Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Break down evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient sound insulation material and manufacturing method thereof

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

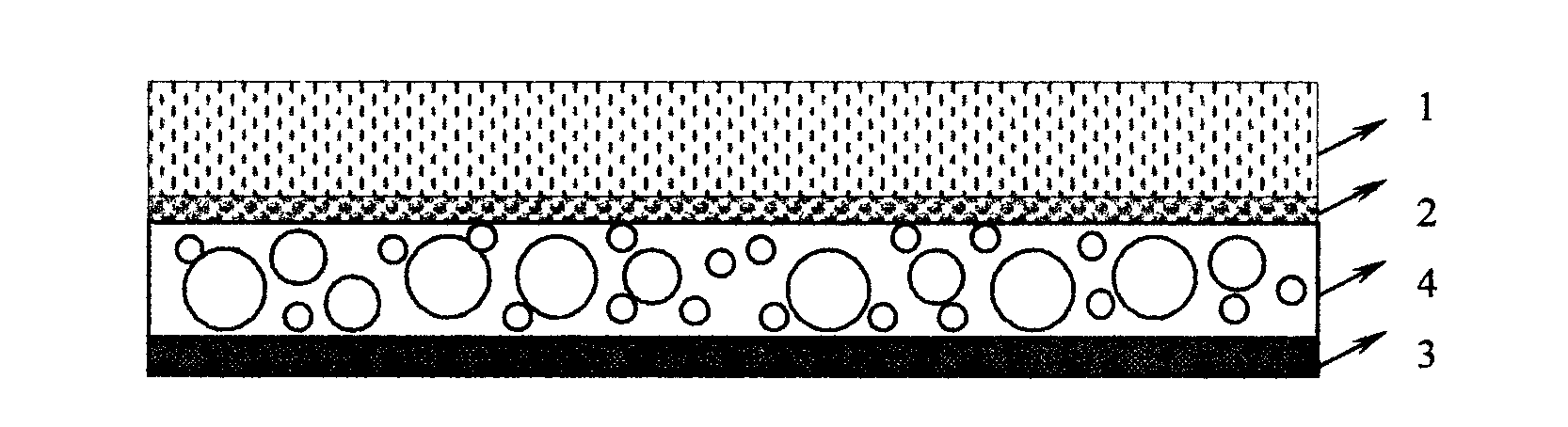

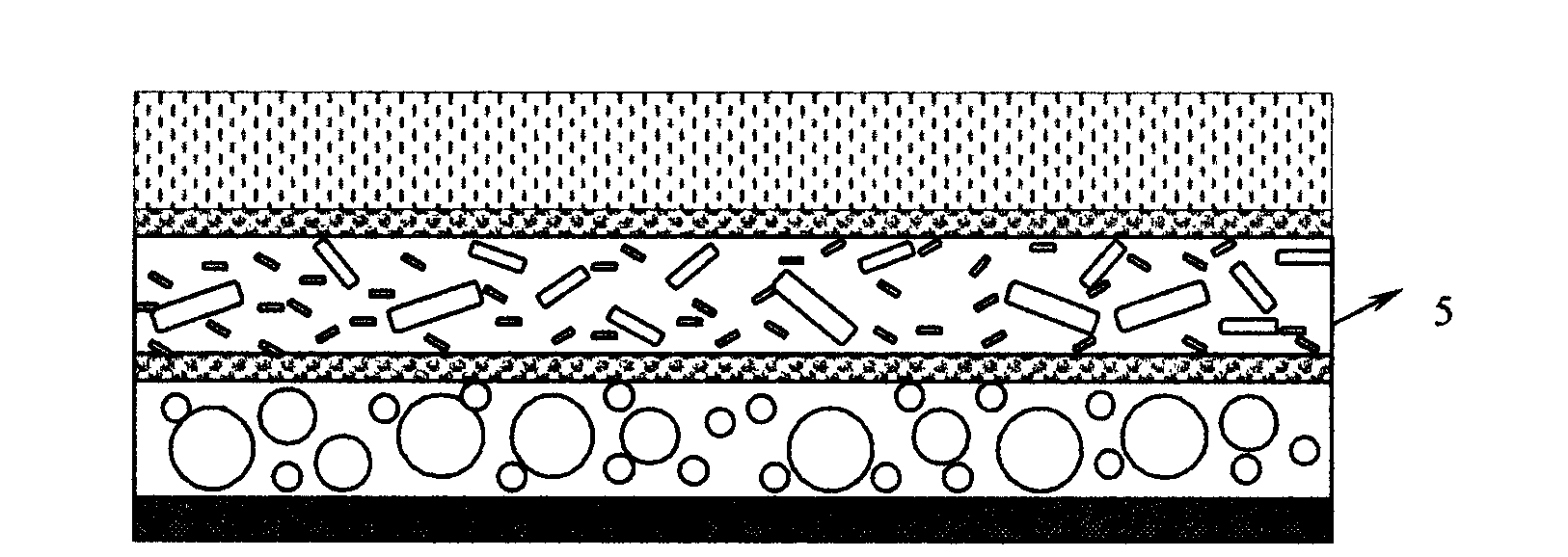

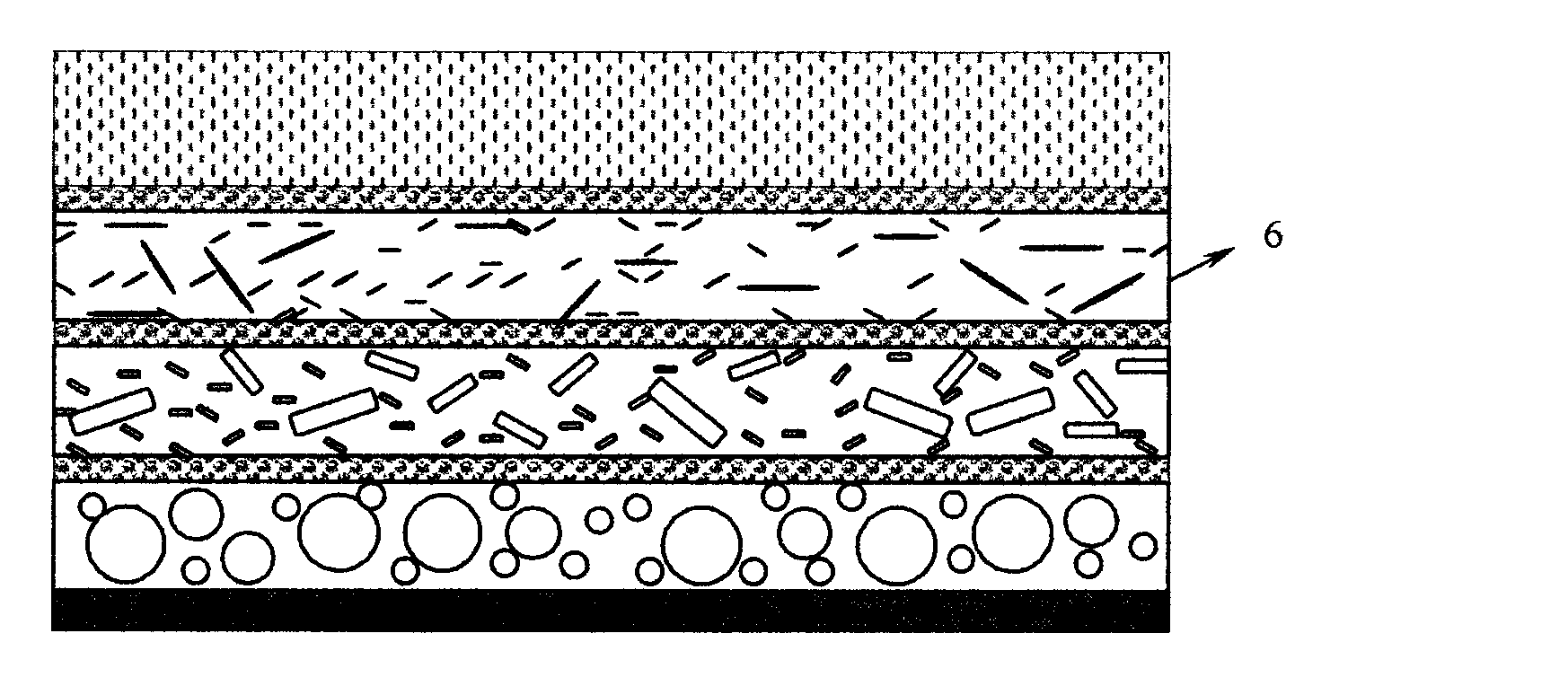

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

Colloid palladium activation solution, preparation method thereof and non-metal surface activation method

InactiveCN101928937ANon-failure decompositionBreak down evenlyLiquid/solution decomposition chemical coatingActivation methodGlyoxylic acid

The invention provides colloid palladium activation solution which comprises colloid palladium, sodium chloride, glyoxylic acid, hydrochloric acid, stannous chloride and stabilizer for stabilizing the stannous chloride, wherein the glyoxylic acid has strong reducibility and can avoid that divalent tin ions in the activation solution are oxidized, and prolong the service life of the action solution; simultaneously, the glyoxylic acid is adsorbed on the periphery of colloid palladium particles, thereby leading the dispersion of the colloid palladium to be more uniform, avoiding the gel coagulation among the colloid particles and enhancing the activity of the activation solution. The invention provides a preparation method of the colloid palladium, and the process is simple. In addition, the adoption of the colloid palladium activation solution for activating the surface of a non-metal substrate can firstly adsorb the glyoxylic acid in the activation solution on the surface of the non-metal substrate, enhance the bonding force between the colloid palladium particles and the non-metal substrate, leading a plated coating after chemical plating to have uniform thickness and flat surface, and leading the adhesion between the plated coating and the substrate to be very high.

Owner:深圳市新合富力科技有限公司

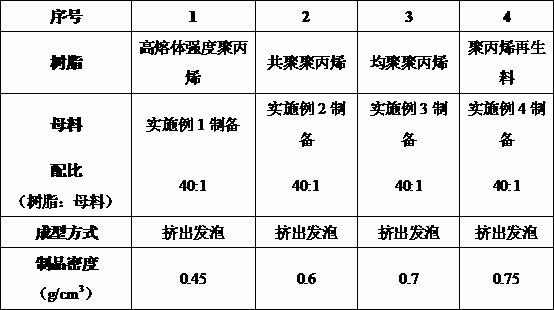

Polypropylene resin foam concentrate and preparation method thereof

ActiveCN102604223AAdvantages and Notable ImprovementsImprove melt strengthMasterbatchPolymer science

The invention relates to a polypropylene resin foam concentrate and a preparation method thereof. The foam concentrate is prepared by taking irradiation modified polypropylene resins as basic raw materials through the steps of adding additives such as a chemical foaming agent, a nucleating agent and a lubricant and the like into the basic raw materials, and uniformly mixing the mixture in a high-speed mixer; and then, adding the obtained mixture into a tandem extruder to carry out extrusion and granulation, thereby