Preparation method of ferrous sulfide/attapulgite composite

A technology of attapulgite and ferrous sulfide, which is applied in catalyst activation/preparation, chemical instruments and methods, separation methods, etc., can solve the problems of limited optical coupling-SCR application, insufficient visible light utilization efficiency, and no reports, etc. High industrial promotion value, beneficial to catalytic activity, and the effect of increasing lattice defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Weigh 0.47g of ferric nitrate, 1.5g of thioacetamide and 0.21g of attapulgite, add 60ml of deionized water to ultrasonic and stir for 30min; transfer the mixture to a reaction kettle at 220°C for 24h; multiple times Wash with water and alcohol, and dry at 100°C for 24 hours to obtain the ferrous sulfide / attapulgite composite material.

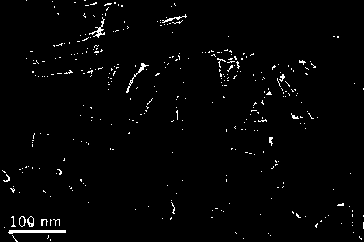

[0023] The morphology and structure of the obtained samples were observed under a transmission electron microscope, such as figure 1 As can be seen from the figure, the small particles of FeS 2 Evenly loaded on the surface of the attapulgite.

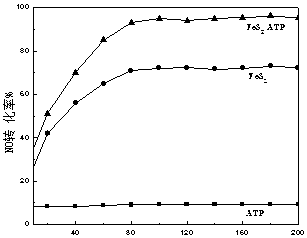

[0024] Add 150 mg of ATP and FeS to the quartz tube of the light-assisted-SCR de-pinning device 2 , FeS 2 / ATP; NH 3 , NO, O 2 The initial concentrations are: 1000ppm, 1000ppm, 3% (relative to the total gas flow), and the space velocity is 25000h -1 , the total gas flow rate is controlled at 100ml / min, the light source used is a 500W xenon lamp, and the light wavelength is: 380-78...

Embodiment 2

[0025] Example 2: Weigh 0.47g of ferric nitrate, 1.5g of thioacetamide and 0.08g of attapulgite, add 60ml of deionized water to ultrasonic and stir for 30min; transfer the mixed solution to a reaction kettle at 200°C for 16h; Wash with water and alcohol, and dry at 60°C for 12 hours to obtain the ferrous sulfide / attapulgite composite material. Subsequent detection was as in Example 1.

Embodiment 3

[0026] Example 3: Weigh 0.47g of ferric nitrate, 1.5g of thioacetamide and 0.32g of attapulgite, add them into 60ml of deionized water and stir for 30min after ultrasonication; transfer the mixed solution to a reaction kettle at 180°C for reaction 20h; washing with water and alcohol, and drying at 80°C for 16h to obtain the ferrous sulfide / attapulgite composite material. Subsequent detection was as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com