Synthetic method for high-activity N-F co-doped bismuth vanadate visible light photocatalytic material

The technology of a photocatalytic material and a synthesis method is applied in the field of preparing N-F co-doped bismuth vanadate photocatalytic material, which can solve the problems of low visible light catalytic efficiency and the like, and achieve the effects of cheap and easy-to-obtain raw materials, good dispersibility and good degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the bismuth vanadate of the present embodiment may further comprise the steps:

[0028] 1) With a mass percentage of 97% Bi(NO 3 ) 3 ·5H 2 O, 98.5% NH 4 VO 3 As the source material, citric acid with a mass percentage of 99.5% was used as a chelating agent, and 4.8580 g (0.01 mol) of Bi(NO 3 ) 3 ·5H 2 O and 4.2028 g (0.02 mol) of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), add citric acid monohydrate to 50mL Bi(NO 3 ) 3 ·5H 2 O solution, A solution was obtained. Weigh 0.01 mol, 1.1698 g of NH at a molar ratio of 1:2 4 VO 3 and 0.02 mol, 4.2028 g of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), solution B dissolved in 50 mL of boiling distilled water. Mix liquid A and liquid B according to the molar ratio of Bi:V=1:1, adjust the pH value to 6-7 with ammonia water, keep stirring at 80 °C, evaporate, and finally obtain the dark blue bismuth vanadate precursor sol.

[0029] 2) The dried bismuth vanadate precursor sol was put i...

Embodiment 2

[0033] 1) With a mass percentage of 97% Bi(NO 3 ) 3 ·5H 2 O, 98.5% NH 4 VO 3 As the source material, citric acid with a mass percentage of 99.5% was used as a chelating agent, and 4.8580 g (0.01 mol) of Bi(NO 3 ) 3 ·5H 2 O and 4.2028 g (0.02 mol) of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), add citric acid monohydrate to 50mL Bi(NO 3 ) 3 ·5H 2 O solution to obtain A solution; weigh 0.01 mol, 1.1698 g of NH with a molar ratio of 1:2 4 VO 3 and 0.02 mol, 4.2028 g of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), dissolved in 50mL boiling distilled water to obtain liquid B; mix liquid A and liquid B according to the molar ratio of Bi:V=1:1, and 4 The molar ratio of F to Bi is 2% and NH is added 4 F in the mixed solution, and then adjust the pH value to 6-7 with ammonia water, continue to stir at 80 ° C, evaporate, and finally obtain the dark blue bismuth vanadate precursor sol.

[0034] 2) The dried bismuth vanadate precursor sol was put into a muffle furna...