obtaining the polypropylene resin foam concentrate. The polypropylene resin foam concentrate provided by the invention can be applied to the extrusion of polypropylene foamed sheets, foamed pipes and foamed profiles; the polypropylene resin foam concentrate is high in modulus of foaming products, good in heat resistance, uniform in foaming hole, and adjustable in density, thereby opening up a new way for the extrusion and foaming of polypropylenes.

Owner:上海萍青工贸有限公司

Nutrient soil for orchid plant cultivation

InactiveCN103396250AImprove breathabilityImprove disease resistanceFertilizer mixturesPlant rootsPeat

Nutrient soil for orchid plant cultivation is characterized by comprising the following raw materials and the following weight ratio: 20 to 40 parts of pine bark, 20 to 40 parts of peat, 20 to 40 parts of peanut shells, 5 to 15 parts of coarse river sand, and 5 to 15 parts of bamboo charcoal. The nutrient soil for the orchid plant cultivation is suitable for the cultivation of orchid plants, can provides long-acting solid phase organic matters with a larger proportion, a stable pH value and good water control and gas control performance, allows cultivating management of the orchid plants to be more convenient, promotes orchid plant root systems after growth to rapidly rejuvenate, is also conducive to preserving orchid colors, allows aroma to be more strong and flower quality to be more beautiful, and is suitable not only for home balcony orchid cultivation but also for mass production.

Owner:邹飞剑

Method for preparing Fe2O3 and expanded graphite composite material of lithium ion battery

InactiveCN104953103AAvoid destructionBreak down evenlyCell electrodesSecondary cellsMicrowaveThermal decomposition method

The invention provides a method for preparing a Fe2O3 and expanded graphite composite material of a lithium ion battery. The method particularly comprises the steps that expanded graphite is used as a carrier material, the ferrocene is used as the precursor of Fe2O3, the expanded graphite and the Fe2O3 are mixed based on the mass ratio being 1:2-12, and the Fe2O3 and expanded graphite composite material is prepared by adopting the high pressure decomposition method or the microwave reaction method or the high temperature thermal decomposition method. The method is wide in raw material source, low in cost, simple in preparation technology, low in investment, high in operability and suitable for large-scale production. The Fe2O3 and expanded graphite composite material can be used as a negative electrode material of a common or flexible lithium ion battery, and has the advantages of being high in capacity, good in circulation and rate capability and the like.

