Preparation method of stannic oxide ceramic electrode

A technology of tin dioxide and ceramic electrodes, applied in the direction of electrodes, electrolytic process, electrolytic components, etc., to achieve the effects of low resistivity at room temperature, improved corrosion resistance, and reduced firing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

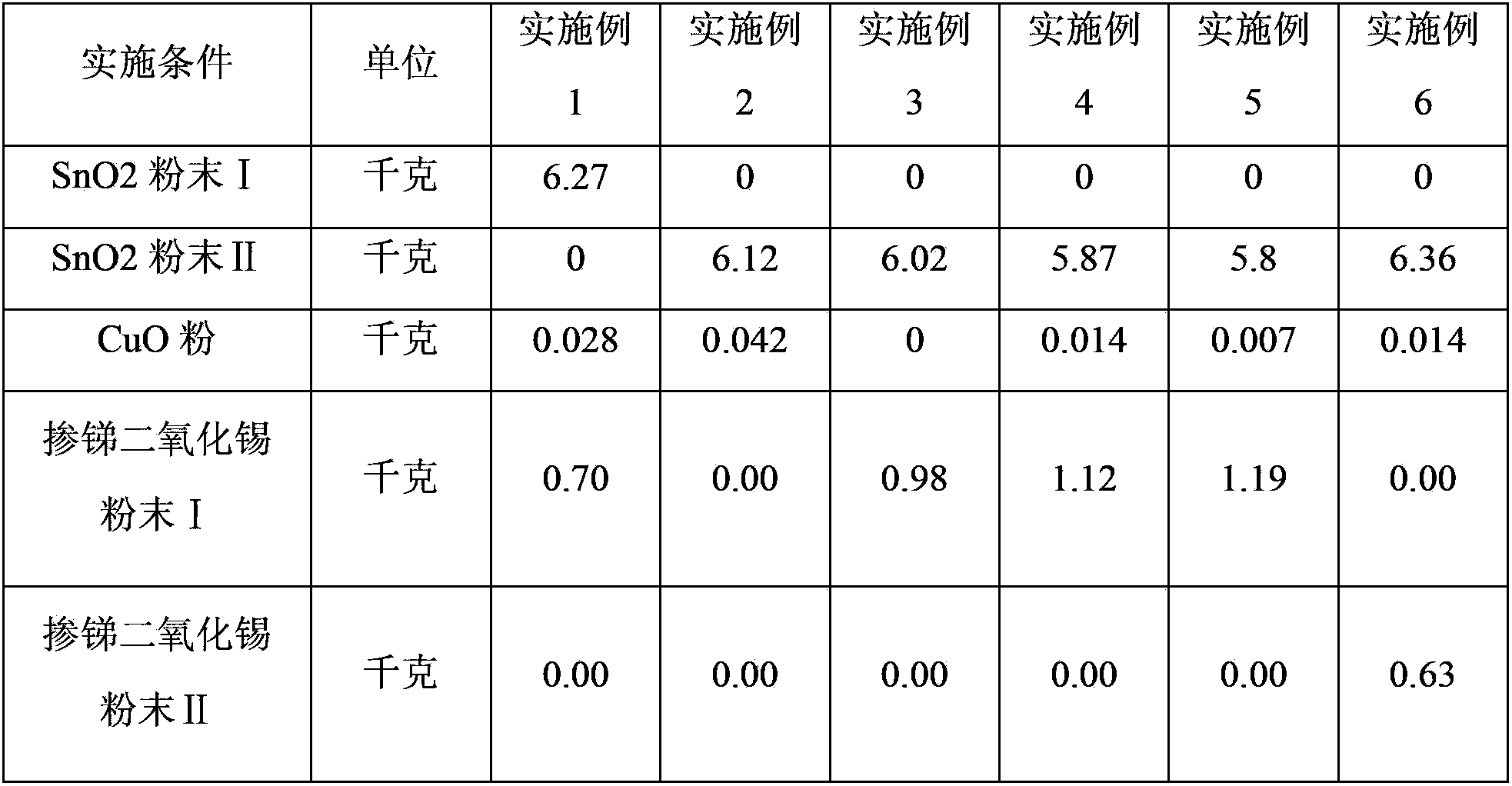

[0032] Ingredients: SnO 2 Powder, nano antimony-doped tin dioxide powder, CuO powder, chemical composition and particle size of binder and dispersant are shown in Table 1 below. Wherein the binder is an aqueous solution of polyvinyl alcohol with a concentration of 6%, and the dispersant is an aqueous solution of ammonium polyacrylate with a concentration of 30%.

[0033] Preparation steps:

[0034] Weigh SnO with particle size ≤ 20um in proportion 2 Powder, particle size ≤ 20nm, containing Sb 2 o 3 It is 10% nano-antimony-doped tin dioxide powder and CuO powder with a particle size of ≤5um, which is loaded into a polyurethane-lined ball mill. Then according to the ingredients: binder: dispersant is 1:0.02:0.0075, put it into the ball mill, add water according to the mass ratio of zirconia balls: ingredients: water is 2:1:1, put in zirconia balls, and grind for 30 minutes .

