Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Increase lattice defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic method for high-activity N-F co-doped bismuth vanadate visible light photocatalytic material

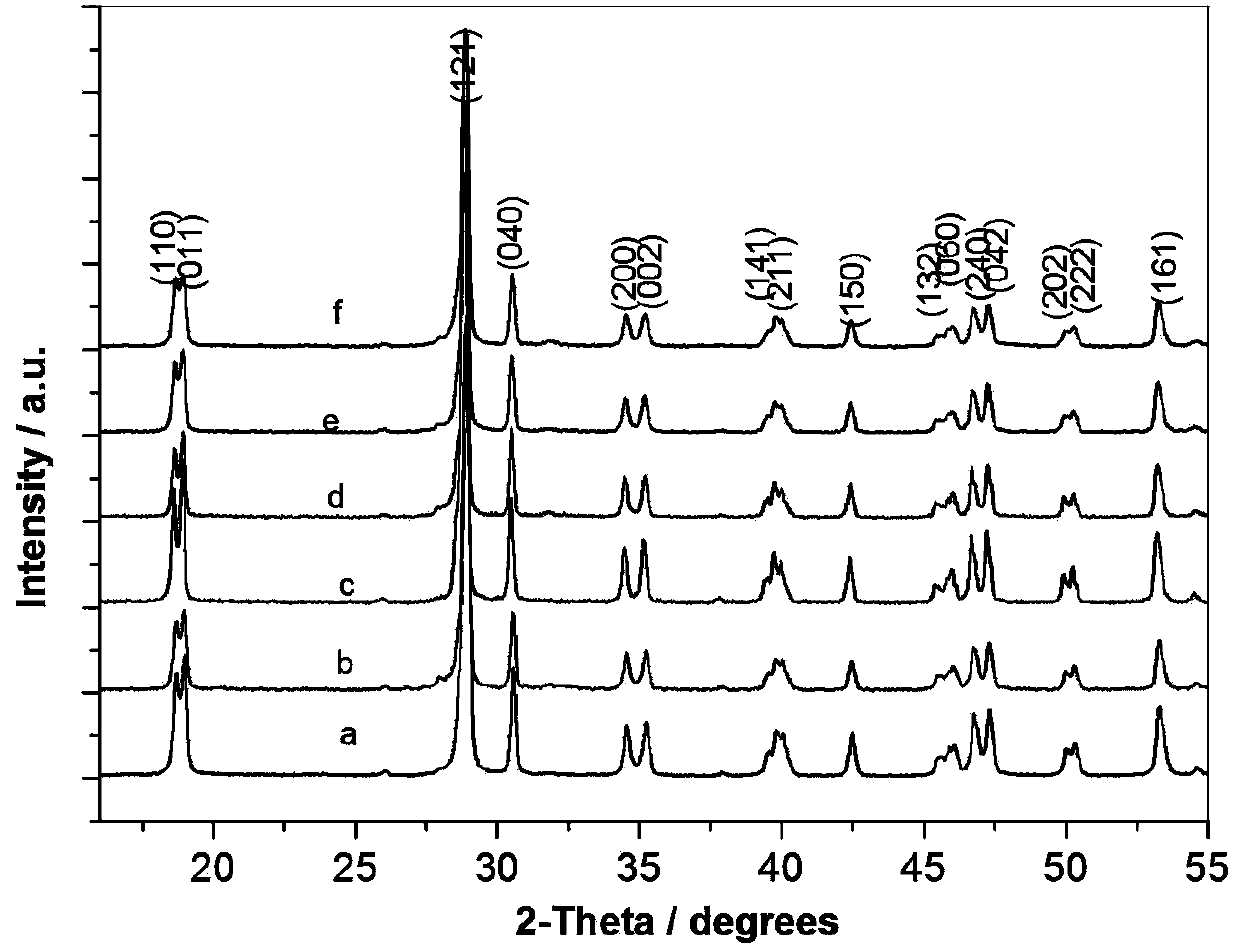

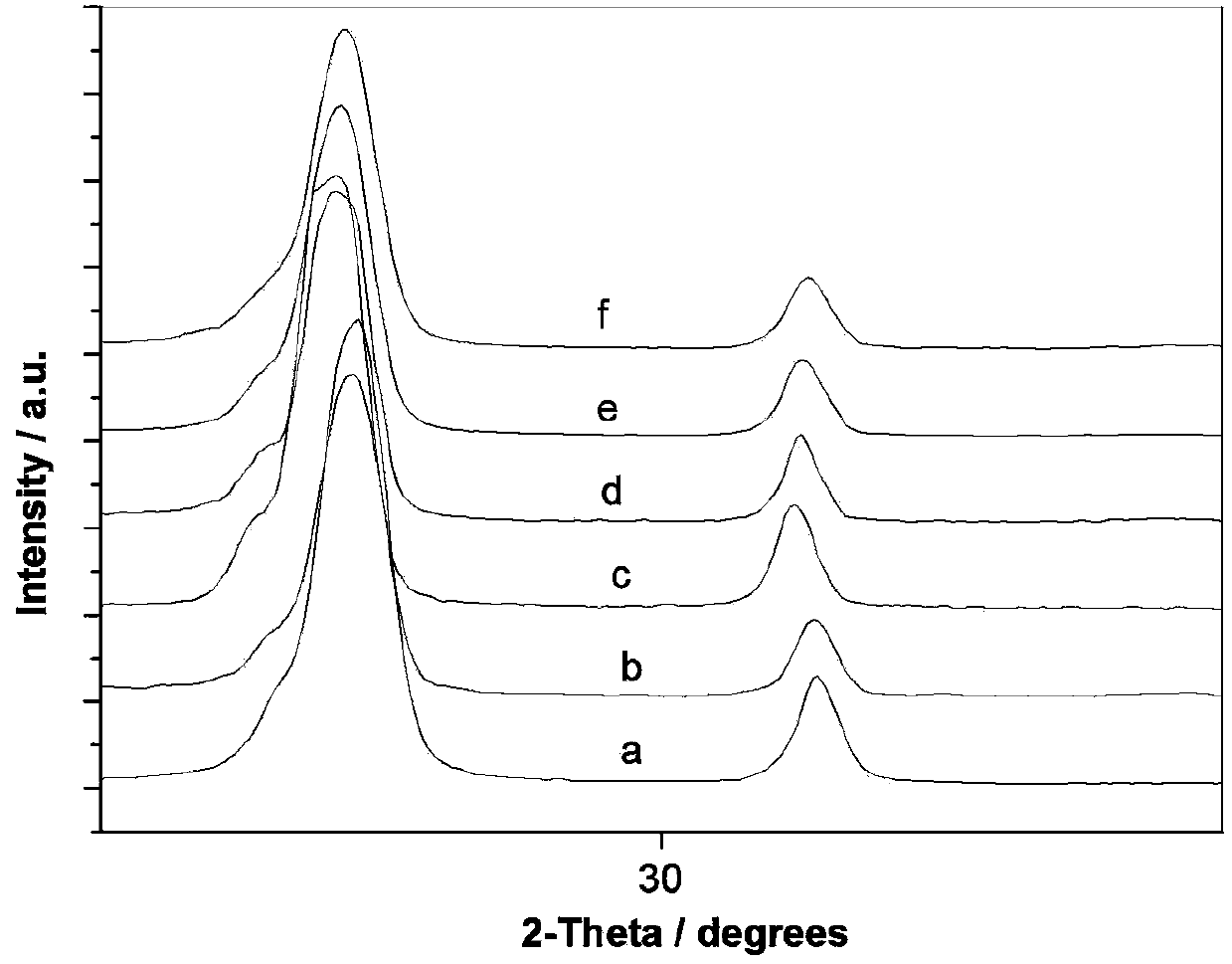

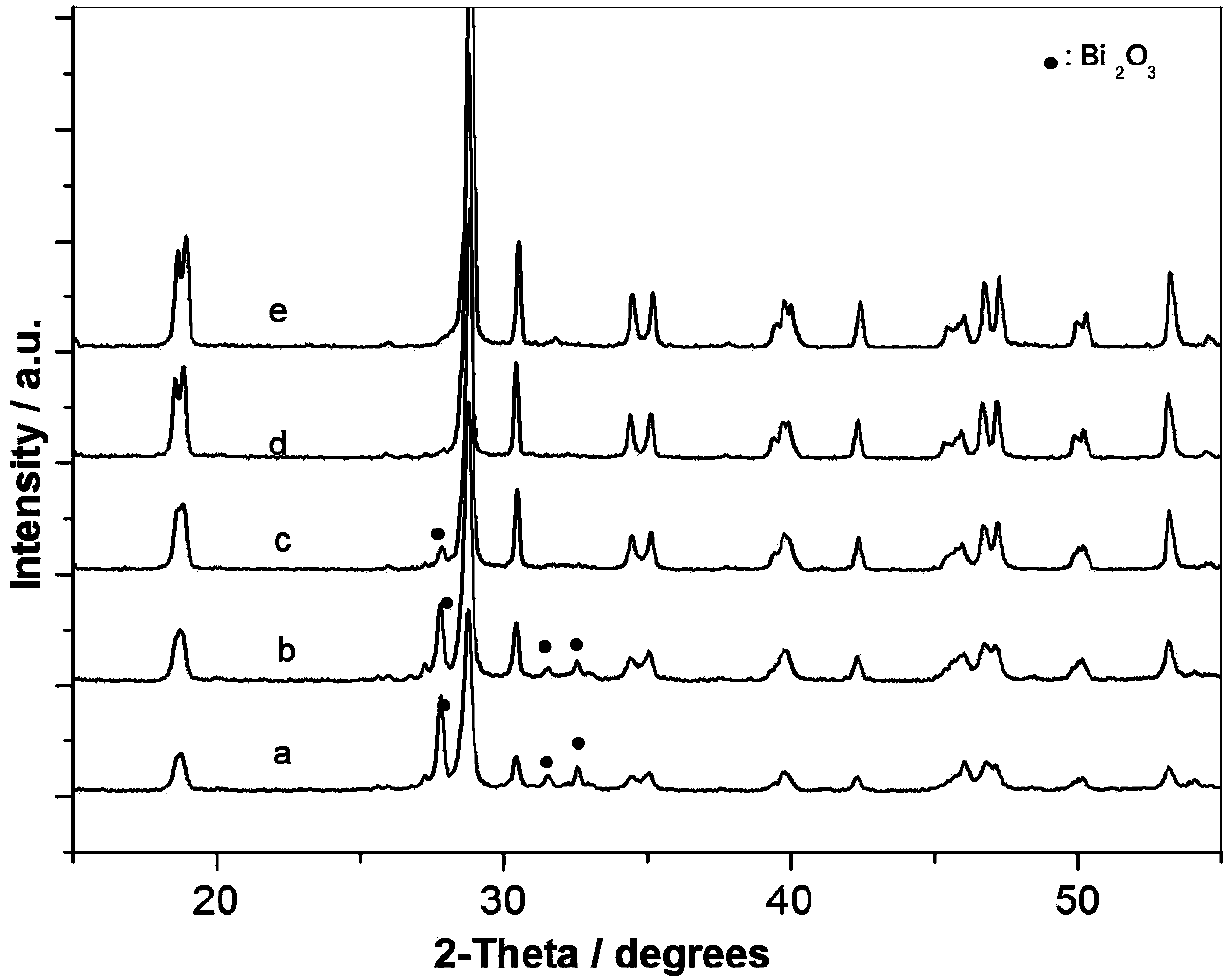

InactiveCN103372424ANot easy to reuniteGood dispersionWater/sewage treatment by irradiationEnergy based wastewater treatmentBismuth vanadateOxygen vacancy

The invention discloses a synthetic method for high-activity N-F co-doped bismuth vanadate visible light photocatalytic material prepared through the citric acid complexation sol-gel method and a preparation process. The method employs Bi(NO3)3.5H2O(97%) and NH4VO3(98.5%) as source materials, citric acid(99.5%) as a chelating agent, NH4F as N and F sources, and utilizes ammonium hydroxide to regulate the pH value, and dark blue sol is prepared, dried, calcined to obtain the N-F co-doped bismuth vanadate photocatalytic material. When the material is compared to bismuth vanadate without being doped, because of the synergistic effects of N and F, oxygen vacancies and V4+ with catalytic activity are increased N-F co-doped bismuth vanadate crystals, the band-gap energy is narrower and the photocatalytic activity is raised obviously in visible light. The method is advantaged by simple process, mild conditions and good repeatability. The photocatalytic material can be widely used in photocatalytic degradation of organic pollutants, and has wide application prospects in environmental governance.