Owner:SHANXI UNIV

Method for blasting plant biomass walls with oxygen

InactiveCN102206928ADecompose thoroughlyBreak down evenlyRaw material divisionProcess engineeringOxygen

The invention discloses a method for blasting plant biomass walls with oxygen, comprising the following steps of: firstly, adding ethanol, hydrogen peroxide with concentration of 30% and water to crushed plant biomass, mixing the materials to oxidize and soak the materials, and conveying the oxidized and soaked materials to an oxygen blasting tank via a feeding port of the oxygen blasting tank; secondly, sealing the feeding port of the oxygen blasting tank, regulating the temperature of the gas in the oxygen blast tank at 80-150 DEG C and the pressure within 1-4 MPa by conveying pressure air to the oxygen blasting tank, preserving heat and keeping pressure for 20-200 seconds to soak the plant biomass into ethanol, hydrogen peroxide with concentration of 30%, steam and water; and finally, completely opening the discharge port of the oxygen blasting tank within 3 seconds to reduce the pressure in the oxygen blasting tank to the normal pressure. The invention aims to provide the method for blasting plant biomass walls with oxygen, which can be used for completely and uniformly decomposing the plant biomass and realizing industrialization production and has high production efficiency.

Owner:BEIJING ZHONGNUO DERUI IND TECH

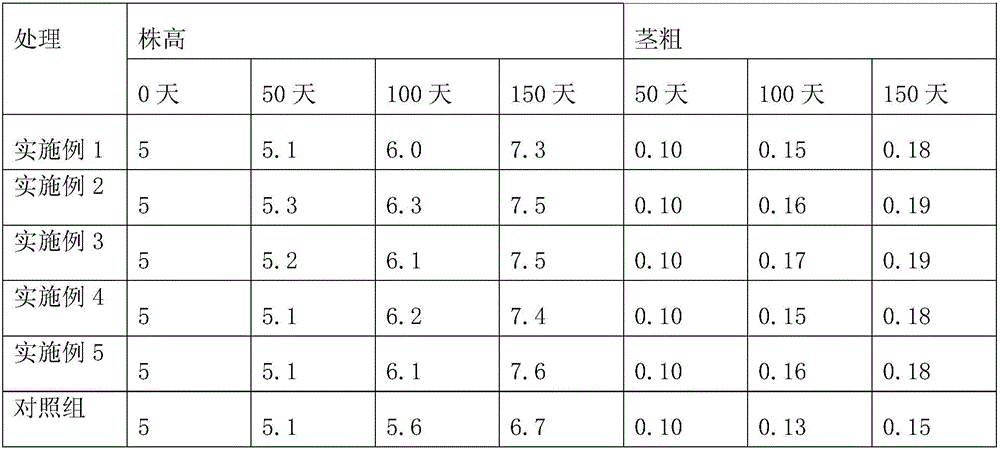

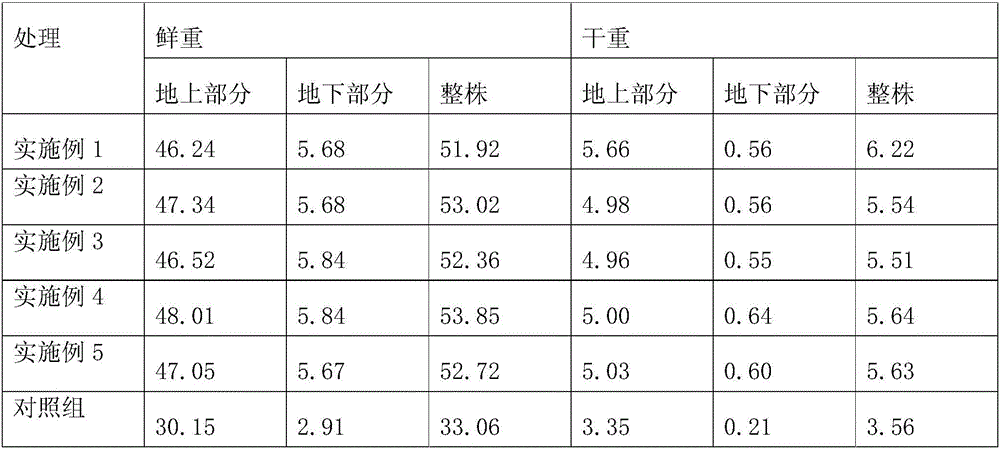

Special cultivation substrate for dendrobium officinale and preparation method of special cultivation substrate

InactiveCN105850682APromote absorptionSimple methodBioloigcal waste fertilisersGrowth substratesBrickAlcohol

The invention discloses a special cultivation substrate for dendrobium officinale. The special cultivation substrate comprises a bottom-layer substrate, a middle-layer substrate and an upper-layer substrate stacked sequentially from bottom to top, wherein the bottom-layer substrate is prepared from 10-20 parts of bean stalk or 15-25 parts of dry sugarcane leaves; the middle-layer substrate is a mixture of 5-15 parts of red brick powder, 15-30 parts of composted alcohol biogas residues and the like; the upper-layer substrate is a mixture of 15-35 parts of modified biological carbon, 15-45 parts of deadwood, 5-15 parts of expanded perlite and the like. The preparation method of the planting substrate comprises steps as follows: preparation of the modified biological carbon, preparation of the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate and stacking of the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate. The preparation method is simple and easy, the prepared planting substrate overcomes the defects that conventional substrates are rotten and air-impermeable and cannot hold water after being used for a long time, is low in cost, has rich nutrition and facilitates growth of dendrobium officinale, stems of dendrobium officinale grow more strongly, and root systems of dendrobium officinale are well developed.

Owner:GUANGXI ZHIBAO TECH CO LTD

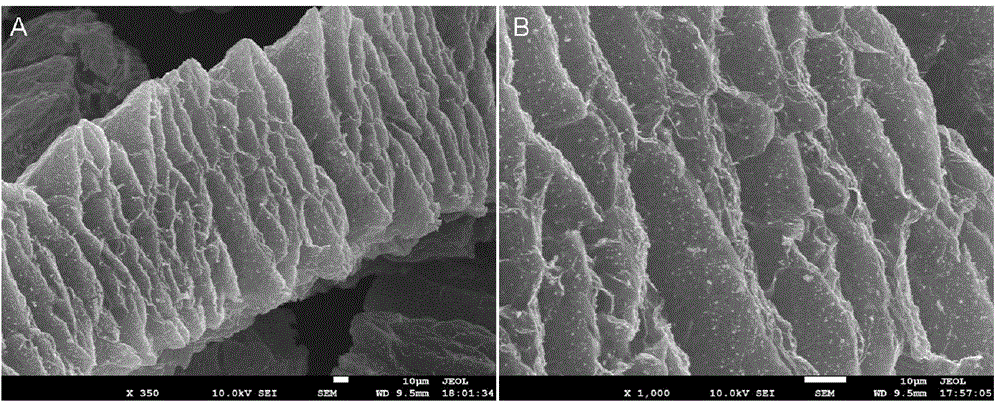

Planting substrate for dendrobium officinale and preparation method for planting substrate

InactiveCN105941107AImprove hydrophobicityGuaranteed water retentionGrowth substratesCulture mediaTwigBiology

