Fermented crystal allium chinense and preparation method thereof

A technology of scallions and crystals, applied in food preparation, bacteria used in food preparation, food science, etc., can solve the problems of easy browning of scallions, poor flavor of scallions, and yellowing of color, so as to avoid browning Effects of yellowing, reduction of salt consumption, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

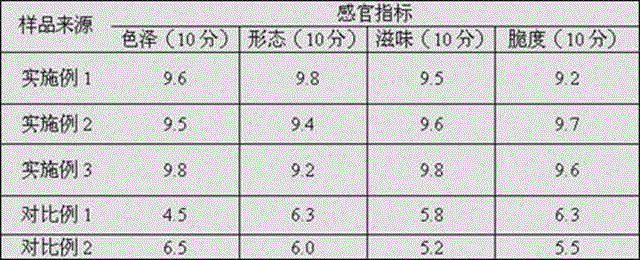

Embodiment 1

[0022] Embodiment 1 A kind of fermented crystal oyster and preparation method thereof, concrete steps are as follows:

[0023] (1) Take 1 kg of good-quality scallions, remove impurities, then wash them with clean water and shape them;

[0024] (2) Add 2 kg of lactic acid with a concentration of 2% (v / v) to the onion obtained in step (1), and soak for 4 hours at room temperature;

[0025] (3) Take the onion head obtained in step (2), drain it, and then quickly freeze it at -18°C for 18 hours;

[0026] (4) Based on the quality of the frozen onion obtained in step (3), add 1% (w / w) L-cysteine, 4% (w / w) salt, 1% (w / w) lactic acid, 1% (w / w) mixed live bacteria, the CFU ratio of Lactobacillus plantarum, Lactobacillus brevis and Lactococcus lactis in the mixed live bacteria is 1:1:1, after mixing, ferment at 15°C for 30 days;

[0027] (5) Take out the scallions obtained in step (4), add seasoning, pack and sterilize to obtain fermented crystal scallions.

Embodiment 2

[0028] Embodiment 2 A kind of fermented crystal oyster and preparation method thereof, concrete steps are as follows:

[0029] (1) Take 1 kg of good-quality scallions, remove impurities, then wash them with water, and shape them;

[0030] (2) Add 2 kg of lactic acid at a concentration of 6% (v / v) to the onions obtained in step (1) and soak for 24 hours at room temperature;

[0031] (3) Take the onion head obtained in step (2), drain it, and then freeze it at -18°C for 36 hours;

[0032] (4) Based on the quality of the frozen onion obtained in step (3), add 1% (w / w) L-cysteine, 8% (w / w) salt, 3% (w / w) lactic acid, 4% (w / w) mixed live bacteria, the CFU ratio of Lactobacillus plantarum, Lactobacillus brevis and Lactococcus lactis in the mixed live bacteria is 2:2:1, after mixing, ferment at 25°C for 6 days;

[0033] (5) Take out the scallions obtained in step (4), add seasoning, pack and sterilize to obtain fermented crystal scallions.

Embodiment 3

[0034] Embodiment 3 A fermented crystal scallop and a preparation method thereof, the specific steps are as follows:

[0035] (1) Take 1 kg of good-quality scallions, remove impurities, then wash them with water, and shape them;

[0036] (2) Add 4% (v / v) lactic acid to the onions obtained in step (1) and soak for 14 hours at room temperature;

[0037] (3) Take the onion head obtained in step (2), drain it, and then freeze it at -18°C for 27 hours;

[0038] (4) Based on the quality of the frozen onion obtained in step (3), add 1% (w / w) L-cysteine, 6% (w / w) salt, 2% (w / w) lactic acid, 2.5% (w / w) mixed live bacteria, the CFU ratio of Lactobacillus plantarum, Lactobacillus brevis and Lactococcus lactis in the mixed live bacteria is 1:1.5:1, after mixing, ferment at 20°C for 18 days;

[0039] (5) Take out the scallions obtained in step (4), add seasoning, pack and sterilize to obtain fermented crystal scallions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com