Owner:SHENYANG LIGONG UNIV

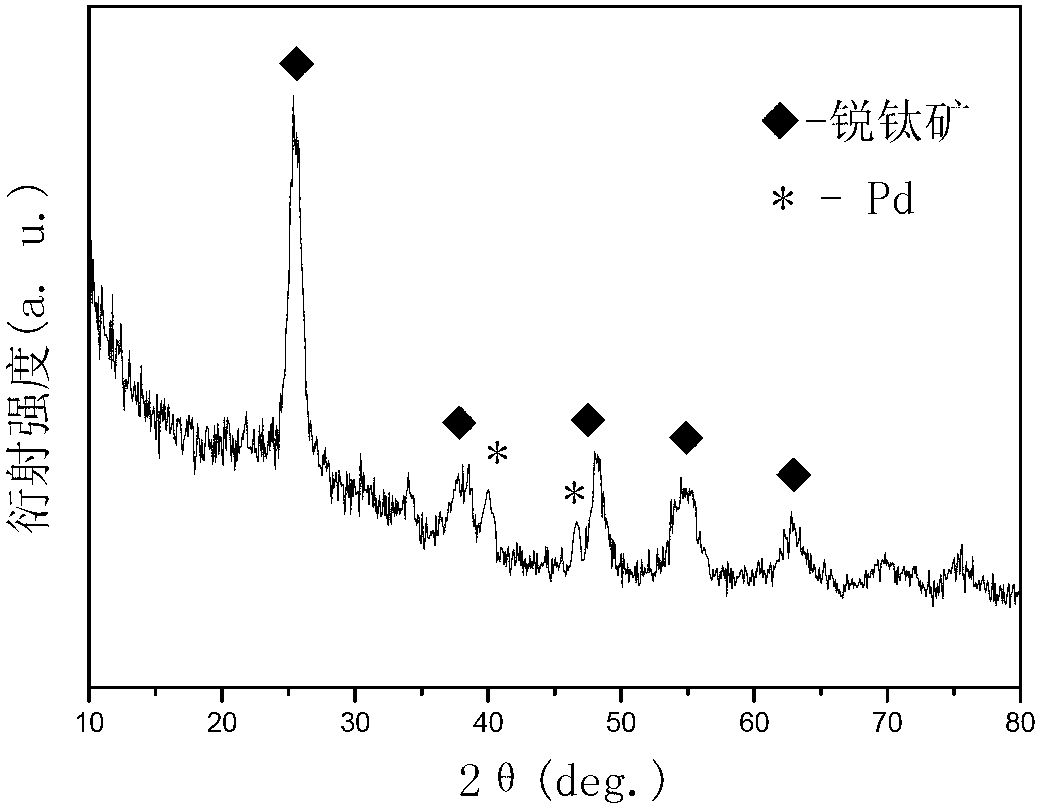

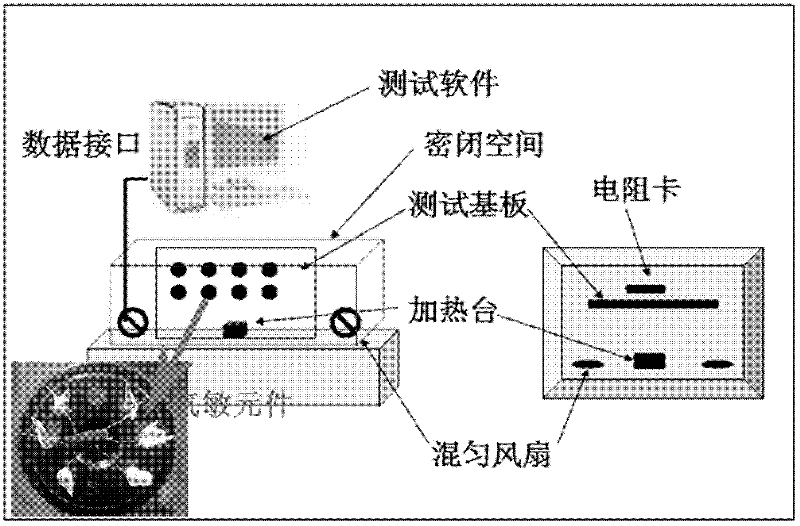

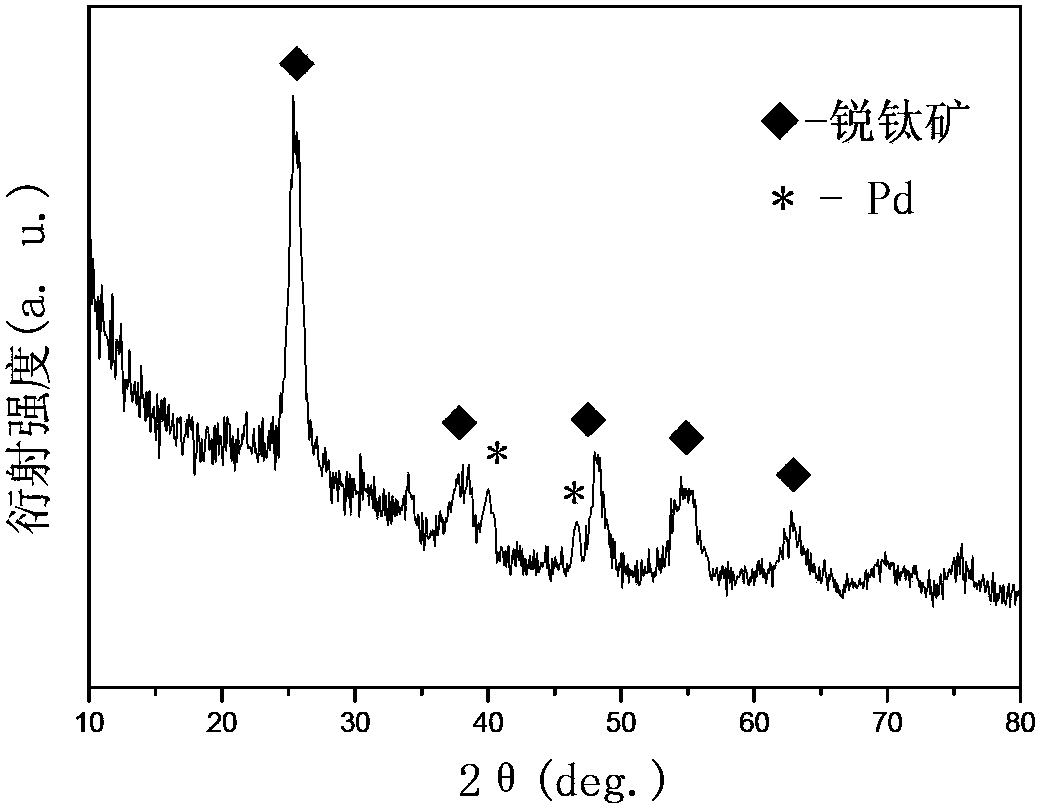

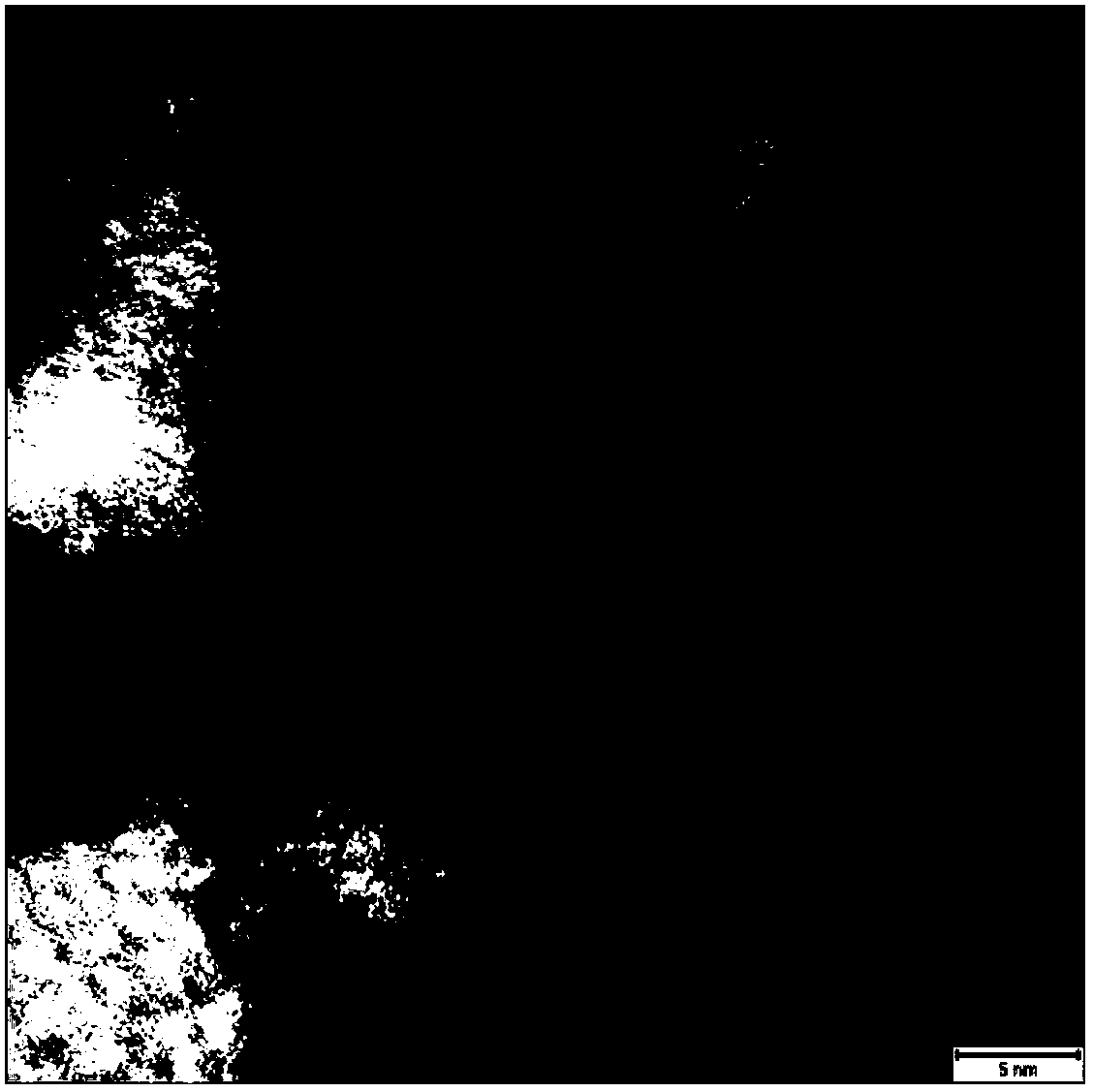

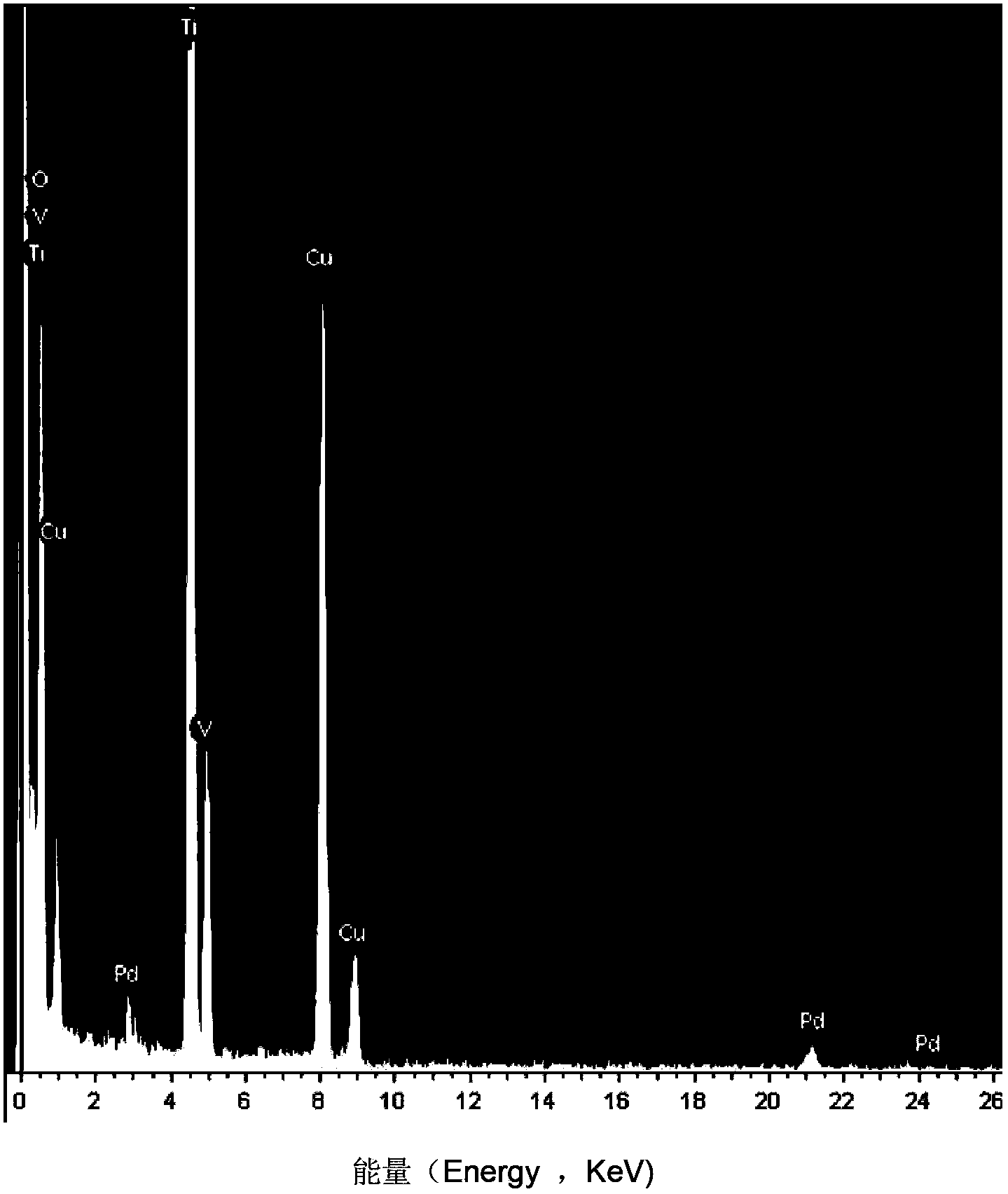

Vanadium and palladium-codoped nanometer titania gas-sensitive material as well as preparation method and applications thereof

InactiveCN103101973AGood effectHigh sensitivityMaterial nanotechnologyTitanium dioxideChlorobenzeneGlycol synthesis

The invention relates to a vanadium and palladium-codoped nanometer titania gas-sensitive material as well as a preparation method and applications thereof. The preparation method of the codoped nanometer titania gas-sensitive material comprises the steps of: taking nanometer titania as a matrix, and doping 0.5-1.5mol% of vanadium and 1.0-3.5mol% of palladium, mixing a Pd(NO3)2 solution with a vanadium triisopropoxy oxide alcohol solution and dropwise adding the mixture into a tetrabutyl titanate ethylene glycol solution to obtain gel, drying, grinding and calcining to obtain the vanadium and palladium-codoped nanometer titania gas-sensitive material, wherein the particle size of the vanadium and palladium-codoped nanometer titania ranges from 8 to 15nm. The invention further provides a preparation method of the material. The gas-sensitive material is used for a gas-sensitive sensor for detecting chlorobenzene, is high in sensitivity, good in selectivity, short in response-restoration time, and beneficial to realizing the fast detection of the chlorobenzene.

Owner:QUFU NORMAL UNIV

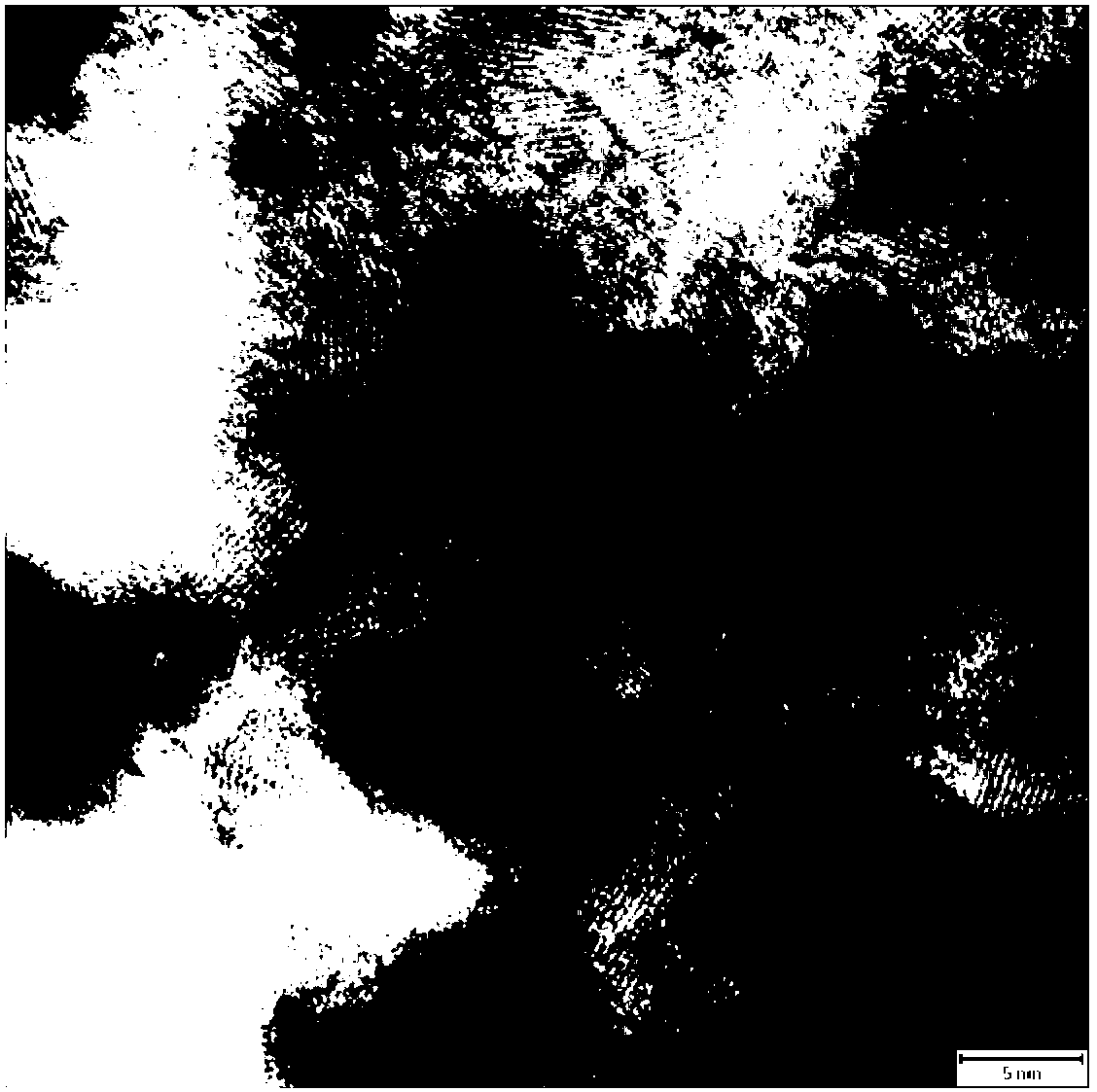

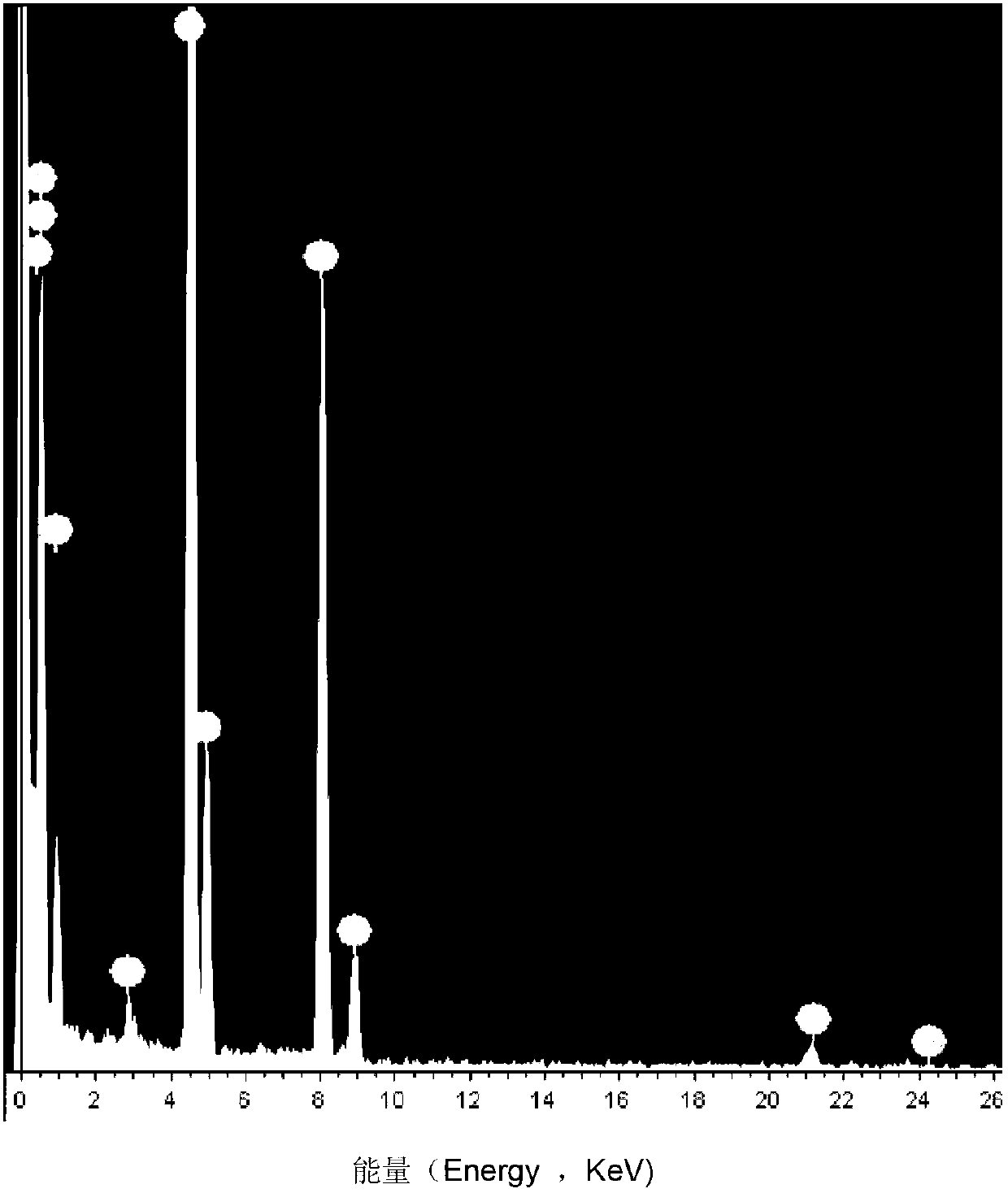

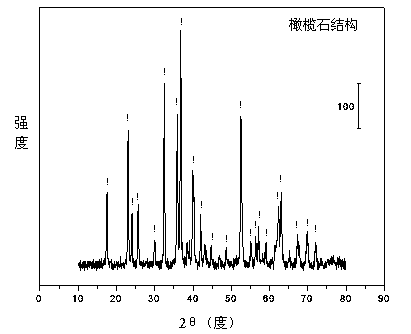

Olivine nickel-based catalyst for preparing hydrogen through autothermal reforming of acetic acid

InactiveCN103657654AIncrease lattice defectsEnhanced autothermal reforming activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel catalystAcetic acid

The invention relates to an olivine nickel-based catalyst for preparing hydrogen through autothermal reforming of acetic acid. Aiming to solve the problems of low hydrogen yield and oxidation / sintering inactivation of active constituents of the conventional supported nickel-based catalyst in an autothermal reforming process of acetic acid, the invention provides a novel catalyst with the effects of large specific surface area, stable structure, sintering resistance, oxidation resistance and stable activity. The catalyst provided by the invention has a chemical component of MgaFebNicSiO4, wherein a is 1.0-1.7, b is 0-0.7 and c is 0.3-0.5. The nickeliferous catalyst taking an olivine structure as a main body is prepared by a hydro-thermal synthesis method; the catalyst has rich hole structures so that the specific surface area and the dispersity of active constituents of the catalyst are effectively improved; meanwhile, the active constituents, such as nickel and iron, and additives substitute for bivalent magnesium to enter an olivine skeletal structure to effectively refrain the phenomenon of oxidation / sintering inactivation of the catalyst, so that the stability and the hydrogen yield of the catalyst in the autothermal reforming process of acetic acid are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

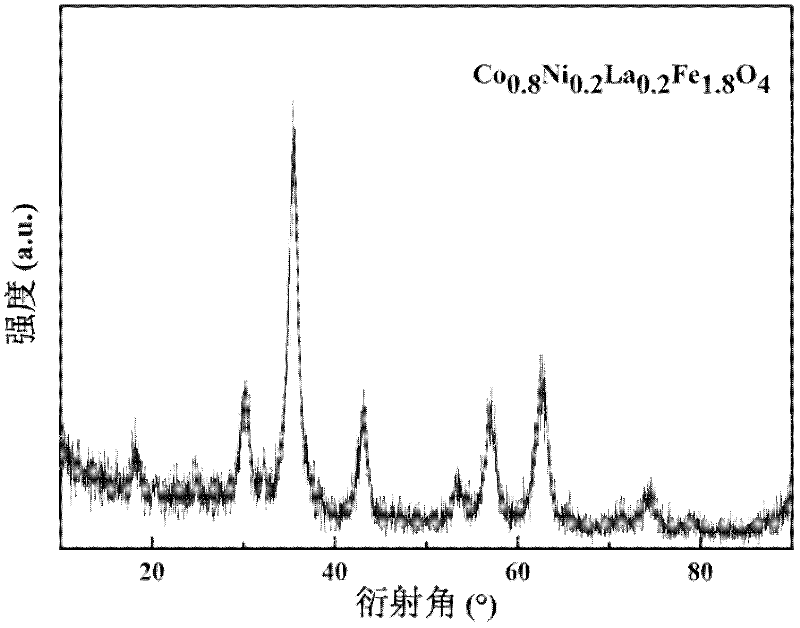

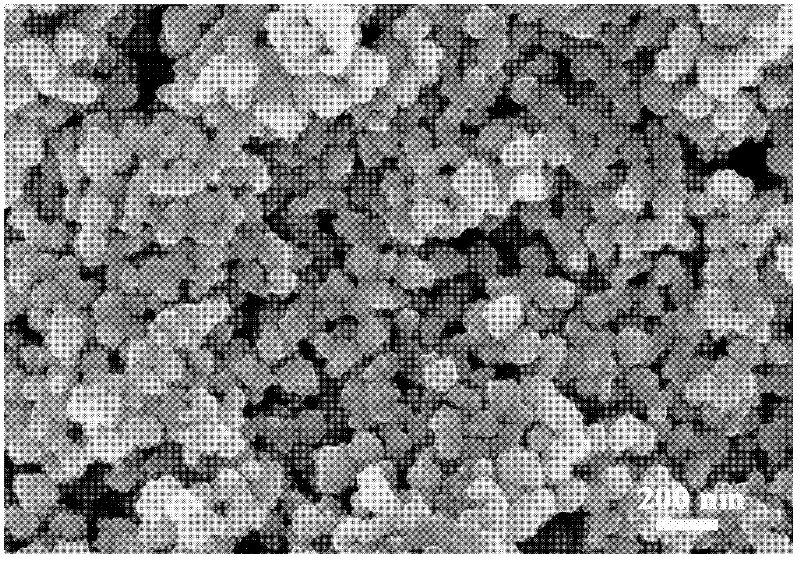

Preparation methods of lanthanum-doped cobalt nickel ferrite gas-sensitive powder and gas sensor

The invention relates to preparation methods of lanthanum-doped cobalt nickel ferrite gas-sensitive powder and a gas sensor. The preparation method of the gas-sensitive powder comprises the following steps: (1) soluble cobalt salt, nickel salt, lanthanum salt and ferric salt are mixed and dispersed into ethylene glycol, and sodium acetate anhydrous is added and stirred to form reaction solution; and (2) the reaction solution is heated and reacted, then is cooled to room temperature after the reaction, and washed, centrifugated and dried. The preparation method of the gas sensor comprises the following steps: the gas-sensitive powder and terpilenol solution of ethyl cellulose are mixed and ground to form gas-sensitive slurry; and then the gas-sensitive slurry is uniformly coated to an Al2O3 ceramic tube with an Au electrode, conducted to gas drying and calcination, and installed on a testing base, and then the gas sensor is obtained after ageing. The preparation methods are simple, the requirement on the production equipment is low, the industrial production is easy, and the prepared gas-sensitive powder has good selectivity, good chemical stability and good sensitivity.

Owner:DONGHUA UNIV

Production method of magnesium-doped hydroxyapatite defluorination filter material

InactiveCN106744766APlay a synergistic roleHigh purityWater/sewage treatment by neutralisationPhosphorus compoundsLattice defectsMagnesium salt

The invention discloses a production method of a magnesium-doped hydroxyapatite defluorination filter material. The method comprises the steps of adopting industrial calcium salt, phosphoric acid, ammonia water and soluble magnesium salt as raw materials; mixing the soluble magnesium salt and calcium salt with determined addition quality into paste, and adding the paste to a reaction kettle for stirring evenly; preparing a phosphoric acid solution according to the volume ratio of the phosphoric acid to water; dropwise adding the solution to the reaction kettle and simultaneously dropwise adding ammonium hydroxide to the reaction kettle to keep the pH value of a reaction system within a set range in real time; and carrying out stirring, standing and ageing, taking out a product, filtering, drying and crushing to obtain a magnesium-doped hydroxyapatite powder filter material. Due to doping of a little of magnesium, the structure of hydroxyapatite can distort, lattice defects are increased, the crystallinity is reduced, the grain size is reduced, the specific surface area is increased, and the physical adsorption reaction of the surface is added, so that the magnesium-doped hydroxyapatite defluorination filter material plays a synergistic role in defluorination of the hydroxyapatite, and the defluorination capacity of a product is improved.