The invention discloses a planting substrate for dendrobium officinale. The planting substrate comprises a substrate A, a substrate B and a substrate C which are arranged in a manner of being superposed sequentially from bottom to top, wherein the substrate A is prepared from 10-20 parts (by weight) of dried rice straws or dried sugarcane leaves; the substrate B is prepared from 5-20 parts (by weight) of medium sand, 10-30 parts (by weight) of edible fungus leftovers, and the like; and the substrate C is prepared from 15-45 parts (by weight) of biocarbon, 15-45 parts (by weight) of semi-corroded miscellaneous tree branches, 15-45 parts (by weight) of tung fruit peels, 15-45 parts (by weight) of corncobs, 15-45 parts (by weight) of pine barks, and the like. A preparation method for the planting substrate comprises the steps of preparing the biocarbon, preparing the substrate A, the substrate B and the substrate C and then carrying out superposition. The preparation method for the planting substrate is simple and easy to understand; and the planting substrate prepared by the preparation method has the advantages that the condition that the substrate is rotted, is air-proof and does not hold moisture in long-term use is overcome, the cost is low, the nutrition is complete, the growth of the dendrobium officinale is better facilitated, dendrobium officinale stems are promoted to grow more sturdy, and dendrobium officinale root systems are promoted to be more developed.

Owner:LINGYUN LONGEVITY IMMORTAL GRASS BIOTECH SCI DEV

Dendrobium officinale culture medium and preparation method thereof

InactiveCN105766591APromotes habitat growthImproves Nutrient AvailabilityGrowth substratesCulture mediaPerliteEcology

The invention discloses a Dendrobium officinale culture medium, which comprises a base layer, a buffer layer and a medium layer, wherein the base layer, the buffer layer and the medium layer are successively overlaid from bottom to top; according to parts by weight, the base layer is prepared from 10-20 parts of dry wheat straw or 10-20 parts of dry sugarcane top, the buffer layer is prepared from the mixture of 5-10 parts of silkworm excrement, 10-20 parts of leaf mold and the like, and the medium layer is prepared from the mixture of 15-25 parts of modified charcoal, 15-45 parts of rotten wood or tree, 5-15 parts of expanded perlite and the like. The preparation method of the plantation medium is obtained by overlapping the preparation of the modified charcoal and the preparation of the base layer, the buffer layer and the medium. The preparation method is simple and easy to understand. The plantation medium prepared from the Dendrobium officinale culture medium overcomes the defects that the medium is rotten and airtight and does not realize water retention after the medium is used for a long time. The Dendrobium officinale culture medium has the advantages of low cost and complete nutrition, is favorable for the growth of Dendrobium officinale and accelerates the stem of the Dendrobium officinale to be thicker and the root system of the Dendrobium officinale to be developed.

Owner:GUANGXI ZHIBAO TECH CO LTD

Amorphous tetratin triphosphate/phosphorus/few-layer graphene negative material for lithium ion batteries and preparation method and application thereof

InactiveCN109841820AImprove efficiencyAlleviate volume changesCell electrodesSecondary cellsLithium iron phosphatePhosphate

The invention discloses an amorphous tetratin triphosphate / phosphorus / few-layer graphene negative material for lithium ion batteries and a preparation method and an application thereof. The negative material is formed by coating amorphous tetratin triphosphate and phosphorus with a few layers of graphene carbon. The preparation method includes the following steps: mixing and ball-milling tin powder and phosphorus powder to obtain tin triphosphate; and mixing the obtained tin triphosphate with expanded graphite and carrying out ball-milling to obtain the amorphous tetratin triphosphate / phosphorus / few-layer graphene negative material. The negative material prepared in the invention is matched with a lithium iron phosphate positive material, and a lithium ion battery assembled by using the negative material and the lithium ferrous phosphate positive material has the advantages of high capacity and stable cycle and has application potential. The preparation method of the invention has theadvantages of simple process, good repeatability, less time consumption and environment friendliness, and is conducive to actual industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Buffer energy-absorbing bumper

InactiveCN105059227AHarm mitigationPlay the role of shock absorption and energy absorptionBumpersEnergy absorptionEngineering

The invention discloses a buffer energy-absorbing bumper, comprising a shell and a bumper collision rod which is erected at the front side of the shell through a plurality of energy-absorbing mechanisms. Each energy-absorbing mechanism comprises a first longitudinal energy-absorbing spring, two horizontal energy-absorbing springs, two fixed baffles, two sliding blocks and two dowel bars, wherein the front end of the first longitudinal energy-absorbing spring is connected with the bumper collision rod, and the rear end of the first longitudinal energy-absorbing spring is connected with the rear end of the shell; the two horizontal energy-absorbing springs are arranged at the rear end of the shell and are respectively positioned at two sides of the first longitudinal energy-absorbing spring; the two fixed baffles are arranged at the rear end of the shell and are respectively connected with one ends, far away from the first longitudinal energy-absorbing spring, of the two horizontal energy-absorbing springs; the two sliding blocks are arranged at the rear end of the shell and are respectively connected with the other ends of the two horizontal energy-absorbing springs; and the rear ends of the two dowel bars are respectively articulated with the two sliding blocks, and the front ends of the two dowel bars are articulated to the bumper collision rod. According to the invention, the collision force is decomposed by the longitudinal energy-absorbing springs and the horizontal energy-absorbing springs so as to realize shock absorption and energy absorption, thereby improving the safety performance of the bumper.

Owner:GUANGXI UNIV

Method and apparatus for light-burning magnesium powder for rotary kiln

The invention relates to a method and a device for soft burning of magnesium powder through a rotary kiln which relate to the technology of soft burning of magnesite pulverized powder, in particular to a method for producing the soft burning magnesium powder by utilization of the rotary kiln. The invention aims to provide a method for fair current soft burning of the magnesium powder through the rotary kiln with low investment, quickness in taking effect and high magnesia activity. The other aim of the invention is to provide a device for implementing the method. The method is as follows: materials and flame after magnesite is crushed enter from the high end of the rotary kiln, are led out from a draught fan on the outside of the low end, and perform fair current heat exchange in the rotary kiln. The device adopts the following structure: the rotary kiln comprises a kiln body; the high end and the low end of the kiln body are respectively provided with a support bracket; and motors on the support brackets are connected with the kiln body through driving mechanisms. The structural key points of the device are as follows: a material hopper and a burner are arranged outside an inlet on the high end of the kiln body, and the draught fan is arranged outside an outlet on the low end of the kiln body.