Embodiment 3

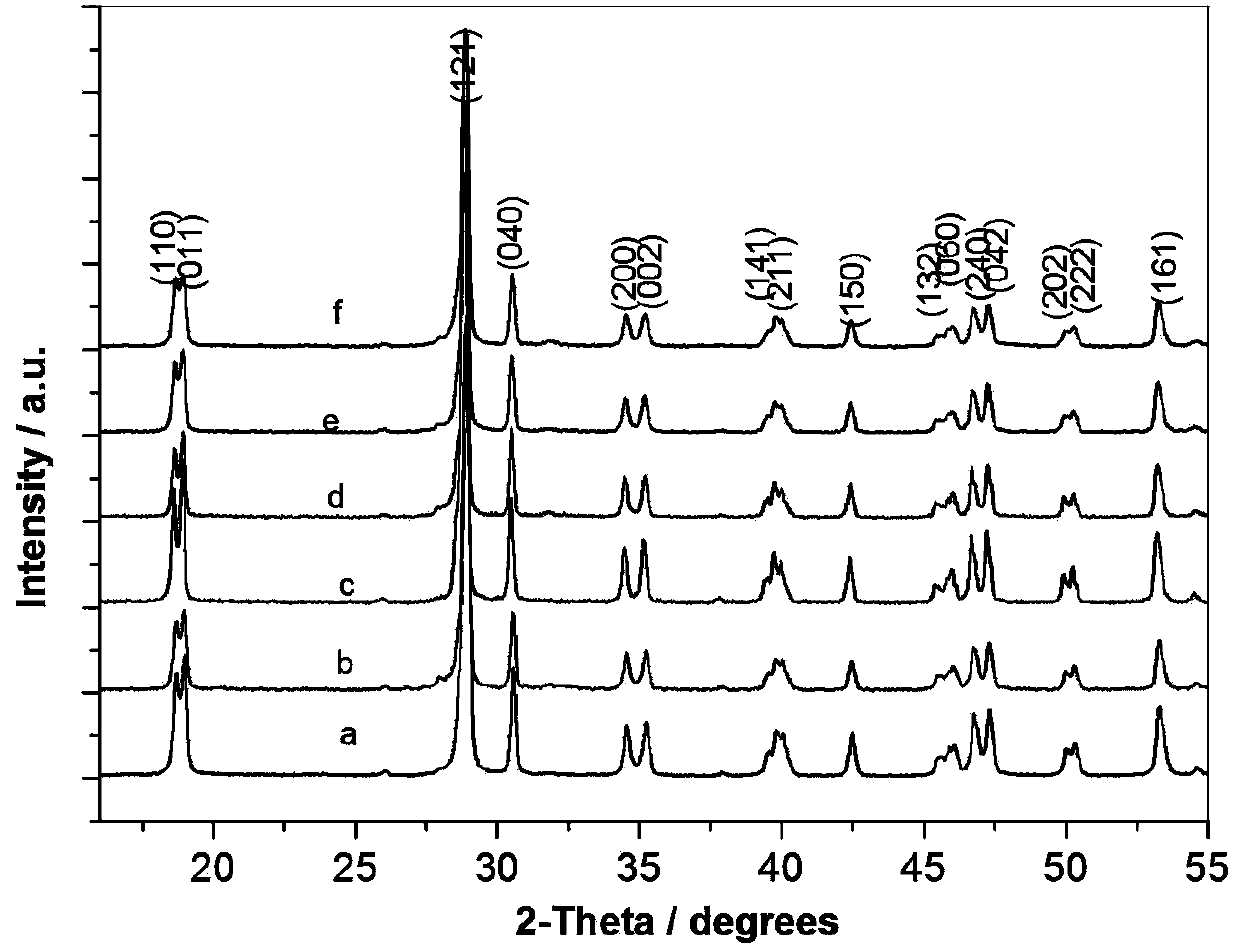

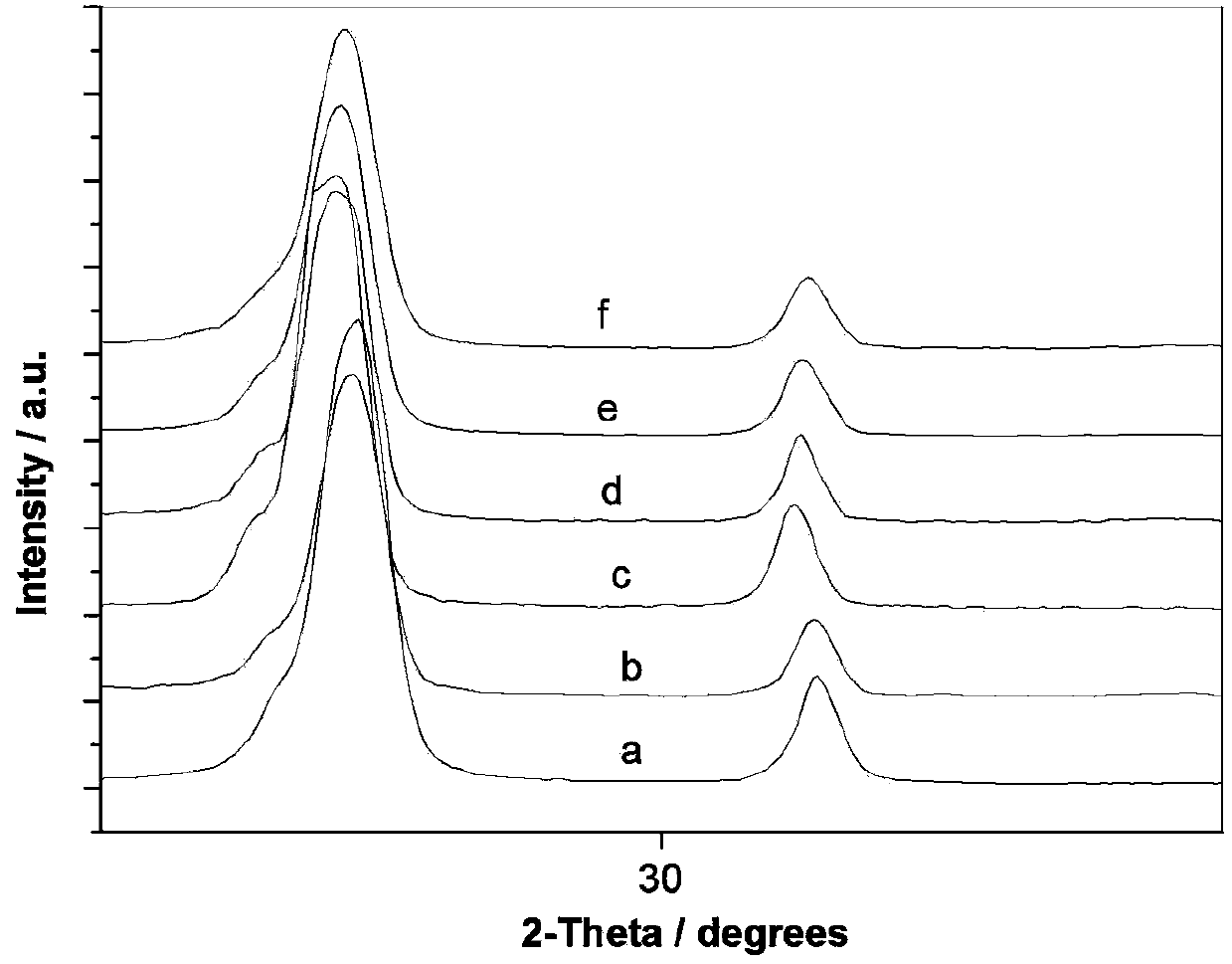

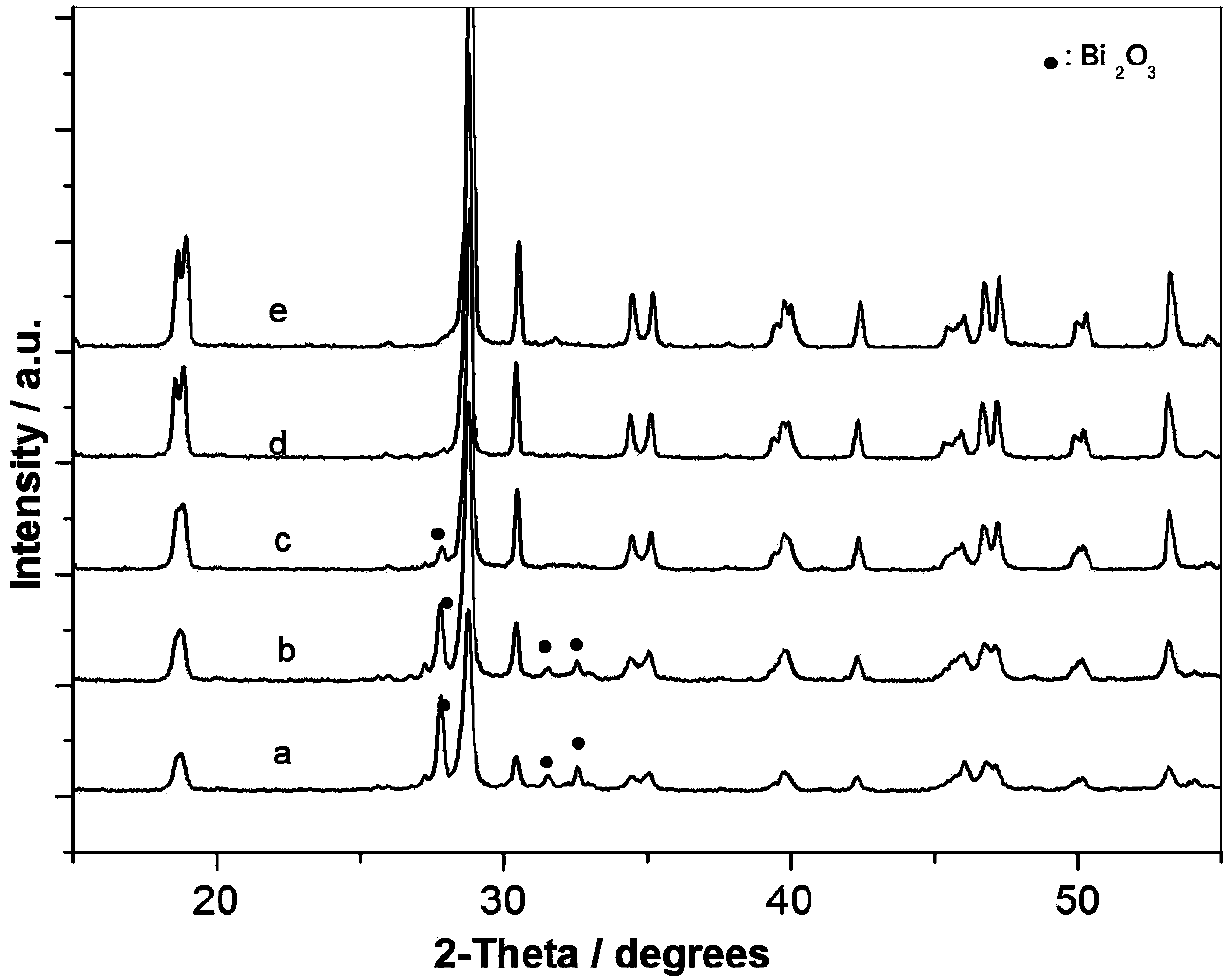

[0038] According to the preparation method of the present invention of embodiment 2, different conditions are: NH 4 The molar ratio of F and Bi is changed to 4%, and the bismuth vanadate photocatalytic material of 4% N-F is prepared, and the UV-vis spectrum of the obtained product is shown in figure 1 (c), BiVO synthesized in this example 4 The optical absorption threshold of 556nm, the forbidden band width is 2.23 eV. figure 2 (c) is the XRD pattern of the product, the BiVO synthesized in this example 4 at 18.7 o , 28.8 o , 30.5 o , 34.5 o , 35.1 o , 37.8 o , 39.8 o , 42.4 o , 47.2 o , 53.2 o , 59.8 o , 63.6 o , 69.3 o The diffraction peak at the position is the characteristic peak of monoclinic bismuth vanadate, but the characteristic peak is obviously shifted to a small angle, and the unit cell volume is 310.33 nm 3 .

[0039] The photocatalytic performance of the synthesized bismuth vanadate was detected according to the method described in Example 1, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com