Owner:CHINA UNIV OF MINING & TECH

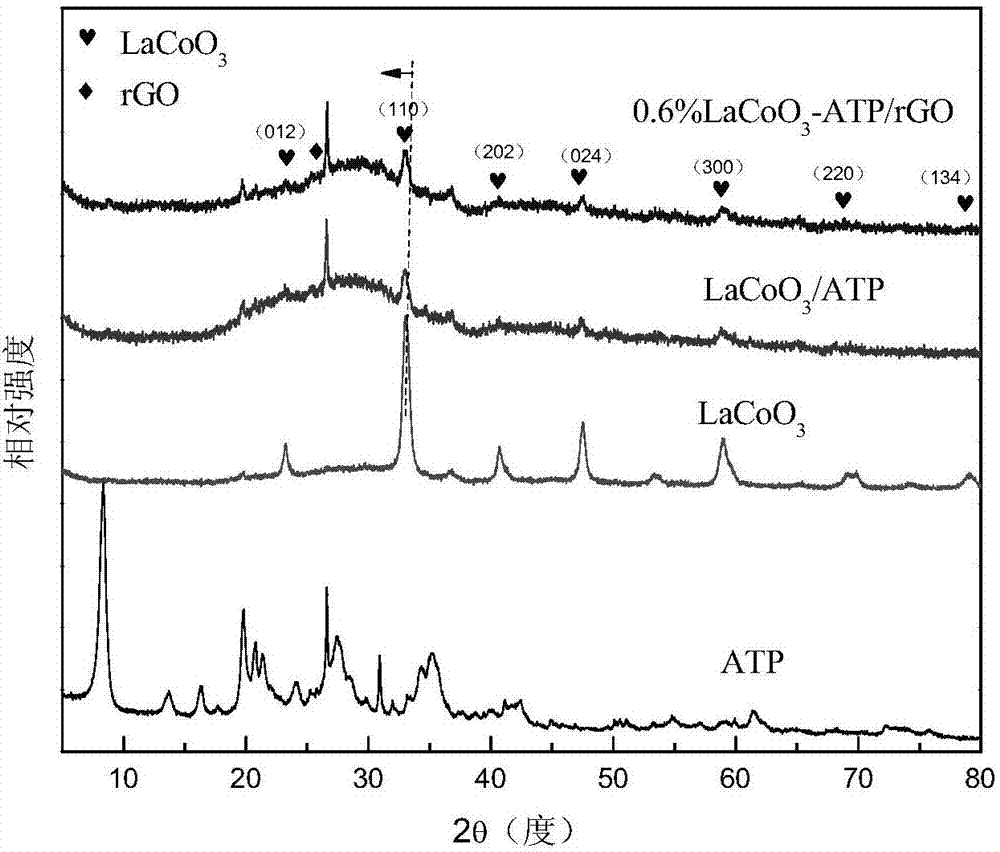

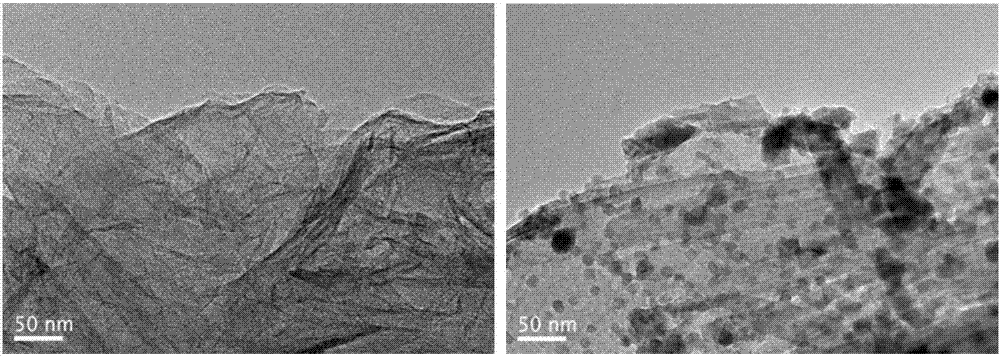

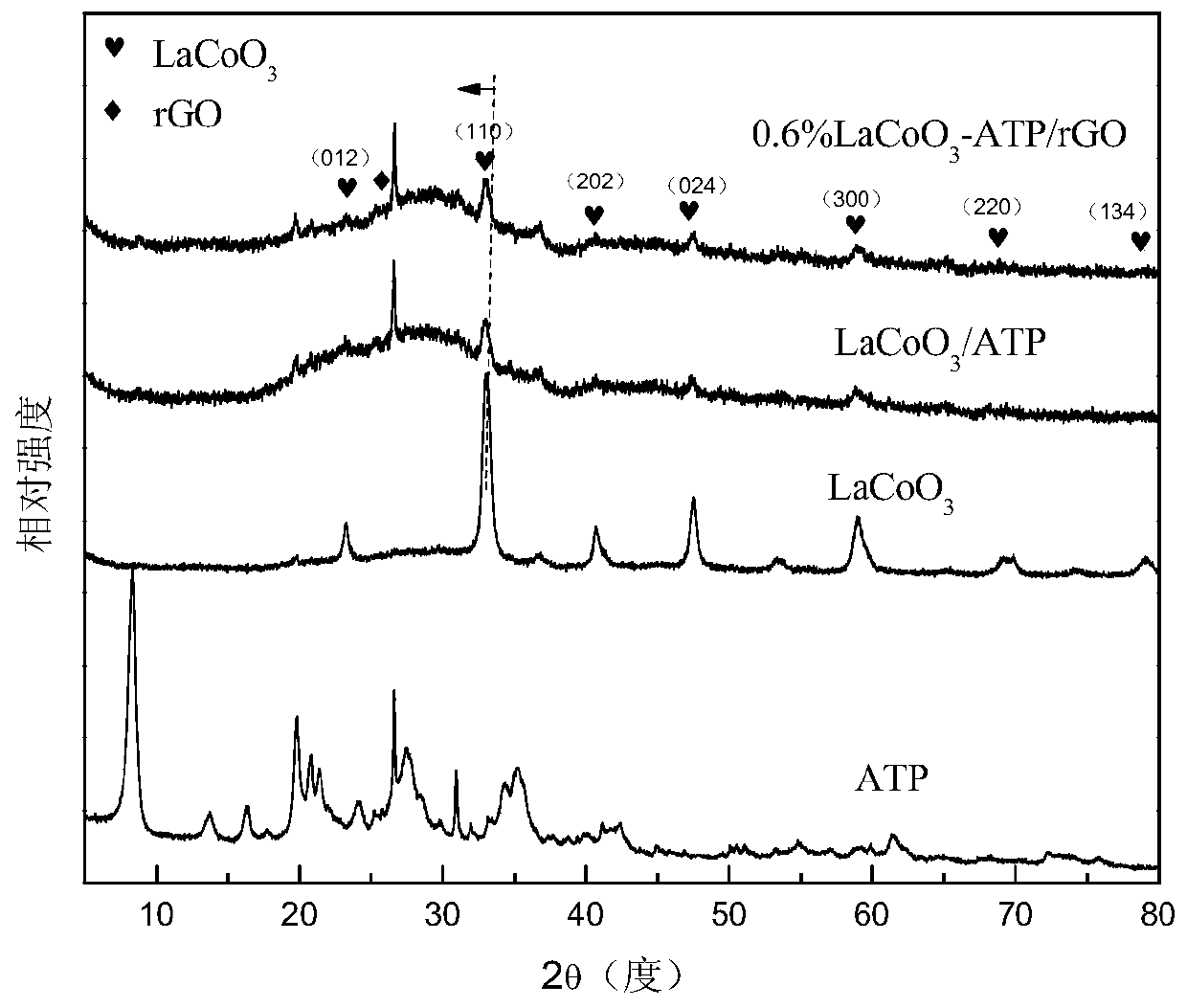

Lanthanum cobaltate/attapulgite/reduced graphene oxide nano-structure composite material, preparation method, and application thereof

ActiveCN107159223AEvenly dispersedImprove composite effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano structuring

The invention belongs to the field of novel chemical materials and especially relates to a lanthanum cobaltate / attapulgite / reduced graphene oxide nano-structure composite material, a preparation method, and an application thereof. The preparation method includes the steps of: 1) preparing lanthanum cobaltate / attapulgite through a sol-gel process, adding the lanthanum cobaltate / attapulgite to deionized water and acidifying the liquid and regulating pH value to obtain a lanthanum cobaltate / attapulgite water solution carrying positive charges; 2) reducing graphite oxide with hydrazine hydrate to produce reduced graphene oxide carrying negative charges, and mixing the reduced graphene oxide with the lanthanum cobaltate / attapulgite water solution, stirring the mixture in water bath, performing a reaction, and drying a reaction product to obtain a perovskite / attapulgite / reduced graphene oxide composite material. With the composite material as a catalyst for performing photo-SCR denitration, conversion rate on NOx in a low-temperature zone (100-200 DEG C) can reach more than 95%.

Owner:CHANGZHOU UNIV

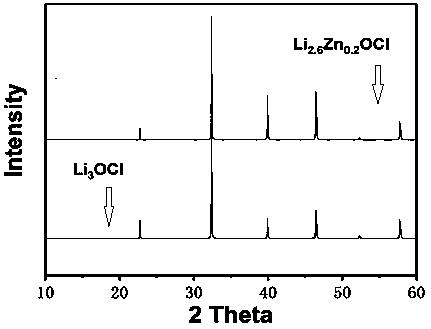

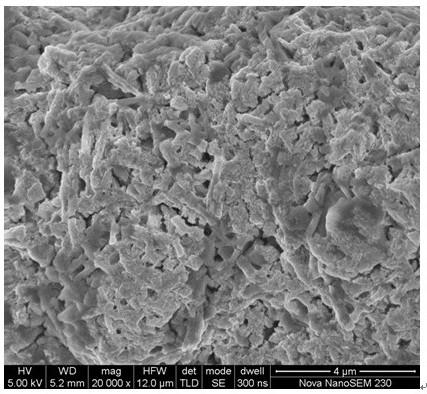

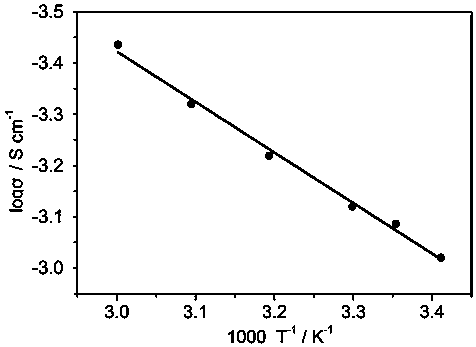

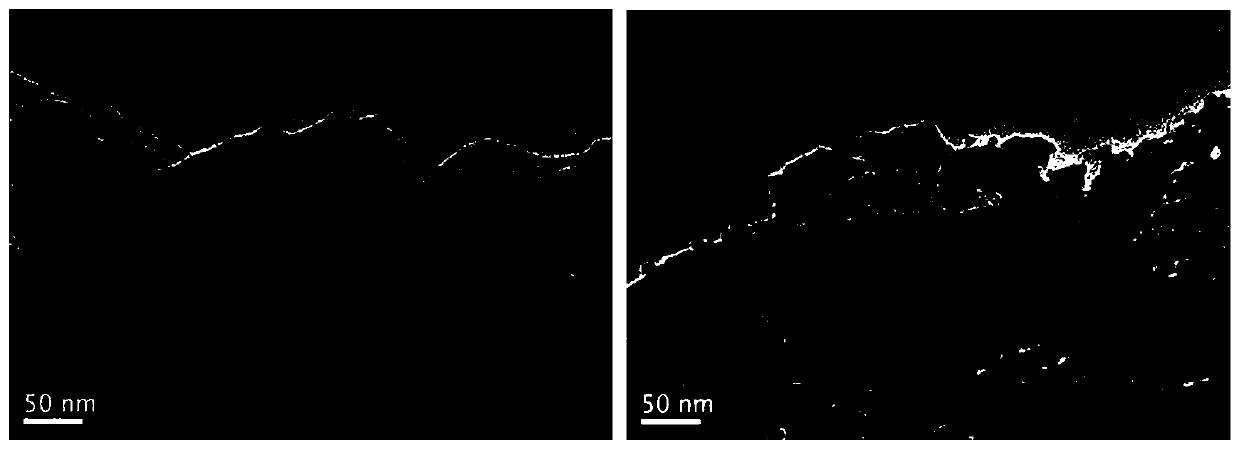

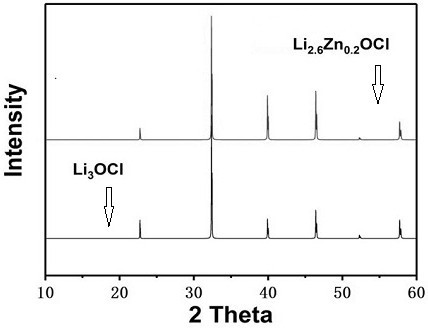

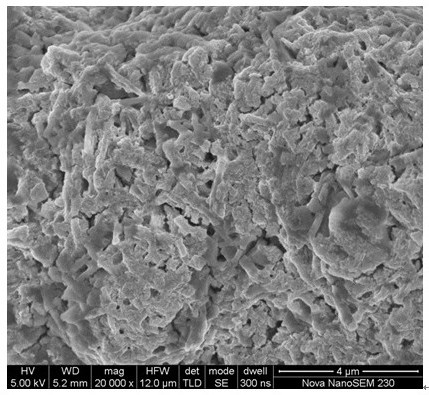

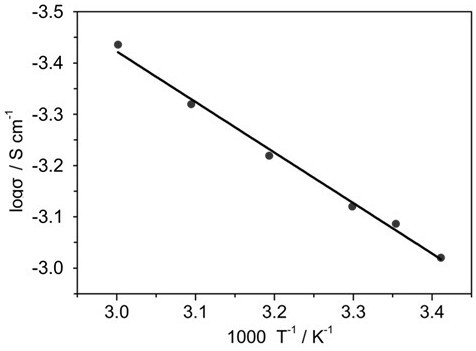

Crystalline Li3OCl inorganic lithium ion conductor as well as preparation method and application thereof

ActiveCN111484042APromote dehydrogenation reactionIncrease lattice defectsSecondary cellsLithium halidesLithium oxideLithium chloride

The invention discloses a crystalline Li3OCl inorganic lithium ion conductor as well as a preparation method and an application thereof. The Li3OCl inorganic lithium ion conductor is Zn-doped Li3OCl,and the preparation method comprises the following steps: uniformly mixing lithium hydroxide, lithium oxide and lithium chloride in proportion, and melting above the eutectic point of lithium hydroxide, lithium oxide and lithium chloride to obtain a precursor; and mixing the precursor with metal zinc powder, and carrying out heat treatment at a temperature higher than the melting temperature of the precursor in a protective atmosphere to obtain the product Zn-doped Li3OCl. The Li3OCl inorganic lithium ion conductor provided by the invention has excellent lithium ion conductivity and environmental stability. The preparation method provided by the invention is short in preparation period, low in cost, high in process controllability and suitable for industrial application.

Owner:CHANGSHA STORM ENERGY TTECH

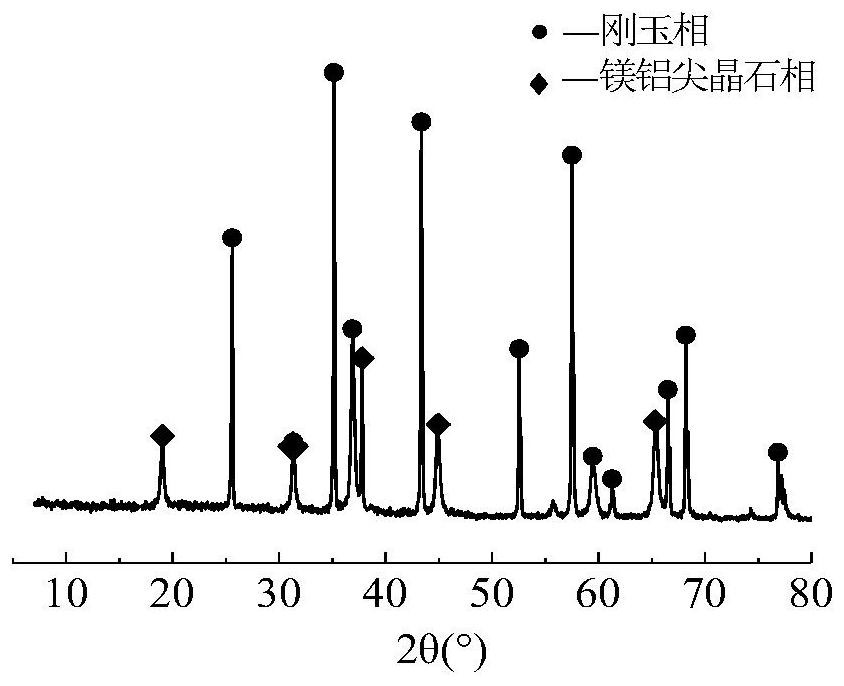

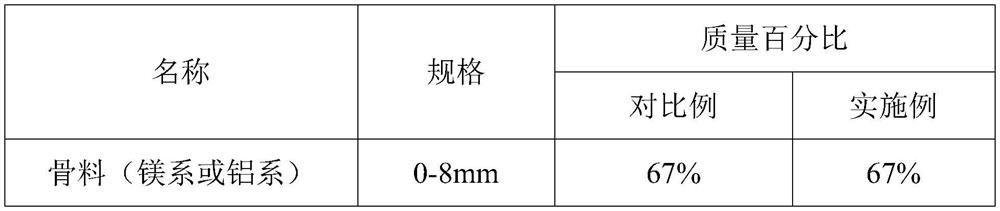

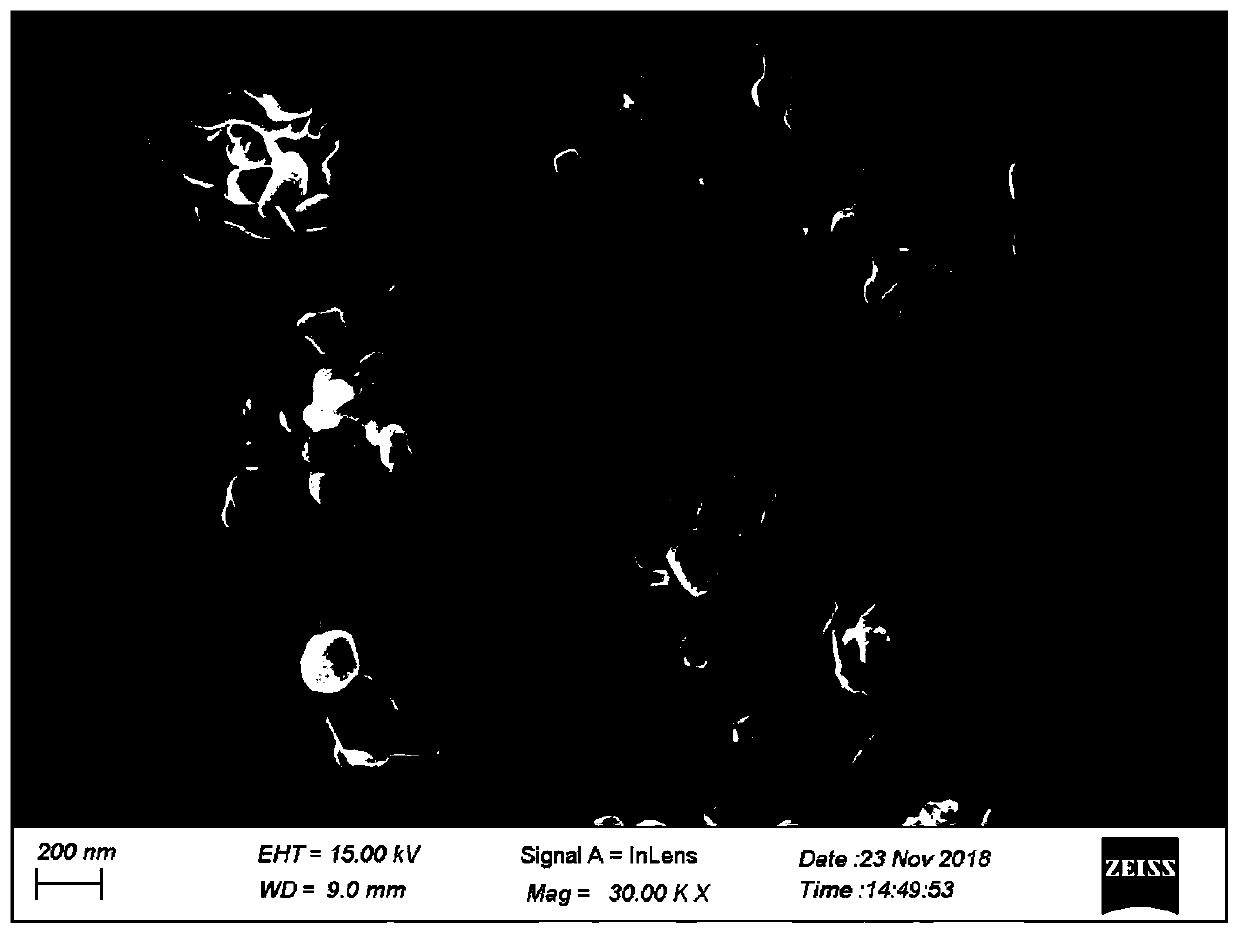

Method for synthesizing aluminum-rich spinel through low-temperature solid-phase reaction

The invention belongs to the field of refractory materials, and particularly relates to a method for synthesizing aluminum-rich spinel through a low-temperature solid-phase reaction. The method specifically comprises the following steps: firstly, mixing 80-90 parts by weight of an aluminum oxide raw material, 10-20 parts by weight of a magnesium oxide raw material, 0.5-2 part by weight of magnesium aluminate spinel micro powder and 0.5-3 part by weight of an additive, and co-grinding the materials until the particle size of the raw materials is in a range of 5-20 microns; transferring the co-ground powder into a high-temperature kiln, heating to 1000-1500 DEG C, and calcining; and finally, keeping for 3-12 hours at the calcining temperature, and implementing naturally cooling or quickly air-cooling to room temperature to obtain the aluminum-rich spinel. A low-temperature synthesis process is adopted, the aluminum-rich spinel synthesized through low-temperature calcination is fine in grain and high in lattice defect degree, and meanwhile the prepared aluminum-rich spinel powder is high in activity. The prepared aluminum-rich spinel does not contain beta aluminum oxide or impurity phases such as free magnesium oxide, and the content of aluminum oxide in the aluminum-rich spinel reaches 80-90%. When the prepared aluminum-rich spinel powder is used in a corundum spinel castable, the aluminum-rich spinel powder has the advantages of high sintering strength and strong slag penetration resistance.

