Oxygen-doped cobalt nickel phosphate-reduction oxygen graphene composite material and application thereof

A technology of composite materials and cobalt phosphide, which is applied in the field of composite materials, can solve the problems of affecting the performance of electrode materials and poor electrochemical performance of materials, and achieve the effects of improving transfer efficiency, excellent electrochemical performance and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

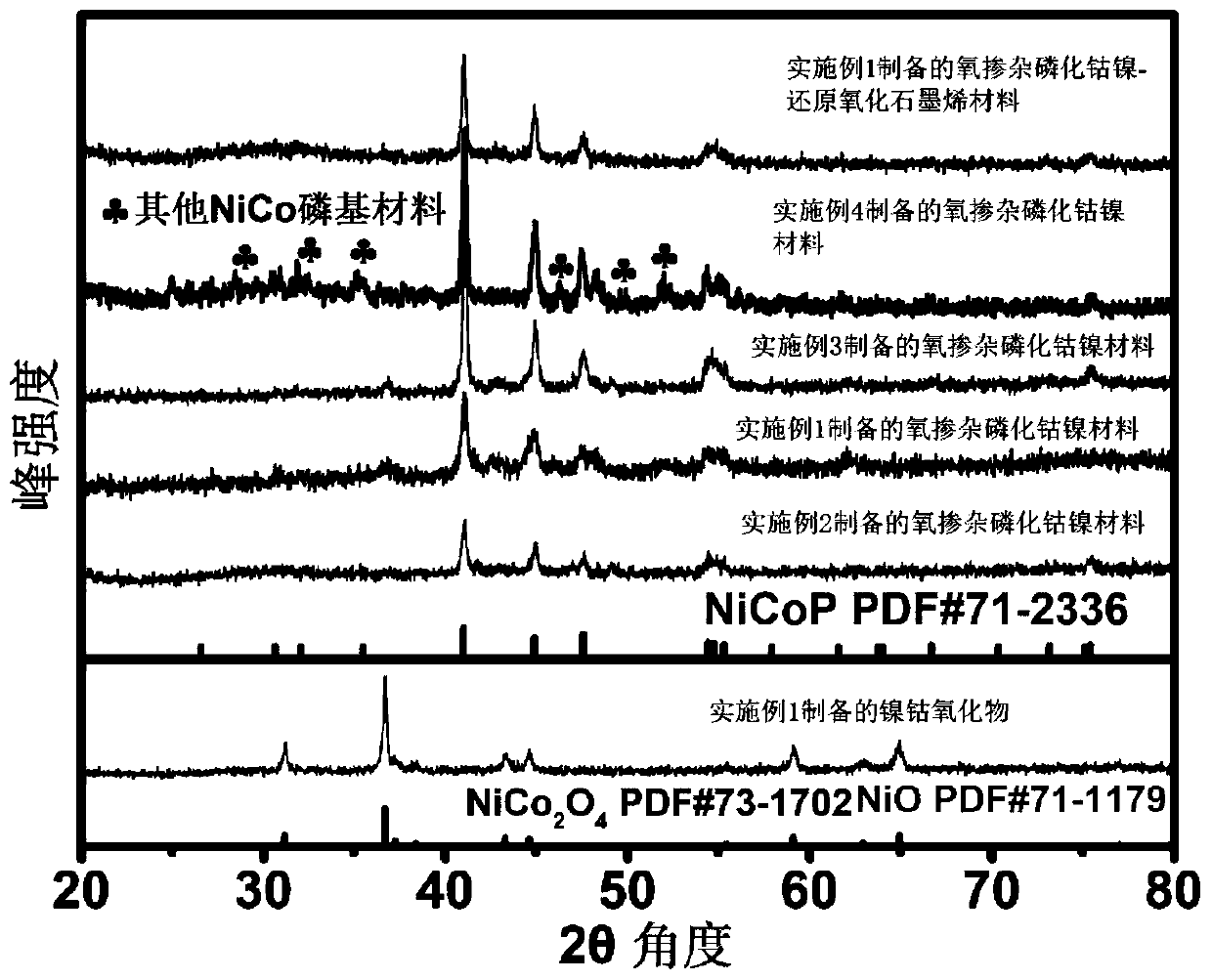

[0055] Evenly disperse 0.02mol cobalt nitrate hexahydrate and 0.02mol nickel nitrate hexahydrate in 20ml deionized water, stir for 60 minutes and put them into a blast oven for drying. When the liquid is dried until it still has fluidity, transfer it to put the corundum crucible into a muffle furnace at a heating rate of 10°C, raise the temperature to 500°C and keep it warm for 2 hours, and collect nickel-cobalt oxide after natural cooling.

