Vanadium and palladium-codoped nanometer titania gas-sensitive material as well as preparation method and applications thereof

A technology of nano-titanium dioxide and gas-sensing materials, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, and nanotechnology for materials and surface science. -Short recovery time, reduced generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

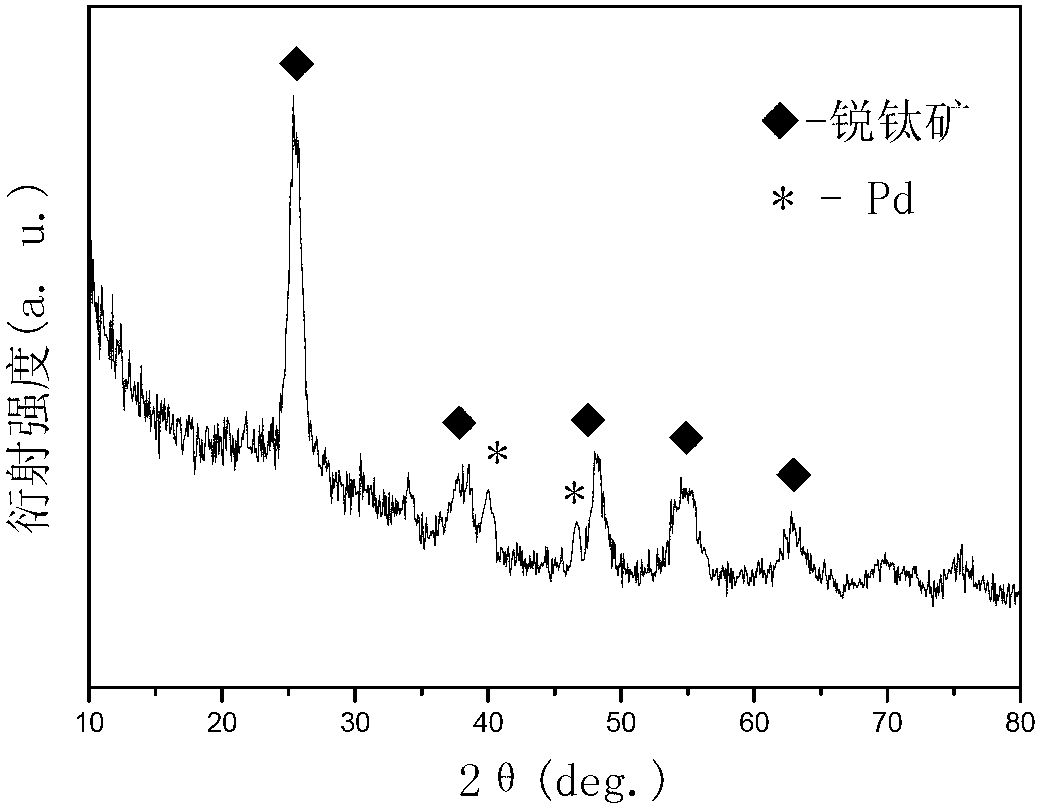

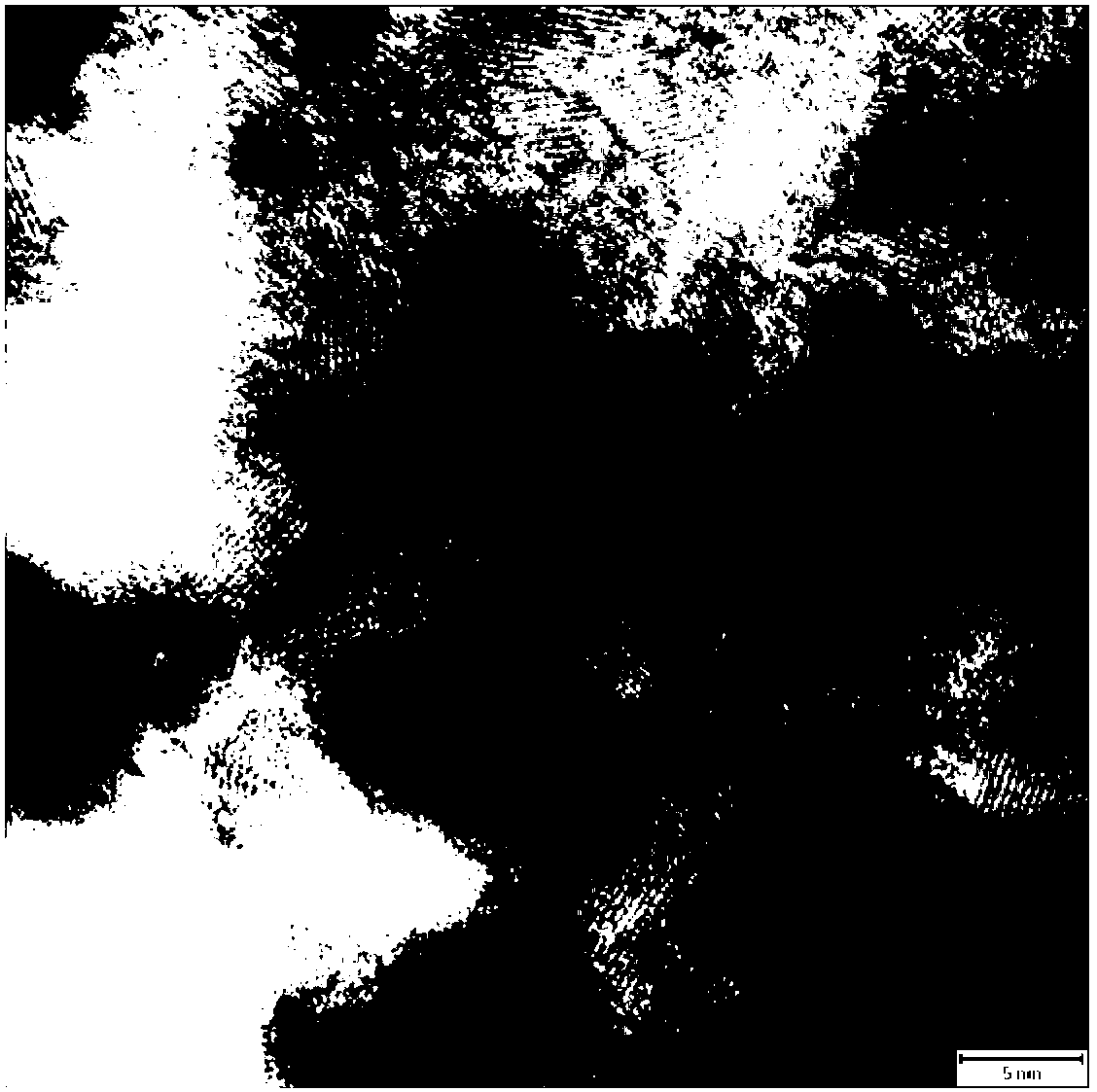

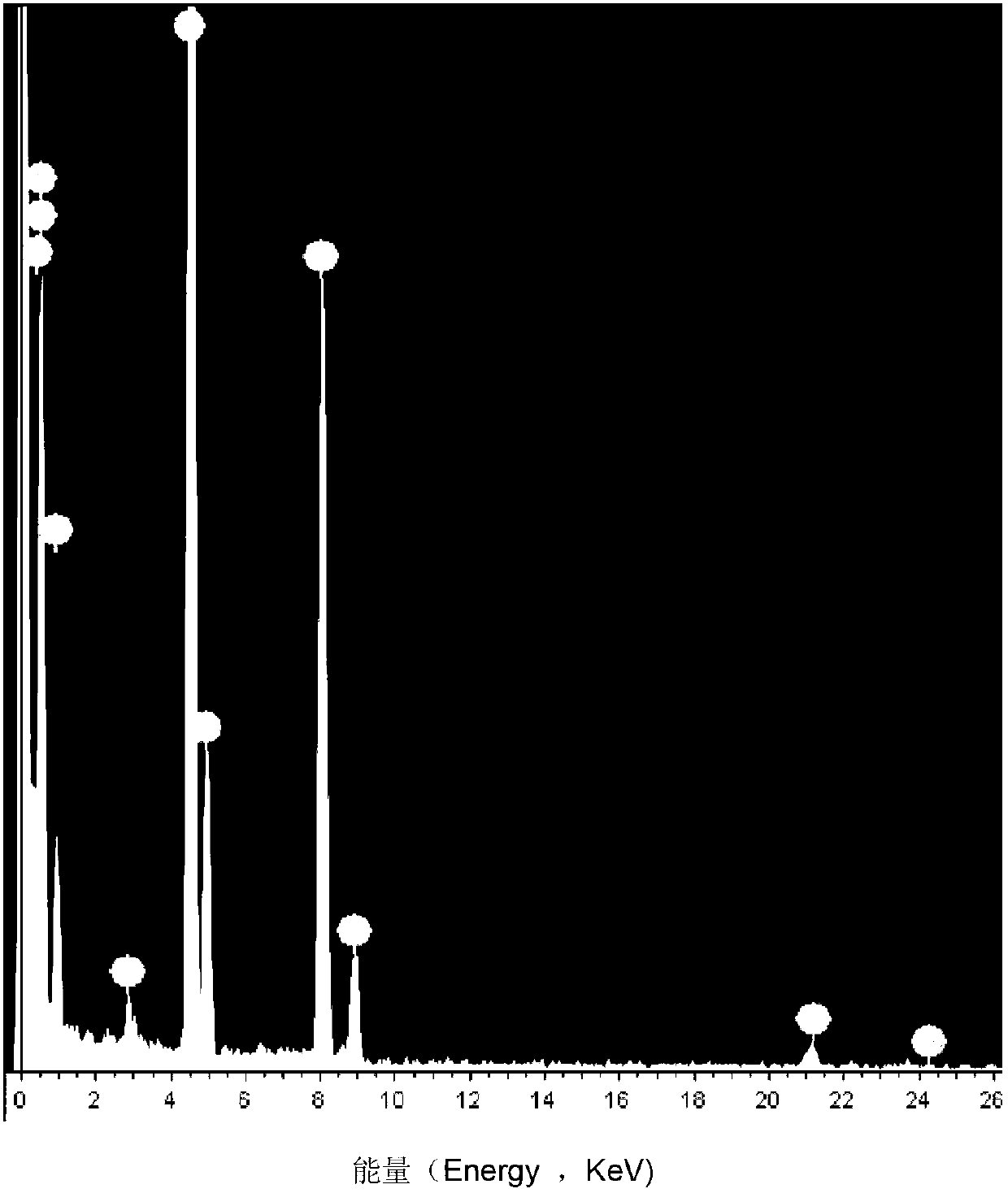

[0040] Vanadium and palladium co-doped nano-titanium dioxide gas-sensing materials, with nano-titanium dioxide as the matrix, based on the amount of titanium dioxide, the molar percentage of doped vanadium is 1.5%; the molar percentage of palladium is 3%; the co-doped nano The average particle diameter of titanium dioxide is 8 nm.

[0041] The preparation steps are as follows:

[0042] (1) Weigh 7.5mgPd(NO 3 ) 2 .2H 2 O was dissolved in 15 mL of double distilled water to obtain solution A.

[0043] (2) Dissolve 3.4 mg of vanadyl triisopropoxide in 10 mL of ethanol to obtain solution B.