Owner:湖北斯曼新材料股份有限公司

Technology for accelerating solid solution speed of indissolvable delta ferrite in martensite heat-resistant steel ingot and refining austenite grains

The invention provides a technology for accelerating a solid solution speed of indissolvable delta ferrite in a martensite heat-resistant steel ingot in a structure after high-temperature long-time solid solution and refining austenite grains; and the technology for generating a lot of lattice defects in delta ferrite by using lower-temperature (below steel austenite grain roughening temperature) austenitizing and deformation accelerates the solid solution speed of the delta ferrite in the martensite heat-resistant steel ingot after high-temperature long-time solid solution, and meanwhile, obtains fine austenite grains. The martensite heat-resistant steel ingot is cooled to reach the room temperature after high-temperature solid solution of 1180-1200 DEG C by 8-10 h, and then, are heated for austenitizing of 1000-1050 DEG C; and the compression deformation of above 60% is performed, so that the solid solution speed of the delta ferrite is accelerated, and meanwhile, the fine austenite grains are obtained. The technology has the following advantages: the solid solution speed of the indissolvable delta ferrite in the martensite heat-resistant steel ingot in the structure after high-temperature long-time solid solution can be greatly accelerated; meanwhile, the austenite grains are refined; and the steps are simple.

Owner:QINGDAO UNIV

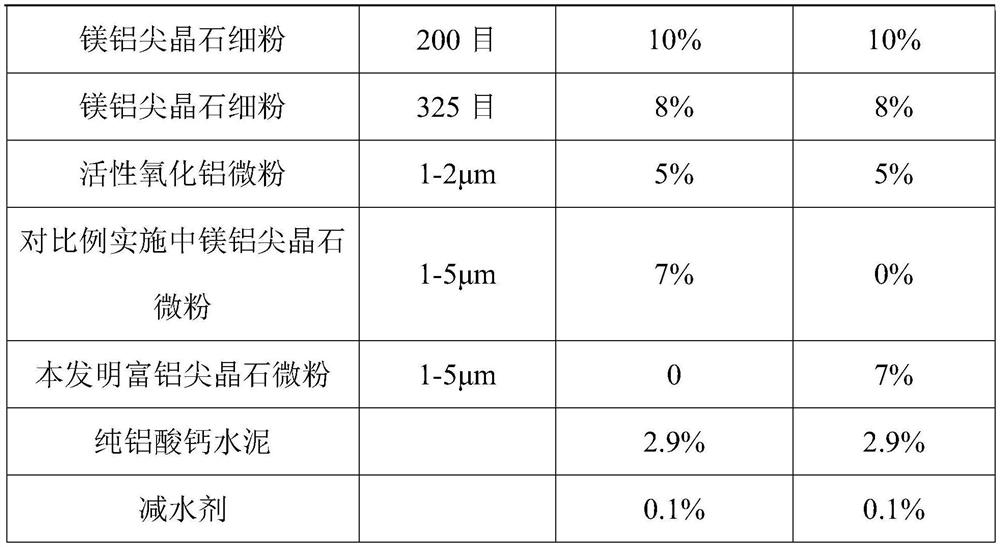

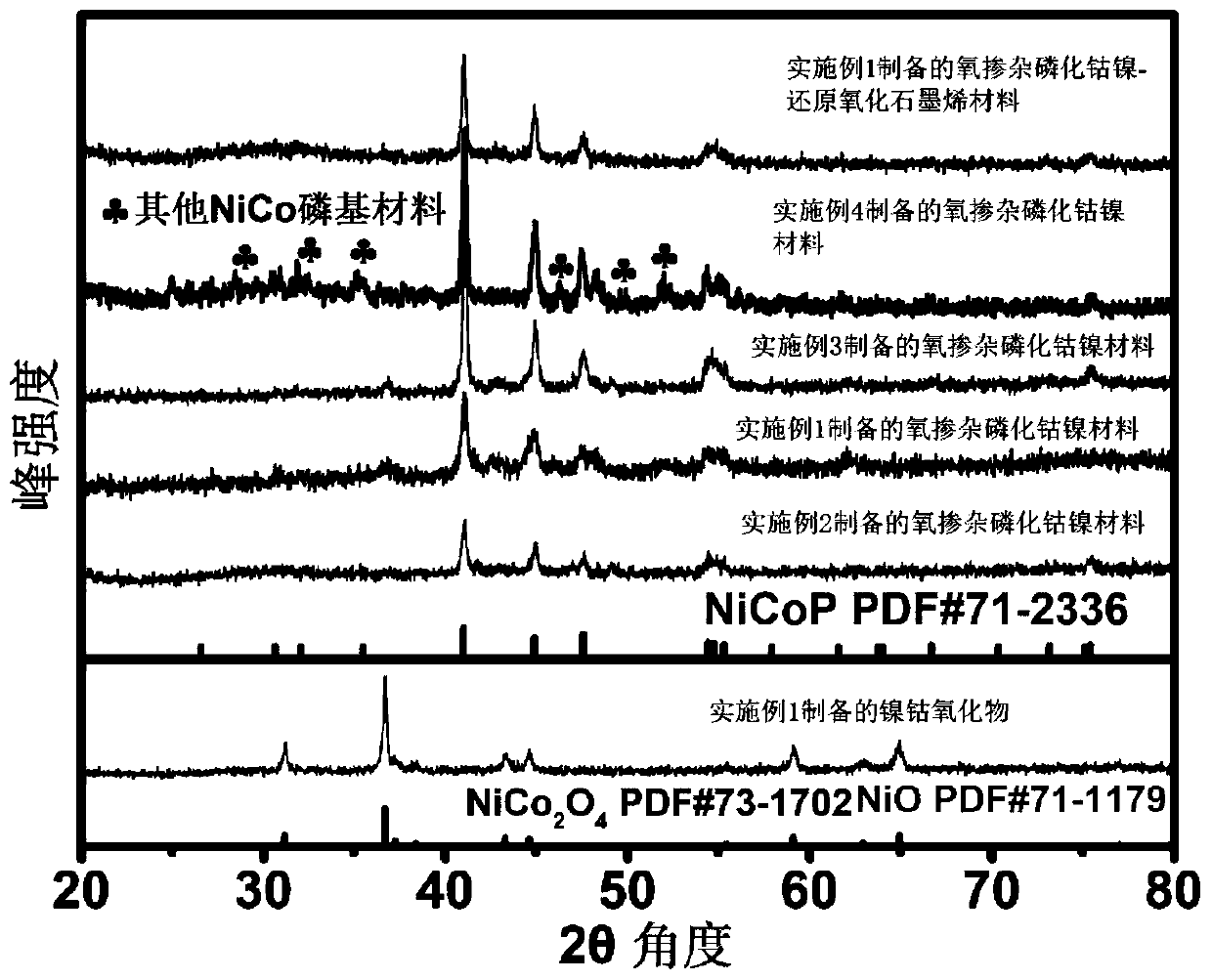

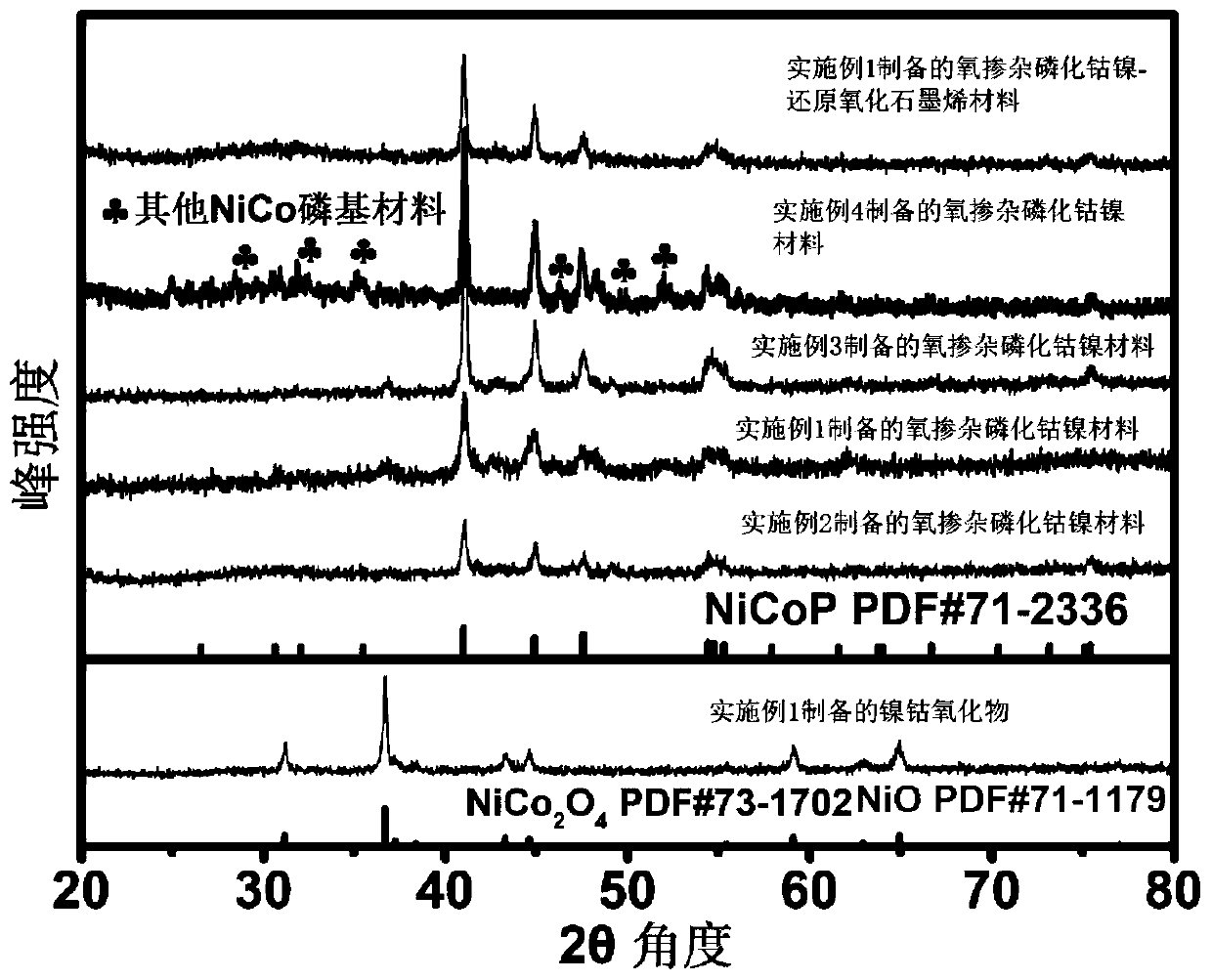

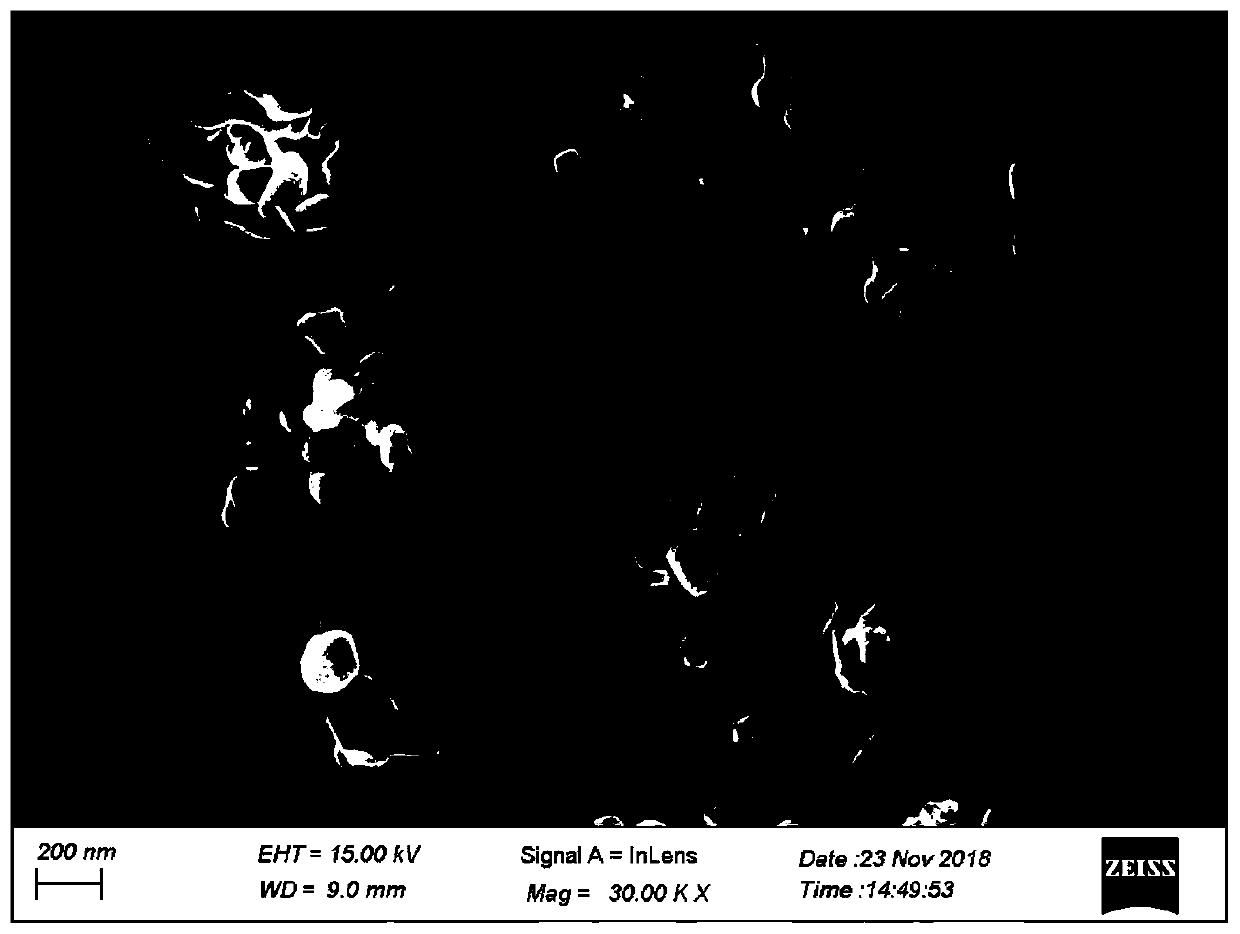

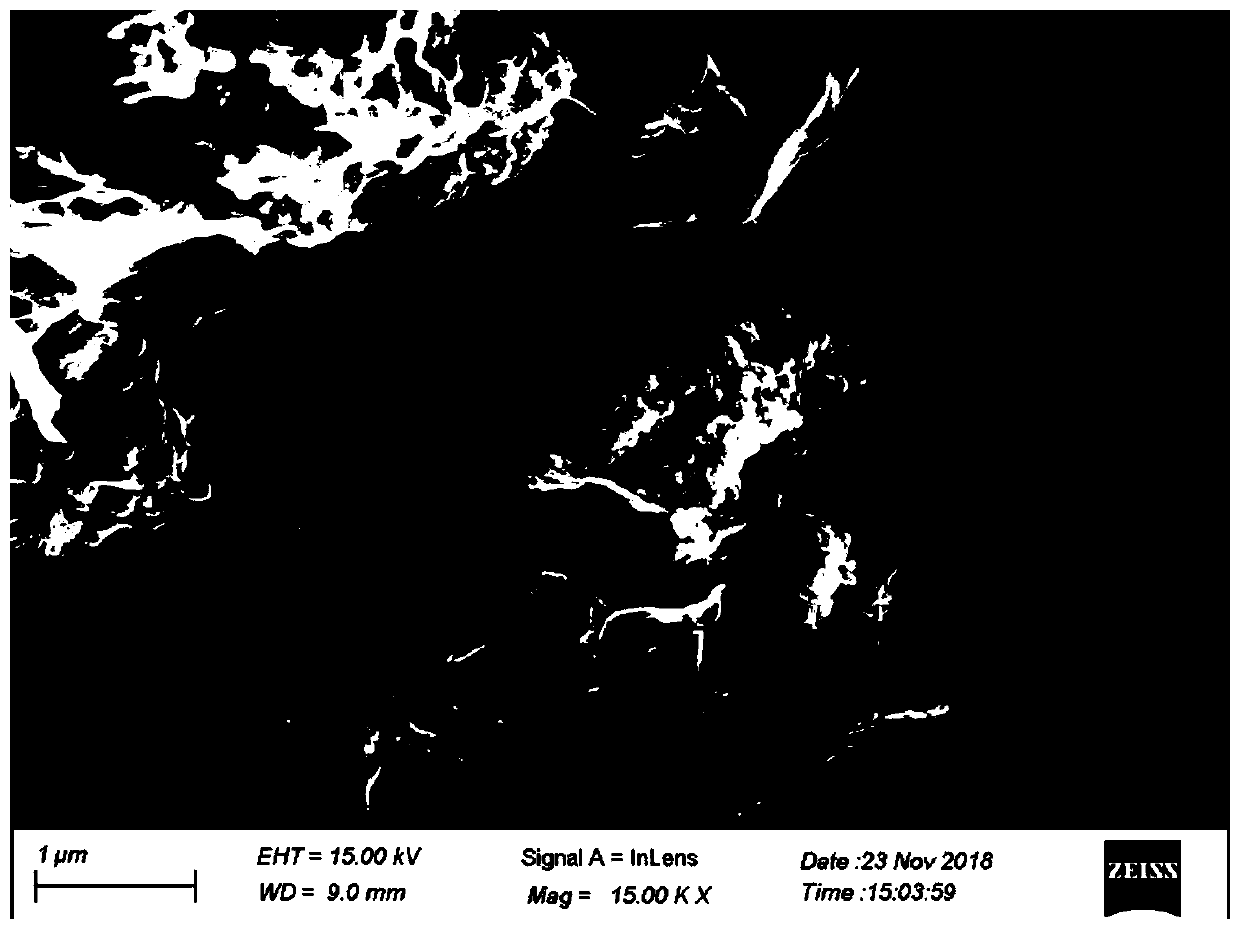

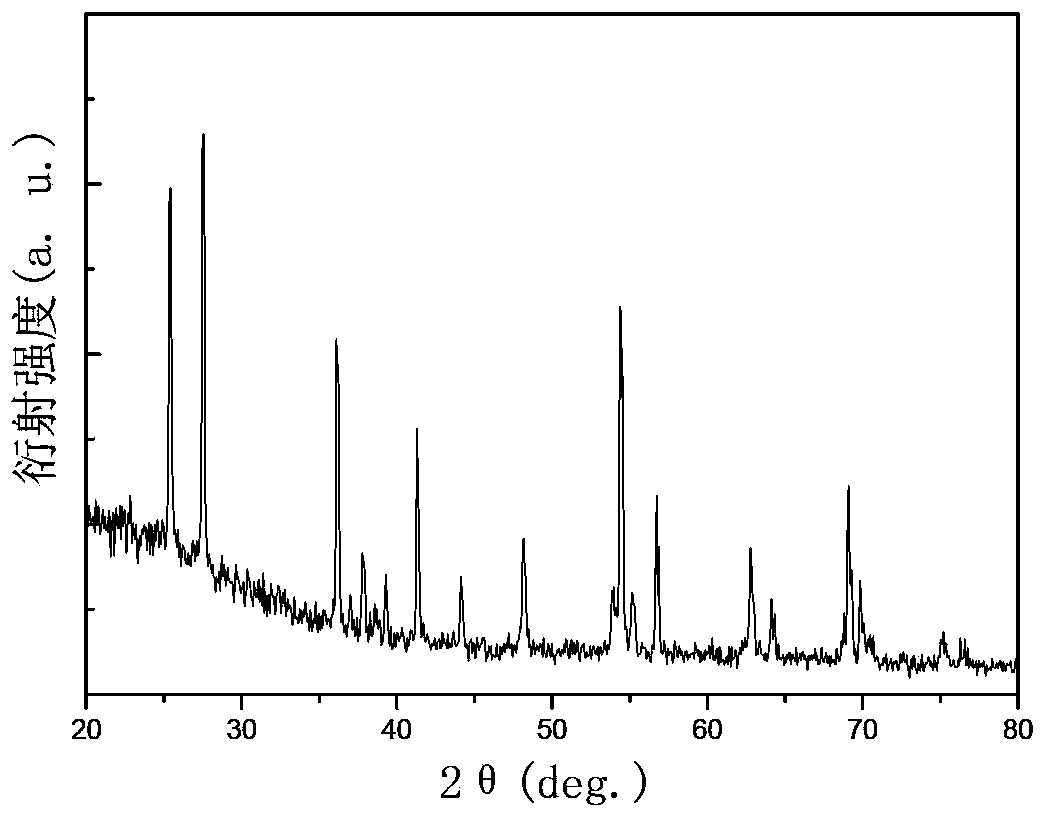

Oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material and application thereof

