Olivine nickel-based catalyst for preparing hydrogen through autothermal reforming of acetic acid

An autothermal reforming, olivine-type technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrogen, etc., can solve problems such as catalyst deactivation, achieve reduced selectivity, The effect of improving activity and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

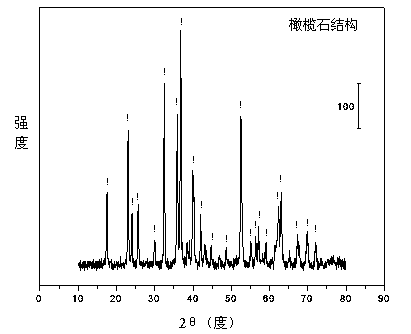

[0028] Weigh 23.106 grams of Ni(NO 3 ) 2 ·6H 2 O and 115.451 grams of Mg(NO 3 ) 2 ·6H 2 O, add 530 ml of deionized water to make solution #1. Weigh 75.274 grams of NaSiO 3 .9H 2 O, add 270 ml of deionized water to make solution #2. Weigh 10.0 g of NaOH and add it to 130 ml of deionized water to prepare solution #3. Co-precipitate the solution #1 and solution #2 at 75 degrees Celsius, and control the pH of the reaction solution within the range of 10.5±0.5 by controlling the addition rate of solution #3. After the co-precipitation is completed, the suspension Add 10.0 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123, Mn=5800), stir for 2 hours, transfer to the reactor, and place at 170 degrees Celsius It is maintained in the oven for 36 hours, and then the suspended matter in the reactor is filtered, washed, dried, and calcined at 800 degrees Celsius to obtain the catalyst CUT-HS-N-101 with olivine structure as the main body. Its typic...

Embodiment 2

[0031] Weigh 22.565 grams of Ni(NO 3 ) 2 ·6H 2 O, 54.005 grams of Mg(NO 3 ) 2 ·6H 2 O and 62.696 grams of Fe(NO 3 ) 3 .9H 2 O, add 530 ml of deionized water to make solution #1. Weigh out 63.008 grams of NaSiO 3 .9H 2 O, add 230 ml of deionized water to make solution #2. Weigh 10.0 g of NaOH and add it to 130 ml of deionized water to prepare solution #3. Co-precipitate the solution #1 and solution #2 at 75 ℃, and control the pH value of the reaction solution within the range of 10.5±0.5 by controlling the addition rate of solution #3. After the co-precipitation is completed, the resulting suspension Add 10.0 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123, Mn=5800), stir for 2 hours, and transfer to the reactor. The subsequent steps are the same as in Example 1, to obtain the catalyst CUT-HS-NF-201, whose typical olivine structure can be figure 1 At the same time, the scanning electron microscope picture shows that the catalyst has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com