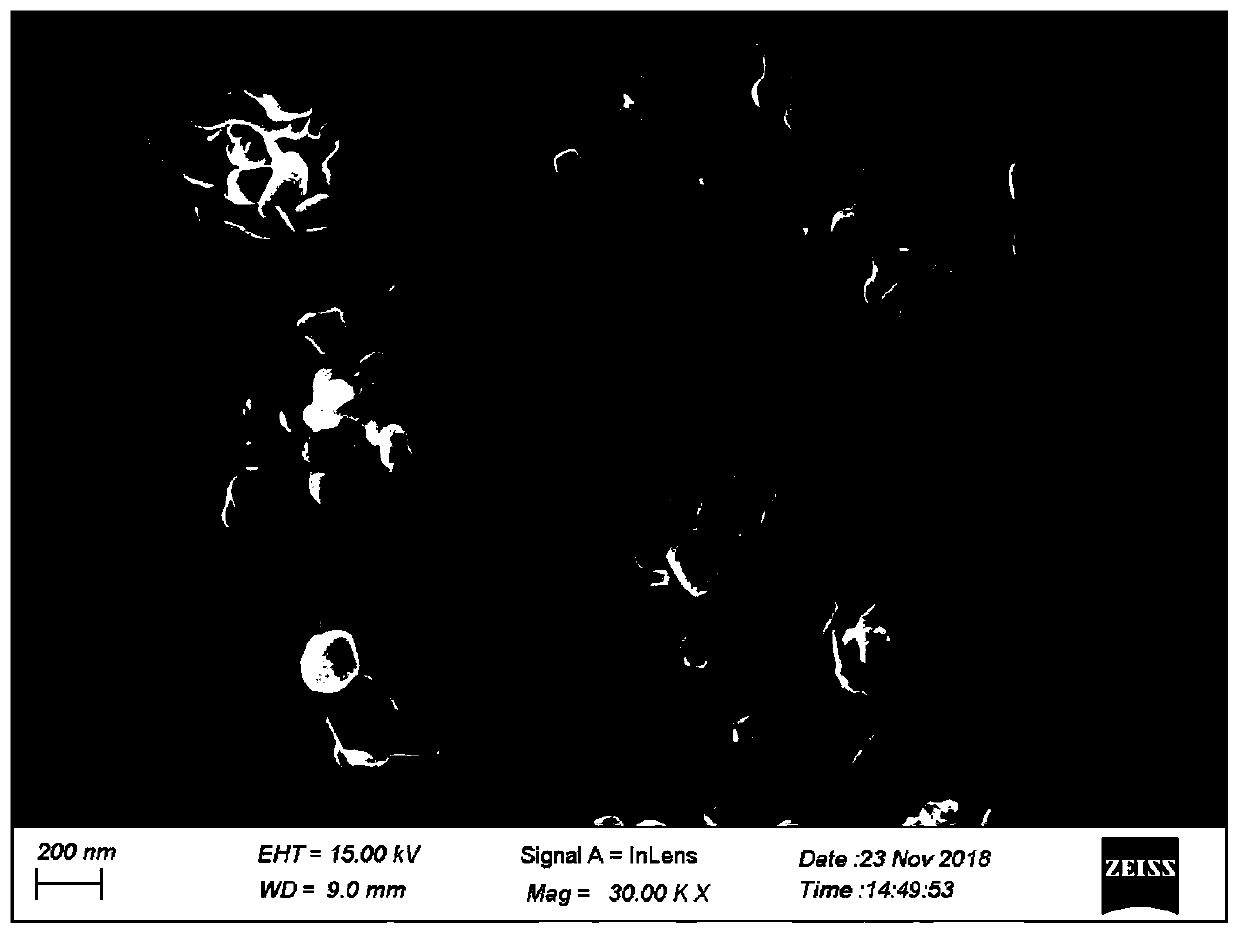

[0056] Disperse 0.01mol of nickel-cobalt oxide and 0.045mol of sodium hypophosphite in both ends of the corundum magnetic boat, put the sodium hypophosphite in the direction of the upper air outlet, and carry out the phosphating reaction at 300°C for 1 hour under the protection of argon. The obtained product was washed with deionized water and ethanol, centrifuged, and vacuum-dried at a low temperature of 60° C. for 10 hours to obtain an oxygen-doped cobalt-nickel phosphide material.