[0035] Pour the uniformly mixed slurry into a container, dry at 110°C for 12 hours, and crush it ...

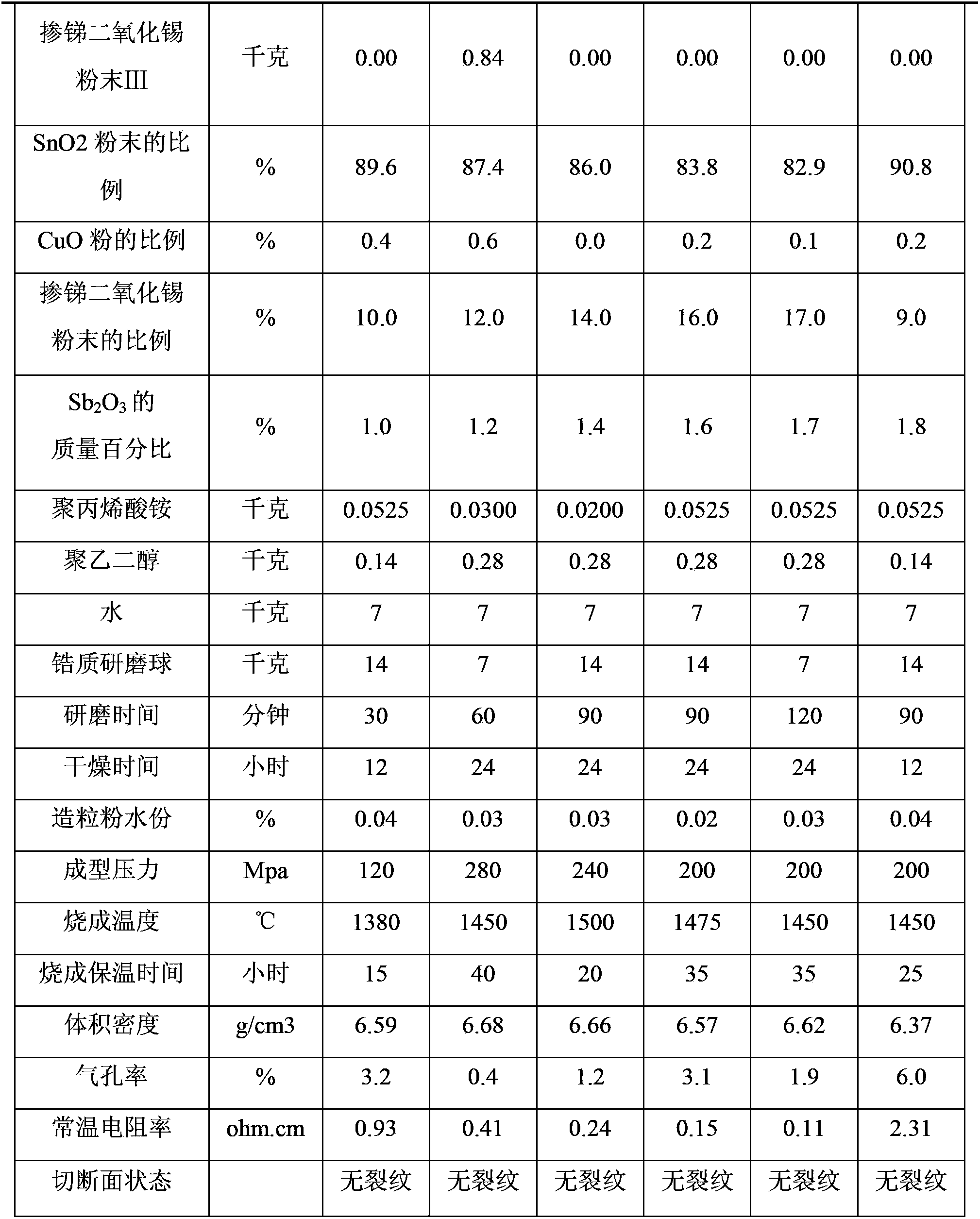

Embodiment 2-6

[0040] Examples 2-6 adopt the same operation steps as in Example 1, changing the types of raw materials, proportion of ingredients, isostatic pressure and sintering temperature and other conditions. The specific examples and test data are shown in Table 2.

[0041] Table 1. Types and specifications of raw materials

[0042] raw material name

Raw material specification

Maximum particle size

SnO 2 Powder Ⅰ

SnO 2

20um

SnO 2 Powder II

SnO 2

10um

CuO powder

CuO≥99.0%

5um

Nano antimony doped tin dioxide powder Ⅰ

SnO 2 : Sb 2 o 3 =90:10

20nm

Nano antimony doped tin dioxide powder Ⅱ

SnO 2 : Sb 2 o 3 =80:20

30nm

Nano antimony doped tin dioxide powder Ⅲ

SnO 2 : Sb 2 o 3 =90:10

40nm

ammonium polyacrylate

30% aqueous solution

/

Grade 1799, 6% aqueous solution

/

[0043] Table two, embodiment and dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com