ActiveCN110323073AImprove conductivityReduce oxygen contentHybrid capacitor electrodesHybrid/EDL manufactureNickel phosphateCapacitance

The invention belongs to the technical field of composite materials, particularly relates to an oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material, and further disclosesapplication of an electrode material of a supercapacitor. In the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material, an oxygen-doped cobalt nickel phosphate electrode material with small grain size and large specific area is effectively prepared by decomposition of sodium hypophosphite in medium and low temperatures, the surface potential is effectively adjusted bymodification, so that tight and uniform recombination with graphene oxide is achieved, the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material is prepared, the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material is richer in surface holes, smaller in grain size of active material and more excellent in electrochemical performance, excellent specific capacitance, charge-discharge cycle stability and rate performance are shown when the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material is used as the supercapacitor electrode material, and the specific capacitance and the charge-discharge cycle stability of the supercapacitor can be remarkably improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

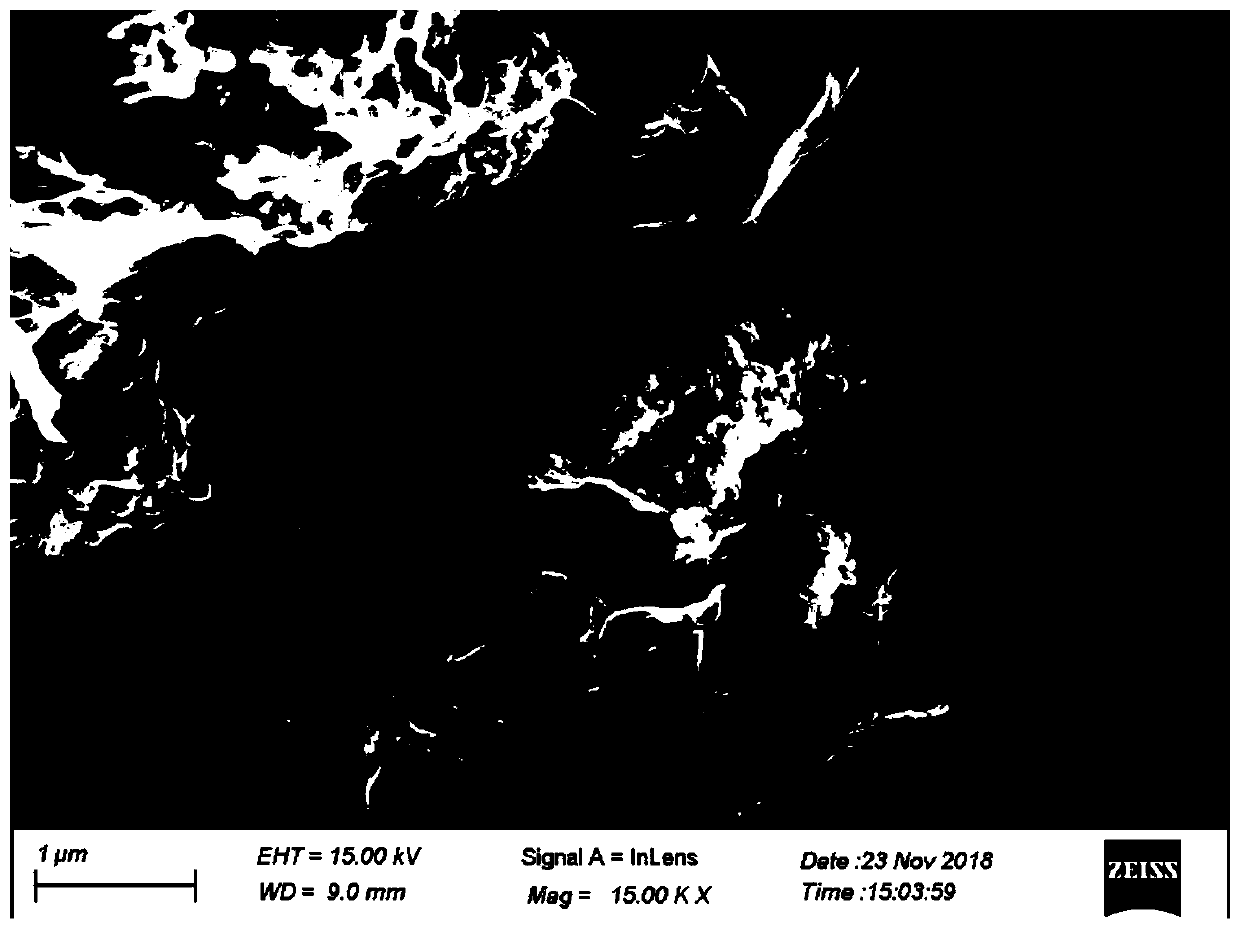

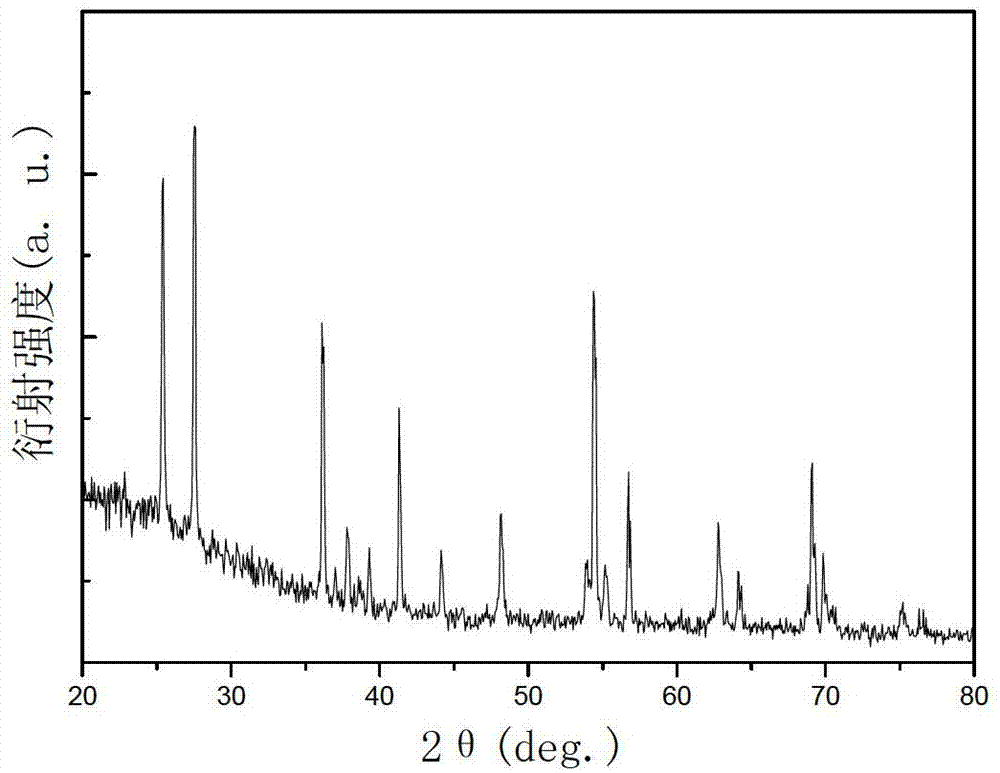

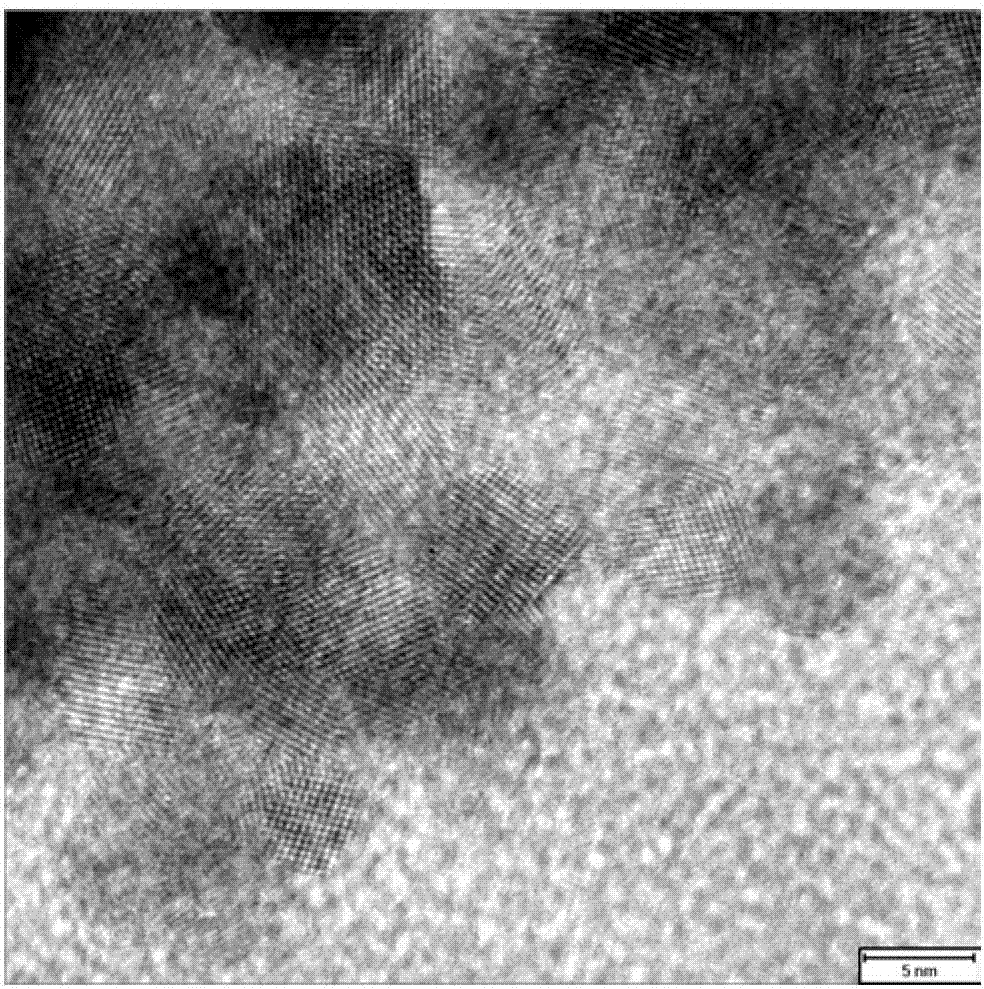

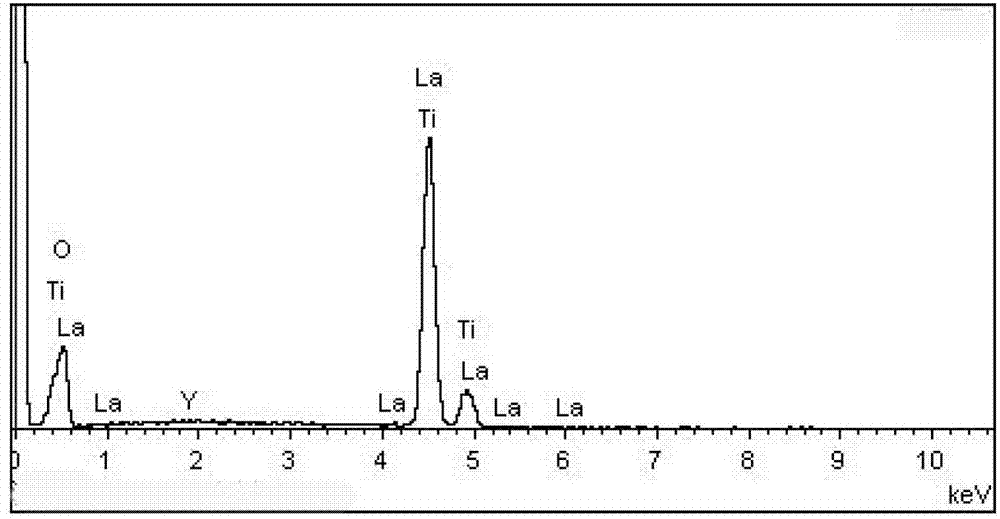

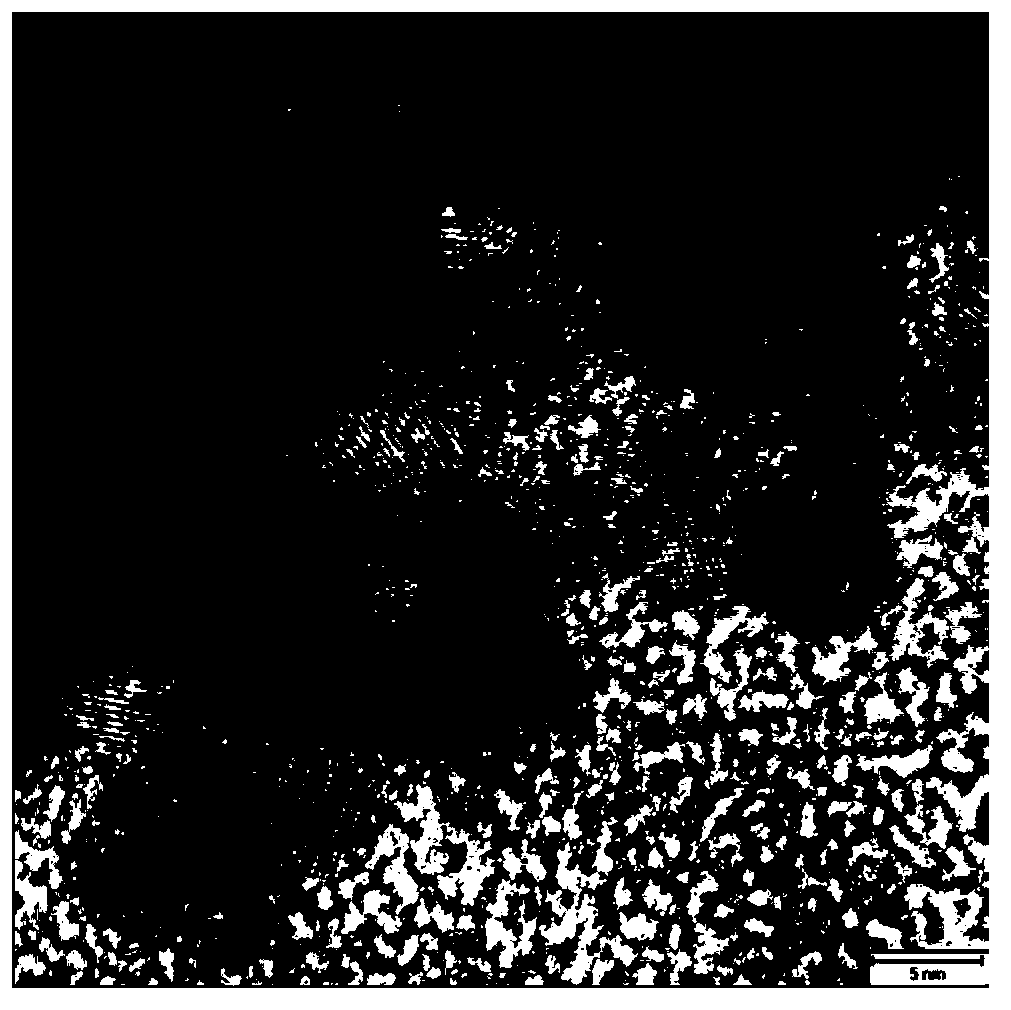

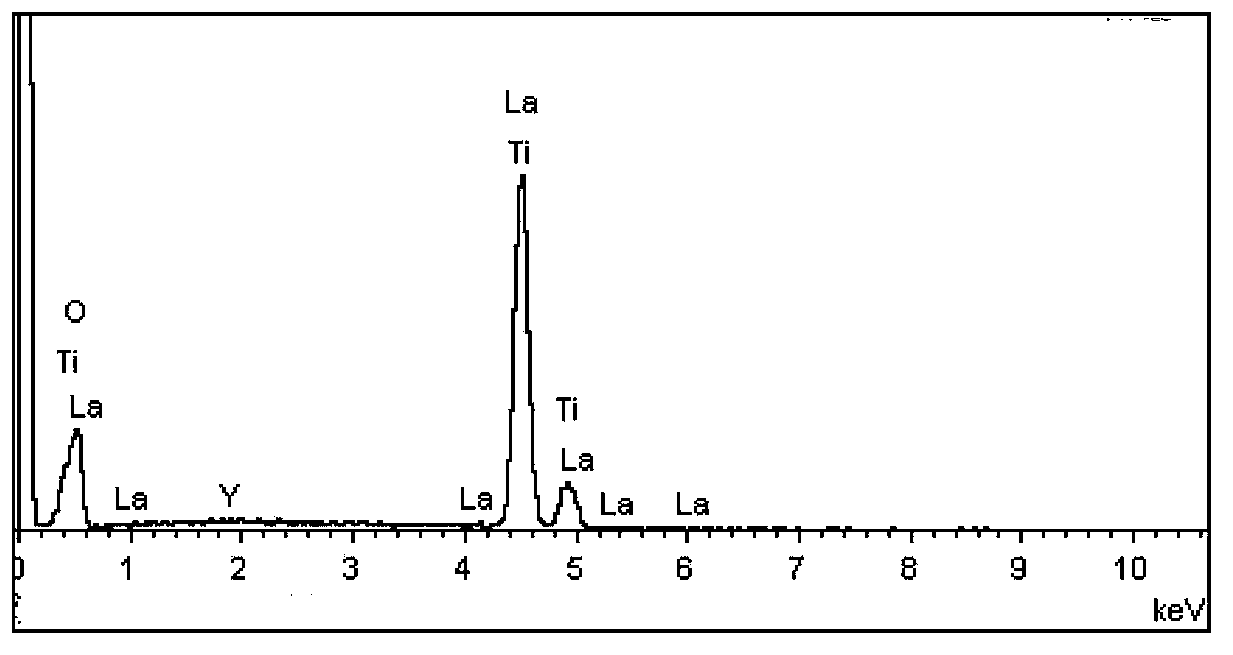

Lanthanum-yttrium-codoped nano-titanium dioxide gas-sensitive material as well as preparation method and application thereof

InactiveCN103159255AChange lattice parametersIncrease lattice defectsMaterial nanotechnologyMaterial analysis by electric/magnetic meansYttriumLanthanum nitrate

The invention relates to a lanthanum-yttrium-codoped nano-titanium dioxide gas-sensitive material as well as a preparation method and an application thereof. The material is prepared by the steps of: by taking nano-titanium dioxide as a matrix and the amount of titanium substances as a base number, doping 0.1-0.8 mol% of lanthanum and 0.1-0.8 mol% of yttrium, dripping ethanol solution of tetrabutyl titanate into the ethanol solution of lanthanum nitrate and yttrium nitrate by utilizing a sol-gel method to prepare sol, and drying, grinding and roasting the sol. The grain diameter of the obtained lanthanum-yttrium-codoped nano-titanium dioxide is 35-70 nm. The invention further provides the preparation method of the material. The obtained gas-sensitive material is used for producing gas-sensitive sensors for detecting o-chlorophenol, is high in sensitivity, good in selectivity and short in response time and is beneficial for realizing fast detection of the o-chlorophenol.

Owner:QUFU NORMAL UNIV

Carbonized fiber paperboard loaded Mo2C/NC catalyst as well as preparation method and application thereof

PendingCN111229288AExcellent electrocatalytic hydrogen evolution performanceWide variety of sourcesPhysical/chemical process catalystsElectrodesFiberPtru catalyst

The invention provides a carbonized fiber paperboard loaded Mo2C / NC catalyst as well as a preparation method and application thereof. The method for preparing the carbonized fiber paperboard loaded Mo2C / NC catalyst comprises the following steps: dissolving a molybdenum source and a nitrogen source in a solvent to obtain an impregnation liquid, impregnating afiber paperboard with the impregnation liquid, and then drying and carbonizing the fiber paperboard impregnated with the impregnation liquid to obtain a carbonized fiber paperboard loaded molybdenum carbide catalyst. According to the methodfor preparing thecarbonized fiber paperboard loaded Mo2C / NC catalyst, the fiber paperboard is used as a substrate (carbon source); dipping of the molybdenum source and thenitrogen source on the fiberpaperboard is carried out; after high-temperature carbonization, Mo2C nanosheets are formed on the fiber paperboard in situ and dispersed in a nitrogen-doped carbon matrix to form a nano composite structure; by doping nitrogen, the dispersity of molybdenum carbide on a carbon material is improved, the fiber paperboard has good conductivity after being carbonized, electron transfer between the catalyst and an electrode is promoted, the catalyst has high electro-catalytic performance, and the fiber paperboard is wide in source and low in price.