[0044] (3) Measure 0.3196mL of tetrabutyl titanate and add it dropwise to 5mL of ethylene glycol, stir at room temperature for 30min, and use 6mol·dm -3 Adjust the pH to 3 with nitric acid to obtain solution C.

[0045] (4) After mixing the solution A prepared in step (1) and the solution B prepared in step (2) and stirring evenly, add the mixed solution dropwise to the solution C prepar...

Embodiment 2

[0049] Embodiment 2, application of vanadium, palladium co-doped nano-titanium dioxide gas-sensing material

[0050] Take 5 mg of the vanadium and palladium co-doped nano-titanium dioxide powder prepared in Example 1, grind it finely, add a small amount of deionized water to make a paste, apply it evenly on the alumina ceramic tube, and place it in a muffle furnace at 300 °C Internally sintered for 2 hours to form a tube core, which is welded and packaged according to the conventional process of side-heated devices to obtain a gas sensor device. After 120 hours of electrical aging, the properties of the gas sensor were measured with a HW-30A gas sensor tester.

[0051] At an operating temperature of 175°C, the sensitivity to 100 ppm of chlorobenzene was tested. From the response-recovery curve of the gas sensor to 100ppm chlorobenzene, such as Figure 4 shown. It can be seen that the response and recovery time of chlorobenzene are 12s and 28s respectively.

Embodiment 3

[0052] Embodiment 3, vanadium, palladium co-doped nano-titanium dioxide gas-sensitive material, as described in Example 1, the difference is: the molar percentage of doped vanadium is 0.5%; the molar percentage of palladium is 1%; co-doped The average particle size of nano titanium dioxide is about 12nm.

[0053] The preparation steps are as follows:

[0054] (1) Weigh 2.5mgPd(NO 3 ) 2 .2H 2 O was dissolved in 15 mL of double distilled water to obtain solution A.

[0055] (2) Dissolve 1.1 mg of vanadyl triisopropoxide in 10 mL of ethanol to obtain solution B.

[0056] (3) Measure 0.3196mL of tetrabutyl titanate and add it dropwise to 5mL of ethylene glycol, stir at room temperature for 30min, and use 6mol·dm -3 Adjust the pH to 3 with nitric acid to obtain solution C.

[0057] (4) After mixing the solution A prepared in step (1) and the solution B prepared in step (2) and stirring evenly, add the mixed solution dropwise to the solution C prepared in step (3) with a const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com