Large-size porcelain thin plate and production method thereof

A production method and large-scale technology, applied in the field of ceramic processing, can solve the problems of high cost, environmental pollution, easy chipping, and reduced green body strength, etc., to improve thermal stability and mechanical strength, reduce production costs, and sintering performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

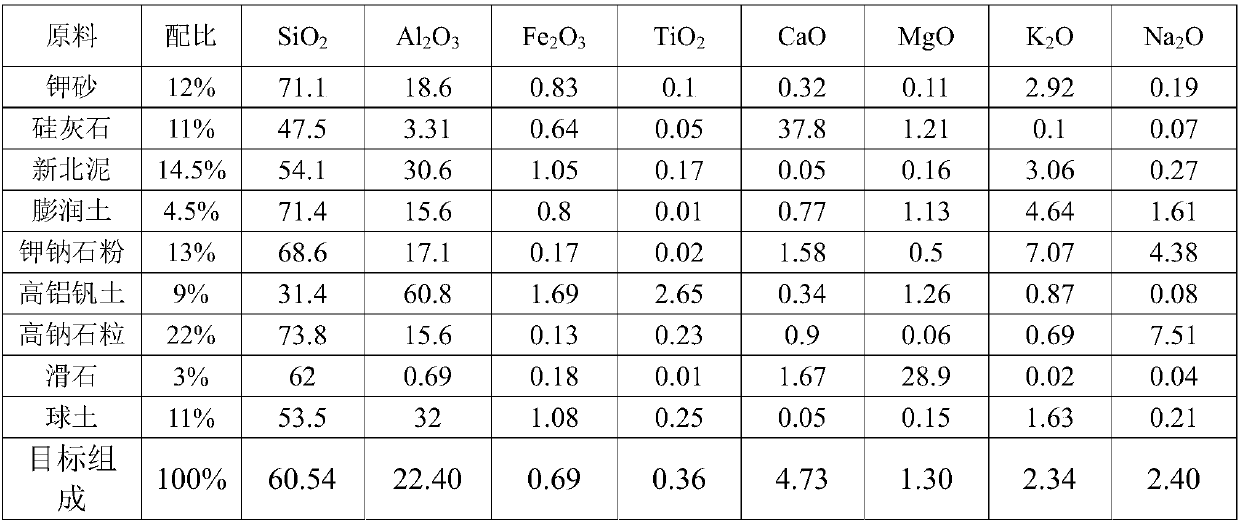

[0039] According to the actual chemical composition of a certain batch of raw materials (see Table 1 for the characteristic chemical composition of raw materials), the ingredients are weighed (wt%) according to the ratio in Table 2 below, and the total amount of ingredients is 48t.

[0040] Table 2

[0041] raw material

Proportion

SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

Potassium sand

10%

71.1

18.6

0.83

0.1

0.32

0.11

2.92

0.19

11%

47.5

3.31

0.64

0.05

37.8

1.21

0.1

0.07

Xinbeini

17.5%

54.1

30.6

1.05

0.17

0.05

0.16

3.06

0.27

4.5%

71.4

15.6

0.8

0.01

0.77

1.13

4.64

1.61

12%

68.6

17.1

0.17

0.02

1.58

0.5

7.07

4.38

9%

31.4

60.8

1.69

2.65

0.34

1.26

0...

Embodiment 2

[0047] According to the actual chemical composition of the same batch of raw materials in Example 1 (see Table 1 for the characteristic chemical composition of the raw materials), the ingredients were weighed (wt %) according to the ratio in Table 3 below, and the total amount of ingredients was 48t.

[0048] table 3

[0049]

[0050] Add 0.05% sodium carboxymethylcellulose of the total weight of raw materials, 0.1% composite sodium phosphate, 0.3% water glass and 33% water and send them into a ball mill together to form a slurry with a million-hole sieve residue of 0.9%. The resulting slurry was spray-dried to make green body powder with a moisture content of 7.2%, which was stale for 60 hours before use. The green body powder is pressed under 16800t pressure to form a large size thin green body with a thickness of 0.9m×2.6m and a thickness of 5.7mm. The body is dried in a hot air drying kiln at 200°C for 10 minutes; the surface is wet-sprayed with glaze, the moisture con...

Embodiment 3

[0055] According to the actual chemical composition of another batch of raw materials (see Table 1 for the characteristic chemical composition of raw materials), the ingredients were weighed (wt%) according to the ratio in Table 4 below, and the total amount of ingredients was 48t.

[0056] Add 0.06% sodium carboxymethylcellulose of the total weight of raw materials, 0.09% composite sodium phosphate, 0.25% water glass and 35% water and send them into a ball mill together to form a slurry with a million-hole sieve residue of 0.7%. Spray-dry the resulting slurry to make green body powder with a moisture content of 7.5%, and stale for 48 hours. The green body powder is pressed into a large-scale thin green body with a thickness of 1m×2m and a thickness of 4.8mm through a pressure of 15000t. The green body is dried in a hot air drying kiln at 180°C for 15 minutes; the surface is wet-sprayed with glaze, the moisture content of the glaze is 30%, and the amount of glaze sprayed is 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com