Owner:QINGDAO UNIV OF SCI & TECH

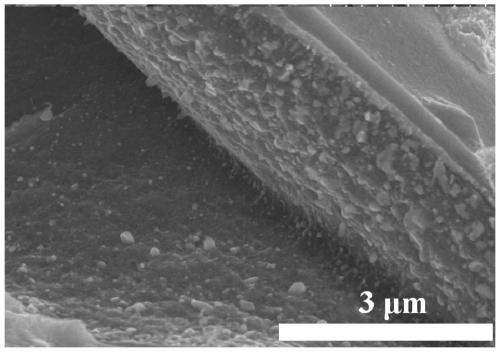

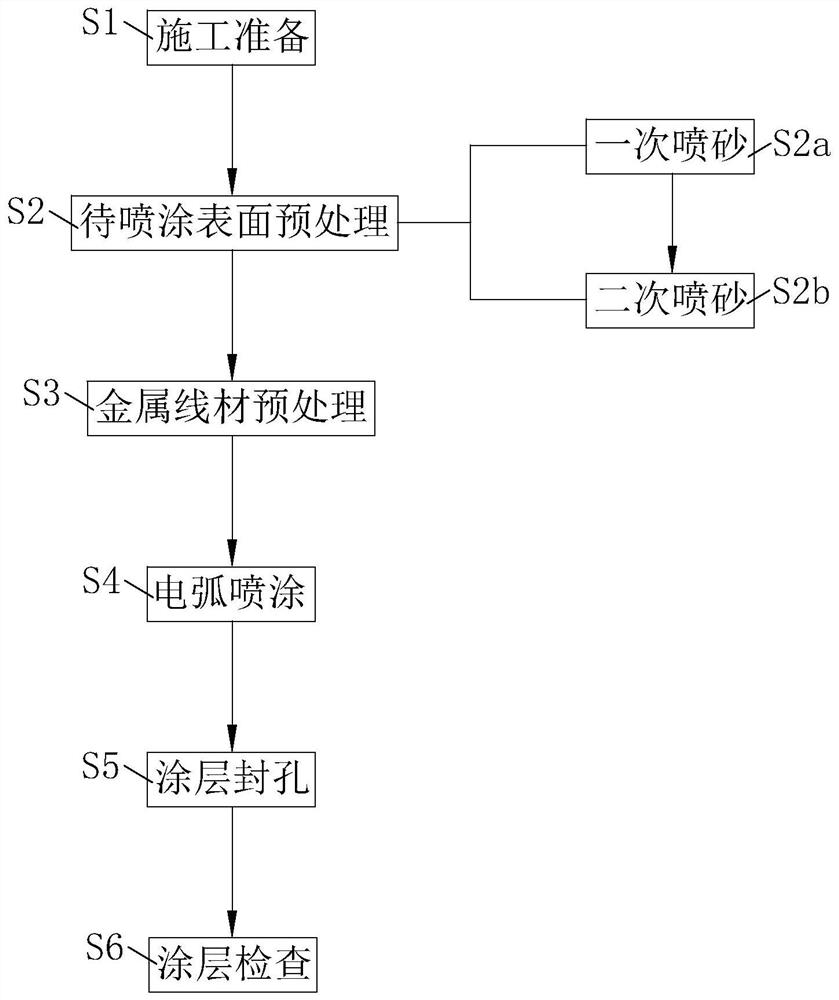

Electric arc spraying method

PendingCN112159947AHigh purityEven and dense coatingMolten spray coatingCorrosion preventionPre treatment

The invention relates to an electric arc spraying method. The electric arc spraying method comprises the following steps that S1, construction preparation is conducted; S2, pretreatment is conducted on the surface to be sprayed, specifically, sand blasting treatment is conducted on the surface of a workpiece through pneumatically-controlled sand blasting equipment, and the roughness of the workpiece reaches 90-120 microns; S3, pretreatment is conducted on a metal wire, specifically, the metal wire is cleaned through a rust remover, straightened through a straightening machine after being cleaned and dried, and polished after being straightened, so that the surface of the metal wire is smooth; S4, electric arc spraying is conducted; S5, coating hole sealing is conducted; and S6, coating inspection is conducted, specifically, the appearance surface obtained after spraying is inspected. According to the electric arc spraying method, the metal wire is cleaned, dried, straightened and polished before spraying, so that the outer surface of the workpiece obtained after spraying is smooth, a coating is uniform, flat and compact, the coating and a base body are well combined, bubbling, cracking, pitted surfaces and peeling are avoided, and accordingly the corrosion resistance and structural strength of the workpiece are improved.

Owner:上海戎实喷涂机械有限公司

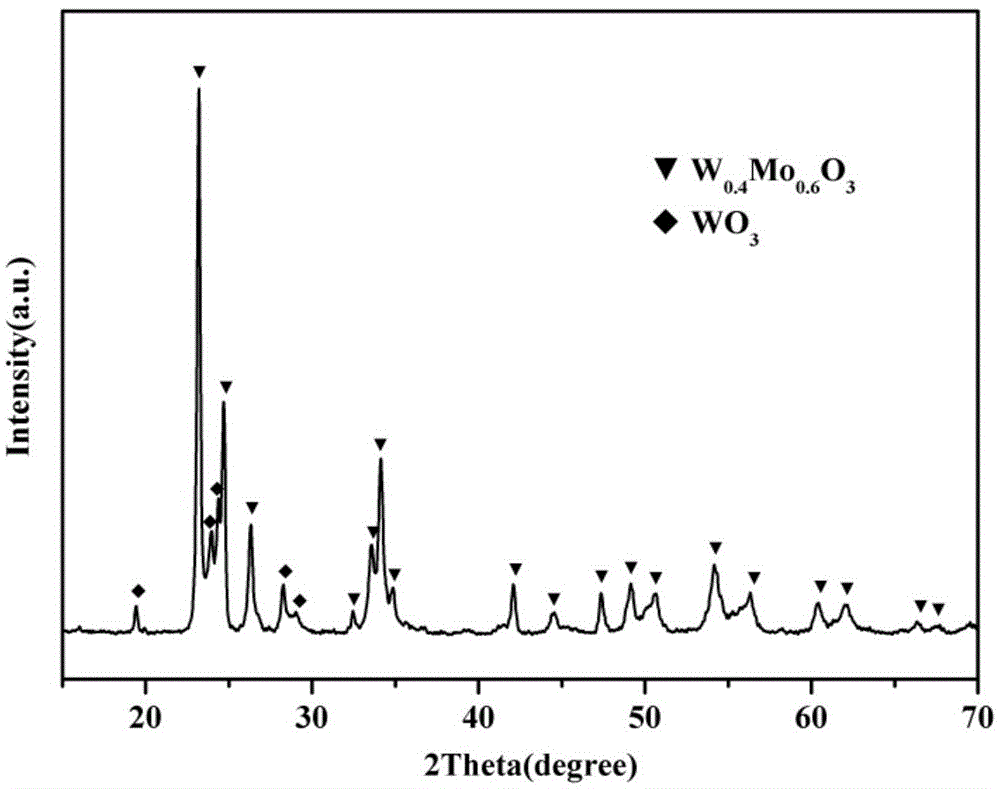

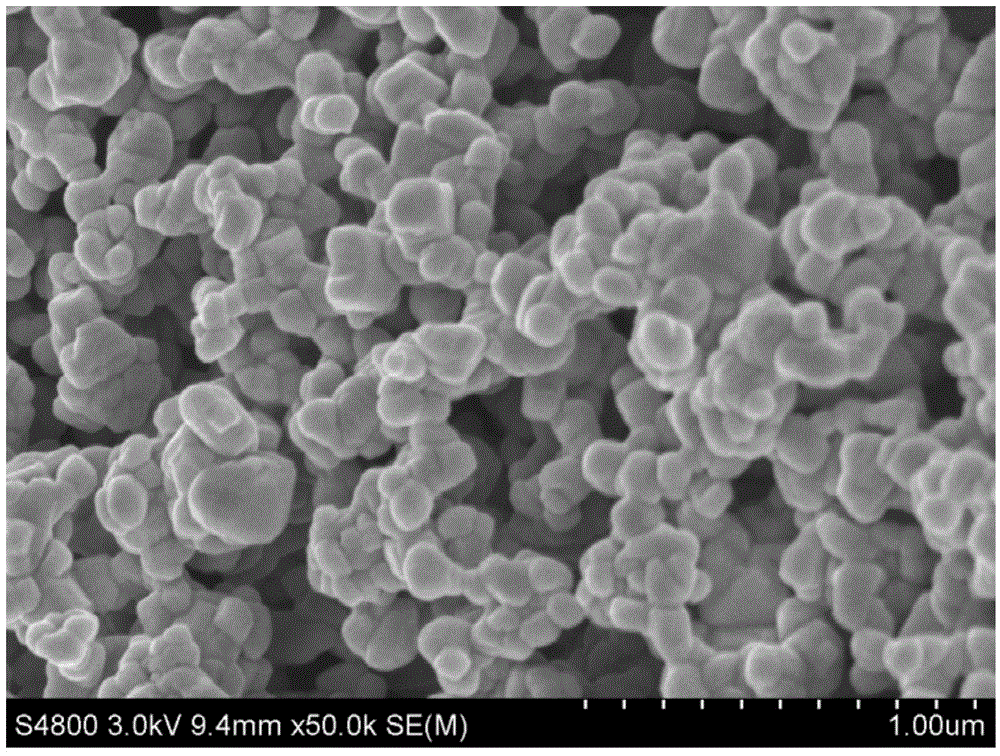

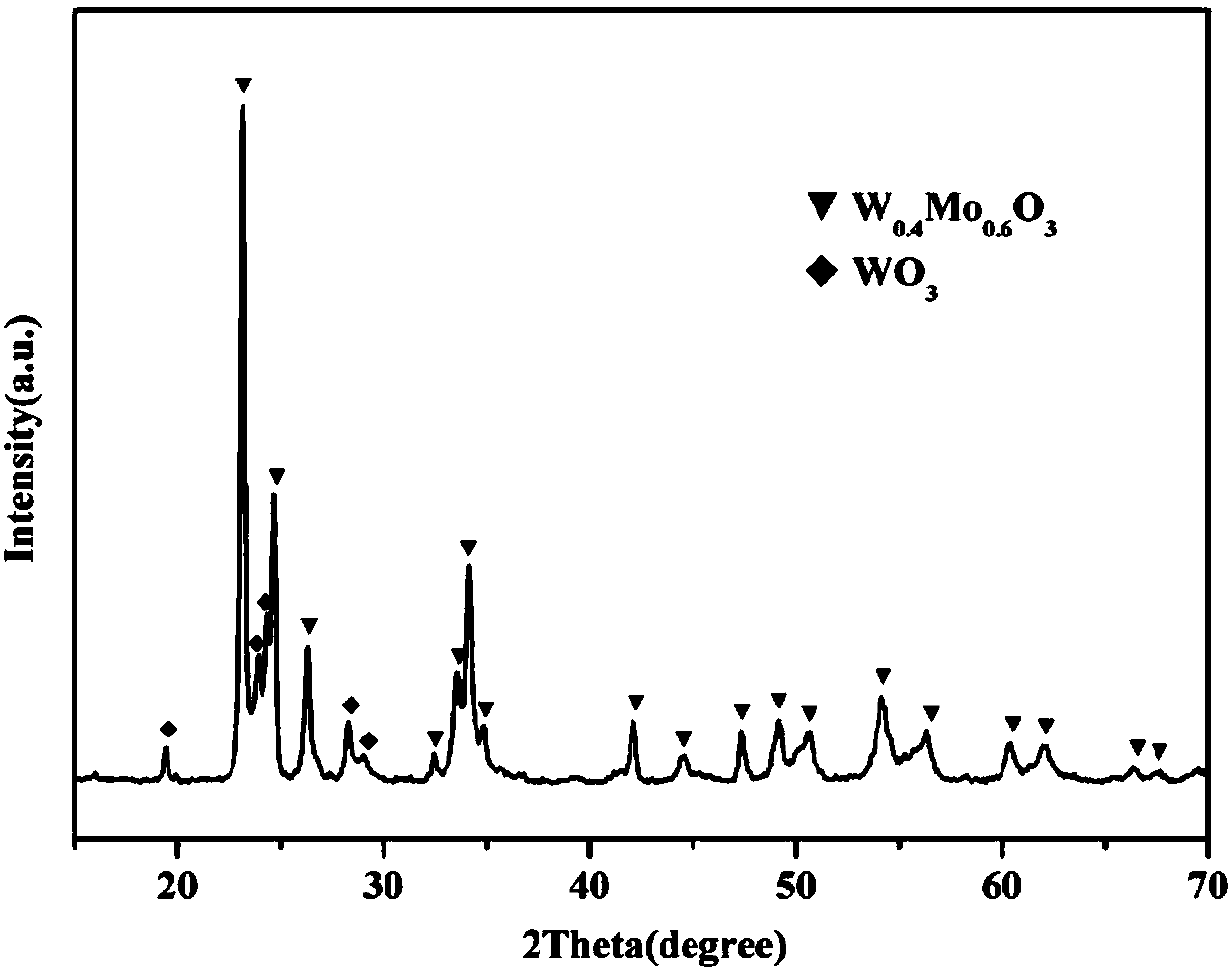

Preparation method of high-performance nano W0.4Mo0.6O3 photocatalyst

ActiveCN105664921AImprove photocatalytic performanceIncrease lattice defectsMetal/metal-oxides/metal-hydroxide catalystsPhoto catalyticPhotocatalytic reaction

The invention discloses a preparation method of a high-performance nano W0.4Mo0.6O3 photocatalyst. The preparation method comprises the following steps: uniformly mixing a C6H12O6.H2O aqueous solution, a Na2WO4.2H2O aqueous solution and a Na2MoO4.2H2O aqueous solution to obtain a solution mixture, adding a polyoxyethylene alcohol ether aqueous solution into the solution mixture, uniformly stirring, regulating the pH value to 1-2, performing hydrothermal reaction at 120-180 DEG C for 5-15 hours, performing aftertreatment to obtain powder, and removing carbon from the powder, thereby obtaining the high-performance nano W0.4Mo0.6O3 photocatalyst. The nano W0.4Mo0.6O3 photocatalyst has a nano granule structure, and has large specific surface area, so that the contact area between the photocatalyst and organic dye is enlarged, and photo-catalytic reaction is facilitated. The preparation method is simple and convenient, and is easy to implement.

Owner:SHAANXI UNIV OF SCI & TECH

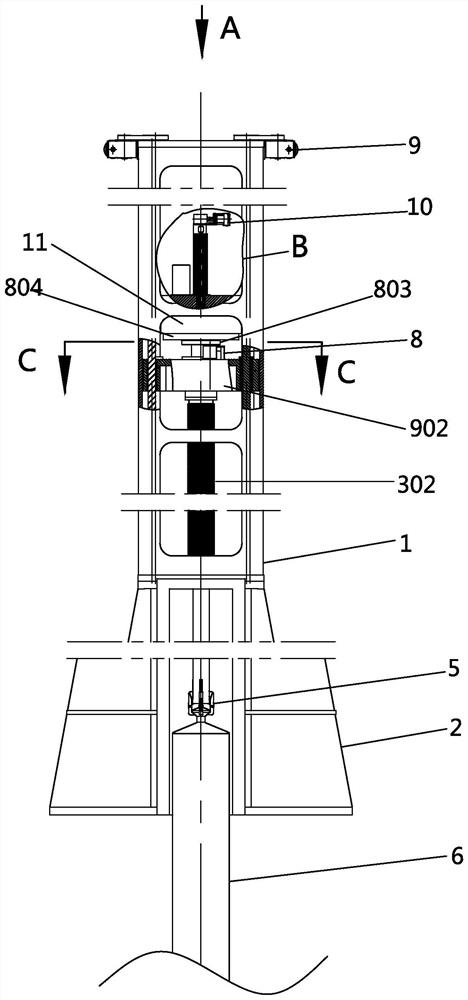

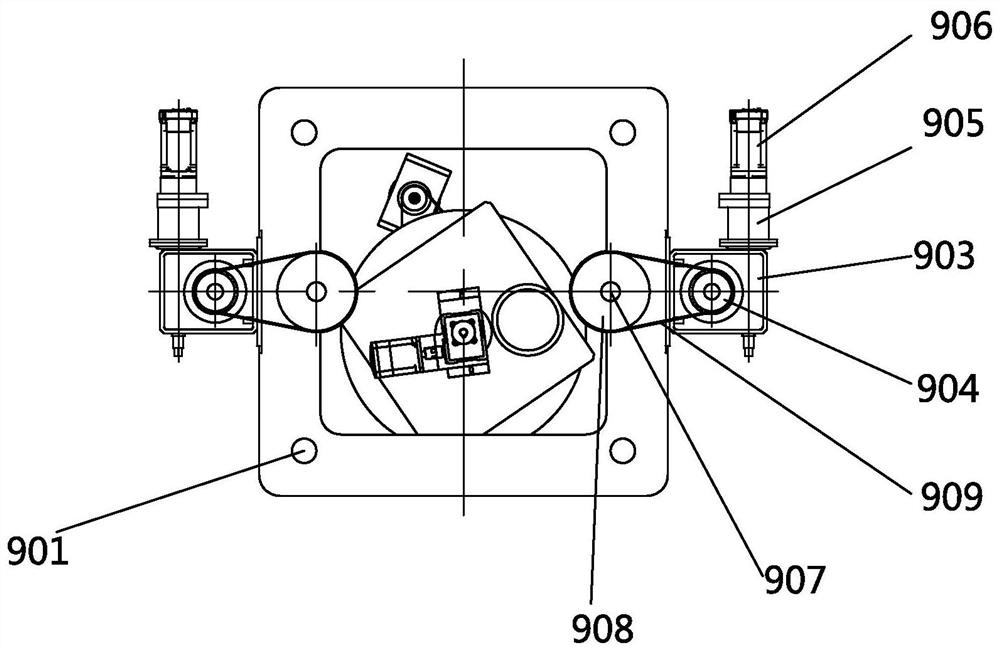

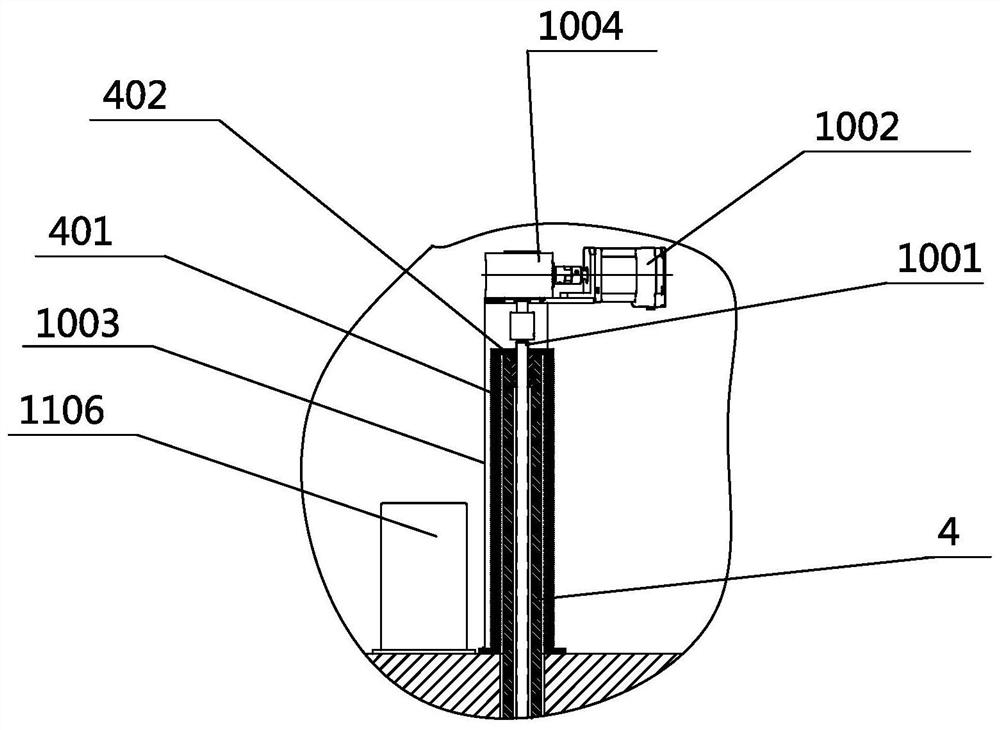

Hard-shaft heavy-load silicon single crystal lifting device

PendingCN111962141AStrong Strength and RigidityMake up for the lack of carrying capacityPolycrystalline material growthBy pulling from meltSeed crystalEngineering

The invention provides a hard-shaft heavy-load silicon single crystal lifting device, which comprises a support structure; a single crystal bearing outer hard shaft, wherein a single crystal claw is mounted at the bottom of the single crystal bearing outer hard shaft; a seed crystal bearing inner hard shaft, wherein a seed crystal chuck is mounted at the bottom of the seed crystal bearing inner hard shaft; a rotary driving device used for driving the single crystal bearing outer hard shaft to rotate; an outer hard shaft lifting device used for driving the single crystal bearing outer hard shaft to lift; and an inner hard shaft lifting device used for driving the seed crystal bearing inner hard shaft to lift. Synchronous rotating motion of the inner hard shaft and the outer hard shaft, independent lifting motion of the outer hard shaft and independent lifting motion of the inner hard shaft are achieved; the device has high strength and rigidity, can bear single crystals with the weightof 500 Kg or above, makes up the defect of insufficient bearing capacity of the flexible shaft lifting device, avoids the phenomena of flexible shaft swinging and simple pendulum resonance in the flexible shaft lifting device, and can overcome crystal disturbance caused by thermal field symmetry deviation, airflow excitation acting force symmetry deviation and the like.

