Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Not easy to chip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

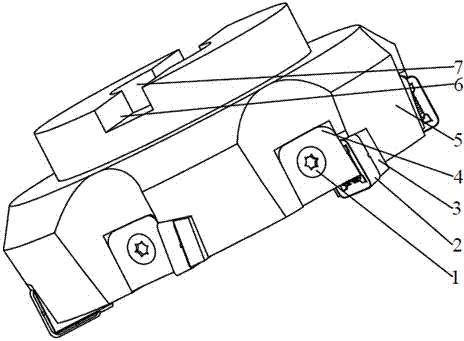

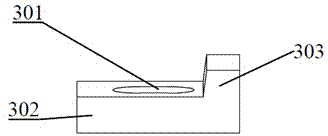

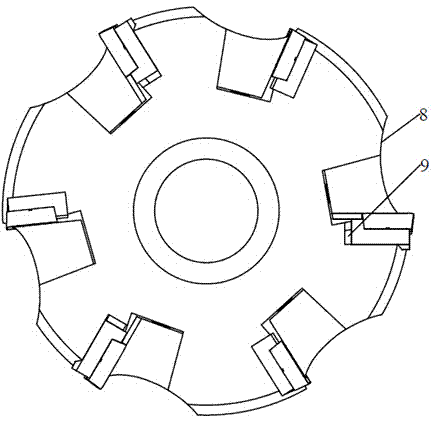

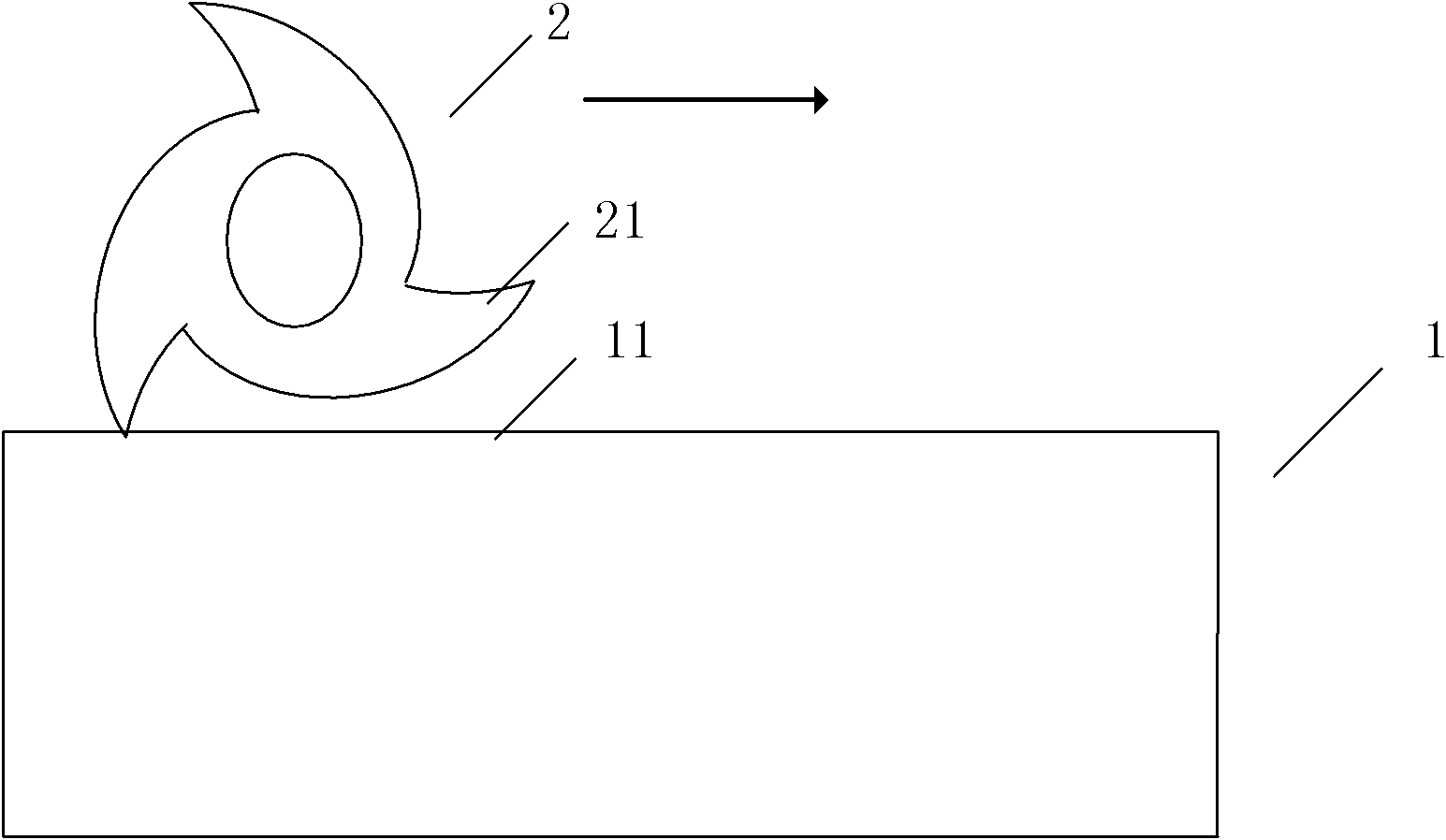

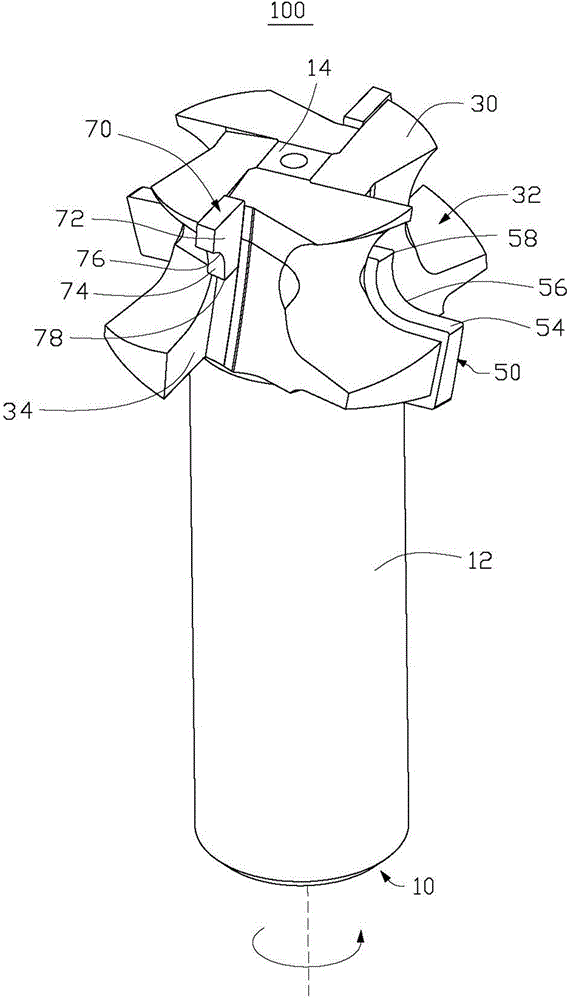

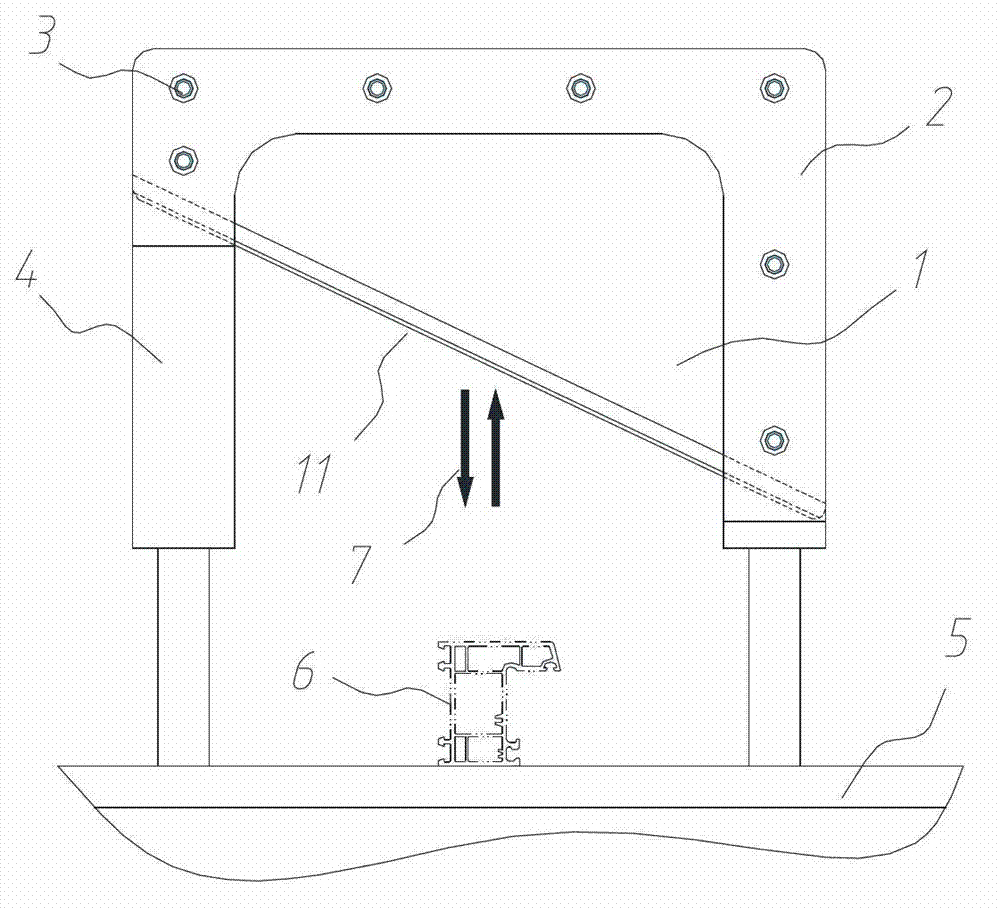

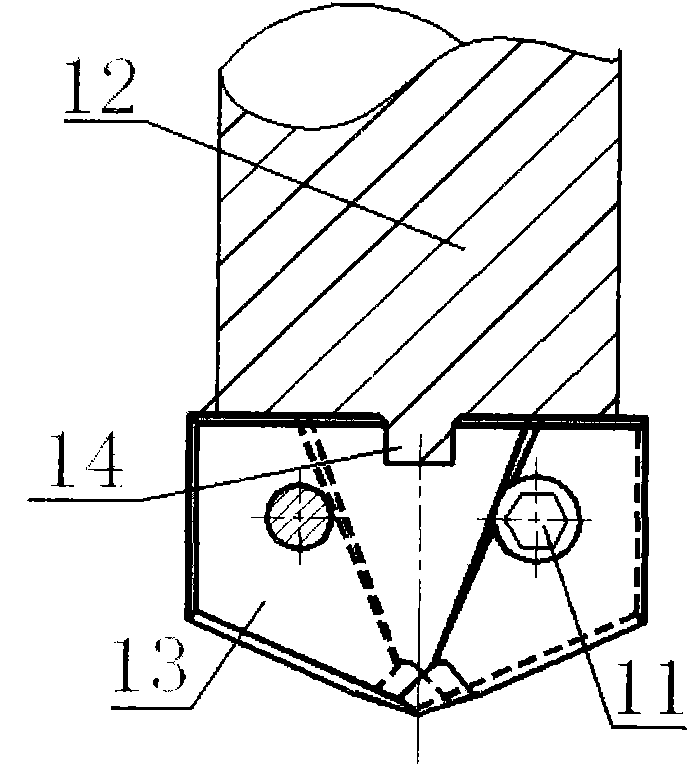

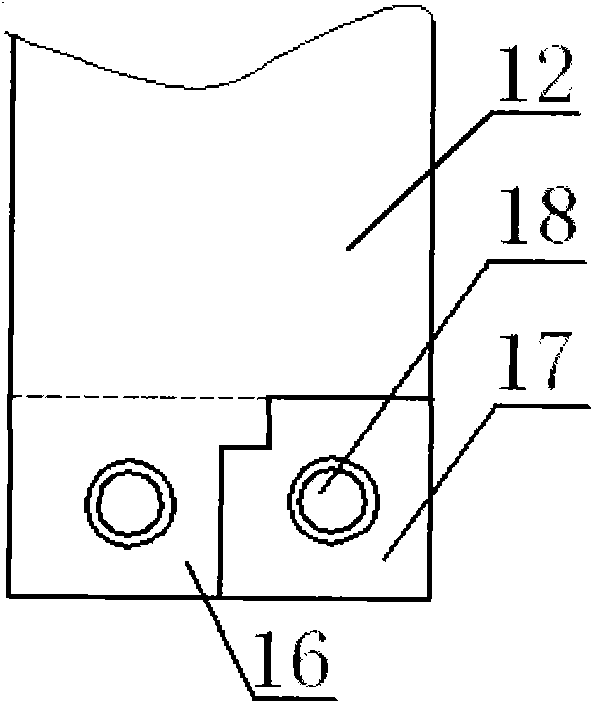

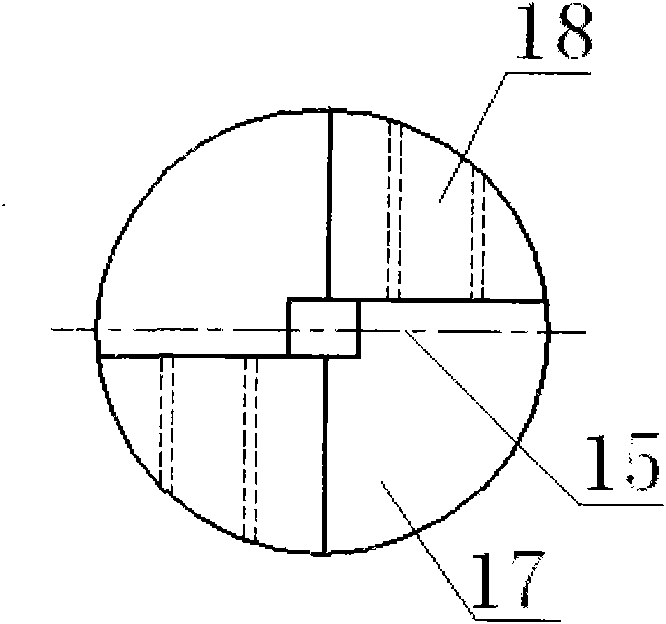

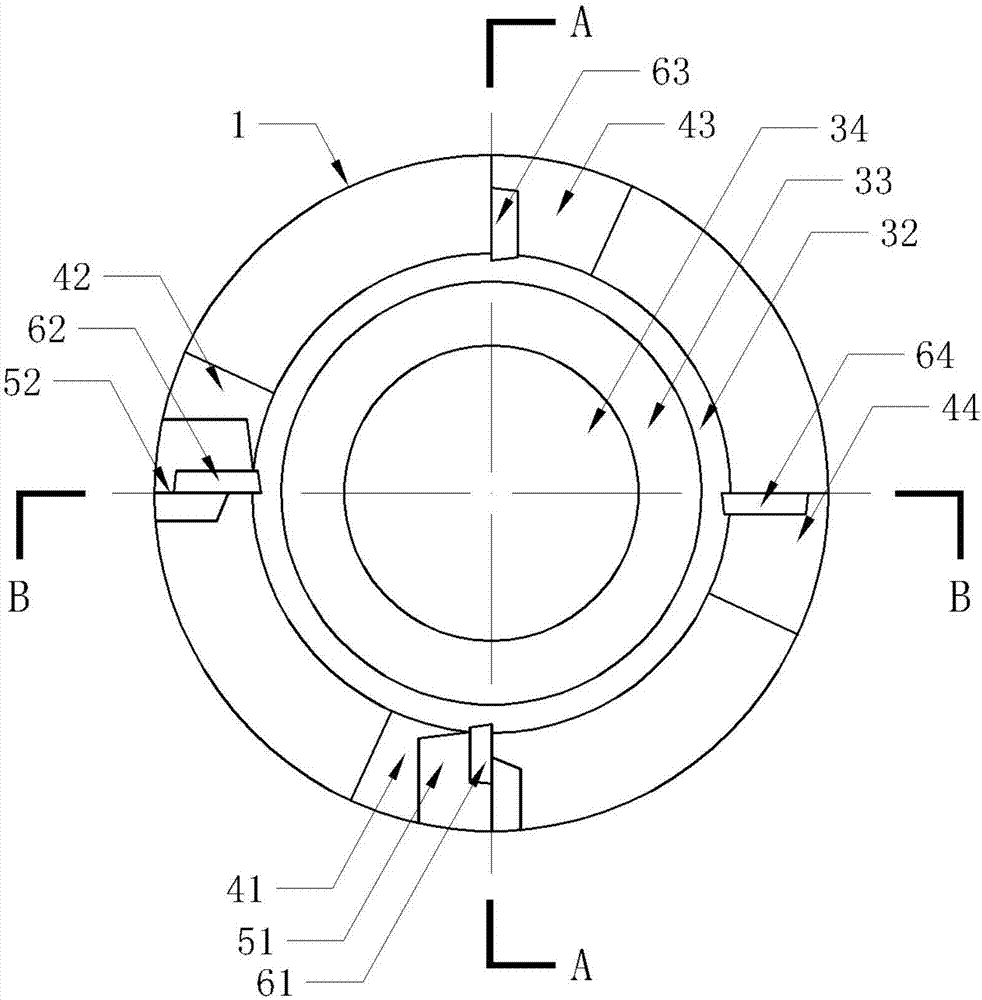

