effective segregation coefficient of B is 0.36‑0.4. The molecular formula obtained in the present invention is A 3 sc 2 B 3 o 12 The rare earth garnet scintillation crystal has excellent characteristics such as high density, high effective atomic coefficient, high melting point, high thermal conductivity, high hardness, low thermal expansion coefficient, high transparency, good chemical stability, and high mechanical strength.

Owner:安徽晶宸科技有限公司

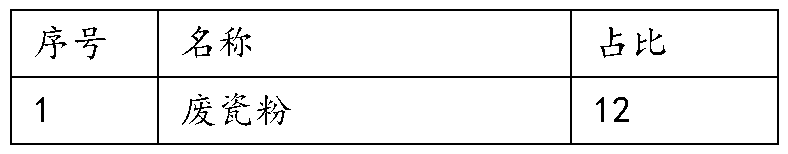

Ceramic floor drain and preparation method thereof

PendingCN109776066ALow costPromote environmental protectionSewerage structuresCeramic materials productionPotassium feldsparDolomite

The invention discloses a ceramic floor drain and a preparation method thereof. The ceramic floor drain is prepared from, by mass, 8.0-12.0% of waste porcelain powder, 9.0-11.0% of potassium feldspar,7.0-9.0% of quartz, 1.5-2.5% of alumina, 2.6-3.2% of dolomite, 0.1-1.0% of a surfactant, 10.0-12.0% of paraffin and the balance kaolin. The ceramic floor drain has the advantages of low cost, high strength, high precision, great deformation resistance and the like.

Owner:JOMOO KITCHEN & BATHROOM

Microporous sintered bricks with interface bonding improved by redispersable rubber powder

InactiveCN106220226AHarm reductionImprove plasticityCeramic materials productionCeramicwareBrickPolyvinyl alcohol

The invention discloses microporous sintered bricks sintered bricks with interface bonding improved by redispersable rubber powder. The microporous sintered bricks are made from, by weight, 40-43 parts of urban sludge, 8-9 parts of mesoporous silica, 22-25 parts of shales, 38-40 parts of coal gangue, 14-15 parts of rice husk, a proper amount of water, 2.5-3 part of potassium feldspar, 2-3 parts of paraffin, 0.8-1 part of polyvinyl alcohol, 2-3 parts of redispersable rubber powder and 11-13 parts of household garbage. The household garbage is added to green brick pug through a series of process modification, the microporous sintered bricks sintered bricks have stronger hydrophily by cooperating with the polyvinyl alcohol and the redispersable rubber powder, water molecules can be absorbed through compounding to form a layer of solvated water film having a certain mechanical strength, so that other raw materials on the surface of the household garbage can be fully hydrated, microcracks are filled through mutual fusion, strong mechanical anchorage is also formed between household garbage and other substrates, accordingly the interface bonding strength is improved, and further the strength of green bricks is improved.

Owner:安庆太极新型建材开发有限公司

Method for reducing firing shrinkage of strontium ferrite magnetic material, and product prepared by method

The invention discloses a method for reducing firing shrinkage of a strontium ferrite magnetic material, and a product prepared by the method. According to the method, partial ferric oxide powder can be replaced by hydroxy iron powder or reduced iron powder to change the formula composition, such that the firing shrinkage of the ferrite magnetic material is controlled so as to reduce the firing deformation rate of the product. According to the present invention, the deformation amount of the prepared product is small, the post-processing amount is small or the post-processing is not required,the product qualification rate is high, the production cost is reduced, and the method is suitable for the industrial mass production.