Owner:海城华宇耐火材料有限公司

Dendrobium candidum planting substrate containing modified biochar and preparation method of Dendrobium candidum planting substrate

InactiveCN105850684ALarge specific surface areaModerate pore sizeGrowth substratesCulture mediaDendrobium candidumPaulownia

The invention discloses a dendrobium officinale planting substrate containing modified biochar, which comprises substrate A, substrate B and substrate C arranged sequentially from bottom to top; according to the ratio of parts by weight, substrate A is 10-20 parts of dry rice straw Or 10-20 parts of dry sugarcane leaves; substrate B is 5-20 parts of silkworm excrement, 10-30 parts of rice bran, etc.; 45 copies etc. The preparation method of the planting substrate is the preparation of modified biochar, the preparation of substrates A, B and C, and then superposition. The preparation method of the present invention is simple and easy to understand, and the planting substrate prepared by the present invention overcomes the long-term use of the substrate, rots and airtight, does not retain water, and has low cost and complete nutrition, which is more conducive to the growth of Dendrobium candidum, and promotes the growth of Dendrobium candidum Stronger and more developed root system.

Owner:LINGYUN LONGEVITY IMMORTAL GRASS BIOTECH SCI DEV

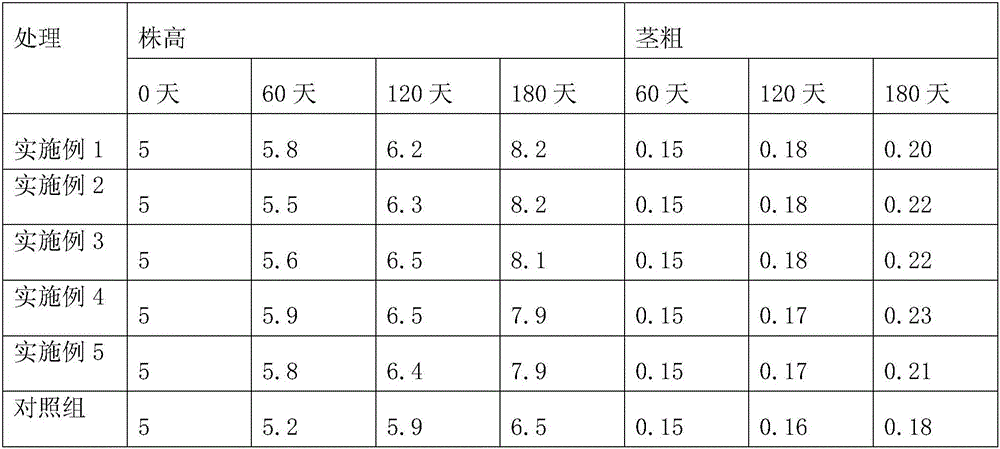

Wild-imitating planting substrate for dendrobium huoshanense and preparation method for wild-imitating planting substrate

InactiveCN105918084AQuality improvementImprove fertilityGrowth substratesCulture mediaBiologyMoisture

The invention discloses a wild-imitating planting substrate for dendrobium huoshanense. The wild-imitating planting substrate comprises a bottom-layer substrate, a middle-layer substrate and an upper-layer substrate which are arranged in a manner of being superposed sequentially from bottom to top, wherein the bottom-layer substrate is prepared from 10-20 parts (by weight) of dried corn stalks or dried sugarcane leaves; the middle-layer substrate is prepared from a mixture of 5-15 parts (by weight) of vermiculite and the like; and the upper-layer substrate is prepared from a mixture of 15-35 parts (by weight) of modified biocarbon, 15-45 parts (by weight) of rotten wood and the like. A preparation method for the planting substrate comprises the steps of preparing the modified biocarbon, preparing the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate and then carrying out superposition. The preparation method for the planting substrate is simple and easy to understand; and the planting substrate prepared by the preparation method has the advantages that the condition that the substrate is rotted, is air-proof and does not hold moisture in long-term use is overcome, the cost is low, the nutrition is complete, the growth of the dendrobium huoshanense is better facilitated, dendrobium huoshanense stems are promoted to grow more sturdy, and dendrobium huoshanense root systems are promoted to be more developed.

Owner:GUANGXI ZHIBAO TECH CO LTD

Production process of ultrathin aluminum nitride ceramic substrate

ActiveCN112876260AHigh degree of densificationDoes not significantly increase production costsAl powderSlurry

The invention relates to the technical field of aluminum nitride ceramics, and provides a production process of an ultrathin aluminum nitride ceramic substrate. The process comprises the following steps: (1) uniformly mixing aluminum nitride powder, a composite sintering aid, a UV monomer, a reactive diluent, a photoinitiator, a dispersant and a silane coupling agent to obtain ceramic slurry; (2) subjecting the ceramic slurry to tape casting on a tape casting machine, initiating a polymerization reaction through ultraviolet radiation, subjecting the slurry to in-situ curing molding to obtain a ceramic green body, and then cutting the ceramic green body into required shapes and sizes through a mold to obtain ceramic green sheets; (3) laminating the ceramic green sheets, and putting the laminated ceramic green sheets into a glue discharging furnace for glue discharging; and (4) carrying out hot pressed sintering on the ceramic blank sheet after glue discharging under the protection of nitrogen atmosphere, cooling to room temperature after the sintering, and then carrying out powder removal and polishing processes to obtain the ultrathin aluminum nitride ceramic substrate. The prepared aluminum nitride ceramic substrate is ultrathin, good in thermal conductivity and high in bending strength.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Dendrobium huoshanense special-purpose planting matrix and preparation method thereof

InactiveCN105918085APromotes habitat growthImproves Nutrient AvailabilityGrowth substratesCulture mediaBiogasRoot system

The invention discloses a dendrobium huoshanense special-purpose planting matrix, comprising a matrix A, a matrix B, and a matrix C which are arranged in an overlaying manner from bottom to top in sequence. According to weight part ratio, the matrix A contains 10-20 parts of dry sorghum stalks or 10-20 parts of dry sugarcane leaves, the matrix B is a mixture of 10-15 parts of silkworm excrement, 10-20 parts of mature ethyl alcohol biogas residue, etc., and the matrix C is a mixture of 10-25 parts of modified charcoal, 15-45 parts of rotten wood, 2-5 parts of a trichoderma spp agent. The manufacturing method for the planting matrix comprises: manufacturing the modified charcoal, manufacturing the matrixes A, B, and C, and overlaying to form the planting matrix. The manufacturing method is simple and easy to understand, and the manufactured planting matrix overcomes problems that a matrix is rotted and does not ventilate and does not retain water after long time use. The matrix is low in cost, complete in nutrition, and is beneficial for growth of the dendrobium huoshanense, and promotes stems of the dendrobium huoshanense to grow thicker, and roots to be more developed.

Owner:覃伟

Method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding

ActiveCN103233279AAvoid damageBreak down evenlyFibre treatment to obtain bast fibreDecompositionColloid

The invention provides a method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding, which comprises three feeding processes and comprises the following specific steps: in the first feeding process, preparing a degumming solution from surfactant, a fiber expanding agent, peroxide stabilizer, a defoaming agent, sodium hydroxide, peroxide and water, mixing raw hemp of ramie and the degumming solution to form a degumming solution system, and heating to remove part of colloid; in the second feeding process 20-50 minutes later, adding peroxide and sodium hydroxide, and keeping the temperature to further remove the colloid; in the third feeding process 20-50 minutes later, adding peroxide, and further keeping the temperature until the reaction is finished and the colloid is completely removed; and finally, washing refined dried hemp fibers with clear water, oiling, drying, opening, and combing to obtain the prepared ramie fibers. The method provided by the invention overcomes the defects in the existing oxidation and degumming technology; a repeated multiple-step method is used, so that the reaction is uniform and moderate, the damage to the fibers caused by over too high initial concentration of initial concentration is reduced, and the quality of the refined dried hemp product is improved; and meanwhile, the ineffective decomposition of the peroxide and the consumption of the defoaming agent are reduced, thereby saving the cost.