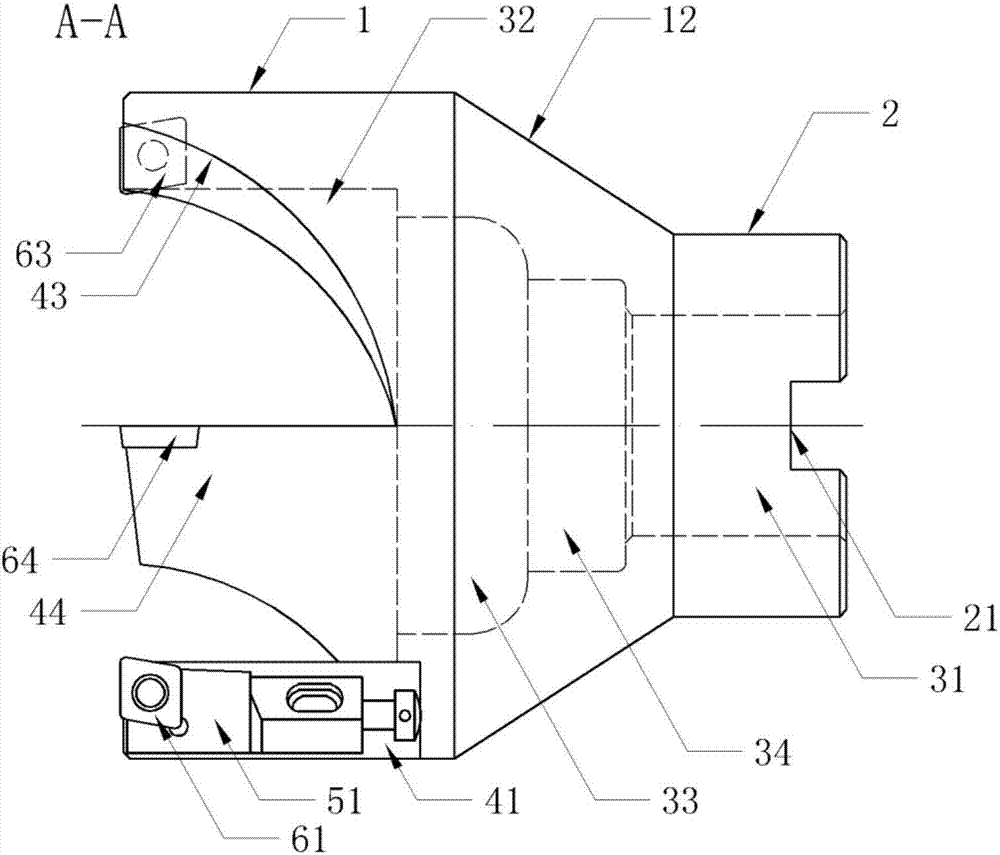

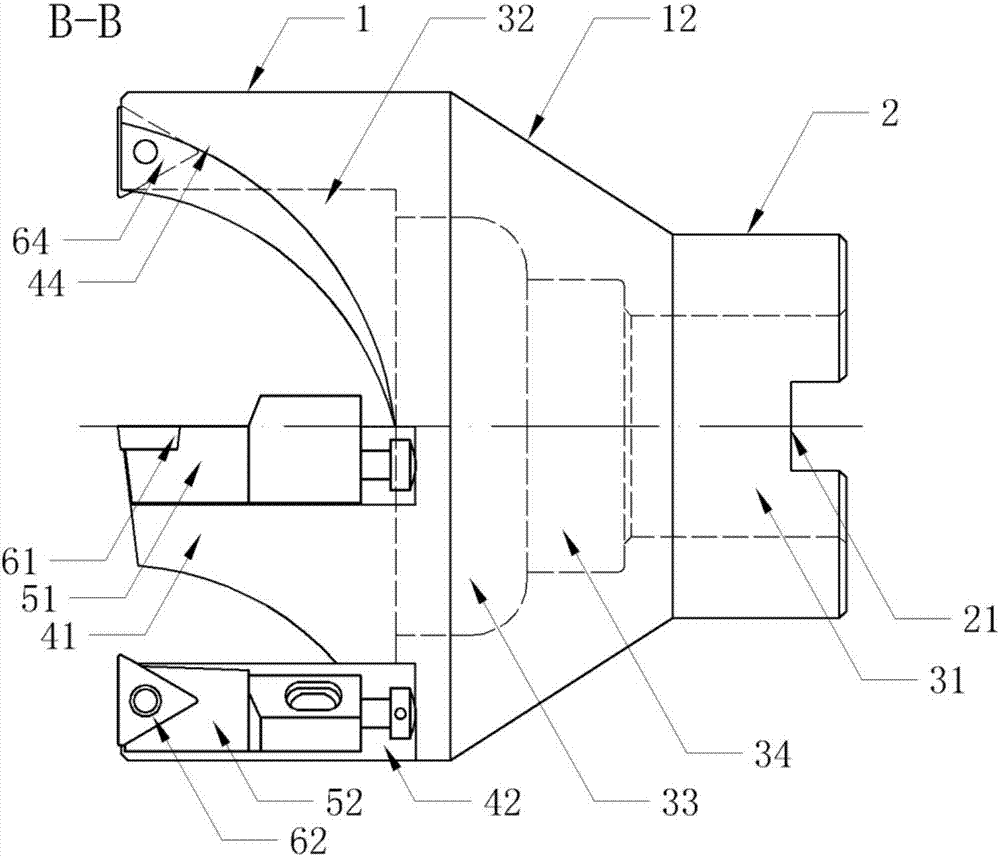

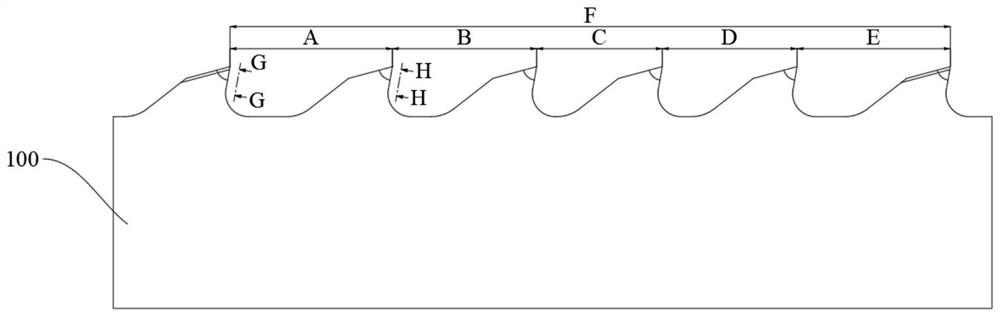

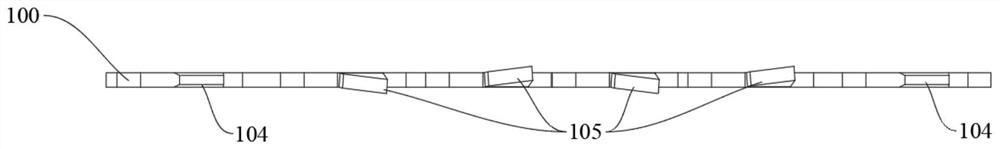

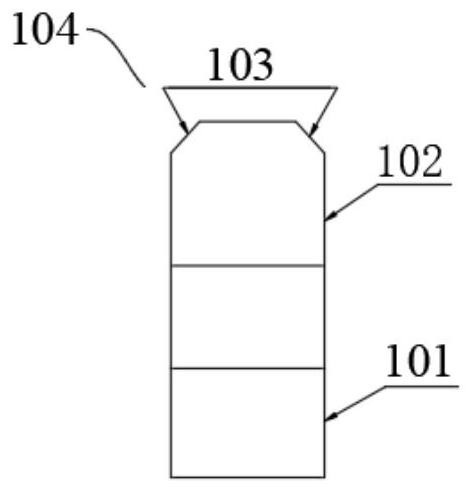

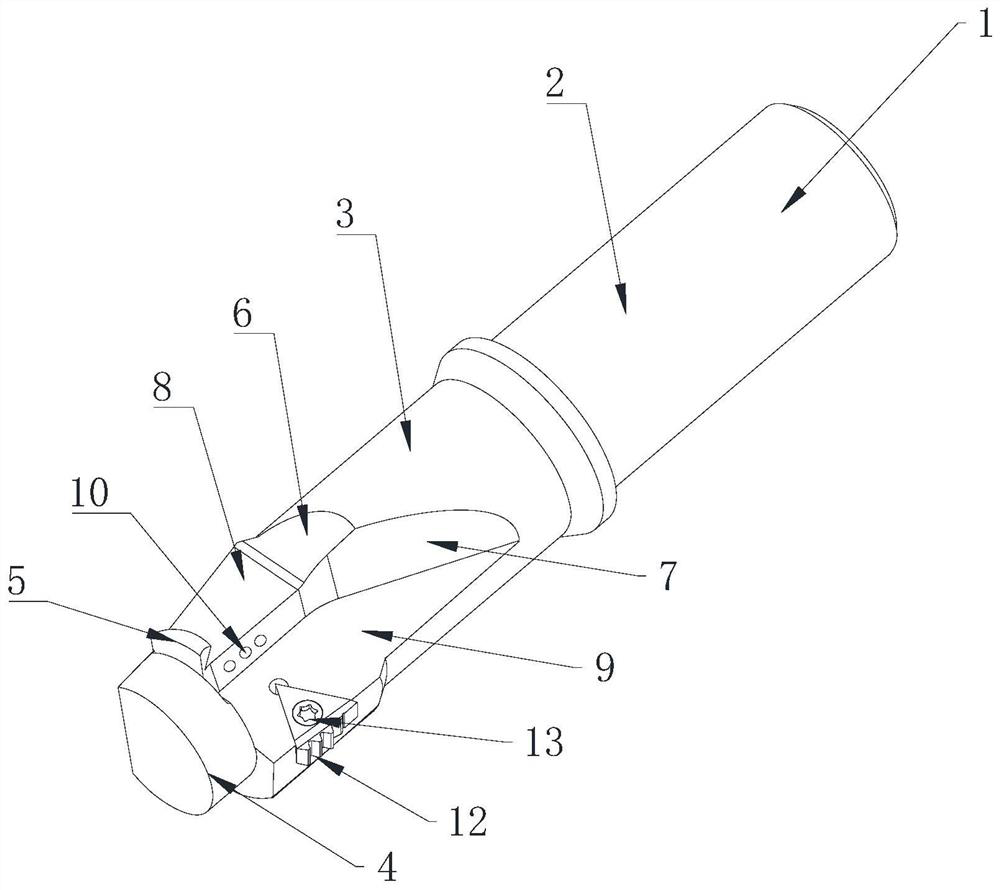

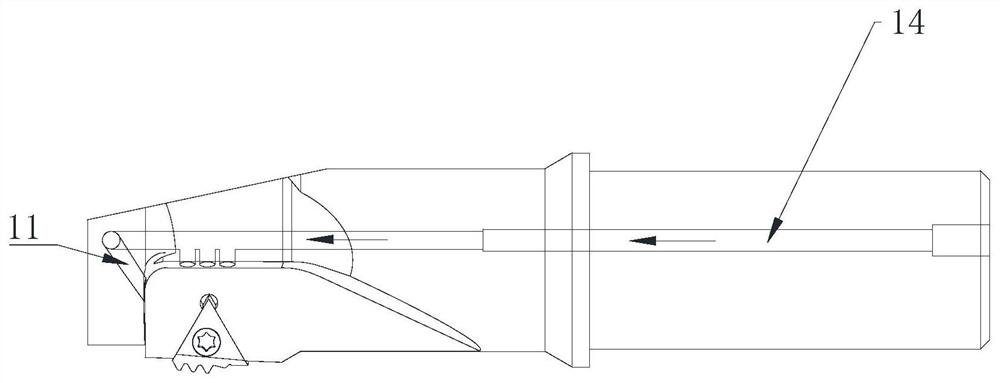

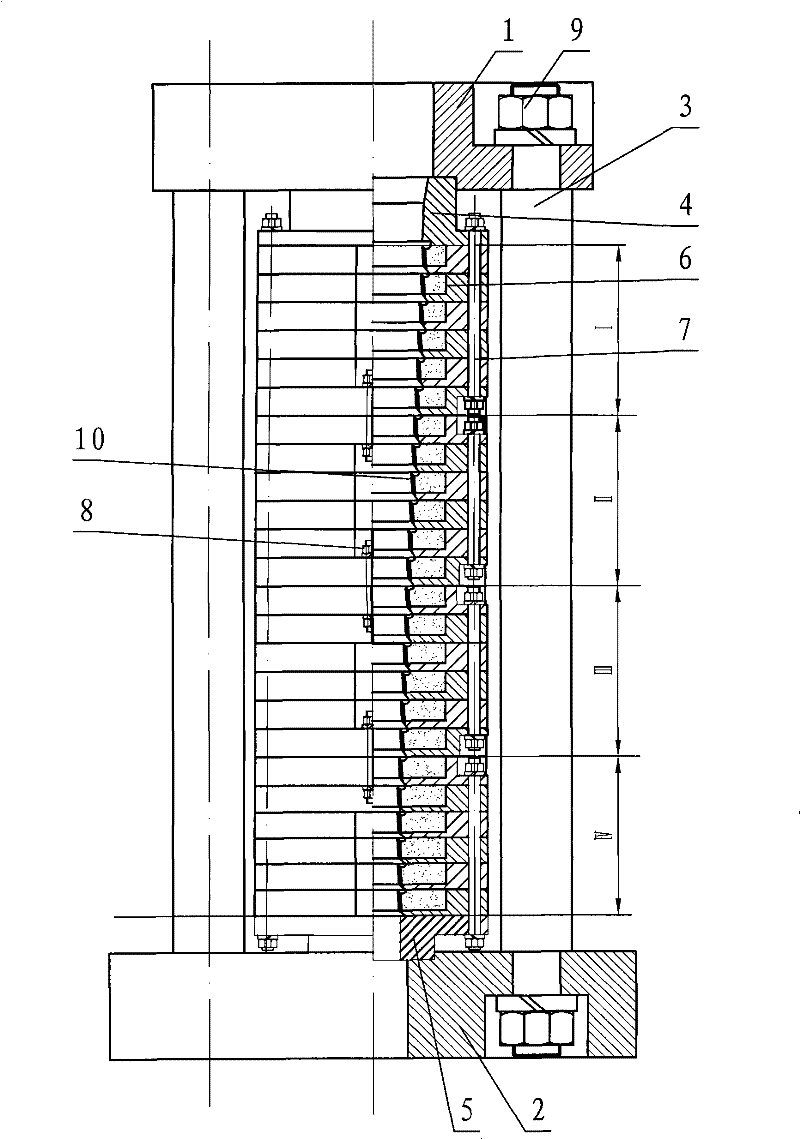

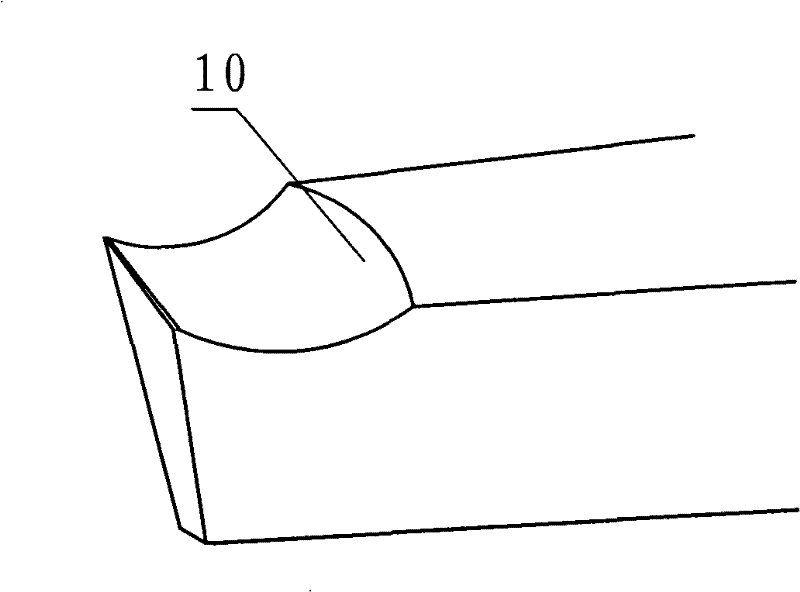

Radially-adjustable heavy-duty cutting layer milling cutter

InactiveCN104841994ARaise the natural frequencyChange milling forceTransportation and packagingMilling cuttersMilling cutterEngineering

