Forging technology for automobile aluminum alloy chassis class parts

An aluminum alloy and chassis technology, applied in the field of material processing, can solve the problems of artificial aging, increase production cycle and production cost, and achieve the effect of reducing production cycle, uniform decomposition and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

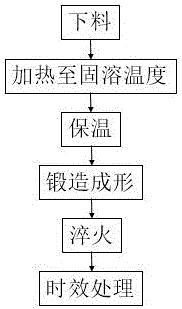

Method used

Image

Examples

example 1

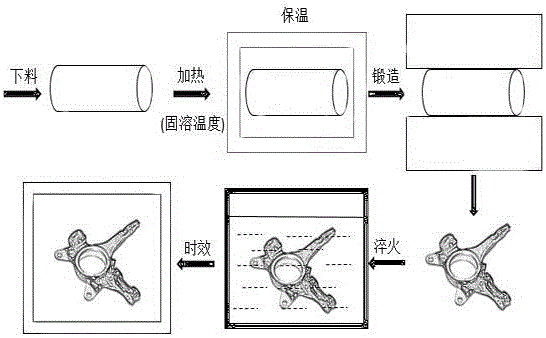

[0029] Example 1: 6061 aluminum alloy was forged by this process.

[0030] The first step: will be as Figure 4 The 6061 aluminum alloy billet shown (the billet is a bar with a height of 15mm and a diameter of 10mm) is heated to 530°C±5°C, and the holding time is 20min.

[0031] The second step: forging the aluminum alloy blank after the first step of heat preservation, the forging temperature is 430°C-480°C, the deformation amount is 40%, the strain rate is 10 / s, and the size of the aluminum alloy forging after deformation is as follows: Figure 5 shown.

[0032] Step 3: Quenching the aluminum alloy forging formed in the second step.

[0033] The fourth step: artificially aging the aluminum alloy forging after the quenching in the third step, the aging temperature is 175°C±5°C, and the aging time is 8h.

[0034] Table 1 is the forging hardness test after implementing Example 1, and the distribution of corresponding hardness test points is as follows Figure 6 shown. For ...

example 2

[0036] Example 2: This process is used to forge 2A14 aluminum alloy.

[0037] Step 1: Heat the 2A14 aluminum alloy billet bar to 500°C±5°C, select the holding time according to the shape and size of the billet, and the holding time range is 10-270min.

[0038] The second step: forging the aluminum alloy billet after the first step of heat preservation, the forging temperature is 380°C-480°C, and the deformation amount is controlled according to the required forging shape, and the deformation amount ranges from 10% to 85%.

[0039] The third step: Quenching the aluminum alloy forging formed in the second step, and controlling the transfer time of the aluminum alloy forging in the process from the second step to the third step within 10 seconds.

[0040] Step 4: Perform artificial aging treatment on the aluminum alloy forging after quenching in the third step. The aging temperature is 160°C±5°C. The aging time is selected according to the shape and size of the forging, and the a...

example 3

[0041] Example 3: Using this process to forge and form 7075 aluminum alloy.

[0042] Step 1: Heat the 7075 aluminum alloy billet bar to 475°C±5°C, select the holding time according to the shape and size of the billet, and the holding time range is 10-270min.

[0043]The second step: forging the aluminum alloy blank after the first step of heat preservation, the forging temperature is 360°C-450°C, and the deformation is controlled according to the shape of the forging required, and the deformation range is 10%-85%.

[0044] The third step: Quenching the aluminum alloy forging formed in the second step, and controlling the transfer time of the aluminum alloy forging in the process from the second step to the third step within 10 seconds.

[0045] The fourth step: artificially aging the aluminum alloy forging after the quenching in the third step, the aging temperature is 120°C±5°C, and the aging time is 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com