Owner:连城凯克斯科技有限公司

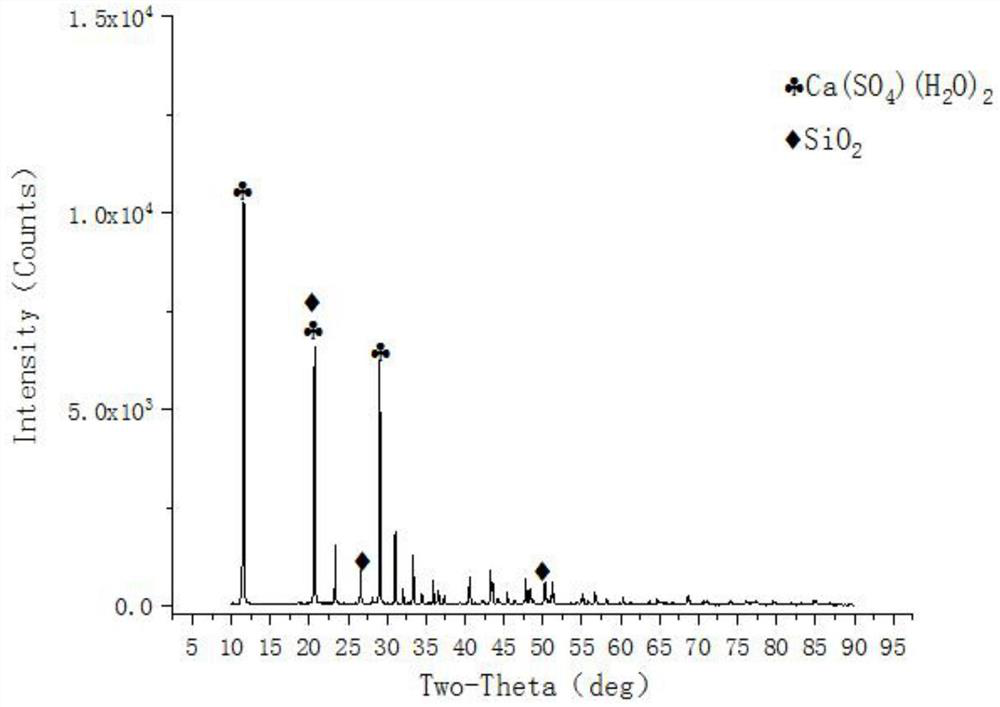

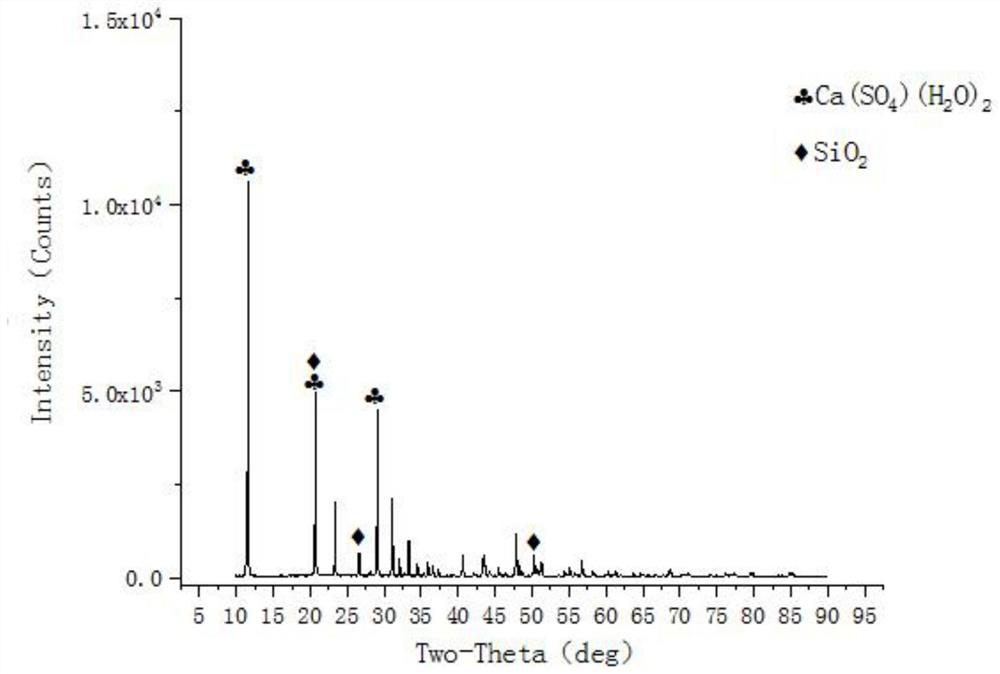

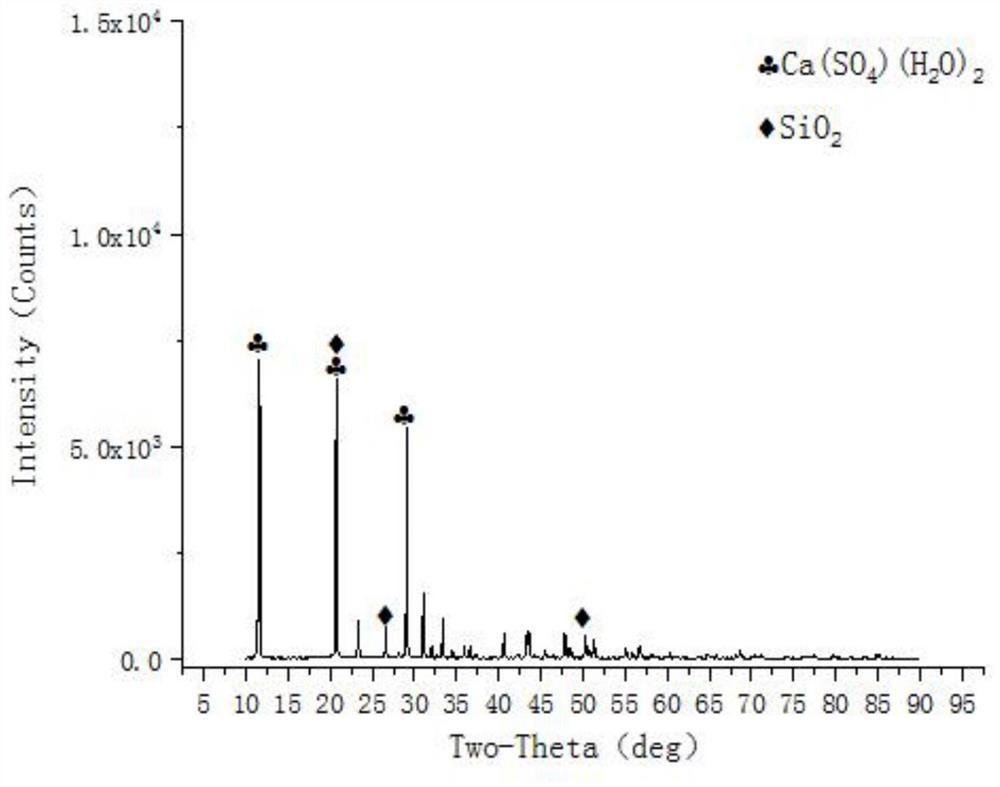

Method for improving gelling activity of ardealite

PendingCN111792862AGuaranteed infiltrationSmall granularityPhysical chemistryEnvironmental engineering

The invention discloses a method for improving the gelling activity of ardealite. The method comprises the following steps: (1) ageing phosphogypsum with water to obtain aged phosphogypsum; (2) carrying out wet grinding on the aged phosphogypsum to obtain wet-ground phosphogypsum; (3) roasting the wet-ground phosphogypsum, and cooling to obtain roasted phosphogypsum; and (4) respectively carryingout two-stage dump leaching on the roasted ardealite by using a medicament 1 and a medicament 2 to obtain the ardealite with improved gelling activity. The method has the advantages that the process is simple, the cost is low, the gelling activity of the phosphogypsum can be greatly improved, a building material prepared from the treated phosphogypsum is high in strength and strong in water leaching resistance, the doping amount can be larger than 70%, and a way is provided for large-scale use and comprehensive utilization of the phosphogypsum.

Owner:GUIZHOU UNIV

Fireproof inorganic quartz stone and preparation method thereof

The invention discloses fireproof inorganic quartz stone and a preparation method thereof. According to the preparation method, the raw materials are lightly sintered and sintered, so that a part of physical and chemical reactions of the raw materials can be completed, cremation of ore is realized, lattice defects are increased, sintering is promoted effectively, therefore, the preparation efficiency can be effectively improved; a double-sided hot-pressing mode is adopted for extrusion molding to obtain a green body, so that the green body is compact in structure, high in strength and small indrying and firing shrinkage, the size is easy to control, the layer density phenomenon of the green body can be effectively reduced, the total porosity of the green body is reduced, the fireproof performance can be effectively improved, and the using efficiency is increased; a plurality of times of extrusion is adopted, and extrusion time is prolonged, so that gas in the green body can be effectively and smoothly exhausted, the elasticity of the green body can be effectively improved, the strength of the green body can be effectively improved, the green body can be effectively prevented fromcracking, and the preparation efficiency of the green body can be effectively improved.

Owner:山东康洁利新材料有限公司

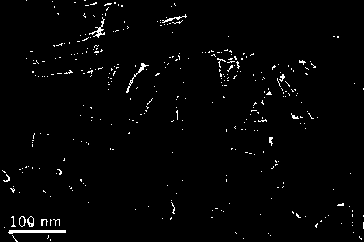

Preparation method of ferrous sulfide/attapulgite composite

InactiveCN108043425AAvoid uneven loadGood dispersionDispersed particle separationCatalyst activation/preparationDispersityAlcohol

The invention relates to a preparation method of a ferrous sulfide / attapulgite composite and belongs to the field of utilization of nonmetal mineral materials. The preparation method comprises the steps as follows: a certain amount of ferric nitrate, thioacetamide and attapulgite are weighed and added to deionized water for ultrasonic treatment and stirring, a mixed liquid is transferred to a reaction kettle to react at the temperature of 160-220 DEG C, water washing and alcohol washing are performed after the reaction, drying is performed, and the ferrous sulfide / attapulgite composite can beobtained. The prepared ferrous sulfide / attapulgite composite is uniform in loading and good in dispersity, experimental raw materials are easy to obtain, no complicated equipment is required, and theferrous sulfide / attapulgite composite has a good low-temperature conversion effect on nitrogen oxide under the assistance of light.

Owner:盱眙县中材凹凸棒石粘土有限公司

Aluminum-doped manganese dioxide-based flexible supercapacitor electrode material and preparation and application thereof

InactiveCN112447416ALow costReduce interventionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceActivated carbon

The invention relates to an aluminum-doped manganese dioxide-based flexible supercapacitor electrode material and preparation and application thereof, and the method comprises the steps: carrying outthe integrated generation of AlMnO2 nanosheets on an activated carbon cloth substrate through a hydrothermal reaction, and obtaining an AlMnO2@CC material, i.e., the aluminum-doped manganese dioxide-based flexible supercapacitor electrode material. Compared with the prior art, the preparation process is simple, the raw materials are simple and easy to obtain, and the prepared material is high in specific capacitance, good in cycling stability and suitable for various wearable portable products.

Owner:TONGJI UNIV

Electric field induced crystallization K<6.15>Zn<0.05>B<0.2>Al<0.1>P<0.05>Zr<0.05>Si<1.6>O<7> potassium fast ion conductor and preparation method thereof

InactiveCN110372348ALower activation energy for migrationFacilitate conductionSolid electrolytesSecondary cellsHigh concentrationElectrical conductor

The invention discloses an electric field induced crystallization K<6.15>Zn<0.05>B<0.2>Al<0.1>P<0.05>Zr<0.05>Si<1.6>O<7> potassium fast ion conductor and a preparation method thereof. Al<3+> and B<3+>are used for partially substituting Si<4+> ions, high-concentration interstitial potassium ions are generated in a crystal, and the reduction of the migration activation energy of potassium ions is facilitated; the electron conductivity of the fast ion conductor is further reduced by doping P<5+>; the size of migration channels of the potassium ions is adjusted by doping B<3+> with a small ionicradius to adapt to the rapid migration of the potassium ions; Zr<4+> is partially doped to form a distorted lattice structure to increase lattice imperfection to facilitate potassium ion conduction; cation vacancies are generated by doping Zn<2+> to increase migratory routes of the potassium ions; and the surface of K6Si2O7 particles is modified during the preparation to form an easy-sintering property. Meanwhile, the introduction of a strong direct current electric field induces crystallization to accelerate the crystallization rate, lower the crystallization temperature and increase the crystal integrity. The synergistic effects enable normal temperature potassium ion conductivity of the potassium fast ion conductor to exceed 5*10<-4> S / cm and to be closer to the potassium ion conductivity of a liquid electrolyte.

Owner:NINGBO UNIV

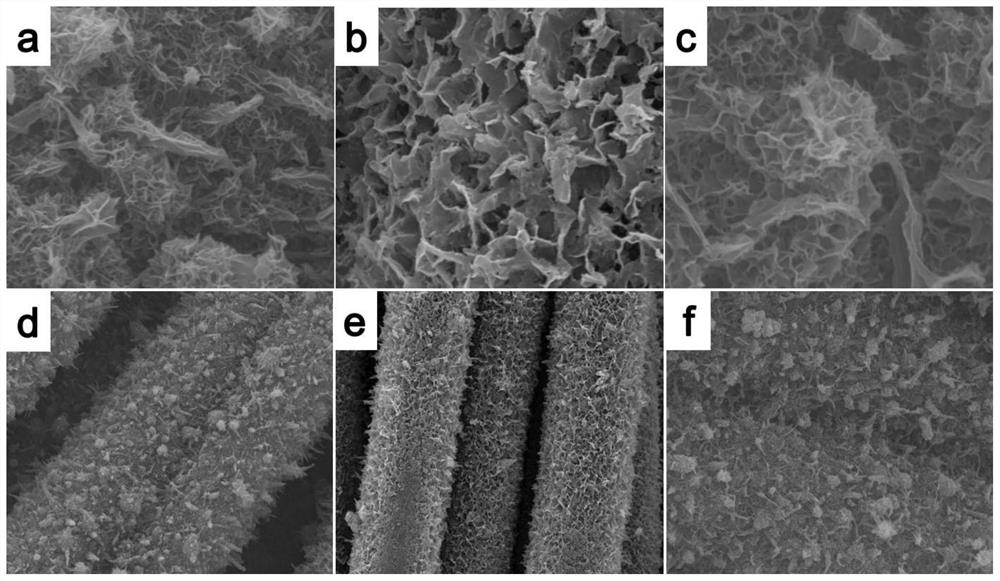

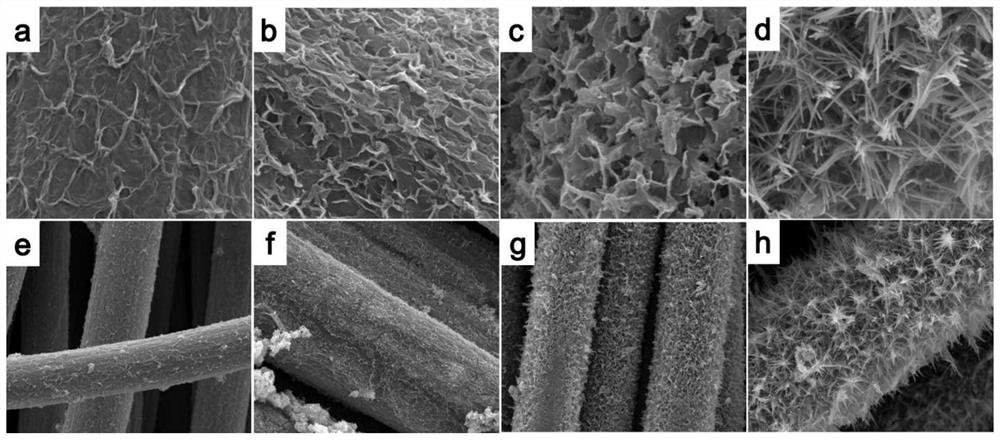

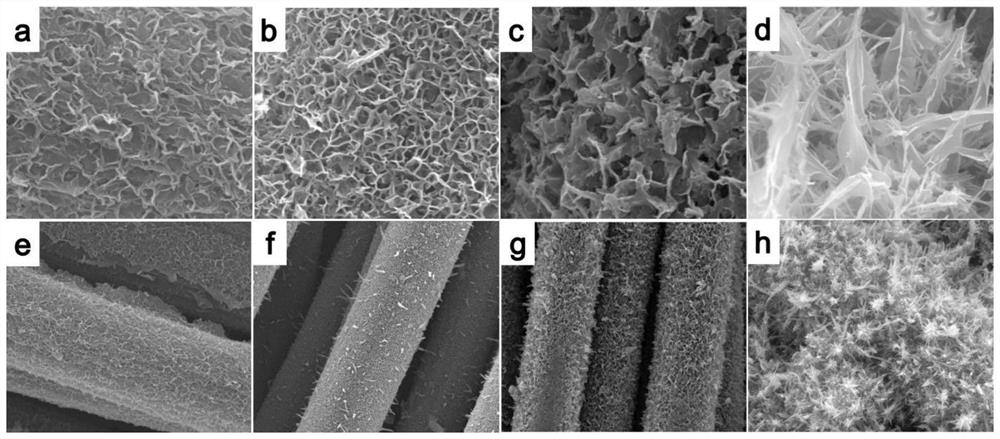

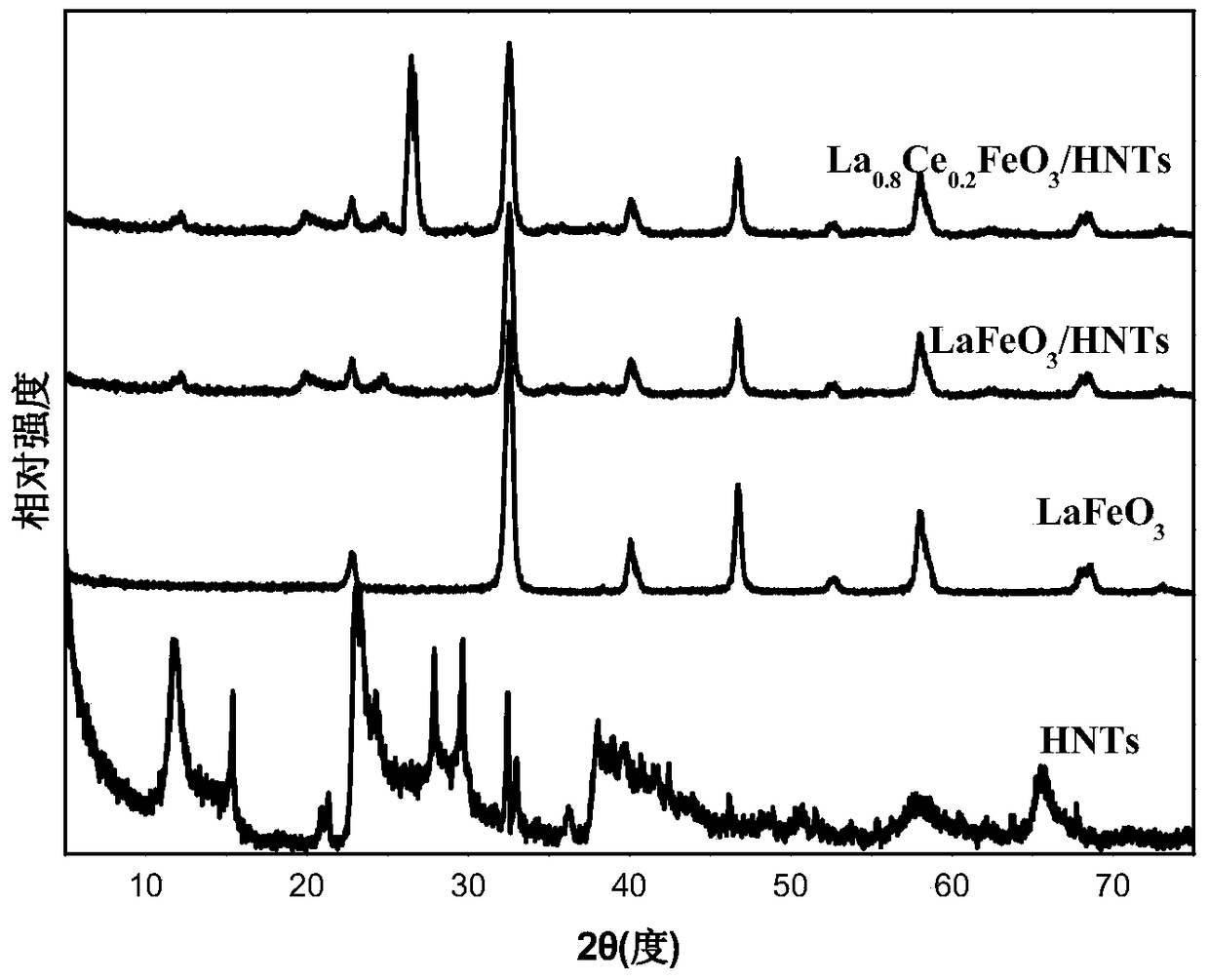

A kind of preparation method and application of clay-perovskite composite material

ActiveCN105688918BSmall particle sizeAvoid uneven loadWater/sewage treatment by irradiationEnergy based wastewater treatmentChemical industryPtru catalyst

The invention belongs to the field of energy and chemical industry, and specifically relates to a preparation method of nanomaterials using clay as a carrier and perovskite compound nanoparticles as active components and its application in photocatalytic degradation of antibiotics. Add lanthanum nitrate, ferric nitrate, cerium nitrate, citric acid and clay to deionized water and stir, then transfer to a water bath to evaporate to obtain a wet gel, dry, calcine, dry and grind to obtain the lanthanum ferrite / clay nanostructure composite Material. The composite material is used to photocatalytically degrade antibiotics, and the high photocatalytic activity of (cerium-doped) lanthanum ferrite is used to quickly decompose antibiotics under visible light; the clay carrier is conducive to the adsorption of antibiotic molecules during the degradation of antibiotics. After adsorption to the surface of the catalyst, it comes into contact with lanthanum ferrite, and the antibiotic molecules decompose under the irradiation of visible light to produce other active species.