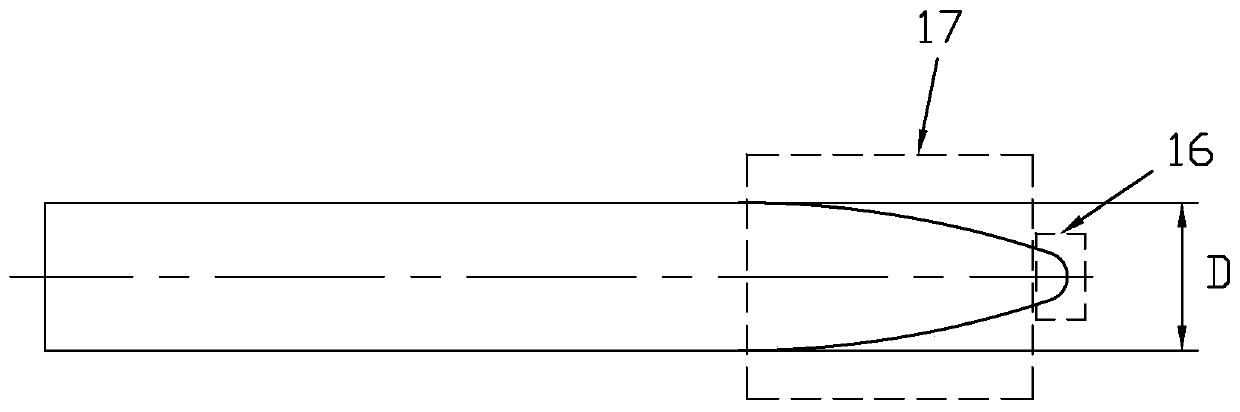

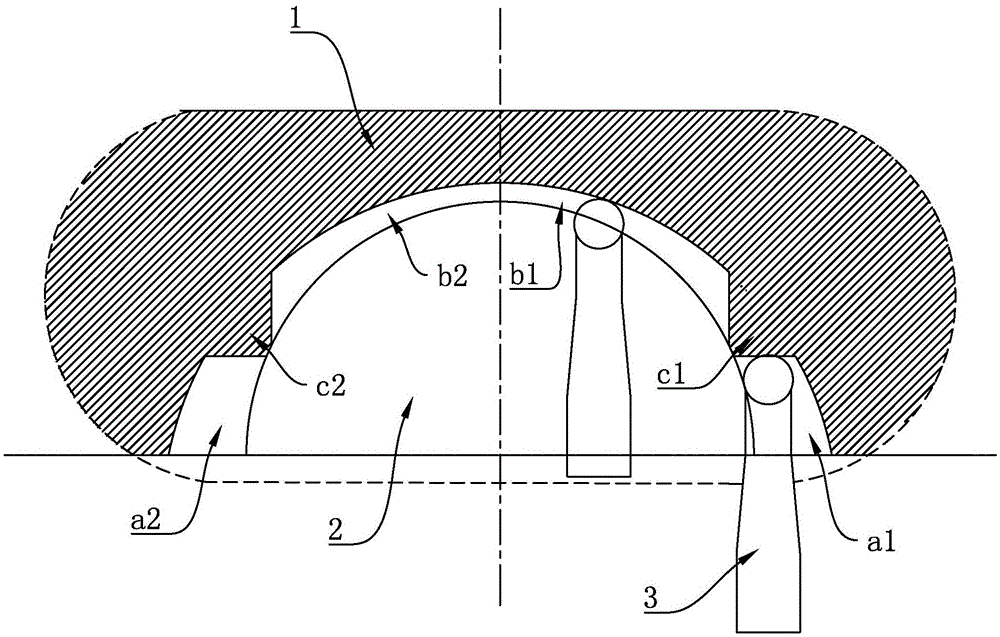

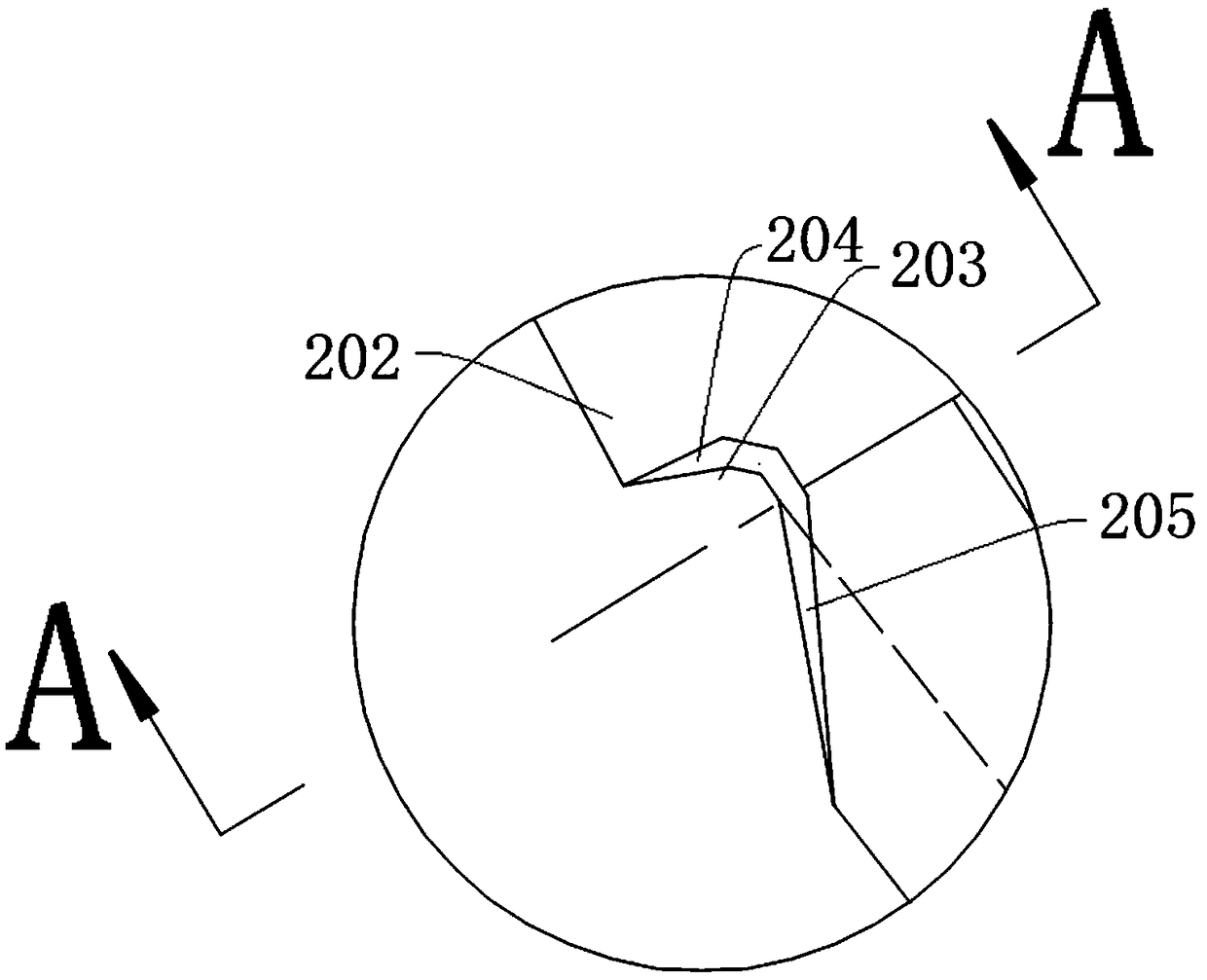

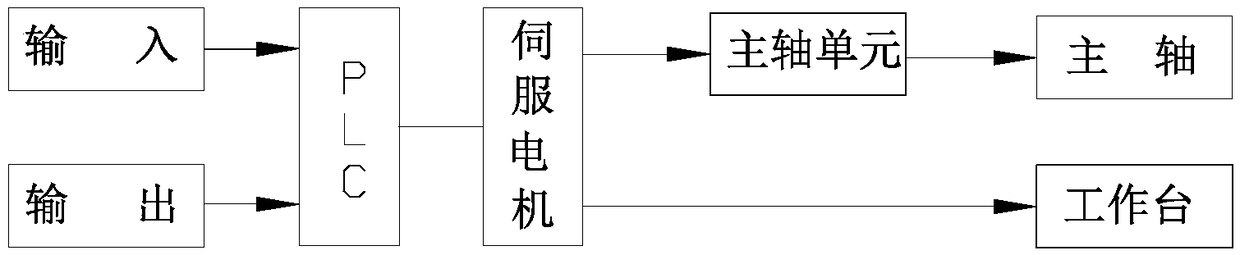

The invention discloses a radially-adjustable heavy-duty cutting layer milling cutter applicable to the field of heavy-type milling processing, and aims to solve the problems that during heavy-duty milling water chamber end enclosing, surfaces of workblanks are uneven, multi-defective and poor in machinability; cutting blades are prone to being damaged by impacts during rough machining or hogging machining; during milling, cutting depth changes frequently, which results in that not all cutter teeth are involved in cutting, utilization rate of the milling cutter is low, the cutting layer milling cutter of a fixed radial stepped structure is short in service life, machining efficiency is influenced and the like. Cutter teeth of the cutting layer milling cutter are designed in a stepped distribution, by means of increasing cutting depth, metal removal rate is increased, and machining efficiency is improved; by the aid of a radial adjusting mechanism, the cutting blades in an upper layer are enabled to move radially, a proper overhang amount can be selected, and strength of the cutting blades is enhanced. A radially-adjustable cutter pad is positioned by a pad block, auxiliary time including cutter amounting time, cutter adjusting time and the like is saved; up-warp chip holding grooves are formed in a cutter body in design, the depths of the positions, close to the cutting blades, of the chip holding grooves are far larger than that of the positions, distant from the cutting blades, of the chip holding grooves, up-warp slopes are formed in the chip holding grooves, and when cutting chips flow in the chip holding grooves, the chips can be separated from the cutter body quickly, friction between the chips and the cutter body is reduced, and service life of the cutter body is prolonged.

Owner:HARBIN UNIV OF SCI & TECH

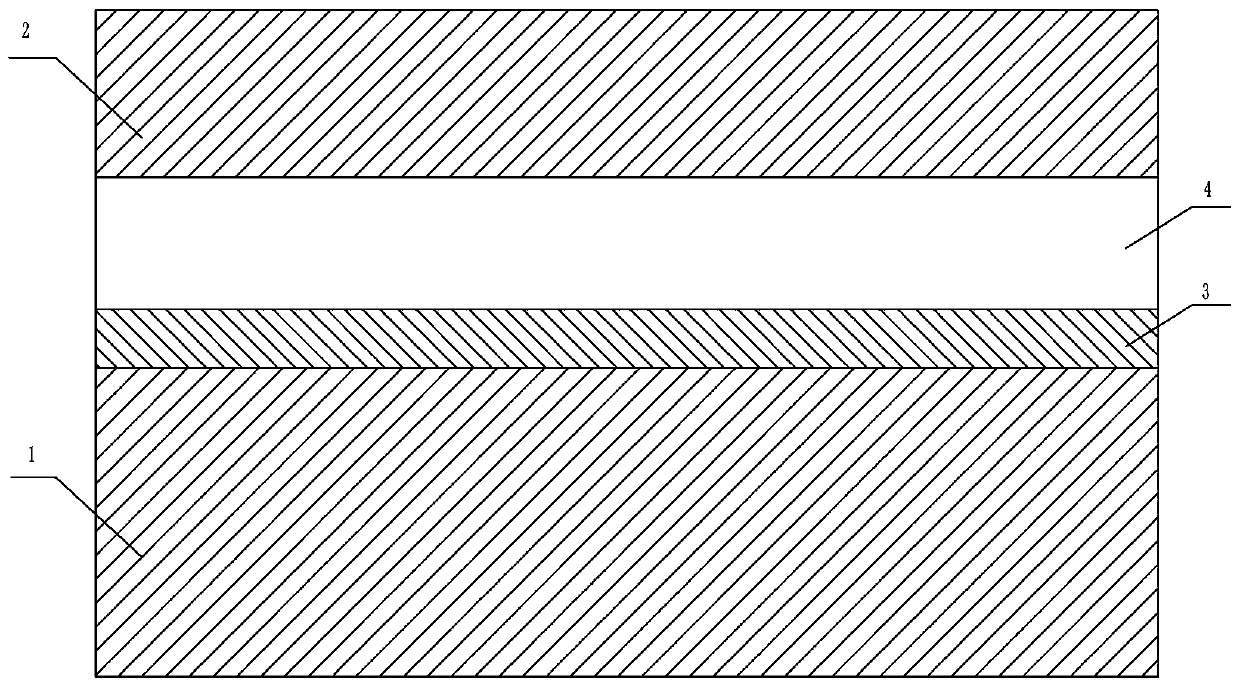

Sandwich-type polycrystalline diamond compact and preparation method thereof and used binding agent

The invention discloses a sandwich-type polycrystalline diamond compact and a preparation method thereof and a used binding agent. The binging agent is made through matching of Co powders, Ni powders, TaC powders and B powders according to a certain proportion. The sandwich-type polycrystalline diamond compact comprises two layers of cemented carbide matrixes and a polycrystalline diamond layer arranged between the two layers of cemented carbide matrixes. The polycrystalline diamond layer and diamond powders are matched in a certain proportion through the binding agent, the polycrystalline diamond layer and the substrate are composited with each other through high-temperature high-pressure sintering, and a superhard composite material with three layers of materials is formed. The cemented carbide layers play the role of a protecting layer, the stress state of the compact when the polycrystalline diamond layer is drilled in is improved, and tipping is avoided. The nanocrystalline metal binding agent can facilitate sintering in high temperature and high pressure, so that the boding density between the diamond (D-D bond) is improved, a good sintering promoting function is achieved, forming of a tough sintering body is facilitated, the impact toughness, the wear-resisting performance and the heat-resisting performance of the sandwich-type polycrystalline diamond compact are increased, and the technological difficulty of high-wearing feature and high impact toughness of the polycrystalline compact is overcome.

