Polypropylene resin foam concentrate and preparation method thereof

A polypropylene resin and foaming masterbatch technology, applied in the field of polypropylene resin foaming masterbatch and its preparation, can solve the problems of unsuitable polypropylene foaming molding, complex masterbatch production process, large equipment investment and the like, and achieve molecular weight The effect of smaller, lower crystallinity, higher melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

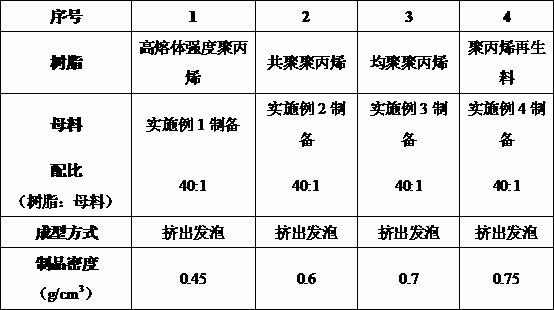

Examples

Embodiment 1

[0040] The preparation of embodiment 1 polypropylene resin foaming masterbatch

[0041] 100 kilograms of polypropylene resin, irradiated by high-energy electron beams under an electron accelerator, the absorbed dose is 15kGy, add 6 kilograms of sodium bicarbonate, 3 kilograms of sodium citrate, 30 kilograms of azodicarbonamide, 5 kilograms of talcum powder, 500 grams of four (3,5-di-tert-butyl-4-hydroxy)pentaerythritol phenylpropionate, 1 kg of stearic acid and 500 g of paraffin, mixed in a high-speed mixer for 6 minutes at a mixing temperature of 40°C and a speed of 600-900r / min . After the material is discharged, it is compounded and extruded in the COPERION two-stage extruder. The temperature of the nine heating zones of the twin-screw extruder is set to 110°C, 115°C, 120°C, 125°C, 125°C, 130°C, and 130°C. °C, 130 °C, 120 °C, the screw speed is 300 r / min, the temperature of the three heating zones of the single-screw extruder is set to 130 °C, 135 °C, 130 °C in turn, and ...

Embodiment 2

[0043] The preparation of embodiment 2 polypropylene resin foam masterbatch

[0044] 100 kilograms of polypropylene resin, irradiated by high-energy electron beams under an electron accelerator, the absorbed dose is 20kGy, add 6 kilograms of sodium bicarbonate, 3 kilograms of sodium citrate, 30 kilograms of azodicarbonamide, 5 kilograms of talcum powder, 500 grams of four (3,5-di-tert-butyl-4-hydroxy)pentaerythritol phenylpropionate, 1 kg of stearic acid and 500 g of paraffin, mixed in a high-speed mixer for 6 minutes at a mixing temperature of 40°C and a speed of 600-900r / min . After the material is discharged, it is compounded and extruded in the COPERION two-stage extruder. The temperature of the nine heating zones of the twin-screw extruder is set to 110°C, 115°C, 120°C, 125°C, 125°C, 130°C, and 130°C. °C, 130 °C, 120 °C, the screw speed is 300 r / min, the temperature of the three heating zones of the single-screw extruder is set to 130 °C, 135 °C, 130 °C in turn, and the ...

Embodiment 3

[0046] The preparation of embodiment 3 polypropylene resin foam masterbatch

[0047] 100 kilograms of polypropylene resin, irradiated by high-energy electron beams under an electron accelerator, the absorbed dose is 25kGy, add 6 kilograms of sodium bicarbonate, 3 kilograms of sodium citrate, 30 kilograms of azodicarbonamide, 5 kilograms of talcum powder, 500 grams of four (3,5-di-tert-butyl-4-hydroxy)pentaerythritol phenylpropionate, 1 kg of stearic acid and 500 g of paraffin, mixed in a high-speed mixer for 6 minutes at a mixing temperature of 40°C and a speed of 600-900r / min . After the material is discharged, it is compounded and extruded in the COPERION two-stage extruder. The temperature of the nine heating zones of the twin-screw extruder is set to 110°C, 115°C, 120°C, 125°C, 125°C, 130°C, and 130°C. °C, 130 °C, 120 °C, the screw speed is 300 r / min, the temperature of the three heating zones of the single-screw extruder is set to 130 °C, 135 °C, 130 °C in turn, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com