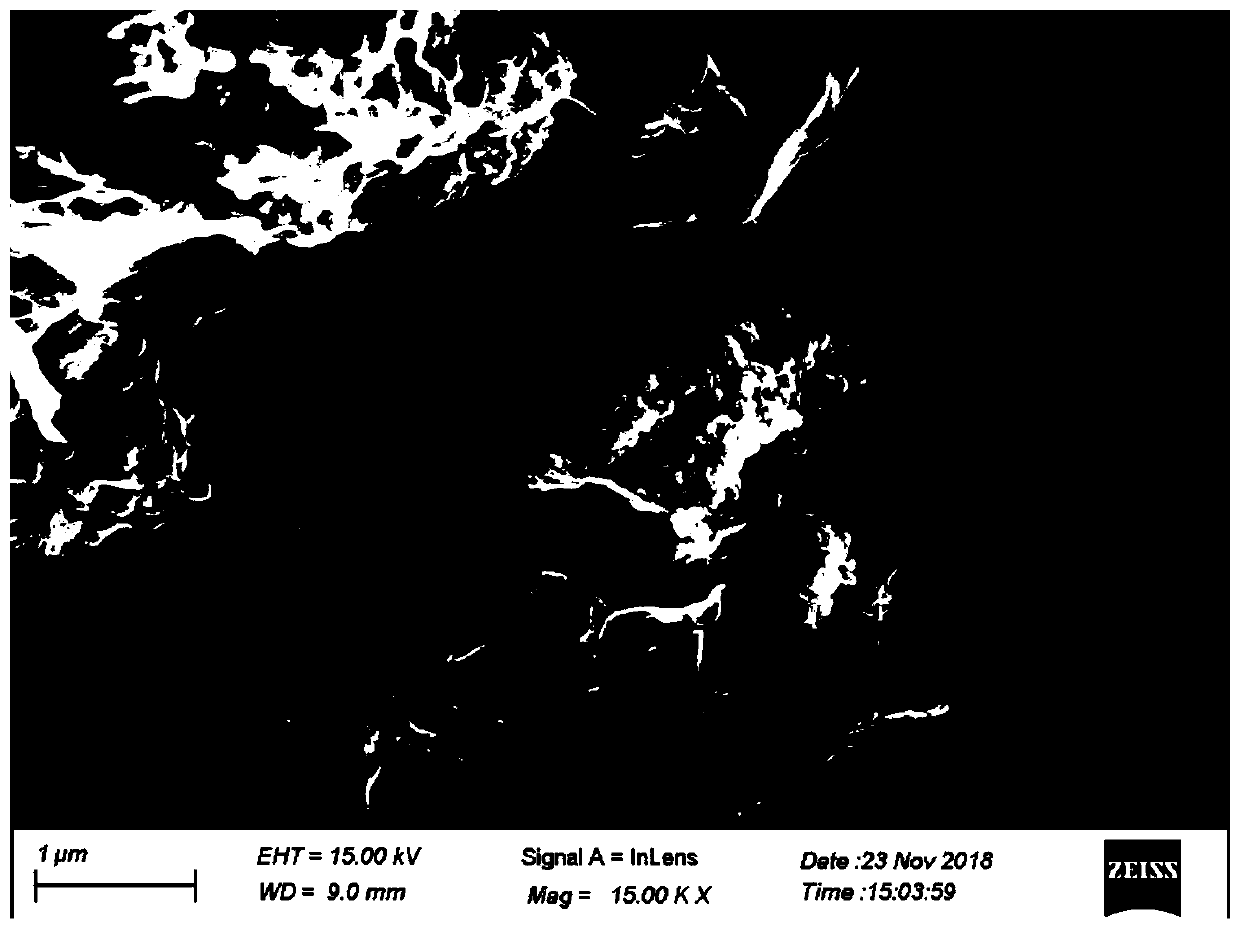

[0057] Mix and stir 150 mg of oxygen-doped nickel-cob...

Embodiment 2

[0069] Evenly disperse 0.04mol cobalt nitrate hexahydrate and 0.02mol nickel nitrate hexahydrate in 20ml deionized water, stir for 60 minutes and put them into a blast oven for drying. When the liquid is dried until it still has fluidity, transfer it to put the corundum crucible into a muffle furnace at a heating rate of 10°C, raise the temperature to 500°C and keep it warm for 2 hours, and collect nickel-cobalt oxide after natural cooling.

[0070] Disperse 0.01mol of nickel-cobalt oxide and 0.045mol of sodium hypophosphite in both ends of the corundum magnetic boat, place the sodium hypophosphite in the direction of the upwind port, and carry out the phosphating reaction at 28°C for 1 hour under the protection of argon. The obtained product was washed with deionized water and ethanol, centrifuged, and vacuum-dried at a low temperature of 60° C. for 10 hours to obtain an oxygen-doped cobalt-nickel phosphide material.

[0071] Mix 150mg of oxygen-doped nickel-cobalt oxide comp...

Embodiment 3

[0074] Evenly disperse 0.02mol cobalt nitrate hexahydrate and 0.03mol nickel nitrate hexahydrate in 20ml deionized water, stir for 60 minutes and put them into a blast oven for drying. When the liquid is dried until it still has fluidity, transfer it to put the corundum crucible into a muffle furnace at a heating rate of 10°C, raise the temperature to 500°C and keep it warm for 2 hours, and collect nickel-cobalt oxide after natural cooling.

[0075] Disperse 0.01mol of nickel-cobalt oxide and 0.045mol of sodium hypophosphite in both ends of the corundum magnetic boat, put the sodium hypophosphite in the direction of the upper air outlet, and carry out the phosphating reaction at 300°C for 1 hour under the protection of argon. The obtained product was washed with deionized water and ethanol, centrifuged, and vacuum-dried at a low temperature of 60° C. for 10 hours to obtain an oxygen-doped cobalt-nickel phosphide material.

[0076] Mix 150 mg of oxygen-doped nickel-cobalt oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com