Owner:ZHONGNAN DIAMOND CO LTD

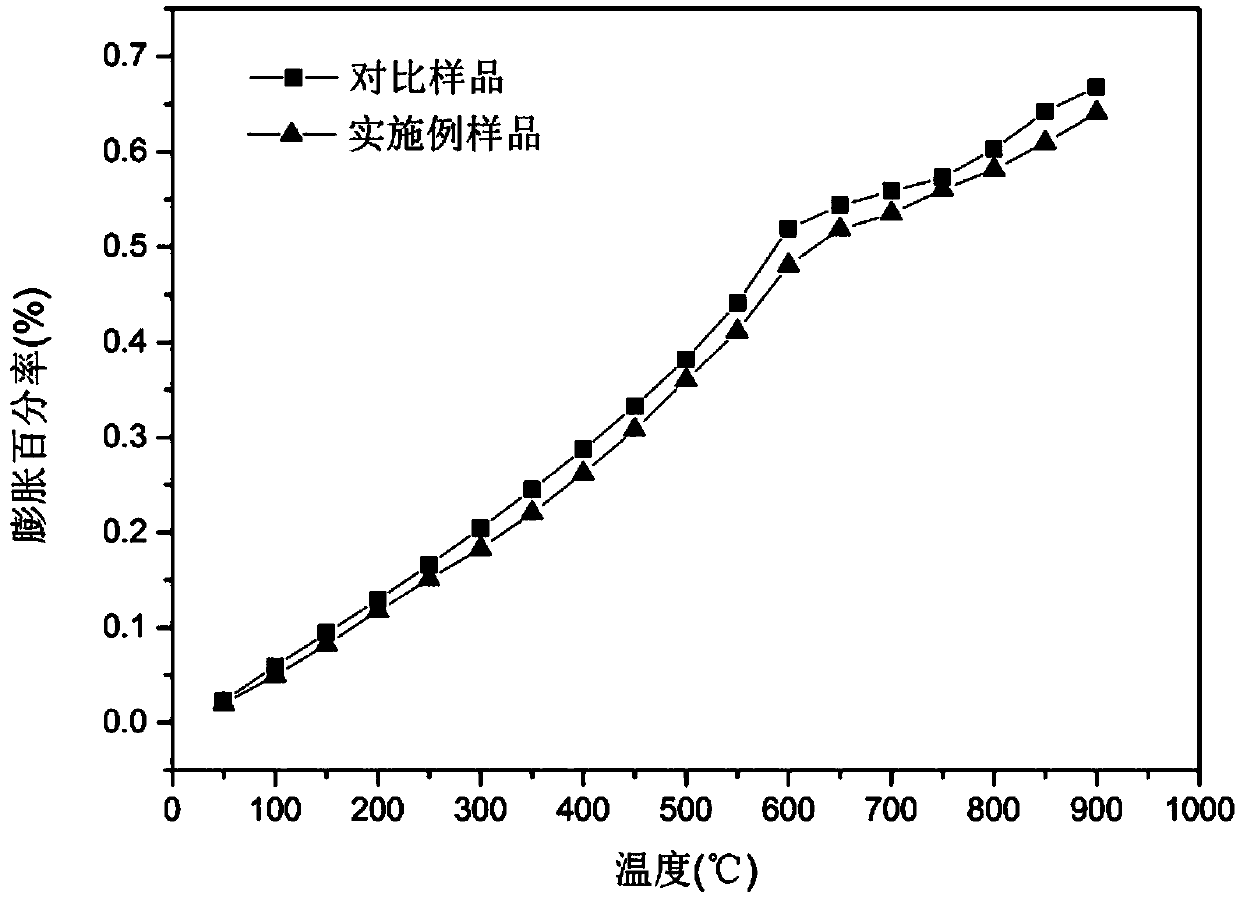

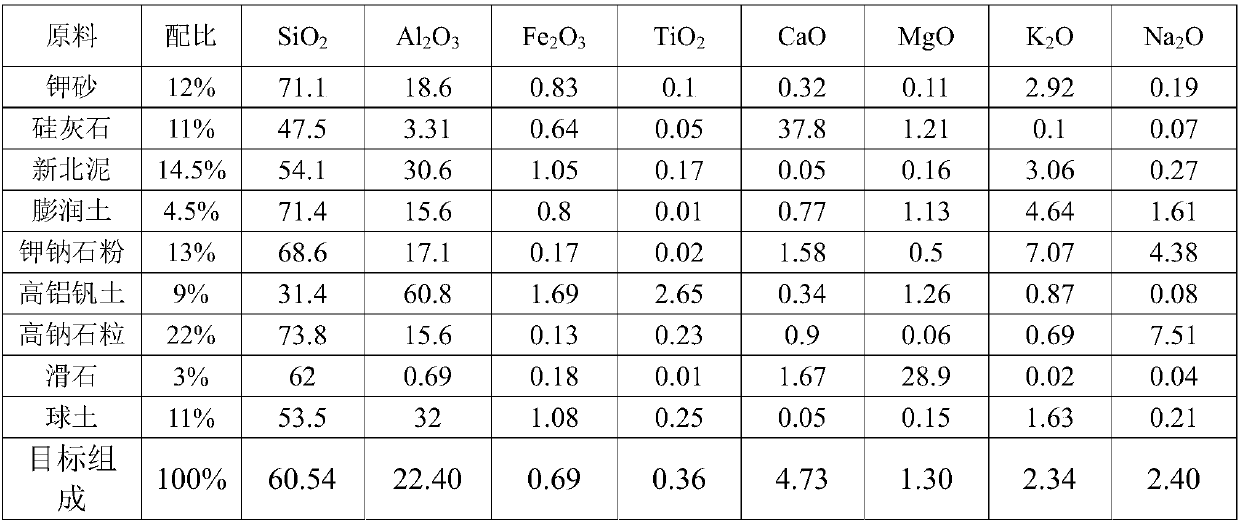

Large-size porcelain thin plate and production method thereof

The invention discloses a large-size porcelain thin plate and a production method thereof, wherein the large-size porcelain thin plate has an upper surface area of 1.62-2.88 m<2> and a thickness of 3.5-5.5 mm, and comprises the following raw materials by weight: 10-12% of potassium sand, 10-11% of wollastonite, 14.5-17.5% of Xinbei mud, 4-4.5% of bentonite, 12-13% of potassium sodium stone powder,7-9% of high bauxite, 21-22% of high sodium stone particles, 3-4% of talc, and 11-13% of ball clay. According to the present invention, by reducing the SiO2 content, the residual stress caused by thevolume change due to the quartz crystal form transformation during the firing cooling stage is reduced, and the content of the SiO2 glass phase is reduced, such that the product structure stability is good, the residual stress is low, no corner-chipping is generated during the machining, and the processing performance is significantly improved.

Owner:佛山市高明贝斯特陶瓷有限公司 +3

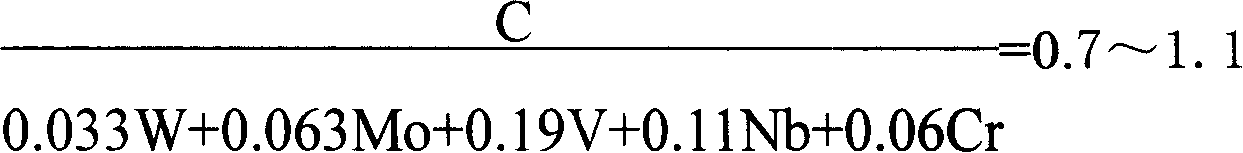

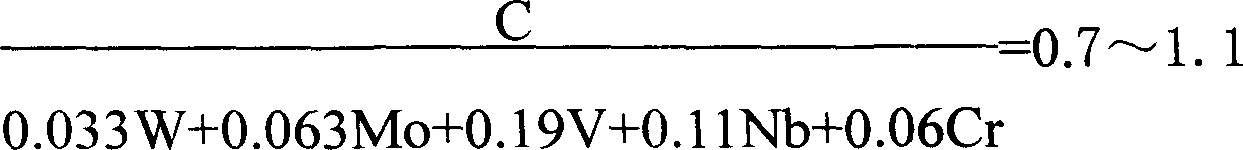

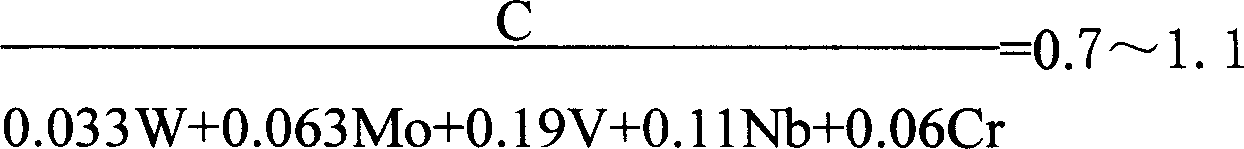

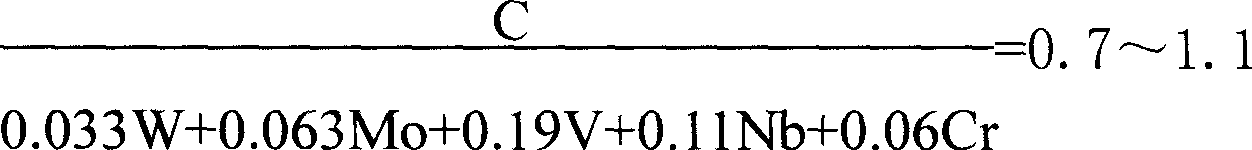

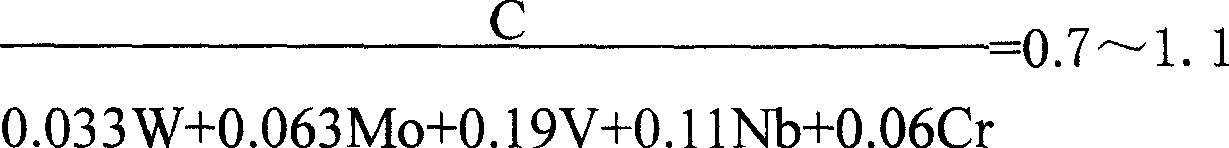

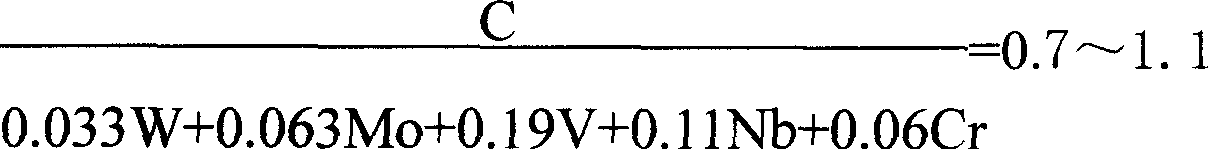

Cold and hot shearing edge steel for shearing thick plate

The present invention discloses one kind of cold and hot shearing edge steel for shearing thick plate and its production process. The cold and hot shearing edge steel has properly matched alloy elements and carbon. Its production process includes the following steps: designing alloy, smelting and on-the-spot sample analysis and regulation, ladle refining at 1650-1670 deg.c, casting ingot, forging rod, electroslag remelting and forging into shear edge material. The cold and hot shearing edge steel has high hardness, high strength, high wear resistance, high impact toughness and high red hardness, and is suitable for making shear for shearing cold and hot thick plate.

Owner:马鞍山市申力特重工机械股份有限公司

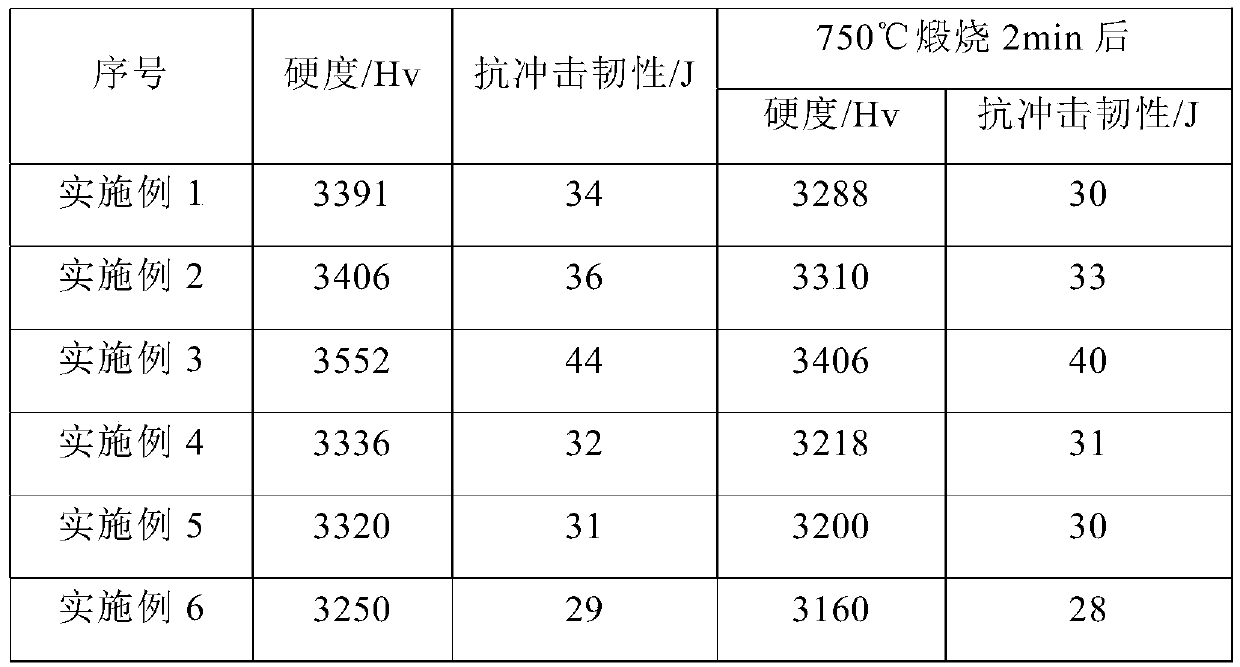

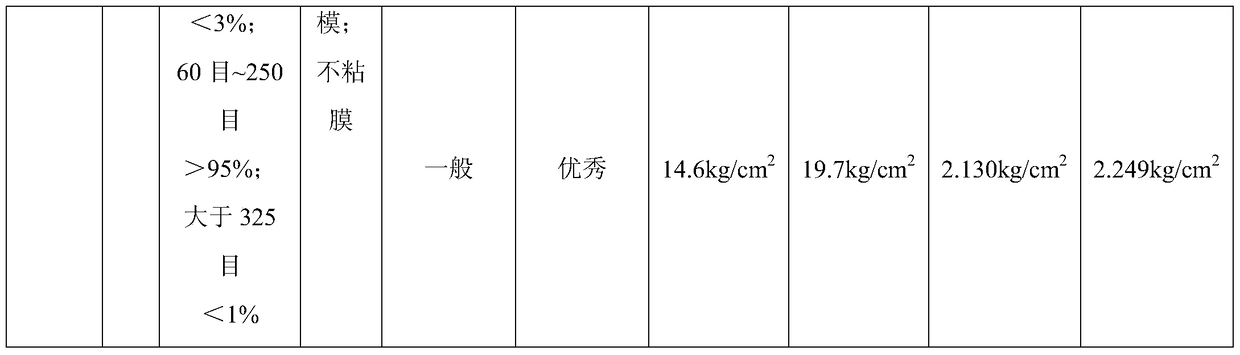

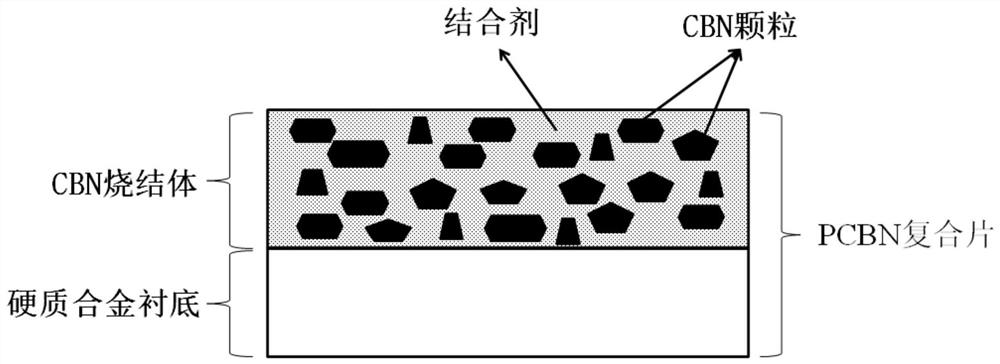

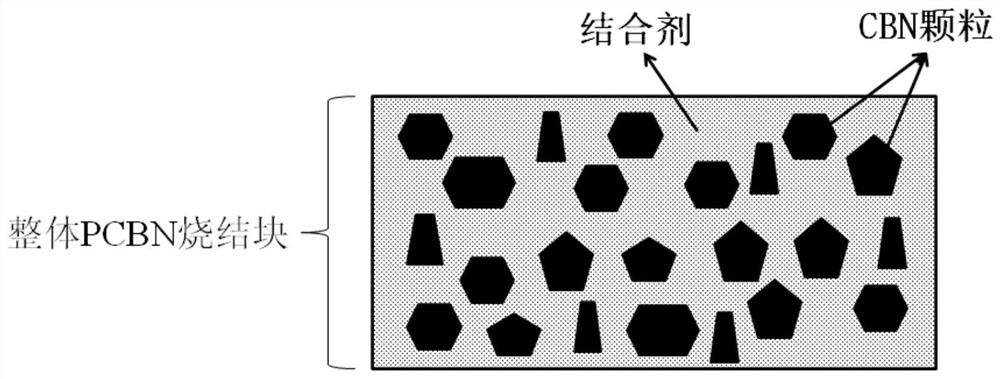

Polycrystalline diamond cubic boron nitride composite sheet and preparation method thereof

ActiveCN111057925AHigh bonding densityIncrease bond densityTransportation and packagingMetal-working apparatusPolycrystalline diamondAlloy substrate

The invention provides a polycrystalline diamond cubic boron nitride composite sheet. The polycrystalline diamond cubic boron nitride composite sheet comprises a hard alloy substrate, a polycrystalline diamond composite layer, a polycrystalline cubic boron nitride composite layer and a hard alloy protective layer which are sequentially arranged from bottom to top, wherein the polycrystalline diamond composite layer is composed of diamond micro powder and a nano metal binding agent, and the polycrystalline cubic boron nitride composite layer is composed of cubic boron nitride micro powder and ametal ceramic bonding agent. The invention further provides a method for preparing the polycrystalline diamond cubic boron nitride composite sheet. The method comprises the following steps that the diamond micro powder and the nano metal bonding agent are used for preparing a diamond bonding agent mixture; the cubic boron nitride micro powder and the metal ceramic bonding agent are used for preparing a cubic boron nitride bonding agent mixture; the hard alloy substrate is put into a tantalum cup, and the diamond bonding agent mixture and the cubic boron nitride binding agent mixture are sequentially poured into the tantalum cup; and the hard alloy protective layer is put into the tantalum cup, then vacuum heat treatment is carried out, and then high-temperature high-pressure sintering treatment is carried out. The composite sheet has high impact toughness and high strength.