Owner:DONGHUA UNIV

Planting matrix for artificial planting of Caulis Dendrobii and preparation method thereof

InactiveCN105766592AQuality improvementImprove fertilityGrowth substratesCulture mediaBiologyBiochar

The invention discloses a planting matrix for artificial planting of Caulis Dendrobii. The planting matrix comprises a matrix A, a matrix B and a matrix C which are sequentially stacked from bottom to top, the matrix A is composed of, in parts by weight, 10-20 parts of dry wheat straw or 10-20 parts of dry rice straw, the matrix B is a mixture of, in parts by weight, 5-10 parts of medium sand and 10-20 parts of leaf mold, and the matrix C is a mixture of, in parts by weight, 15-25 parts of modified biochar, 15-45 parts of rotten wood, 5-15 parts of expanded perlite and 10-35 parts of pine bark. The preparation method of the planting matrix includes: preparing the modified biochar, preparing the matrixes A, B and C, and stacking the matrixes A, B and C. The preparation method is simple and easy to understand, the planting matrix prepared by the method overcomes the defect that existing matrixes after being used for a long time are rotten and airtight and do not conserve water, and is low in cost, complete in nutrient, more conducive to growing of Dendrobium Officinale and capable of promoting stems of Dendrobium Officinale to grow thicker and stronger and promoting root systems to be more developed.

Owner:覃伟

Low-emission TVOC foamed polypropylene product and preparation method thereof

The invention discloses a low-emission TVOC foamed polypropylene product and a preparation method thereof and relates to the field of polypropylene products. The low-emission TVOC foamed polypropylene product is mainly prepared by taking nitrogen as foaming gas to foam. The raw materials comprises the following components in parts by weight: 70-80 parts of polypropylene resin, 0.5-2 parts of a deodorant, 1-10 parts of fibers, 5-15 parts of a coupling interlinking agent and 1-10 parts of a porous adsorption material. The foamed polypropylene overcomes the defect of high release amount of TVOC. The preparation method of the low-emission TVOC foamed polypropylene product comprises the following steps of: mixing the polypropylene resin with fibers; then mixing the mixture with the porous adsorption material and the coupling interlinking agent to form a mixture; and extruding the mixture to foam under the action of nitrogen. By using nitrogen to foam the polypropylene resin, in addition to the action of adsorption, coupling cross-linking reaction and fibers, purposes of reducing the TVOC content of the foamed polypropylene and improving the odor grade are achieved.