Owner:CHANGZHOU UNIV

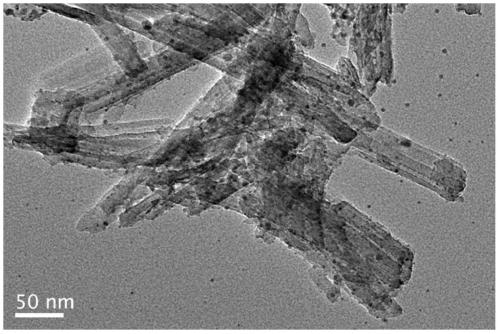

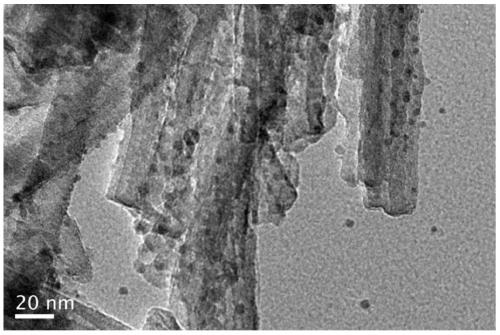

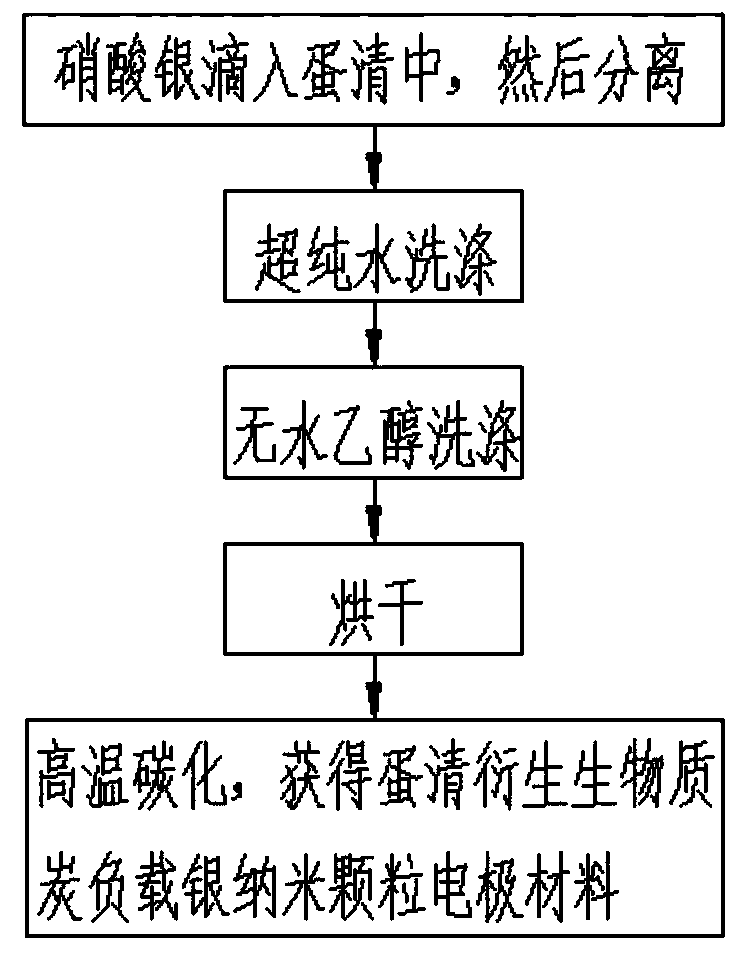

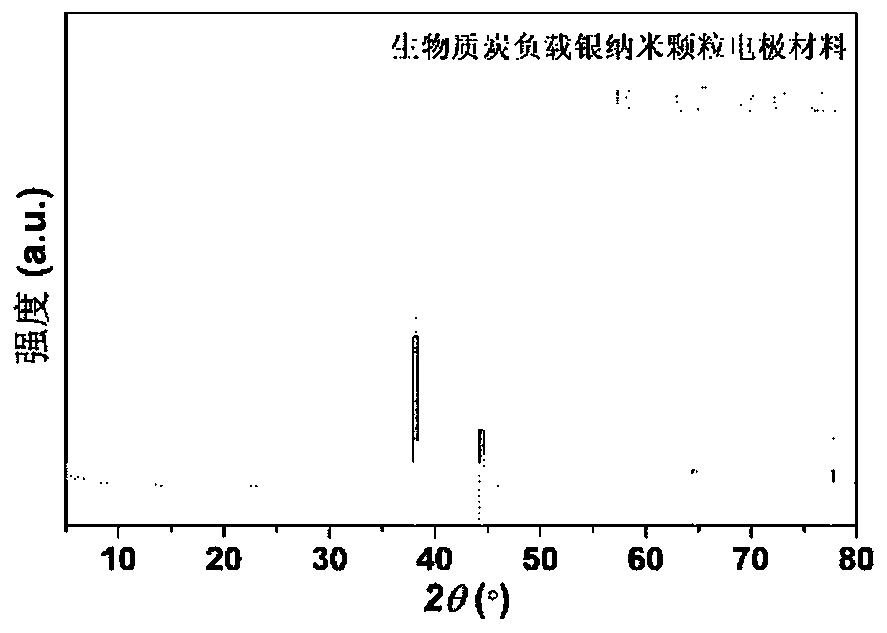

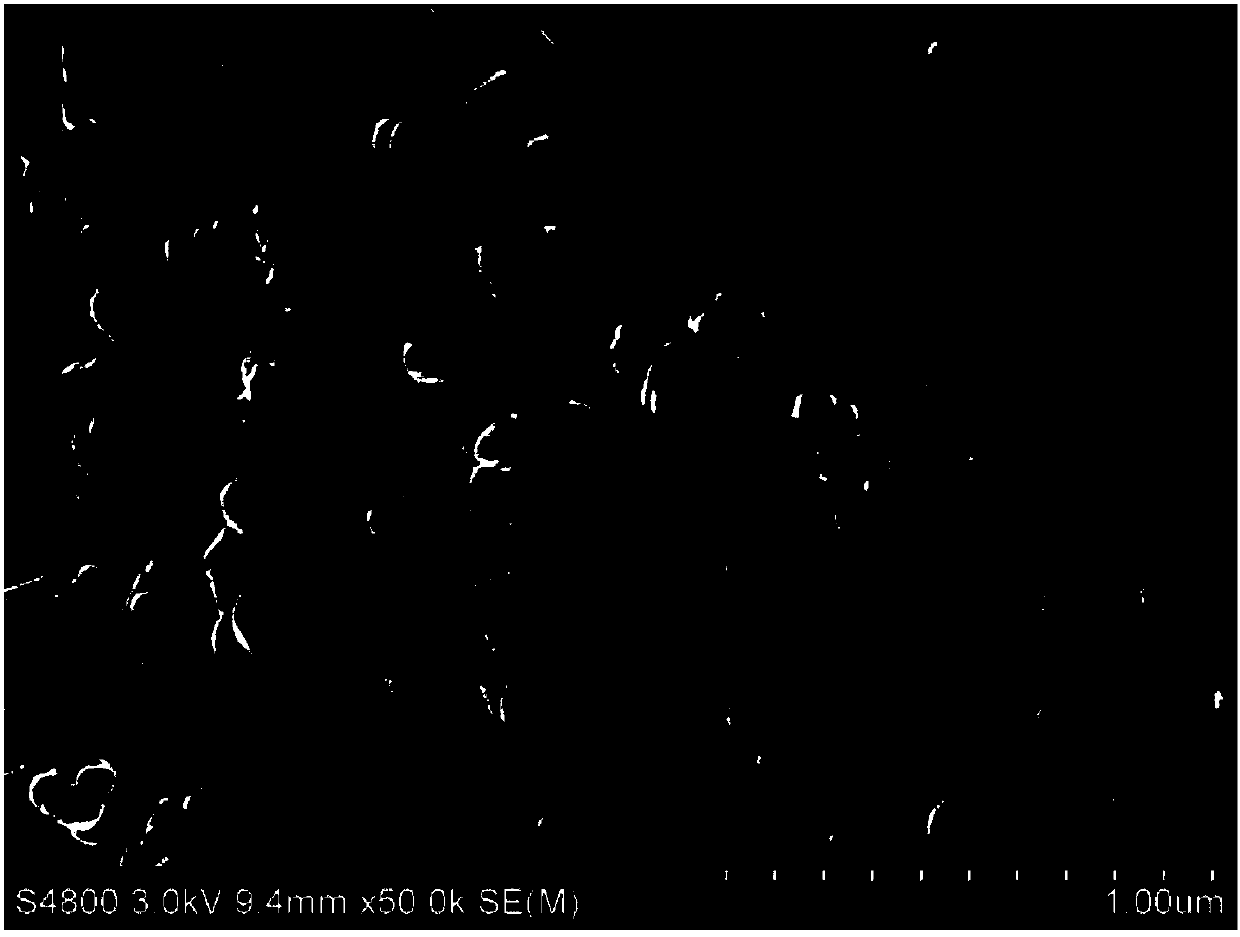

Egg white derived biomass charcoal loaded silver nanoparticle electrode material and preparation method thereof

ActiveCN111029168AIncrease contentSimple structureHybrid capacitor electrodesHybrid/EDL manufactureHeat treatedProtein

The invention relates to an egg white derived biomass charcoal loaded silver nanoparticle electrode material and a preparation method thereof. The material is characterized in that the characteristicthat protein in egg white carries negative charge functional groups is utilized, the egg white is selected as a biomass carbon source, the protein denaturation reaction with metal silver ions with positive charges is carried out, a multi-heteroatom doped biomass charcoal loaded silver nanoparticle electrode material is prepared through one-step high-temperature heat treatment reaction on the premise of not using other chemical reagents by utilizing the distribution uniformity of atoms and charges of biomass, and the obtained material has a stable super-large sheet structure and excellent electrochemical performance. The method has the advantages of being scientific, reasonable, safe, easy to implement, simple, low in cost, controllable in product morphology and structure and the like, is suitable for the batch production of biomass charcoal loaded silver nanoparticle electrode materials, and can also be expanded to be used for the controllable and macro preparation of biomass charcoalloaded other metal elementary substance electrode materials.

Owner:NORTHEAST DIANLI UNIVERSITY

A kind of production method of magnesium-doped hydroxyapatite defluoridation filter material

InactiveCN106744766BPlay a synergistic roleHigh purityWater/sewage treatment by neutralisationPhosphorus compoundsLattice defectsApatite

The invention discloses a production method of a magnesium-doped hydroxyapatite defluorination filter material. The method comprises the steps of adopting industrial calcium salt, phosphoric acid, ammonia water and soluble magnesium salt as raw materials; mixing the soluble magnesium salt and calcium salt with determined addition quality into paste, and adding the paste to a reaction kettle for stirring evenly; preparing a phosphoric acid solution according to the volume ratio of the phosphoric acid to water; dropwise adding the solution to the reaction kettle and simultaneously dropwise adding ammonium hydroxide to the reaction kettle to keep the pH value of a reaction system within a set range in real time; and carrying out stirring, standing and ageing, taking out a product, filtering, drying and crushing to obtain a magnesium-doped hydroxyapatite powder filter material. Due to doping of a little of magnesium, the structure of hydroxyapatite can distort, lattice defects are increased, the crystallinity is reduced, the grain size is reduced, the specific surface area is increased, and the physical adsorption reaction of the surface is added, so that the magnesium-doped hydroxyapatite defluorination filter material plays a synergistic role in defluorination of the hydroxyapatite, and the defluorination capacity of a product is improved.

Owner:CHINA UNIV OF MINING & TECH

a nano w 0.4 mo 0.6 o 3 Preparation method of high-performance photocatalyst

ActiveCN105664921BImprove photocatalytic performanceIncrease lattice defectsMetal/metal-oxides/metal-hydroxide catalystsPhoto catalyticPhotocatalytic reaction

A kind of nano W 0.4 Mo 0.6 O 3 Preparation method of high-performance photocatalyst, C 6 H 12 O 6 ·H 2 O aqueous solution, Na 2 WO 4 ·2H 2 O aqueous solution, Na 2 MoO 4 ·2H 2 Mix the O aqueous solution evenly to obtain a mixed solution. Add the polyoxyethylene fatty alcohol ether aqueous solution to the mixed solution. Stir evenly and adjust the pH value to 1 to 2. Then perform a hydrothermal reaction at 120 to 180°C for 5 to 15 hours. Post-processing Obtain powder, remove the carbon element in the powder, and obtain nano-W 0.4 Mo 0.6 O 3 High performance photocatalyst. W prepared by the present invention 0.4 Mo 0.6 O 3 Nanomaterials have a nanoparticle structure and have a large specific surface area, which increases the contact area between the photocatalyst and the organic dye, which is beneficial to the progress of the photocatalytic reaction. The preparation method of the invention is simple and easy to implement.

Owner:SHAANXI UNIV OF SCI & TECH

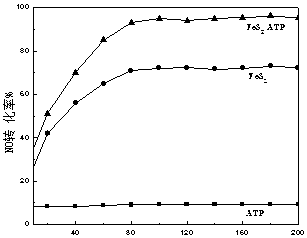

A kind of lanthanum cobaltate/attapulgite/reduced graphene oxide nanostructure composite material and its preparation method and application

ActiveCN107159223BEvenly dispersedImprove composite effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano structuring

The invention belongs to the field of new chemical materials, and particularly relates to a lanthanum cobaltate / attapulgite / reduced graphene oxide nanostructure composite material and its preparation method and application. First, prepare lanthanum cobaltate / attapulgite by sol-gel method, add it to deionized water, acidify and adjust the pH to obtain a positively charged lanthanum cobaltate / attapulgite aqueous solution; prepare graphite oxide through hydrazine hydrate reduction method That is, the negatively charged reduced graphene oxide is obtained, and is mixed with the lanthanum cobaltate / attapulgite aqueous solution. After the water bath stirring reaction is dried, the perovskite / attapulgite / reduced graphene oxide composite material is obtained. The composite material is The catalyst performs photo-SCR denitration and removes NO in the low temperature range of 100℃-200℃. x The conversion rate can reach more than 95%.

Owner:CHANGZHOU UNIV

a crystalline state 3 ocl inorganic lithium ion conductor and its preparation method and application

ActiveCN111484042BPromote dehydrogenation reactionIncrease lattice defectsSecondary cellsLithium halidesLithium oxideLithium chloride

The invention discloses a crystalline Li 3 OCl inorganic lithium ion conductor and its preparation method and application; The Li 3 OCl inorganic Li-ion conductor is Zn-doped Li 3 OCl, the preparation method is as follows: mix lithium hydroxide, lithium oxide and lithium chloride in proportion, and melt them above the eutectic point of the three to obtain a precursor; Zn-doped Li 3 OCl. Li provided by the present invention 3 OCl inorganic lithium ion conductor has excellent lithium ion conductivity and environmental stability. The preparation method provided by the invention has short preparation period, low cost and high process controllability, and is suitable for industrial application.

Owner:CHANGSHA STORM ENERGY TTECH

Vanadium and palladium-codoped nanometer titania gas-sensitive material as well as preparation method and applications thereof

InactiveCN103101973BGood effectHigh sensitivityMaterial nanotechnologyTitanium dioxideChlorobenzeneAlcohol

The invention relates to a vanadium and palladium-codoped nanometer titania gas-sensitive material as well as a preparation method and applications thereof. The preparation method of the codoped nanometer titania gas-sensitive material comprises the steps of: taking nanometer titania as a matrix, and doping 0.5-1.5mol% of vanadium and 1.0-3.5mol% of palladium, mixing a Pd(NO3)2 solution with a vanadium triisopropoxy oxide alcohol solution and dropwise adding the mixture into a tetrabutyl titanate ethylene glycol solution to obtain gel, drying, grinding and calcining to obtain the vanadium and palladium-codoped nanometer titania gas-sensitive material, wherein the particle size of the vanadium and palladium-codoped nanometer titania ranges from 8 to 15nm. The invention further provides a preparation method of the material. The gas-sensitive material is used for a gas-sensitive sensor for detecting chlorobenzene, is high in sensitivity, good in selectivity, short in response-restoration time, and beneficial to realizing the fast detection of the chlorobenzene.

Owner:QUFU NORMAL UNIV

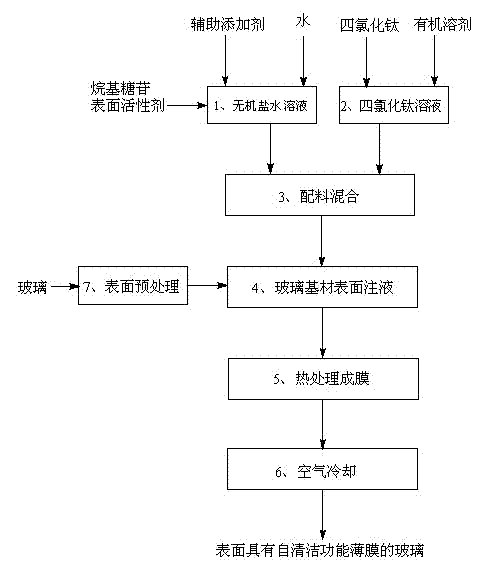

Preparation method of glass with surface having self-cleaning function film

ActiveCN102951847BQuality improvementImprove self-cleaning functionInorganic saltsElectrical battery

A preparation method of glass with the surface having a self-cleaning function film comprises the following steps: 1, preparing an aqueous solution of an inorganic salt; 2, preparing a titanium tetrachloride solution; 3, ingredient mixing: carrying out dispersion mixing of the aqueous solution of the inorganic salt prepared in step 1 and the organic solution of titanium tetrachloride prepared in step 2 to obtain an oil-water type liquid-liquid dispersion system; 4, injecting an adhesive to the surface of the base of glass; 5, carrying out heat treatment to form a film; and 6, carrying out air cooling to obtain the glass with the surface having the self-cleaning function film. The glass with the surface having the self-cleaning function film is used as a functional glass product used for solar photovoltaic batteries or electric light sources. The preparation method has the advantages of reasonable and convenient preparation technology, low production cost, safe and reliable preparation process, thorough reaction, good prepared product quality, high yield, and benefiting for the large-scale production. The preparation method provides conditions for the process industrialization, and the preparation method is simple, convenient and rapid.

Owner:YANGZHOU TONGHE GLASS

Preparation method and application of oxygen-doped cobalt nickel phosphide-reduced graphene oxide composite material

ActiveCN110323073BImprove conductivityReduce oxygen contentHybrid capacitor electrodesHybrid/EDL manufactureNickel phosphateCapacitance

The invention belongs to the technical field of composite materials, particularly relates to an oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material, and further disclosesapplication of an electrode material of a supercapacitor. In the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material, an oxygen-doped cobalt nickel phosphate electrode material with small grain size and large specific area is effectively prepared by decomposition of sodium hypophosphite in medium and low temperatures, the surface potential is effectively adjusted bymodification, so that tight and uniform recombination with graphene oxide is achieved, the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material is prepared, the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material is richer in surface holes, smaller in grain size of active material and more excellent in electrochemical performance, excellent specific capacitance, charge-discharge cycle stability and rate performance are shown when the oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material is used as the supercapacitor electrode material, and the specific capacitance and the charge-discharge cycle stability of the supercapacitor can be remarkably improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Lanthanum-yttrium-codoped nano-titanium dioxide gas-sensitive material as well as preparation method and application thereof

InactiveCN103159255BQuick checkGood effectMaterial nanotechnologyMaterial analysis by electric/magnetic meansGas detectorYttrium

Owner:QUFU NORMAL UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com