Owner:FUNIK ULTRAHARD MATERIAL

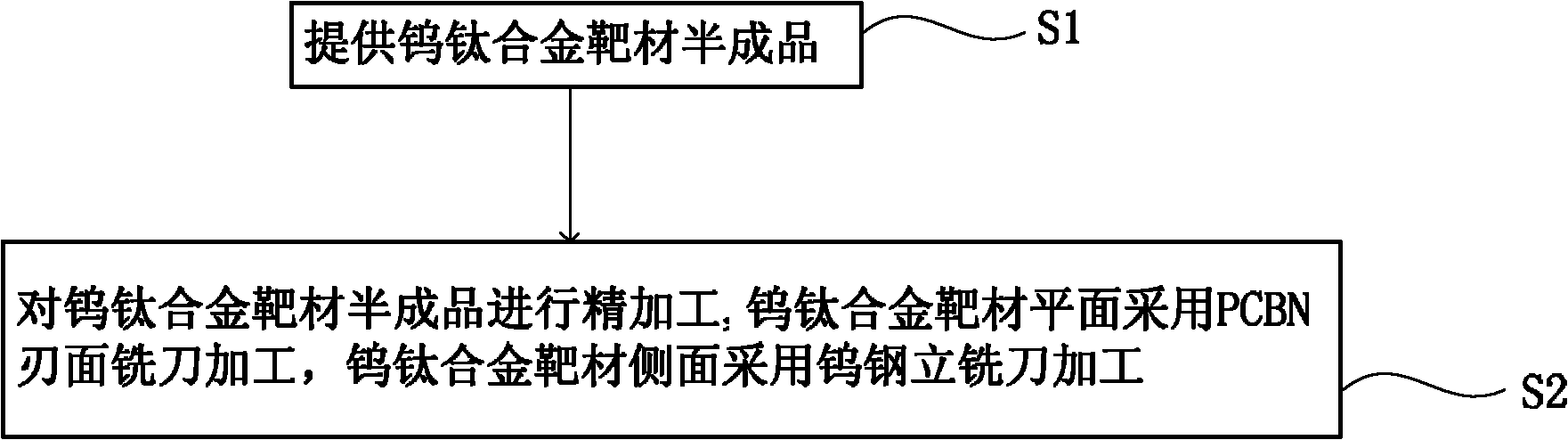

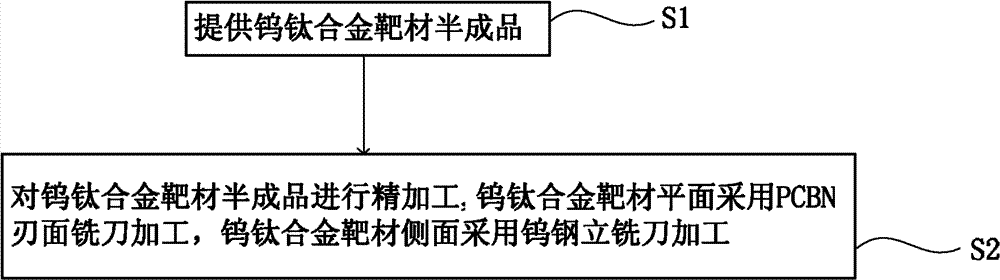

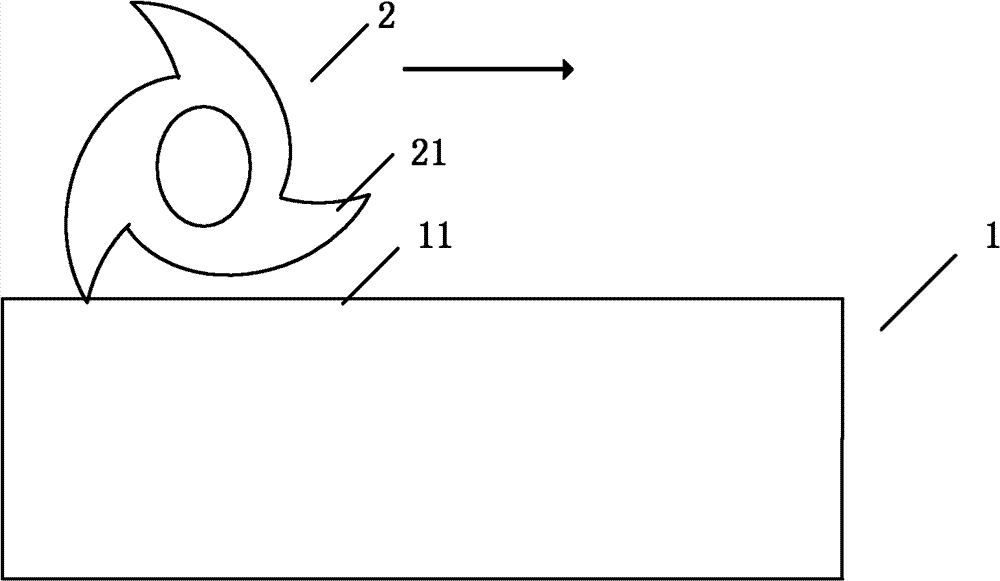

Machining method for milling tungsten alloy target material

ActiveCN102145403AUniform cutting forceAvoid cornersMilling equipment detailsBoron nitrideWork in process

The invention discloses a machining method for a tungsten alloy target material, which comprises the steps of providing a semi-finished product of the tungsten alloy target material and carrying out finish machining on the semi-finished product of the tungsten alloy target material, wherein in the finish machining step, the plane of the tungsten alloy target material is machined by a PCBN (Polycrystalline Cubic Boron Nitride) face mill, and the side face of the tungsten alloy target material is machined by a tungsten steel end mill. By adopting the machining method for the tungsten alloy target material provided by the invention, the arris defect in the machining process is avoided, the machining of the tungsten alloy target material with complex curved surface can be realized, and the problems of long machining cycle and low production efficiency are solved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

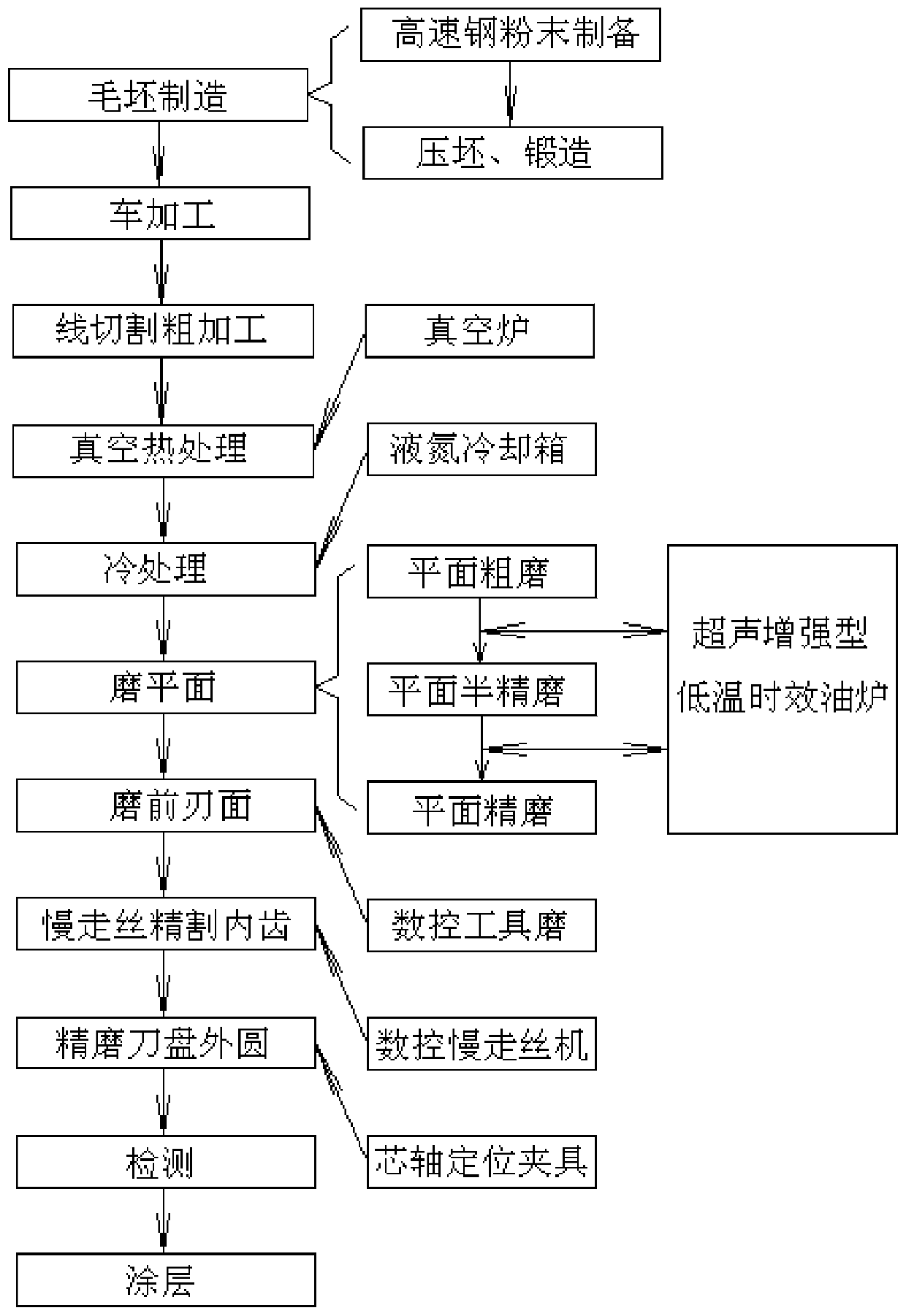

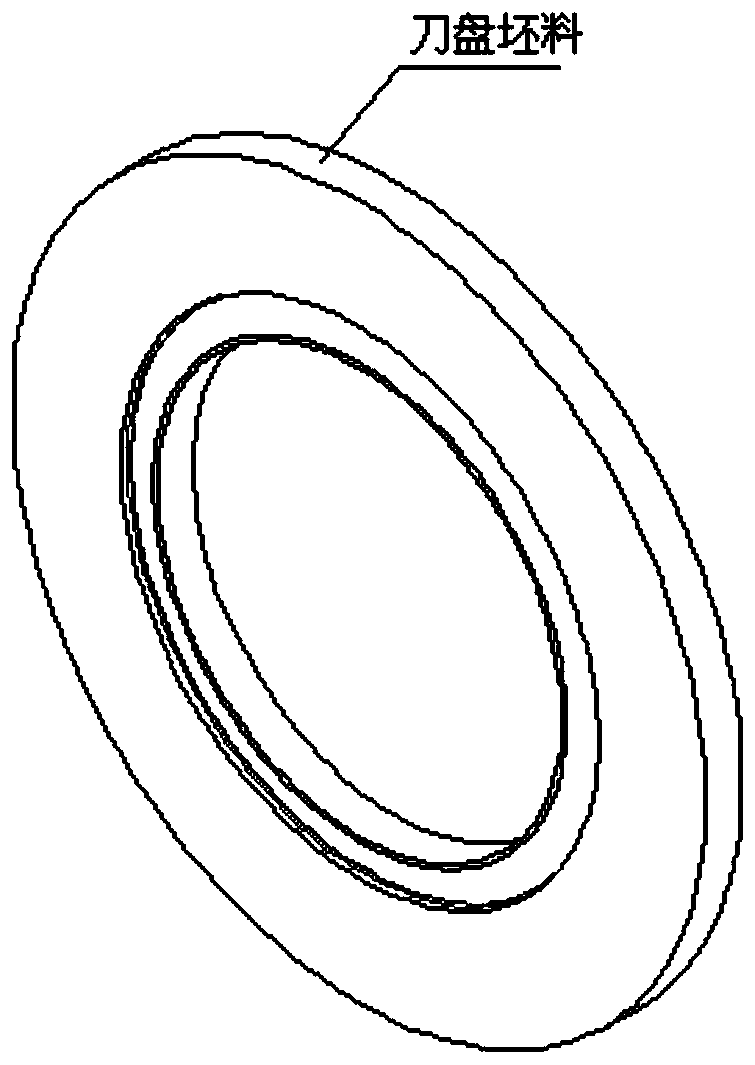

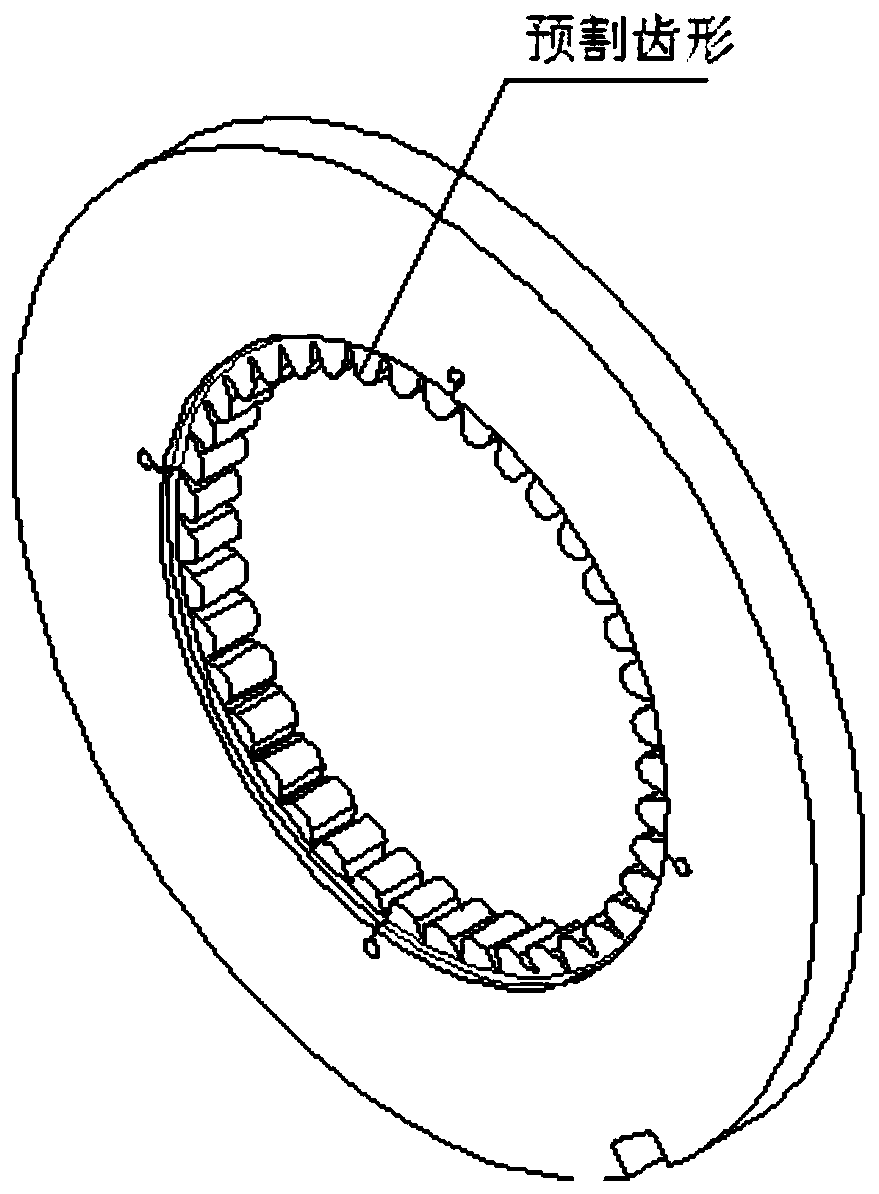

Manufacturing process of external gear drum type broach fine gear cutter disc

The invention relates to the technical field of metal cutting tool manufacturing, and particularly relates to a manufacturing process of an external gear drum type broach fine gear cutter disc. The process comprises the technological steps of blank manufacturing, turning machining, wire cutting rough machining, vacuum heat treatment, cold treatment, surface grinding, rake face grinding, walking wire slowly for inner tooth fine cutting, cutter fine grinding through cylindrical grinding and the like, wherein in the surface grinding working procedure, low-temperature stress-removing aging treatment procedures are arranged between the surface rough grinding and the surface semi-fine grinding and between the surface semi-fine grinding and the surface fine grinding correspondingly to eliminate the surface stress generated in the grinding process so as to reduce the deformation after the surface fine grinding. According to the process, the manufacturing precision of the drum type broach cutter disc is improved, the wear resistance of the cutter disc is improved, and the manufacturing cost of the cutter disc is reduced.

Owner:JIANGYIN SAITE PRECISION TOOL

Milling cutter

InactiveCN105562801AExtended service lifeNot easy to roll the bladeMilling cuttersMilling equipment detailsMilling cutterMechanical engineering

The invention provides a milling cutter used for machining a workpiece to obtain a predetermined contour line. The predetermined contour line comprises a first part and a second part connected with the first part. The milling cutter comprises a cutter handle provided with a center shaft and further comprises a plurality of first cutting edges and a plurality of second cutting edges, wherein the first cutting edges and the second cutting edges are arranged in a stagger mode, the first cutting edges are used for rotating around the center shaft to form a first rotation track to machine the first part of the predetermined contour line of the workpiece, the second cutting edges are used for rotating around the center shaft to form a second rotation track different from the first rotation track to machine the second part of the predetermined contour line of the workpiece, and the first rotation track is connected with the second rotation track. The milling cutter is relatively low in cutting resistance and long in service life.