Owner:CHENGDU SOLVER TECH

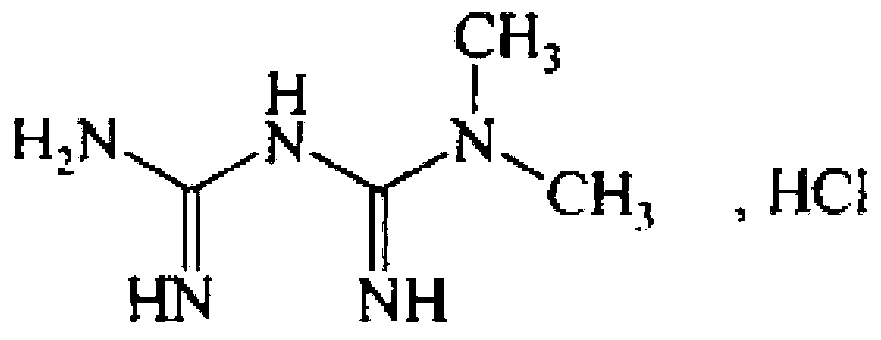

Repaglinide/metformin combo tablet

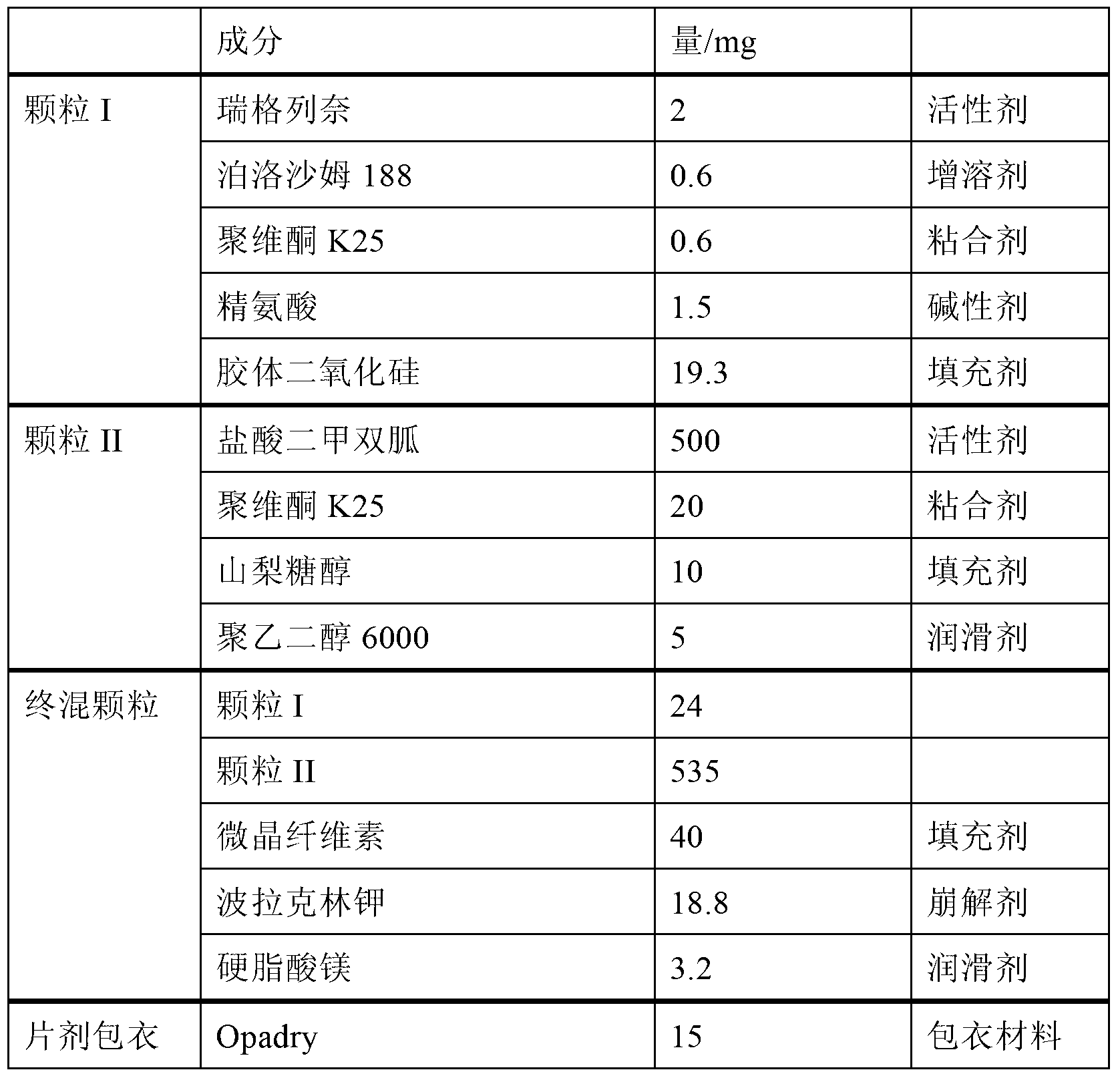

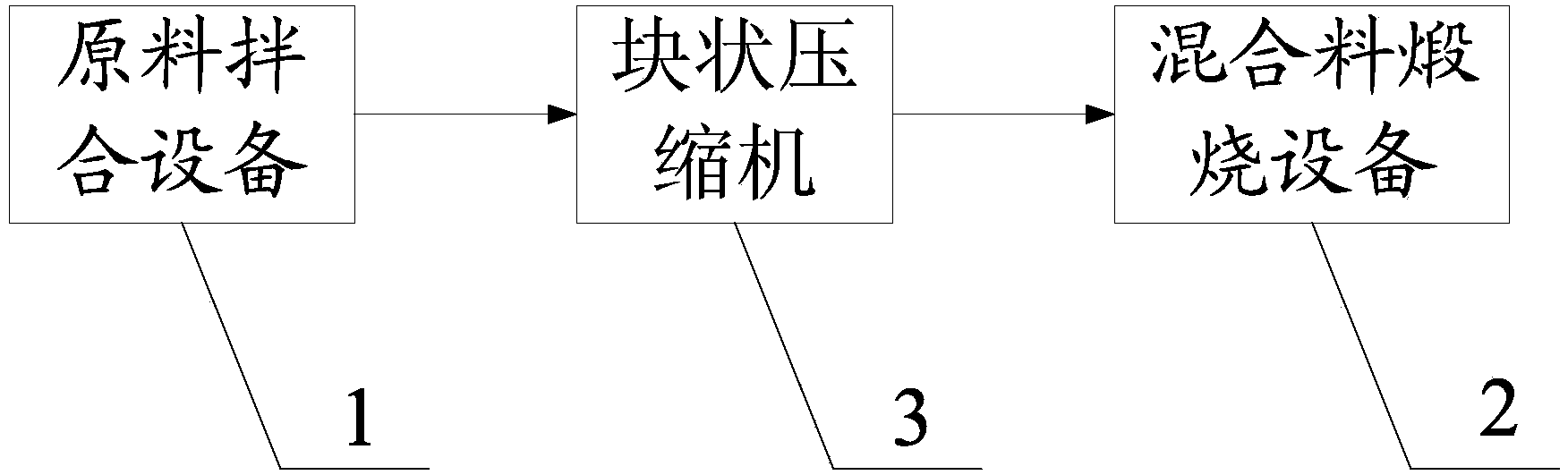

ActiveCN103251594AImplement synchronous releaseExcellent in vitro dissolutionOrganic active ingredientsMetabolism disorderDrugMetformin Hydrochloride

The invention relates to a repaglinide / metformin combo tablet, particularly a pharmaceutical composition in the form of a tablet, which comprises the following components in parts by weight: 500 parts of metformin hydrochloride, 0.5-5 parts of repaglinide and 10-200 parts of medicinal auxiliary materials. The medicinal auxiliary materials include, but are not limited to filler, disintegrant, binding agent, alkali and lubricant. The invention also relates to a method for preparing the pharmaceutical composition. The pharmaceutical composition provided by the invention has favorable pharmaceutical properties.

Owner:HANGZHOU ZHUYANGXIN PHARMA

Nutrient soil for orchid plant culture

InactiveCN102919110AEasy to cultivate and manageGood color retentionCultivating equipmentsSoilless cultivationDiseaseOrchidaceae

The invention discloses nutrient soil for orchid plant culture. The nutrient soil is characterized by comprising the following raw materials in part by weight: 20-40 parts of pine bark, 20-40 parts of grass carbon, 20-40 parts of walnut shell, 5-15 parts of vermiculite and 5-15 parts of bamboo carbon. The nutrient soil is suitable for all orchid plants and improvement of disease resistance, and can provide higher-ratio long-acting solid phase organic matters, stable pH value and good water and air control performance. Therefore, the culture management of the orchid plants is more convenient, the root systems of the orchid plants are promoted to grow and then are quickly rejuvenated, the color of orchids is kept, the fragrance of the orchids is stronger, and the orchids are more beautiful. The nutrient soil can be suitable for orchid culture in household balconies and can also be used for industrial large-scale production.

Owner:徐仁鹏

Homo-polypropylene/carbon fiber/montmorillonite composite material and preparation method thereof

The invention relates to a homo-polypropylene / carbon fiber / montmorillonite composite material and a preparation method of the homo-polypropylene / carbon fiber / montmorillonite composite material. The homo-polypropylene / carbon fiber / montmorillonite composite material is prepared from the following raw materials in parts by weight: 85 to 95 parts of homo-polypropylene, 5 to 10 parts of carbon fibers, 2 to 3 parts of organic montmorillonite, and 3 to 5 parts of foaming masterbatches, the foaming masterbatches are prepared from the following raw materials in parts by weight: 60 to 70 parts of polyethylene, 20 to 30 parts of foaming agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of nucleating agents, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1 part of a titanate coupling agent NDZ-201, 3 to 5 parts of PE wax and 0.5 to 1 part of zinc stearate. According to the homo-polypropylene / carbon fiber / montmorillonite composite material disclosed by the invention, the mechanical properties are excellent, the tensile strength reaches 36.9 MPa, the impact strength reaches 55.1 kJ / m<2>, and the flexural modulus reaches 1590 MPa. The foaming material has best foaming and biggest cell density, the cell density reaches 2.3*10<7> / cm3, and the porosity of the foaming material is 17.7%.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Composite foaming agent and polypropylene foam material prepared from same

The invention discloses a composite foaming agent and a polypropylene foam material prepared from the same. The foaming agent comprises the following components in parts by weight: 100 parts of azodicarbonamide, 10-20 parts of N,N'-dimethyl-N,N-dinitrosoterephthalamide, 10-30 parts of zinc oxide and 10-30 parts of sodium citrate. The polypropylene foam material comprises the following blended components in parts by weight: 100 parts of high-melt strength polypropylene and 3-15 parts of composite foaming agent. The composite foaming agent disclosed by the invention has controllable foaming temperature, uniform foam cell, smooth surface and high physical heat resistance; and the polypropylene foam material prepared from the composite foaming agent meets the environmental protection requirement, is degradable and low in production cost, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