Owner:JINGDEZHEN CERAMIC UNIV

Preparation method of stannic oxide ceramic electrode

ActiveCN102875142BImprove corrosion resistanceFiring shrinkage is smallElectrodesTin dioxideOxide ceramic

The invention discloses a preparation method of a stannic oxide ceramic electrode, belonging to the field of a ceramic technology. The method comprises the steps of: by taking nano antimony-doped stannic oxide powder and CuO powder as sintering aids, blending SnO2 powder with the sintering aids; then, adding a dispersing agent and a bonding agent into the mixture obtained from the former step; and carrying out wet grinding, drying, crushing granulation and isostatic compaction and then firing to prepare the stannic oxide ceramic electrode, wherein the mass percent of the SnO2 powder is 83-91% of the ingredients, the mass percent of the nano antimony-doped stannic oxide powder in the sintering aids is 9-17% of the ingredients, and the mass percent of the CuO powder is 0-0.6% of the ingredients. The preparation method is simple in technology and high in product pass rate, and the obtained stannic oxide ceramic electrode is high in density and low in resistivity at the room temperature and the high temperature.

Owner:ZIBO GT INDAL CERAMICS

A kind of preparation technology of high refractory fused silica

A preparation process of high-refractory fused silica, comprising the following steps: (1) preparation of high-purity fused silica; (2) ingredients: the high-refractory fused silica, in parts by mass, mainly comprises the following components: 50-60 parts of high-purity fused silica powder, 40-50 parts of binder, 20-30 parts of cordierite, and 10-15 parts of sillimanite; batching is carried out according to the mass parts of each component in the formula; ( 3) Pretreatment: crushing, sieving and classifying high-purity fused silica powder, and wet ball milling, granulating, sieving, granulating and stale for binder, cordierite and sillimanite respectively; (4) mixing (5) molding; (6) drying; (7) firing. The preparation process of the high refractory fused silica of the present invention has the advantages of simple and efficient preparation process, reasonable formula design, high refractoriness and excellent thermal shock resistance, good chemical stability, small expansion coefficient, and thermal shock resistance. Low conductivity and broad application prospects.

Owner:徐州赛诺石英有限公司

Zirconium oxide base complex phase ceramic and preparation process thereof

The invention discloses a zirconia based complex phase ceramic and the manufacture method that belongs to zirconia based structure ceramic field. It contains 2-3mol% Y2O3, 50-65%mol% Y-TZP and 35-50mol% alpha-Al2O3, and sintering assistant agent MgO 0.6-1.0wt% and SiO2 0.6-2.5wt%. The process includes the following steps: mixing zirconia powder that contains Y2O3 with alpha-Al2O3, MgO powder, and SiO2, adding 55-70wt% water, and 1-2wt% ammonium polyacrylate dispersant, taking ball milling, spraying and graining, molding from powder under 150-200MPa, sintering in 1450-1480 degree centigrade to gain the material. The advantages of the invention are that it has simple process, low cost, and has high percent of qualification.

Owner:TIANJIN UNIV

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340BReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingBrick

The invention discloses a building ceramics prepared by using industrial solid waste slag dry method and its technology, which comprises 30-60% of solid waste slag, 40-70% of ceramic raw materials and 1-3% of ceramic additives in terms of mass percentage. Wherein, the ceramic raw material is selected from one or more compositions of clay raw materials, feldspar raw materials or talc, and the ceramic additives are sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate , Sodium humate, Sodium lignosulfonate, Disodium EDTA, EDTA, or a combination of several. The solid waste slag has finer particles after pretreatment. It is mixed with the spray-dried ingredients by dry mixing method and then directly used for brick pressing or put into the silo for standby, which reduces the energy consumption of ball milling and degumming costs, and saves the need for humidification. Granules and fluidized bed drying, and the formula can be quickly adjusted according to the functional characteristics of the product. The process control is simple, and the product has good properties such as thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

A kind of environment-friendly, low-shrinkage ceramics and preparation method thereof

ActiveCN110698176BEfficient use ofFiring shrinkage is smallCeramic materials productionClaywaresCarbide siliconFoaming agent

The invention provides an environment-friendly, low-shrinkage ceramic and a preparation method thereof. The raw materials of the ceramic body include basic raw materials and silicon carbide, and the silicon carbide is 0.005% to 0.01% of the mass of the basic raw materials. The present invention reduces the firing shrinkage of the green body without affecting the strength of the green body by adding a small amount of silicon carbide foaming agent.

Owner:MONALISA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com