Owner:JIZHUN PRECISION IND HUIZHOU

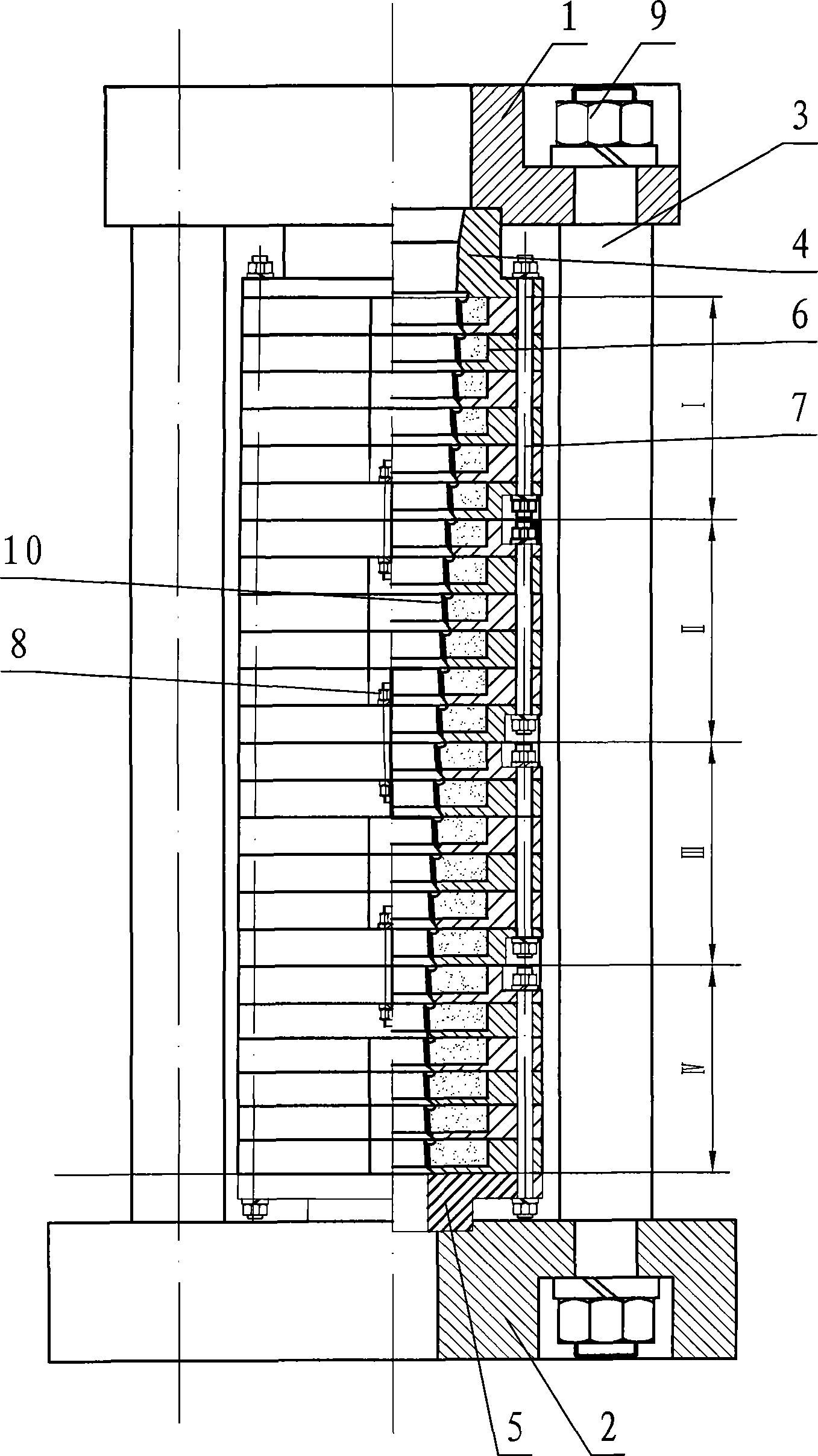

External push broach

InactiveCN101486115AIncrease productivitySave energyBroaching toolsGear teeth manufacturing toolsPush and pullEngineering

The invention discloses an external push-and-pull cutter for machining the shape of a columnar part. The cutter comprises a front guide platen, a rear guide platen, a connecting rod and a cutting part compression jointed between the front guide platen and the rear guide platen; the cutting part is formed by vertically superposing a plurality of annular inner tooth cutting blades of mold cavities with different dimension; the annular inner tooth cutting blade is provided with a plurality of inner cutting blade teeth which are wholly matched with the shape of a gear; the inner cutting blade teeth are in a ladder arrangement axially; and the annular inner tooth cutting blades are fixedly connected by positioning pins. The external push-and-pull cutter has the advantages of high production efficiency, energy conservation, raw materials conservation, equipment conservation, environmental protection, low cost, and the like, and has the characteristics of easy machining of blade teeth, simple structure, convenient assembly, low processing cost, high machining precision, high strength of the whole cutter, convenient maintenance, low maintenance cost, long service life, and the like.

Owner:杨方洲

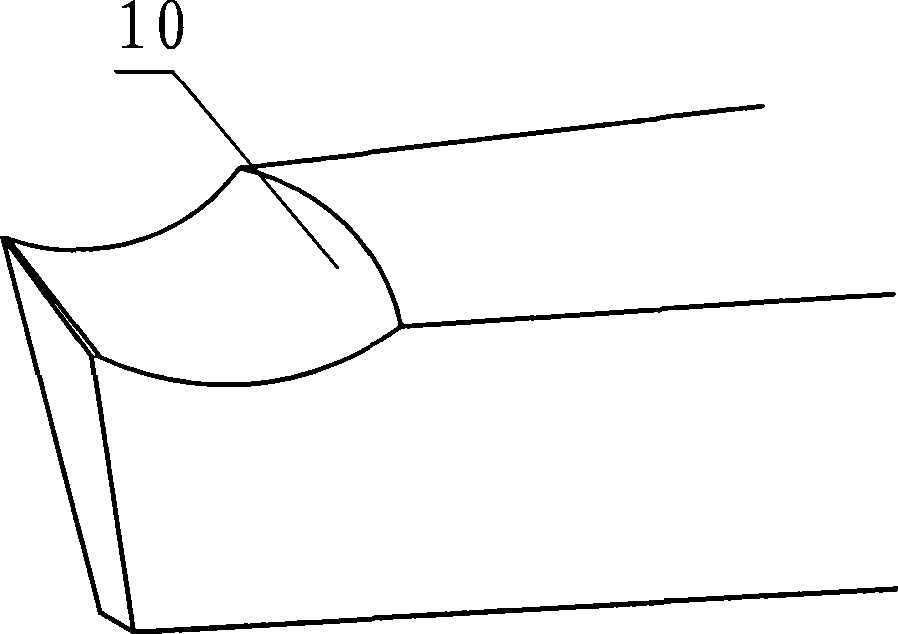

Efficient drum-shaped profiling end mill

PendingCN110695426AHigh cutting lengthImprove processing efficiencyMilling cuttersStructural engineeringEnd mill

The invention discloses an efficient drum-shaped profiling end mill. The efficient drum-shaped profiling end mill comprises a cutting part and a handle part, wherein the cutting part is provided witha plurality of chip grooves which spirally extend from the bottom end to the handle part; the surface, facing the cutting rotation direction, of each chip groove is a front cutter surface; the front cutter surfaces and the peripheral surface of the cutting part are intersected to form cutting edges; the cutting edges are wave-shaped cutting edges by machining the front cutter surfaces, and are divided into circumferential cutting edges and ball head cutting edges; the outlines of the circumferential cutting edges are two sections of symmetrical arcs; the bottom end cutting edges are the ball head cutting edges; included angles of the edges are unequal; the surface, connected with the cutting edges, in the peripheral surface of the cutting part is a first rear cutter surface; the first rearcutter surface extends from the bottom end of the cutting part to the handle part; chip breaking grooves are spirally distributed in the first rear cutter surface. The efficient drum-shaped profilingend mill has the advantages that the semi-finish machining and finish machining efficiency of a workpiece can be greatly improved, a narrow workpiece can be machined, the strength is high, and the service life is long.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Machining method for spindle hole oil groove of large diesel engine body

ActiveCN105583449AProtectImprove rigidityWorkpiecesMilling equipment detailsMilling cutterDiesel engine

The invention relates to a machining method for a spindle hole oil groove of a large diesel engine body. The method comprises the following implementation steps that most margins are removed with a short ball milling cutter with the good rigidity; margins of the interference portion are removed with a long ball milling cutter; remaining margins are removed for one time with a three-edge milling cutter, and the groove is finally obtained. The machining method has the advantages that the machining time is short, the machining efficiency is high, the cutters are not prone to be tipped, the using effect is good, and the life is long.

Owner:WEICHAI HEAVY MACHINERY

Machining technology of head integral PCD drill bit

The invention aims to provide a machining technology of a head integral PCD drill bit. Firstly PCD parent metal is welded to a hard alloy handle part, and then the hard alloy handle part is subjectedto diamond grinding wheel grinding; then a copper wheel is utilized to conduct fluting grinding and grinding electrolysis on a head of the PCD parent metal, an excircle of a grinding wheel is adoptedto conduct edge cleaning and electrolysis and edge line producing, in this way, the concentricity of the PCD parent metal and the handle part is ensured; an arc drill point is adopted to conduct grinding electrolysis on an arc slag containing tank, so that force can be borne more stably, and blade breaking is not prone to happening; and finally a four-plane form is adopted to conduct grinding electrolysis on a rear corner, thus force bearing is more stable, and the quality of a radial angle of the drill bit is ensured as well. The produced drill bit can sharply improve the production efficiency for machining titanium alloys, compared with a hard alloy, the rotation speed can be improved, and feeding can be accelerated. Compared with traditional diamond grinding wheel grinding forming, theprecision of the drill bit machined by adopting the technology is high and stable by using the copper wheel.

Owner:芜湖保泰精密工具制造有限公司

Food cutter and manufacturing method thereof

PendingCN109483623AImprove cutting effectNot easy to dullMetal working apparatusEngineeringMechanical engineering

The invention discloses a food cutter and a manufacturing method thereof and belongs o the field of cutter machining. The food cutter comprises a cutter body and a cutter blade. The cutter body and the cutter blade form a food cutter body. The cutter body comprises a mounting portion located at one end of the cutter body. The profile of the cutter blade is in an arc shape and is a single-face arc-shaped blade. The arc-shaped blade comprises a toothed blade end and a non-toothed blade end. The toothed blade end and the non-toothed blade end are connected to form a cutter blade body. The side, not connected with the non-toothed blade end, of the toothed blade end is connected with the mounting portion. The food cutter can be used for cutting food smoothly and uniformly, food does not stick to the cutter, abrasion of the cutter blade edge is small, the service life is long, the manufacturing method of the food cutter is easy and convenient to implement and combined with practical production, and manufacturing is easy.

Owner:安徽华天机械股份有限公司

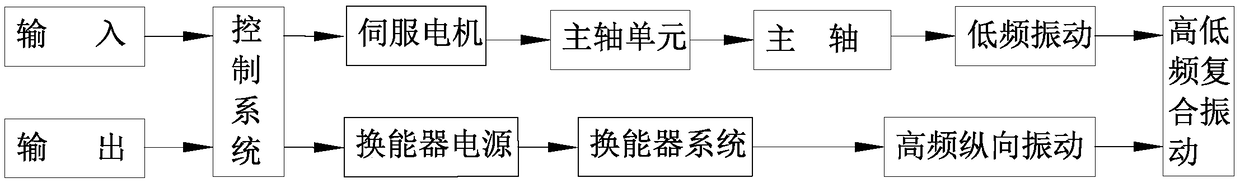

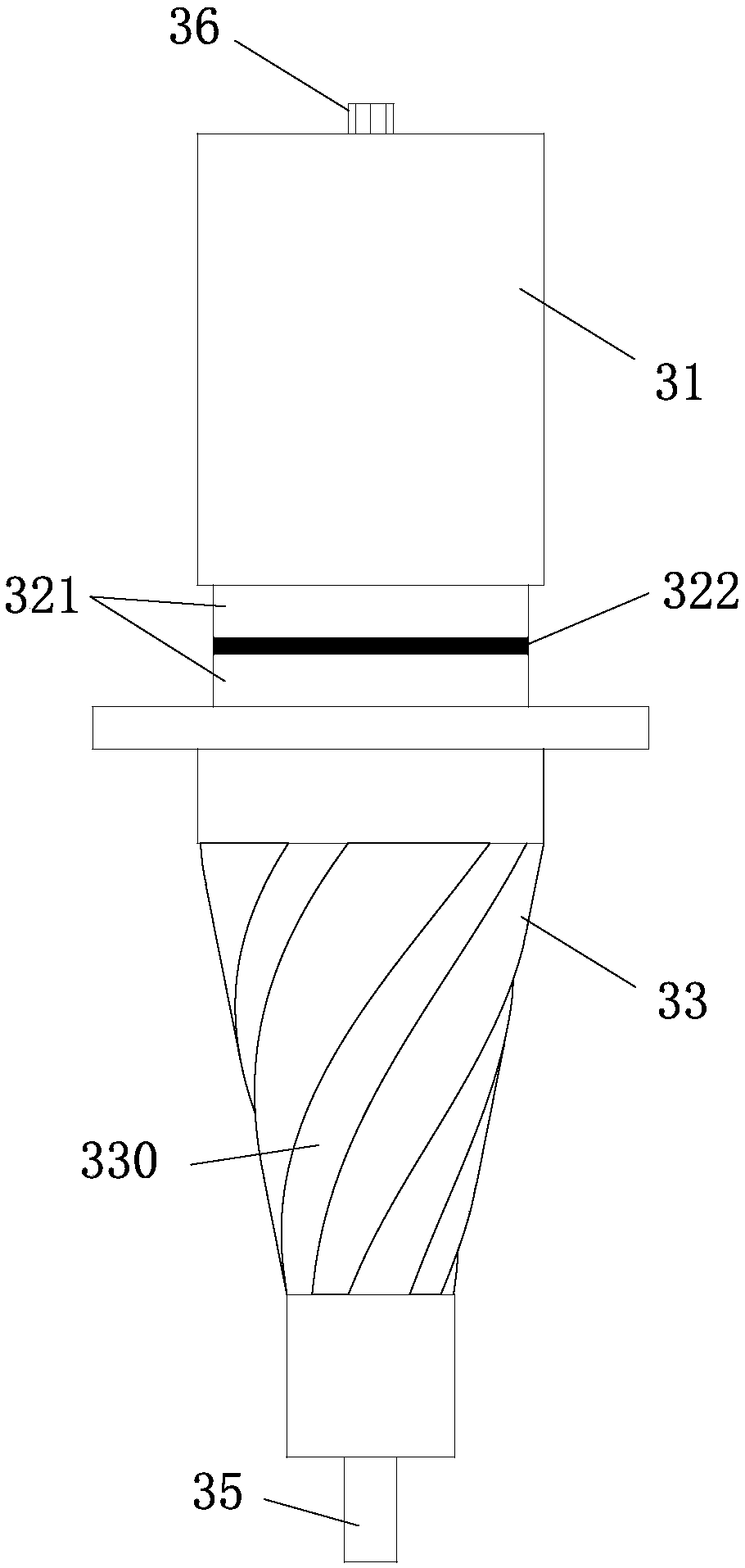

Ultrasonic transduction equipment for tapping processing and torsional tapping machine

InactiveCN109290642AFast processingEfficient processingThread cutting machinesMechanical vibrations separationEnergy transferLow load

The invention discloses ultrasonic transduction equipment for tapping processing and a torsional tapping machine. The ultrasonic transduction equipment comprises an upper load block which weakens thelongitudinal vibration energy transfer and has a heat-dissipating function and a lower load block which enhances transfer of the longitudinal vibration energy to a screw tap and generates torsional vibration transformation. A transduction component capable of achieving converting to generate longitudinal vibration mechanical energy is mounted between the upper load block and the lower load block.When the longitudinal vibration generated by the transduction component is diffused to the outer surface of the lower load block, the lower load block where a spiral groove is machined converts part of longitudinal vibration into torsional vibration, and vibration and torsion are coupled to from a torsional vibration effect which is diffused to the screw tap mounted on the bottom surface of the lower load block, so that the screw tap generates a torsional vibration action force for tapping processing of a workpiece. The ultrasonic transduction equipment provided by the invention can generate acompound vibration mode combining torsion and vibration to drive the screw tap to generate the torsional vibration effect for a tapping processing course well.