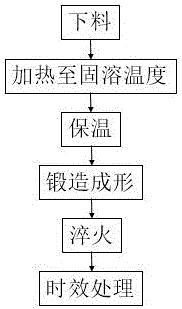

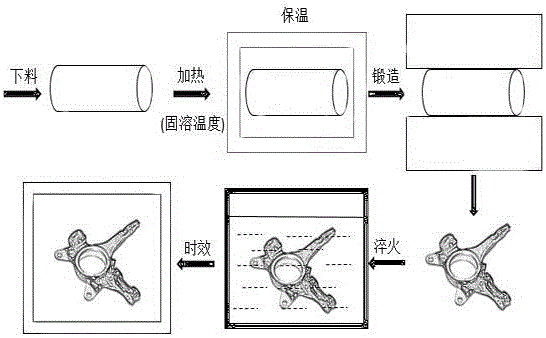

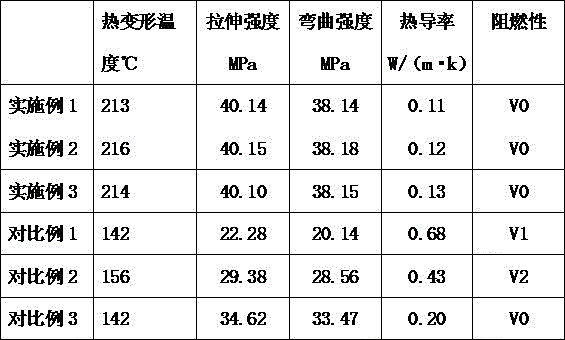

Forging technology for automobile aluminum alloy chassis class parts

The invention relates to a forging technology for automobile aluminum alloy chassis class parts. The forging technology comprises the following steps: 1), heating an aluminum alloy blank to a solid dissolving temperature and preserving heat so as to fully dissolve a strengthening phase; 2), carrying out forging molding on the aluminum alloy blank preserving heat; 3), carrying out quenching treatment on an aluminum alloy forged piece molded; and 4), carrying out aging treatment on the aluminum alloy forged piece quenched. The technology reduces production cycle and production cost and improves production efficiency under the condition of fully meeting product performance requirements.

Owner:WUHAN UNIV OF TECH

A high-performance capacitor plastic housing

ActiveCN106519600AImprove mechanical propertiesLow costPolytetramethylene terephthalateDibutyl sebacate

A high-performance capacitor plastic housing is disclosed. The plastic housing is prepared from polybutylene terephthalate, ABS plastic, a filler, a color concentrate, dibutyl sebacate, polyamide, a lubricant and an auxiliary agent. The auxiliary agent is prepared from, by weight, carboxyl cellulose, sorbitan trioleate, rosin, sodium hexametaphosphate, alkali lignin, acrylamide, diatomite, sodium tripolyphosphate, methyl salicylate, tea seed oil and mint oil. The plastic housing has characteristics of good mechanical properties, good processing performance, a low cost, a low melt viscosity, high impact strength, good thermal aging resistance and excellent thermal stability.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Repaglinide/metformin composition

ActiveCN103251593AImplement synchronous releaseExcellent in vitro dissolutionOrganic active ingredientsMetabolism disorderMetformin HydrochlorideRepaglinide

The invention relates to a repaglinide / metformin composition, particularly a pharmaceutical composition which comprises the following components in parts by weight: 500 parts of metformin hydrochloride, 0.5-5 parts of repaglinide and 10-200 parts of medicinal auxiliary materials. The medicinal auxiliary materials include, but are not limited to filler, disintegrant, binding agent, alkali and lubricant. The invention also relates to a method for preparing the pharmaceutical composition. The pharmaceutical composition provided by the invention has favorable pharmaceutical properties.

Owner:HANGZHOU ZHUYANGXIN PHARMA

High-strength aluminum nitride ceramic substrate and preparation method thereof

The invention relates to the technical field of ceramic materials, and provides a high-strength aluminum nitride ceramic substrate and a preparation method thereof. The high-strength aluminum nitride ceramic substrate comprises the following raw materials by weight: 78-85 parts of modified aluminum nitride powder, 36-42 parts of a solvent, 1.2-2 parts of a dispersant, 8-11 parts of a binder and 2-4 parts of a plasticizer; and the aluminum nitride ceramic substrate is prepared through the procedures of ball milling, vacuum foaming, tape casting, isostatic pressing, rubber discharging, primary sintering and secondary sintering in sequence. The thermal conductivity of the prepared aluminum nitride ceramic is 180 W / (m.K) or above, the bending strength is 520 MPa or above, and the problem that the bending strength of the aluminum nitride ceramic is not high in the prior art is solved.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Plastic foaming catalyst for replacing zinc oxide and preparation method thereof

ActiveCN105037782ANo irritating ammonia smellResidue reductionPigment treatment with non-polymer organic compoundsOrganic acidPolymer science

The invention discloses a plastic foaming catalyst for replacing zinc oxide and a preparation method thereof. The plastic foaming catalyst is zinc oxide modified by an organic acid. The preparation method includes the steps of: adding the organic acid and the zinc oxide according to the molar ratio of 0.9-1.0:1 into a reaction kettle, heating the reaction kettle to 145-155 DEG C with stirring, maintaining the temperature, and carrying out a reaction for 0.3-0.4 h to obtain the plastic foaming catalyst. The plastic foaming catalyst can achieve the performance requirements, which cannot be satisfied with zinc oxide as the catalyst, in a foamed product. The plastic foaming catalyst allows the foamed product to be free of stimulating ammonia smell and enables residue of formamide to be reduced.

Owner:东莞豪峻橡塑有限公司

165-steel-grade drill rod weld joint heat treatment method

ActiveCN105803162AFully transformedBreak down evenlyFurnace typesHeat treatment furnacesFriction weldingHardness

The invention discloses a 165-steel-grade drill rod weld joint heat treatment method. A drill rod weld joint is formed by conducting friction welding on a drill rod connector and a drill rod pipe body, the steel grade of the drill rod connector is 135 ksi, and the steel grade of the drill rod pipe body is 165 ksi. The 165-steel-grade drill rod weld joint heat treatment method comprises the steps of 1 quenching, 2 first-time tempering and 3 second-time tempering, wherein during the second-time tempering of the step 3, the center of a tempering coil is aligned to the position, deviating from one side of the pipe body, of the weld joint for 8-12 mm. The 165-steel-grade drill rod weld joint heat treatment method reduces the side hardness of the weld joint pipe body and makes the structure of a whole welding area more uniform, better comprehensive mechanical properties are obtained, and the service life is prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com