Owner:常晓旺 +2

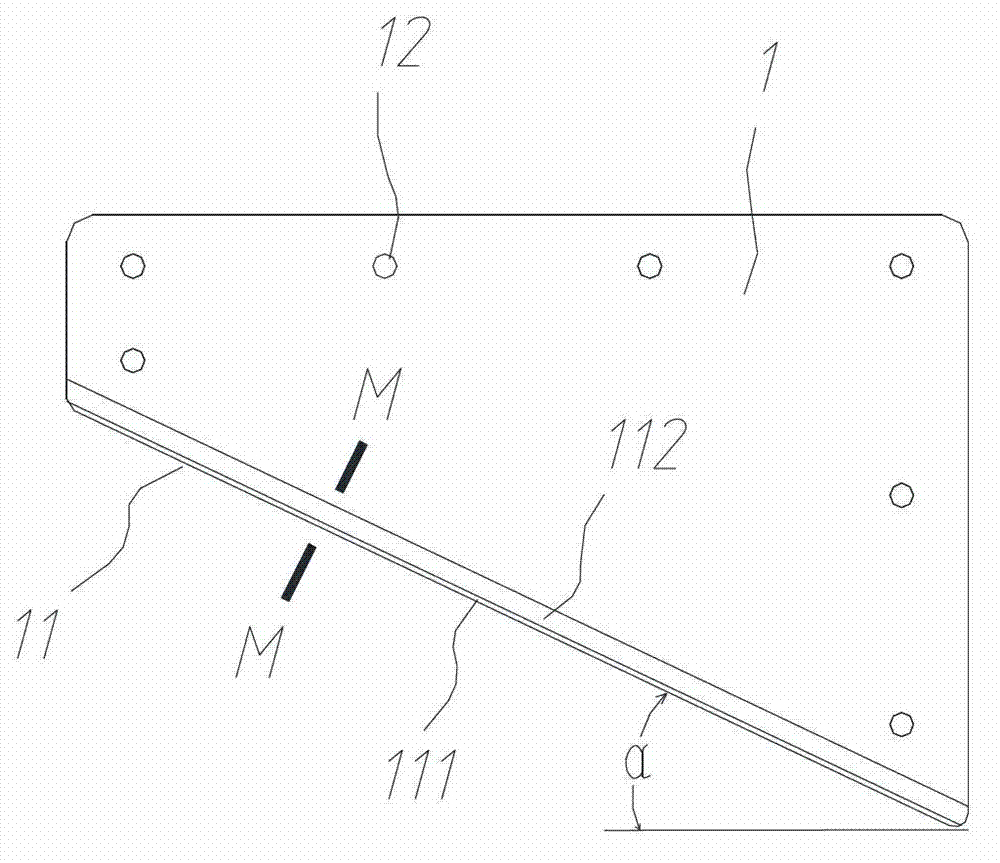

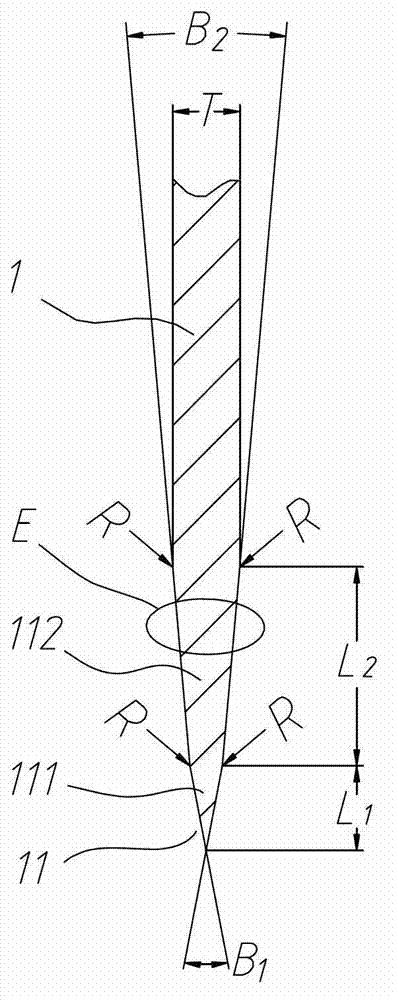

Cutting knife used for thermal cutting of plastic material

ActiveCN103112025AEliminate longitudinal wavy gapsReduce cutting noiseMetal working apparatusPlastic materialsEngineering

The invention relates to a cutting knife used for thermal cutting of plastic material. The cutting knife used for the thermal cutting of the plastic material comprises a blade body, and an inclined double-edged cutting edge which is arranged at the lower end of the blade body, the inclination angle alpha of the cutting edge relative to the horizontal line is 22-28 degrees, and the blade is grinded along the feeding direction of the blade by a grinding appliance to form the cutting edge. The cutting edge at least comprises a first level cutting edge and a second level cutting edge, the angle B1 of the first level cutting edge is 21-23 degrees, and the angle B2 of the second level cutting edge is 8-10 degrees. The plastic material cut by the blade is smooth in end face and free of the appearance of burs and silkings, and cutting end face quality of the material can be improved. Besides, in a cutting process, the resistance stressed on the blade is even, the blade is not prone to tipping, not only is the service life of the blade prolonged, but also cutting noise is reduced observably, and the production environment is improved.

Owner:TONGLING GREAT EXTRUSION TECH

Machining method for milling tungsten alloy target material

ActiveCN102145403BUniform cutting forceAvoid cornersMilling equipment detailsMilling cutterBoron nitride

The invention discloses a machining method for a tungsten alloy target material, which comprises the steps of providing a semi-finished product of the tungsten alloy target material and carrying out finish machining on the semi-finished product of the tungsten alloy target material, wherein in the finish machining step, the plane of the tungsten alloy target material is machined by a PCBN (Polycrystalline Cubic Boron Nitride) face mill, and the side face of the tungsten alloy target material is machined by a tungsten steel end mill. By adopting the machining method for the tungsten alloy target material provided by the invention, the arris defect in the machining process is avoided, the machining of the tungsten alloy target material with complex curved surface can be realized, and the problems of long machining cycle and low production efficiency are solved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

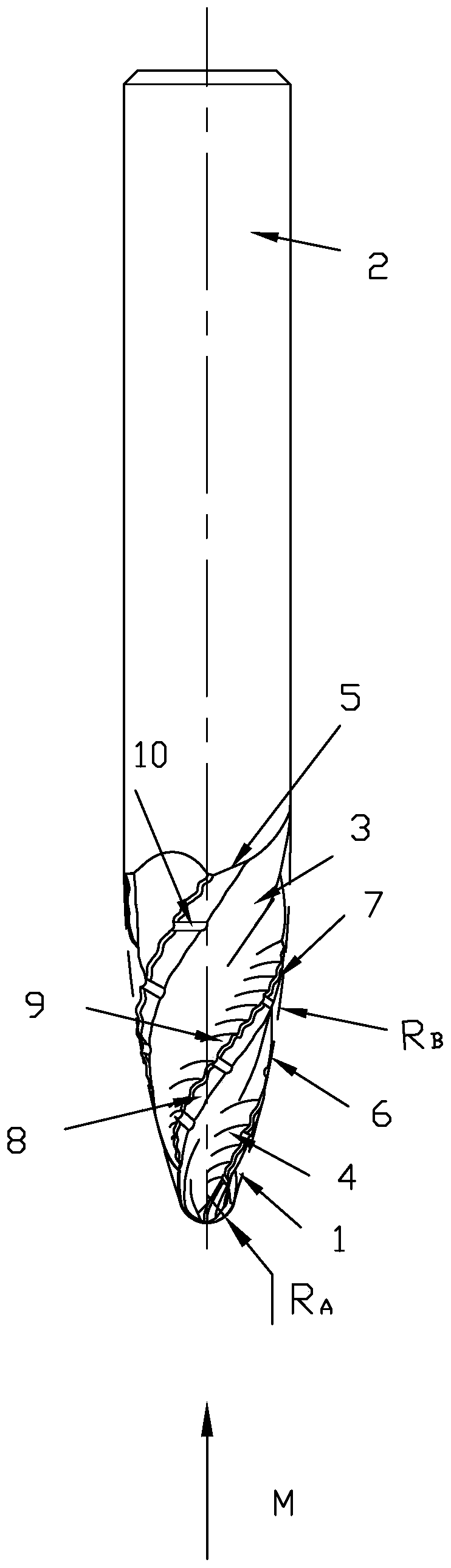

Indexable hard alloy shallow hole drilling method and drilling blade

InactiveCN101879620AHigh strengthEasy to useTransportation and packagingTrepanning drillsCentre of rotationAlloy

The invention relates to an indexable hard alloy shallow hole drilling method and a drilling blade. A combined-type drilling tool is used for drilling holes. A hard alloy blade is positioned through a groove and is installed on a cutter body through a tightening device to form a combined-type hard alloy drilling tool which is used for drilling holes. The combined-type hard alloy drilling tool is combined by the cutter body and the hard alloy blade, wherein the hard alloy blade is clamped on the cutter body and is fixed on the cutter body by the tightening device. The hard alloy blade is an integral indexable replaceable blade, is a flaky structure and is rotatably and symmetrically distributed by taking the rotating central axis of the drilling tool as a symmetrical line. Two reverse counter bores are symmetrically distributed on the two surfaces of the hard alloy blade by taking the rotating central axis as a symmetrical line. The front end part of the cutter body is provided with a through groove. The hard alloy blade is installed in the through hole of the cutter body and is fixed on the cutter by using tightening screws which penetrate through the counter bores of the blade. End holes of rails are machined through the integral hard alloy blade embedded into the front end part of the cutter body.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

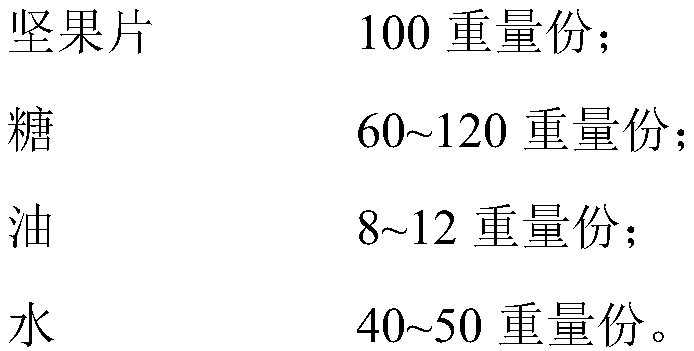

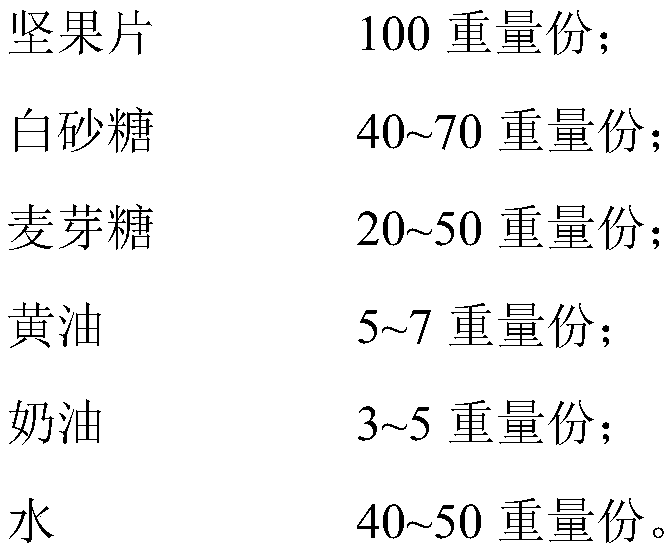

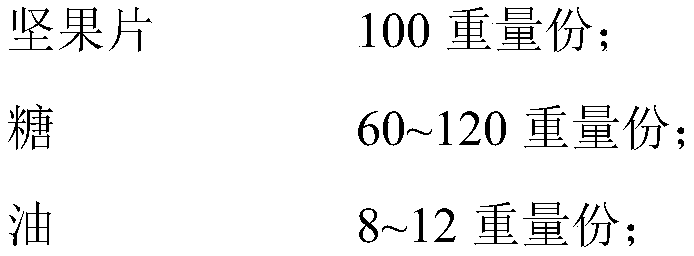

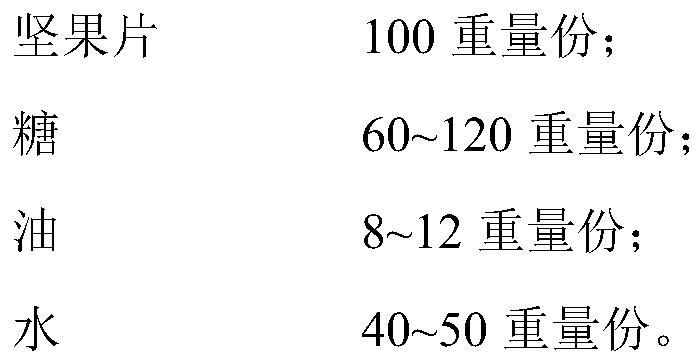

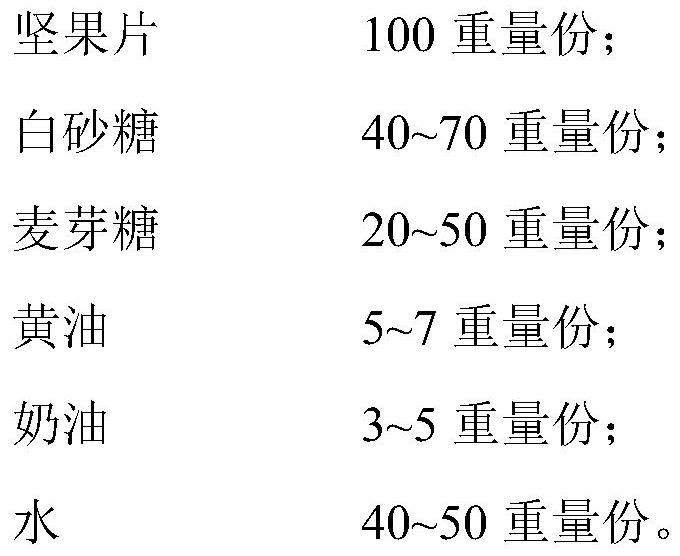

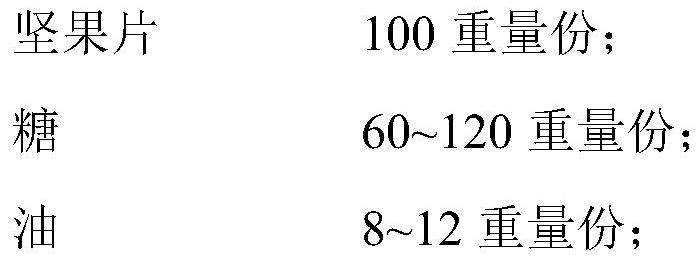

Making method of nut crisp fritters and nut crisp fritters

ActiveCN108740246AThin and brittle molding stabilityReduce churnConfectionerySweetmeatsEngineeringSugar

The invention discloses a making method of nut crisp fritters and the nut crisp fritters made by the making method, and belongs to the field of food processing. In order to solve the problems that when people eat conventional nut kernels, the nut kernels are knocked and broken with large force so that teeth are damaged possibly, if the nut kernels are swallowed wholly, life risks are caused possibly, besides, seasoning powder is on the external surfaces of the nut kernels, and when people eat the nut kernels, the seasoning powder sticks to hands easily, the invention provides the making methodof nut crisp fritters. The making method comprises the following steps of firstly performing cooking to obtain a sugar solution, then adding nut pieces to the sugar solution, performing cold storage,performing cutting and performing baking. According to the making method disclosed by the invention, the nut kernels are innovatively changed into the nut pieces, and besides, the nut crisp frittersare obtained through subsequent steps of performing cold storage, performing cutting and performing baking; the nut crisp fritters are immediately broken after being bitten, are crisp in mouth feel, can be bitten to be broken without large force when being eaten; and besides, after cold storage and baking, the sugar solution closely coats the surfaces of the nut pieces, so that the nut crisp fritters do not stick to hands when being eaten.

Owner:CHACHA FOOD CO LTD

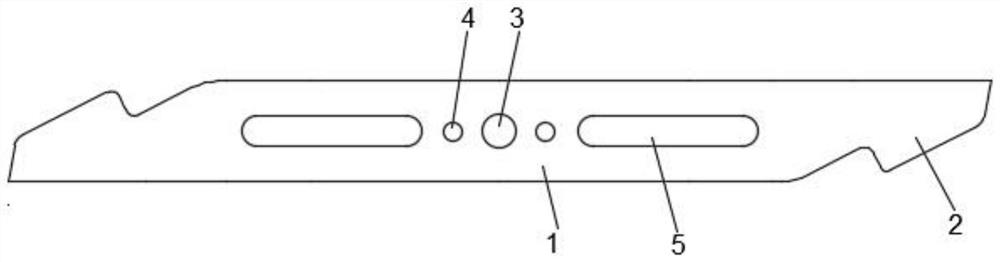

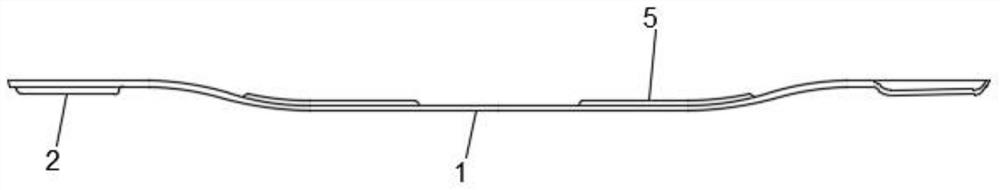

Machining method of high-strength handheld mower blade

ActiveCN113427203ASolve the crash problemSolve the problem of heat treatment deformationMowersFurnace typesMolten stateTempering

The invention relates to the technical field of hay mower blade machining, and discloses a machining method of a high-strength handheld hay mower blade. The machining method comprises the following steps: S1, cutter forming is carried out, molten steel in a molten state is injected into a mold, and cooling is carried out after the blade is formed; S2, cutting edge punching is carried out, and the cutting edge position is continuously punched multiple times; S3, thermal forming and heat treatment are carried out, specifically, a cutter is put into a heating furnace at the temperature of 1000 DEG C to be subjected to thermal forging forming, isothermal quenching is carried out for 10 minutes, and the hardness of the quenched blade is 40-45 HRC; S4, tempering is conducted, the temperature in the heating furnace is reduced to 500 DEG C at the speed of reducing 100 DEG C per minute, and tempering is conducted for 30 minutes at the temperature of 500 DEG C; S5, shot blasting is conducted, the cutter is put into a shot blasting machine to be subjected to surface polishing for 2 minutes; and S6, surface treatment is conducted, and the cutter is put into an electrophoresis device to be subjected to black electrophoresis. The problem of cutting edge breakage can be solved, the cutting edge strength is high, the process steps are shortened, the machining efficiency is improved, and the manufacturing cost is low.

Owner:安徽博行机械有限公司

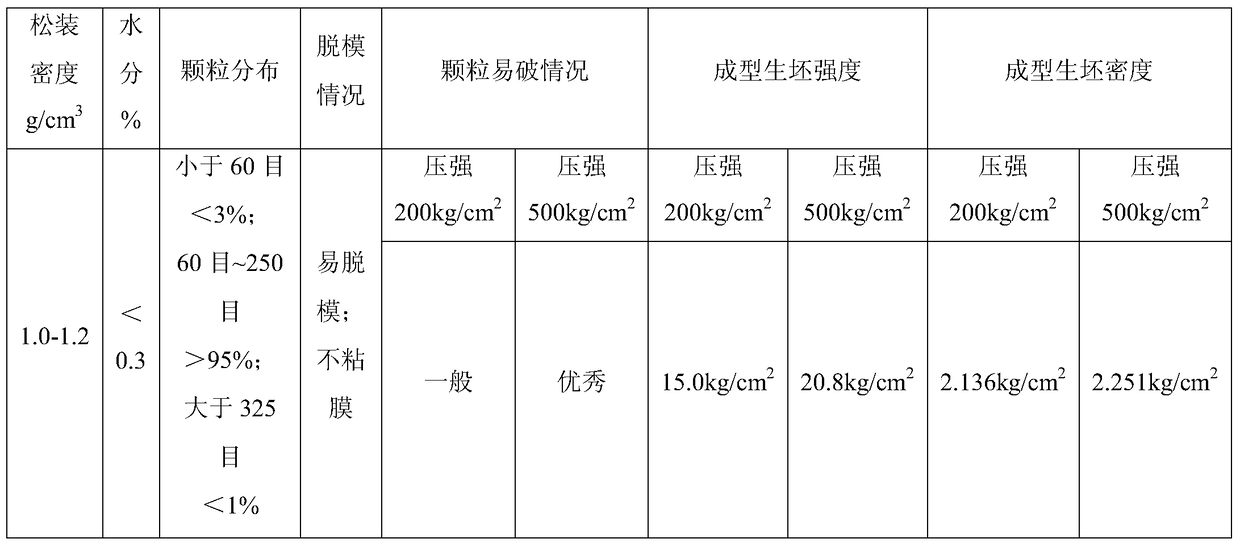

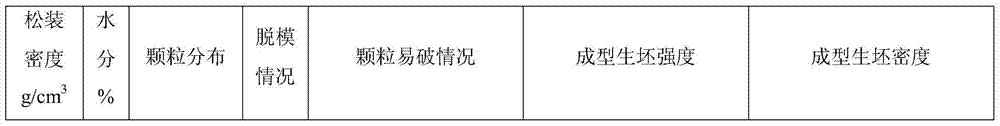

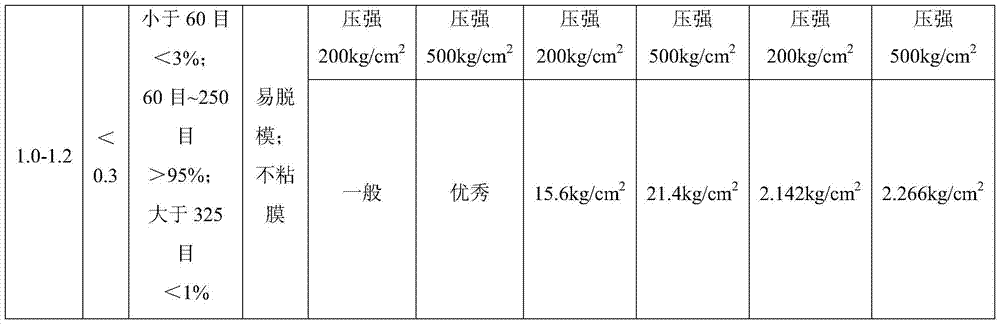

A 99% or more alumina granulated powder and its preparation method

The invention relates to 99%-above alumina granulating powder and a preparation method thereof. The 99%-above alumina granulating powder comprises the following components in parts by weight: 100-200 parts of high-aluminum alumina balls, 50-150 parts of a calcined material CT-3000SG, 1-5 parts of a binder, 0.1-1 part of a dispersant, 0.1-1 part of a demolding agent, 0.1-1 part of yttria, 0.1-1 part of magnesia and 50-150 parts of deionized water. The preparation method comprises the following steps: carrying out ball milling, sieving after pulp is obtained, stirring, and processing with magnets; carrying out centrifugal spraying granulation; removing coarse and fine particles from granulated powder by virtue of a sieve, then removing iron and impurities, and finally homogenizing. The granulating powder is low in water content and high in apparent density; after blank molding, a green body is high in density, good in stability and tenacity and excellent in post-machining performance and does not easily collapse from corners; the preparation method is simple in process and low in cost and has good application prospect.

Owner:SHANGHAI COMPANION PRECISION CERAMICS

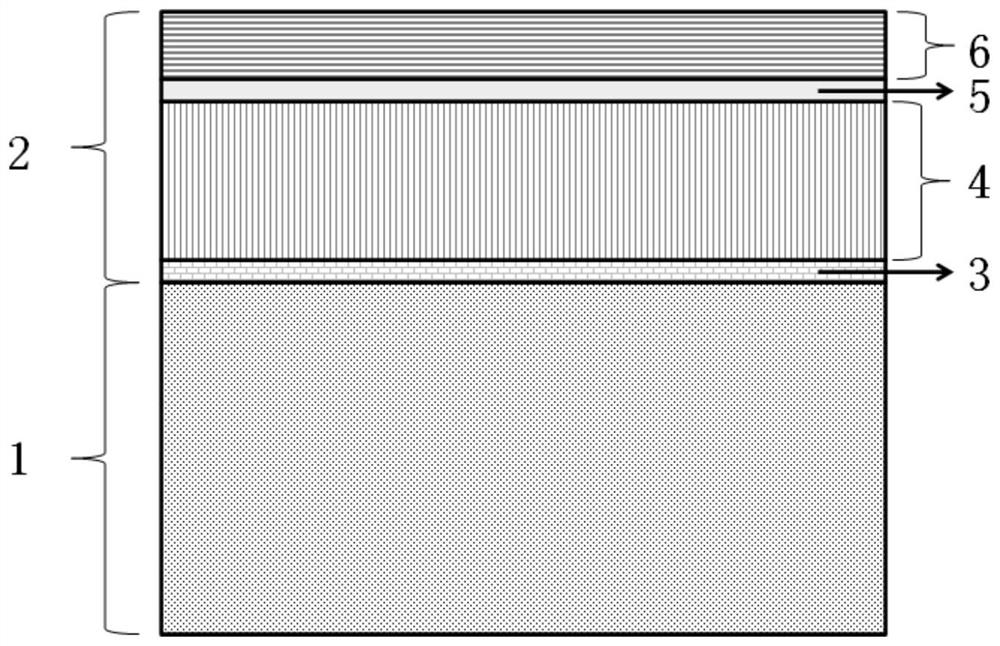

Composite coating PCBN cutting tool and preparation method thereof

ActiveCN111910172AImprove wear resistanceHigh bonding strengthVacuum evaporation coatingSputtering coatingChemical vapor depositionBonding strength

The invention discloses a composite coating PCBN cutting tool and a preparation method thereof. The cutting tool comprises a PCBN tool base body and a composite coating applied to the PCBN tool base body, the composite coating comprises a coating A located on the inner layer and a coating B located on the outer layer, wherein the coating A at least comprises an AlxTi1-xCyN1-y coating prepared through a low-pressure chemical vapor deposition method, and the coating B at least comprises a Ti1-a-bAlaMebN coating prepared by adopting a physical vapor deposition method; and the preparation method comprises the following steps of preparing the PCBN tool base body, depositing the AlxTi1xCyN1y coating by adopting a low-pressure CVD process, and depositing the Ti1-a-bAlaMebN coating by adopting a PVD process. The cutting tool has the advantages of being good in bonding strength between the coating and the base body, high in abrasion resistance, excellent in tipping resistance and the like, theservice life of the tool is long, and stability is good.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Discarded type sleeve cutterhead

InactiveCN107971545AAvoid Dimensional InstabilityBig R angleMilling cuttersMilling cutterCutting force

The invention provides a discarded type sleeve cutterhead. The discarded type sleeve cutterhead comprises a cutterhead body, a cutter handle, cutter clamps and cutter blades; a transitional bevel edgeis arranged between the cutterhead body and the cutter handle; the end face of the cutter handle is provided with a first hole groove used for mounting a milling cutter handle, and a groove is formedin the end face of the cutter handle, and the milling cutter handle and the groove are mounted in a matched mode; the end face of the cutterhead body is provided with a second hole groove for accommodating cutting chippings, and the bottom end of the second hole groove is provided with a third hole groove for avoiding interference of parts; the end face of the cutterhead body is provided with four protrusion parts, the cutter blade is locked and fixed to the corresponding pair of adjacent protrusion parts, the cutter clamps are mounted on the other pair of adjacent protrusion parts, and the cutter blades are locked and fixed to the cutter clamps; and an included angle of the cutting faces of the adjacent cutter blades is 90 degrees, the cutting edges of the cutter blades are located on the same plane and perpendicular to the axis of the cutterhead body. The discarded type sleeve cutterhead adopts fixed and floating blade edge design, the cutter blades fixed to the cutterhead body canbear large cutting force, the size cannot be adjusted, and the cutter clamps can avoid the situations of vibration edge, poor finish degree and the unstable workpiece size due to uniformity of blank oxide skin by adjusting the size.

Owner:上海泰锋精密刀具有限公司

Interface, leveling, same-color, anti-cracking and four-in-one substrate matched coating

The invention discloses an interface, leveling, same-color, anti-cracking and four-in-one substrate matched coating, and relates to the technical field of coatings. The interface, leveling, same-color, anti-cracking and four-in-one substrate matched coating consists of four portions including a mortar leveling layer, a four-in-one substrate, color points and glossy overprint. The four-in-one substrate consists of the following raw materials: water, 100000 celluloses, a multifunctional assistant, ethylene glycol, a coalescing agent, wood fibers, polypropylene short fibers, titanium dioxide, styrene-acrylic emulsion, pure acrylic emulsion, a bactericide, a thickening agent, sand with meshes of 80-100, sand with meshes of 100-120, sand with meshes of 120-180, bentonite and color paste. Afterthe technical scheme is adopted, the interface, leveling, same-color, anti-cracking and four-in-one substrate matched coating has the beneficial effects that the substrate is four-in-one, energy is saved and consumption is reduced, the labor intensity is reduced, the construction period is shortened, the quality of a paint film is improved, the substrate is the paint film dried and synthesized byemulsion, the toughness of the whole paint film is enhanced, the paint film can be used on a wall surface and a wall corner, and is not easy to damage, and corner breakage of the paint film is not easily caused; after the coating is used, the inside of a wall body is not easily soaked in water, and the paint film is not easy to change color or fade; and the coating can be used for construction ofold wall surfaces such as tiles, and the service life is long.

Owner:龙岩市申耀装饰建材有限公司

Bimetal road grinding band saw blade

The invention discloses a bimetal road grinding band saw blade. The bimetal road grinding band saw blade comprises a saw blade body and a plurality of groups of saw tooth groups arranged on the saw blade body. Each group of saw tooth groups comprises at least one first saw tooth, and the blade end width of each first saw tooth is greater than the width of the saw blade body in the thickness direction of the saw blade, chamfers are arranged on the two sides, in the width direction, of the blade end of each first saw tooth, and at least one side surface of each first saw tooth is an acute-angledinclined surface. The saw blade has a smooth and level saw cutting surface, a small saw kerf and a high advance, the saw cutting margin can be greatly reduced, the saw blade tooth tip wears slowly, and the service life is long.

Owner:新昌县智超邦金属材料科学技术研究院

A kind of preparation method of nut crisp and nut crisp

The invention discloses a method for preparing nut crisps and nut crisps, which belong to the field of food processing. When people eat the existing nuts, they need to use a lot of force to break them open, which may damage the teeth, and if swallowed whole, it may cause life-threatening. At the same time, because the outer surface of the nuts has seasoning powder, it is easy to eat To solve the problem of sticking to hands, the invention provides a method for preparing nuts that are crispy. In the preparation method of the present invention, the sugar solution is boiled first, then the nut slices are added, refrigerated, cut and baked. In the preparation method of the present invention, the nut kernels are innovatively changed into nut slices, and at the same time, the nuts are crispy after being refrigerated, cut, and baked in the later stage. The crispy nuts can be broken when bitten, and the taste is crispy, and it does not need to be crushed hard when eating. , after being refrigerated and baked at the same time, the sugar liquid is tightly wrapped on the surface of the nut slices, and it does not stick to your hands when you eat them.

Owner:CHACHA FOOD CO LTD

Cold and hot shearing edge steel for shearing thick plate

The present invention discloses one kind of cold and hot shearing edge steel for shearing thick plate and its production process. The cold and hot shearing edge steel has properly matched alloy elements and carbon. Its production process includes the following steps: designing alloy, smelting and on-the-spot sample analysis and regulation, ladle refining at 1650-1670 deg.c, casting ingot, forging rod, electroslag remelting and forging into shear edge material. The cold and hot shearing edge steel has high hardness, high strength, high wear resistance, high impact toughness and high red hardness, and is suitable for making shear for shearing cold and hot thick plate.

Owner:马鞍山市申力特重工机械股份有限公司

More than 99% alumina granulated powder for cold isostatic pressing and preparation method thereof

The invention relates to a 99% or more alumina granulated powder for cold isostatic pressing and a preparation method thereof. The components include: in parts by mass, 100 to 200 parts of high-alumina alumina balls, calcined material CT‑ 50-150 parts of 3000SG, 1-5 parts of binder, 0.1-1 part of dispersant, 0.1-1 part of yttrium oxide, 0.1-1 part of magnesium oxide and 50-150 parts of deionized water. The preparation method comprises the following steps: ball milling, sieving after pulping, and stirring with a magnet; then performing centrifugal spray granulation; using a sieve to remove coarse and fine particles from the granulated powder, removing iron to remove impurities, and finally homogenizing. The powder of the present invention has low water content, high bulk density, high green density after billet making, good stability, good toughness, not easy to chipping, and excellent post-processing performance; the preparation method is simple in process, low in cost, and has good application prospect.

Owner:SHANGHAI COMPANION PRECISION CERAMICS

Novel small-pipe-diameter thread machining chip removal tool

ActiveCN113351947ANot easy to chipExtended service lifeThread cutting toolsMetal particleMachining process

The invention discloses a novel small-pipe-diameter thread machining chip removal tool, and relates to the technical field of machining tools. According to the technical scheme, the novel small-pipe-diameter thread machining chip removal tool is characterized by comprising a mounting part, a cutting part and a cooling part, the cutting part and the cooling part are mounted on the mounting part, and the mounting part is further provided with a winding part capable of allowing linear metal chips generated during machining to be wound in a concentrated manner and a chip removal part capable of allowing granular metal particles to be discharged. The novel small-pipe-diameter thread machining chip removal tool has the effects of solving the problem that chip removal is difficult in the small-pipe-diameter thread machining process and avoiding the conditions of cutter tipping, cutter wear acceleration and product smoothness reduction.

Owner:CHENGDU TOOL RES INST

Sandwich type diamond polycrystalline composite sheet and its preparation method and used binder

ActiveCN104959616BRealize high temperature and high pressure sinteringImprove stress conditionSuperhard materialPolycrystalline diamond

Owner:ZHONGNAN DIAMOND CO LTD

External push broach

InactiveCN101486115BIncrease productivitySave energyBroaching toolsGear teeth manufacturing toolsPush and pullEngineering

The invention discloses an external push-and-pull cutter for machining the shape of a columnar part. The cutter comprises a front guide platen, a rear guide platen, a connecting rod and a cutting part compression jointed between the front guide platen and the rear guide platen; the cutting part is formed by vertically superposing a plurality of annular inner tooth cutting blades of mold cavities with different dimension; the annular inner tooth cutting blade is provided with a plurality of inner cutting blade teeth which are wholly matched with the shape of a gear; the inner cutting blade teeth are in a ladder arrangement axially; and the annular inner tooth cutting blades are fixedly connected by positioning pins. The external push-and-pull cutter has the advantages of high production efficiency, energy conservation, raw materials conservation, equipment conservation, environmental protection, low cost, and the like, and has the characteristics of easy machining of blade teeth, simple structure, convenient assembly, low processing cost, high machining precision, high strength of the whole cutter, convenient maintenance, low maintenance cost, long service life, and the like.

Owner:杨方洲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com